Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Unin13001-3-1 2005 Een

Caricato da

alfonxxlTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Unin13001-3-1 2005 Een

Caricato da

alfonxxlCopyright:

Formati disponibili

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola.

Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

Apparecchi di sollevamento

SPECIFICA TECNICA

Criteri generali per il progetto

Parte 3-1: Stati limite e verica della sicurezza delle strutture di acciaio

UNI CEN/TS 13001-3-1

SETTEMBRE 2005

Cranes

General design

Part 3-1: Limit states and proof of competence of steel structures La specica tecnica specica, con le parti 1 e 2, le condizioni generali, i requisiti e i metodi per prevenire pericoli di natura meccanica degli apparecchi di sollevamento attraverso il progetto e le veriche teoriche.

TESTO INGLESE

La presente specica tecnica la versione ufciale in lingua inglese della specica tecnica europea CEN/TS 13001-3-1 (edizione dicembre 2004).

ICS

53.020.20

UNI Ente Nazionale Italiano di Unicazione Via Battistotti Sassi, 11B 20133 Milano, Italia

UNI Riproduzione vietata. Tutti i diritti sono riservati. Nessuna parte del presente documento pu essere riprodotta o diffusa con un mezzo qualsiasi, fotocopie, microlm o altro, senza il consenso scritto dellUNI. www.uni.com UNI CEN/TS 13001-3-1:2005 Pagina I

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

PREMESSA

La presente specica tecnica costituisce il recepimento, in lingua inglese, della specica tecnica europea CEN/TS 13001-3-1 (edizione dicembre 2004), che assume cos lo status di specica tecnica nazionale italiana. La scadenza del periodo di validit del CEN/TS 13001-3-1 stata ssata inizialmente dal CEN per dicembre 2007. Eventuali osservazioni sulla specica tecnica devono pervenire allUNI entro dicembre 2006. La presente specica tecnica stata elaborata sotto la competenza della Commissione Tecnica UNI Apparecchi di sollevamento e relativi accessori La presente norma stata raticata dal Presidente dellUNI ed entrata a far parte del corpo normativo nazionale il 14 settembre 2005.

Le norme UNI sono elaborate cercando di tenere conto dei punti di vista di tutte le parti interessate e di conciliare ogni aspetto conittuale, per rappresentare il reale stato dellarte della materia ed il necessario grado di consenso. Chiunque ritenesse, a seguito dellapplicazione di questa norma, di poter fornire suggerimenti per un suo miglioramento o per un suo adeguamento ad uno stato dellarte in evoluzione pregato di inviare i propri contributi allUNI, Ente Nazionale Italiano di Unicazione, che li terr in considerazione per leventuale revisione della norma stessa. Le norme UNI sono revisionate, quando necessario, con la pubblicazione di nuove edizioni o di aggiornamenti. importante pertanto che gli utilizzatori delle stesse si accertino di essere in possesso dellultima edizione e degli eventuali aggiornamenti. Si invitano inoltre gli utilizzatori a vericare lesistenza di norme UNI corrispondenti alle norme EN o ISO ove citate nei riferimenti normativi. UNI CEN/TS 13001-3-1:2005 UNI Pagina II

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

TECHNICAL SPECIFICATION SPCIFICATION TECHNIQUE TECHNISCHE SPEZIFIKATION

ICS 53.020.20

CEN/TS 13001-3-1

December 2004

English version

Cranes - General design - Part 3-1: Limit states and proof of competence of steel structures

Appareils de levage charge suspendue - Conception gnrale - Partie 3-1: Etats limites et vrification d'aptitude des structures mtalliques Krane - Konstruktion allgemein - Teil 3-1: Grenzzustnde und Sicherheitsnachweis von Stahltragwerken

This Technical Specification (CEN/TS) was approved by CEN on 25 November 2003 for provisional application. The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard. CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached. CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMIT EUROPEN DE NORMALISATION EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels

2004 CEN

All rights of exploitation in any form and by any means reserved worldwide for CEN national Members.

Ref. No. CEN/TS 13001-3-1:2004: E

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Contents

Page

Introduction .............................................................................................................................................5 1 2 3 4 4.1 4.1.1 4.1.2 4.2 4.2.1 4.2.2 4.2.3 4.2.4 4.3 4.4 4.5 5 5.1 5.2 5.2.1 5.2.2 5.2.3 5.2.4 5.2.5 5.3 5.3.1 5.3.2 5.3.3 5.3.4 6 6.1 6.2 6.2.1 6.2.2 6.2.3 6.2.4 6.3 6.3.1 6.3.2 6.4 6.5 6.5.1 6.5.2 6.5.3 7 8 Scope...........................................................................................................................................5 Normative references...................................................................................................................5 Terms and definitions ..................................................................................................................6 General ......................................................................................................................................10 Materials ....................................................................................................................................10 Structural members...................................................................................................................10 Connecting devices ...................................................................................................................13 Bolt connections........................................................................................................................13 General ......................................................................................................................................13 Shear and bearing connections .................................................................................................13 Slip resistant connections .........................................................................................................13 Connections loaded in tension..................................................................................................14 Pin connections.........................................................................................................................14 Welded connections ..................................................................................................................14 Proofs of structural members and connections.........................................................................14 Proof of static strength..............................................................................................................14 General ......................................................................................................................................14 Limit design stresses and forces...............................................................................................15 General ......................................................................................................................................15 Limit design stress in structural members ................................................................................15 Limit design forces in bolt connections.....................................................................................16 Limit design forces in pins ........................................................................................................22 Limit design stresses in welded connections............................................................................24 Execution of the proof ...............................................................................................................25 Proof for structural members ....................................................................................................25 Proof for bolt connections .........................................................................................................26 Proof for pin connections..........................................................................................................26 Proof for welded connections....................................................................................................27 Proof of fatigue strength............................................................................................................27 General ......................................................................................................................................27 Limit design stresses.................................................................................................................28 Characteristic values of the stress range ..................................................................................28 Weld quality...............................................................................................................................30 Effect of test loads.....................................................................................................................30 Requirements for fatigue testing ...............................................................................................31 Classes S of stress history parameter s....................................................................................31 Simplified method based on service conditions ........................................................................31 Selection based on experience..................................................................................................35 Execution of the proof ...............................................................................................................35 Determination of the permissible stress range ..........................................................................36 Applicable methods...................................................................................................................36 Direct use of stress history parameter ......................................................................................36 Use of class S............................................................................................................................36 Proof of static strength of hollow section girder joints..............................................................38 Proof of elastic stability.............................................................................................................38

Annex A (normative) Values of inverse slope of /N-curve m and permissible stress range c, c ..39 Annex B (informative) Guidance for selection of classes S due to experience .....................................54 2

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Annex C (normative) Calculated values of permissible stress range Rd ............................................55 Annex D (normative) Design weld stress W,Sd and W,Sd .......................................................................57 D.1 Butt joint ....................................................................................................................................57 D.2 Fillet weld and groove weld with uniform distributed load.........................................................58 D.3 Relevant distribution length under punctiform load ..................................................................59 Annex E (informative) Hollow Sections .................................................................................................60 Annex F (informative) Selection of a suitable set of crane standards for a given application ...............71 Annex ZA (informative) Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC ............................................................................................................72 Bibliography ..........................................................................................................................................73

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Foreword

This document (CEN/TS 13000-3.1:2004) has been prepared by Technical Committee CEN/TC 147 Cranes Safety, the secretariat of which is held by BSI. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive 98/37/EC, amended by 98/79/EC. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to announce this Technical Specification: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary Iceland, Ireland, Italy, Latavia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and the United Kingdom. This European Standard is one Part of EN 13001. The other parts are as follows: Part 1: Part 2: General principles and requirements Load actions

The annexes A, C and D are normative. The annexes B, E and F are informative.

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Introduction

This European Standard has been prepared to be a harmonised standard to provide one means for the mechanical design and theoretical verification of cranes to conform with the essential health and safety requirements of the Machinery Directive, as amended. This standard also establishes interfaces between the user (purchaser) and the designer, as well as between the designer and the component manufacturer, in order to form a basis for selecting cranes and components. This European Standard is a type C standard as stated in EN 1070. The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this document. When provisions of this type C standard are different from those which are stated in type A or B standards, the provisions of this type C standard take precedence over the provisions of the other standards, for machines that have been designed and built according to the provisions of this type C standard. The machinery concerned and the extent to which hazards are covered are indicated in the scope of this standard.

Scope

This European Standard is to be used together with Part 1 and Part 2 and as such they specify general conditions, requirements and methods to prevent mechanical hazards of cranes by design and theoretical verification.

NOTE Specific requirements for particular types of crane are given in the appropriate European Standard for the particular crane type.

The following is a list of significant hazardous situations and hazardous events that could result in risks to persons during normal use and foreseeable misuse. Clauses 4 to 8 of this standard are necessary to reduce or eliminate the risks associated with the following hazards: a) Exceeding the limits of strength (yield, ultimate, fatigue); b) Exceeding temperature limits of material or components; c) Elastic instability of the crane or its parts (buckling, bulging). This European Standard is applicable to cranes which are manufactured after the date of approval by CEN of this standard and serves as reference base for the European Standards for particular crane types.

NOTE prCEN/TS 13001-3-1 deals only with limit state method according to EN 13001-1.

As an alternative to the herein presented limit state method using partial safety factors, the allowable stress method using a global safety factor according to Part 1 and Part 2 may also be applied for special crane systems with linear behaviour. As crane structures are basically dynamically loaded only the linear theory of elasticity is applicable and only limited local plasticity is allowed. The use of the theory of plasticity for calculation of ultimate load bearing capacity is not allowed.

Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These 5

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of, any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments). EN 1070:1998, Safety of machinery Terminology. EN 1990-1:2002, Eurocode Basic of structural design EN 1993-1-1:1992: Eurocode 3: Design of steel structures Part 1-1: General rules and rules for buildings. EN 10025:1990/A1:1993, Hot rolled products of non-alloy structural steels Technical delivery conditions (includes amendment A1:1993). EN 10045-1:1989, Charpy impact test on metallic material Part 1: Test method. EN 10113-1:1993, Hot-rolled products in weldable fine grain structural steels Part 1: General delivery conditions. EN 10113-2:1993, Hot-rolled products in weldable fine grain structural steels Part 2: Delivery conditions for normalized/normalized rolled steels. EN 10113-3:1993, Hot-rolled products in weldable fine grain structural steels Part 3: Delivery conditions for thermomechanical rolled steels. EN 10137-2:1995, Plates and wide flats made of high yield strength structural steels in the quenched and tempered or precipitation hardened conditions Part 2: Delivery conditions for quenched and tempered steels. EN 10149-1:1995, Hot-rolled flat products made of high yield strength steels for cold forming Part 1: General delivery conditions. EN 10149-2:1995, Hot-rolled flat products made of high yield strength steels for cold forming Part 2: Delivery conditions for thermomechanically rolled steels. EN 10149-3:1995, Hot-rolled flat products made of high yield strength steels for cold forming Part 3: Delivery conditions for normalized or normalized rolled steels. EN 10164:1993, Steel products with improved deformation properties perpendicular to the surface of the product Technical delivery conditions. EN 12345:1996, Welding Multilingual terms for welding joints with illustrations (trilingual version). EN 13001-1:2004, Cranes General Design Part 1:General principles and requirements. EN 13001-2:2004, Cranes General Design Part 2: Load actions. EN 22553:1994, Welded, brazed and soldered joints Symbolic representation on drawings (ISO 2553:1992). EN 25817:1992, Arc-welded joints in steel Guidance on quality levels for imperfections (ISO 5817:1992). EN ISO 898-1:1999, Mechanical properties of fasteners Part 1: Bolts, screws and studs (ISO 898-1:1999). EN ISO 9013:2002, Thermal cutting Classification of thermal cuts Geometrical specification and quality tolerances (ISO 9013:2002). EN ISO 12100-1:2003, Safety of machinery Basic concepts, general principles for design Part 1: Basic terminology, methodology (ISO 12100-1:2003). EN ISO 12100-2:2003, Safety of machinery Basic concepts, general principles for design Part 2: Technical principles and specifications (ISO 12100-2:2003).

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

ISO 286-2:1990, ISO system of limits and fits Part 2: Tables of standard tolerance grades and limit deviations for holes and shafts. ISO 4306-1:1990, Cranes Vocabulary Part 1: General.

Terms and definitions

3.1 Terms and definitions For the purposes of this European Standard, the terms and definitions given in EN 292-1, EN 292-2 and EN 1070 and the basic list of definitions as provided in EN 1990-1 apply. For the definitions of loads, clause 6 of ISO 4306-1:1990 applies. 3.2 Symbols and abbreviations The symbols and abbreviations used in this Part of the EN 13001 are given in Table 1. Table 1 Symbols and abbrevations Symbols, abbreviations

A AS ar D o , Di d do e1, e2 Fb Fd FK Fp FRd Ft Fb, Rd Fb, Sd ; Fbi, Sd Fp, d Fs, Rd Ft, Rd Fv, Rd Fv, Sd F, fd fK fRd cross section stress area of a bolt relevant weld thickness outer, inner diameter of hollow pin diameter (shank of bolt, pin) diameter of hole distances tensile force in bolt limit force characteristic value (force) preloading force in bolt limit design force external force (on bolted connection) limit design bearing force design bearing force design preloading force limit design slip force per bolt and friction interface limit design tensile force in bolt limit design shear force per bolt/pin and shear plane design shear force per bolt/pin and shear plane acting normal/shear force limit stress characteristic value (stress) limit design stress

Description

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Table 1 (continued) Symbols, abbreviations

fu fub fw, Rd fy fyb fyk fyp Gt h Kb Kc k* ultimate strength of material ultimate strength of bolts limit design weld stress yield point of material yield point of bolts yield point (nominal value) of material or member yield point of pins mass of the moving crane parts during a representative working cycle distance between weld and contact area of acting load stiffness (slope) of bolt stiffness (slope) of flanges specific spectrum ratio factor

Description

k(m) k(m=3) lr lW MRd MSd m NC min , max PS p1, p2 Q q Rd r Sd s(m) T t W el

stress spectrum factor based on m of the detail under consideration stress spectrum factor based on m = 3 relevant weld length weld length limit design bending moment design bending moment inverse slope of /N-curve notch class extreme values of stresses probability of survival distances mass of the maximum hoist load impact toughness parameter design resistance radius of wheel design strain stress history parameter temperature thickness elastic section modulus characteristic factor for bearing connection characteristic factor for limit weld stress general resistance coefficient fatigue strength specific resistance factor

w m Mf

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Table 1 (concluded) Symbols, abbreviations Description partial safety factor resulting resistance coefficient specific resistance factor resulting resistance coefficient of bolt

specific resistance factor of bolt resulting resistance coefficient of members specific resistance factor of members resulting resistance coefficient of pins specific resistance factor of pins resulting resistance coefficient of slip-resistance connection specific resistance factor of slip-resistance connection resulting resistance coefficient of welding connection specfic resistance factor of welding connection dynamic factor spread angle width of contact area in weld direction elongation from preloading additional force additional elongation slip factor characteristic value of stress range (normal stress) characteristic value of stress range (shear stress) design stress (normal) design stress (shear) design weld stress (normal) design weld stress (shear) permissible (limit) stress range (normal) permissible stress range for k* = 1 permissible (limit) stress range (shear) design stress range (normal) design stress range (shear)

p R S Rb

sb Rm sm Rp sp Rs ss Rw sw 2 p Fb

c c Sd Sd w, Sd w, Sd Rd Rd,1 Rd Sd Sd

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

4

4.1

General

Materials

Structural members

4.1.1

European Standards specify materials and specific values. This standard gives a preferred selection. For structural members, steel according to following European Standards should be used: Non-alloy structural steels EN 10025. Weldable fine grain structural steels in conditions: normalised (N) EN 10113-2;

thermomechanical (M) EN 10113-3.

High yield strength structural steels in the quenched and tempered condition EN 10137-2. High yield strength steels for cold forming in conditions: thermomechanical (M) EN 10149-2; normalised (N) EN 10149-3.

Table 2 shows specific values for the nominal value of strength fu, fy and limit design stress fRd (see 5.2). For more information see the specific European Standard. Grades and qualities other than those mentioned in the above standards and in Table 2 can be used if the mechanical properties and the chemical composition are guaranteed by the manufacturer and conform to the relevant European Standard. If necessary, the weldability shall be demonstrated by the steel manufacturer. When selecting grade and quality of the steel for tensile members, the sum of impact toughness parameters qi shall be taken into account. Table 3 gives the impact toughness parameters qi for various influences. Table 4 gives the required steel quality and impact energy/test temperature in dependence of qi. Grades and qualities of steel other than mentioned in Table 4 may be used, if the steel manufacturer guarantees and certifies an impact energy/test temperature, tested according to EN 10045-1.

10

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Table 2 Specific values of steels for structural members

Nominal strength Steel Standard Thickness t (mm) fy yield 2 (N/mm )

235 225 215 195 275 265 255 245 235 225 355 345 335 325 315 295 355 345 335 325 315 295 420 400 390 370 360 340 460 440 430 410 400 460 440 500 480 550 530 620 580 690 650 890 830 960 550 590 640 700 770 760 940 880 980 530 500 450 490 430 340

Limit design stress for Rm=1,1 fRd, normal 2 (N/mm )

214 205 195 177 250 241 232 223 214 205 323 314 305 296 287 268 323 314 305 295 286 268 382 364 355 336 327 309 418 400 391 373 364 418 400 455 436 500 482 564 527 627 591 809 755 873

fu ultimate 2 (N/mm )

fRd, shear 2 (N/mm )

123 118 113 102 144 139 134 129 123 118 186 181 176 171 166 155 186 181 176 171 165 155 220 210 205 194 189 178 241 231 226 215 210 241 231 262 252 289 278 325 304 362 341 467 436 504

t16 S235 16<t40 40<t100 100<t150 t16 16<t40 S275 EN 10025 40<t63 63<t80 80<t100 100<t150 t16 16<t40 S355 40<t63 63<t80 80<t100 100<t150 t<16 16<t40 S355 40<t63 63<t80 (N) 80<t100 (N) 100<t150 (N) t<16 EN 10113-2 (N) S420 EN 10113-3 (M) 16<t40 40<t63 63<t80 (N) 80<t100 (N) 100<t150 (N) t<16 16<t40 S460 40<t63 63<t80 (N) 80<t100 (N) S460 S500 S550 S620 S690 S890 S960 EN 10137-2 3<t50 50<t100 3<t50 50<t100 3<t50 50<t100 3<t50 50<t100 3<t50 50<t100 3<t50 50<t100 3<t50

11

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Table 2 (concluded) Nominal strength Steel Standard Thickness t (mm) fy yield (N/mm2)

315 355 420 460 EN 101492 (M) all t 500 550 550 S550 (M) S600 (M) S650 (M) EN 10149-3 (N) t8 t>8 S700 (M) t8 t>8 600 600 650 700 630 700 750 680 618 357 573 636 331 367 650 545 591 315 341 500 289

Limit design stress for Rm =1,1 fRd, normal (N/mm2)

286 323 382 418 455

fu ultimate (N/mm2)

390 430 480 520

fRd, shear (N/mm2)

165 186 220 241 262

S315 S355 S420 S460 (M) S500 (M)

Table 3 Impact toughness parameters qi

i Influence 0T 1 Temperature T (C) -20 T < 0 -40 T < -20 -50 T < -40 fy 300 300 < fy 460 2 Yield point fy (N/mm )

2

qi 0 1 2 4 0 1 2 3 4 0 1 2 3

460 < fy 700 700<fy 1 000 1 000<fy

Material thickness t (mm) Equivalent thickness t for solid bars:

t 10 10 < t 20 20 < t 50

50 < t 100

t=

d b b for < 1,8 : t = 1,8 1,8 h

t > 100 c > 125

4 0 1 2 3

Stress concentration and notch class c 2 (N/mm ) (see annex A and annex E)

80 < c 125 56< c 80 c 56

12

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Table 4 Impact toughness requirement and corresponding steel quality for qi

qi 3

Impact energy/ test temperature requirement EN 10025 EN 10113 EN 10137-2 EN 10149

a)

4 qi 6

27 J / 0C J0 N, M Q NC, MC

7 qi 9

27 J / -20C J2 N, M Q NC, MC

qi 10

27 J / -40C

a)

27 J / +20C JR N, M Q NC, MC

NL, ML QL

a)

May be used if the steel manufacturer guarantees and certifies an impact energy/test temperature of at least 27 J at 40 C, tested according to EN 10045-1.

4.1.2

Connecting devices

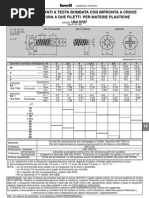

For bolt connections bolts of the property classes 4.6, 5.6, 8.8, 10.9 or 12.9 according to EN ISO 898-1 shall be used. Nominal values of the strengths: Table 5 Property classes Property class

fyb (N/mm ) fub (N/mm )

2 2

4.6

240 400

5.6

300 500

8.8

640 800

10.9

900 1 000

12.9

1 080 1 200

4.2

4.2.1

Bolt connections

General

For the purpose of this standard bolt connections are specified as connections, where bolts are tightened and thus compress the joint surfaces together; the joint surfaces are secured against rotation (e. g. by using multiple bolts). 4.2.2 Shear and bearing connections

Connections with fitted bolts, where the loads act perpendicular to the bolt axis and cause shear and bearing stresses in the bolts; clearance between bolt and hole shall be according to ISO 286-2 tolerances h13 and H11; at maximum 10 % of the clamping length may be covered by the threaded part of the bolt; special surface treatment of the contact surfaces is not required. 4.2.3 Slip resistant connections

Connections with high strength bolts of property classes 8.8, 10.9 or 12.9, where 13

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

the loads are transmitted by friction between the joint surfaces; bolts are tightened by a controlled method to the full preloading state; the surface condition of the contact surfaces shall be specified and taken into account accordingly. 4.2.4 Connections loaded in tension

Connections with high strength bolts of property classes 8.8, 10.9 or 12.9, where the loads act in the direction of the bolt axis and cause axial stresses in the bolts; bolts are tightened by a controlled method to the full preloading state; fatigue assessment of the bolts shall be done considering the structural features of the joint, e. g. stiffness of the connected parts and the leverage action caused by the joint geometry; an even contact over the whole intended contact area of the joint shall be ensured.

4.3

Pin connections

Pin connections are regarded as connections that allow turning of the connected parts.

4.4

Welded connections

Terms for welded joints shall be as given in EN 12345. Symbolic representation on drawings shall be according to EN 22553.

4.5

Proofs of structural members and connections

It has to be proven that the strains S d do not exceed the resistances Rd :

S d Rd

(1)

The strains Sd shall be determined by applying the loads, load combinations and partial safety factors according Table 10 of EN 13001-2. In the following clauses, the resistances Rd are presented as limit stresses f d or limit forces Fd . For the ultimate limit state, the following proofs shall be delivered: proof of strength of structural members and connections under quasi-static stress according to 5; proof of fatigue strength according to 6; proof of strength of hollow section girder joints under quasi-static stress according to 7; proof of elastic stability of structural members and special elements according to 8.

5

5.1

Proof of static strength

General

The proof of strength under quasi-static stress protects against excessive deformations due to yielding of the material or sliding of friction-grip connections as well as against static rupture of structural members or connections. 14

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

The proof shall be delivered for structural members and connections taking into account the most unfavourable load effects from the load combinations A, B or C according to Table 10 of EN 13001-2: and applying the resistances according to 5.2.

5.2

5.2.1

Limit design stresses and forces

General

The limit design stresses and forces shall be calculated by: Limit design stresses

f Rd = function ( f k , R ) or

(2)

Limit design forces where

FRd = function ( Fk , R )

f k or Fk

are characteristic values (or nominal values) is the resulting resistance coefficient is the resistance coefficient

R = m s

m s

NOTE

m = 1,1 (see Table 10 of EN 13001-2)

is the general specific resistance coefficient for special parts of this standard

f Rd

and

FRd

are equivalent to

R/ m

in Figure 2 of EN 13001-1.

5.2.2

Limit design stress in structural members

The limit design stress f Rd , used for the design of structural members, shall be calculated by:

f Rd =

f yk

Rm

f yk

for normal stresses

(3)

f Rd =

with where

Rm 3

for shear stresses

(4)

Rm = msm

f yk

sm

is the nominal value of the yield point of the material (see Table 2) is the specific resistance coefficient for material as follows: For non-rolled material

sm =1,0

For rolled materials (e. g. plates and profiles): 15

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

sm = 1,0 for stresses in the plane of rolling sm = 1,0 for compressive and shear stresses

For tensile stresses perpendicular to the plane of rolling (see Figure 1):

sm = 1,0 for material in quality classes Z25 or Z35 according to EN 10164 sm = 1,16 for material in quality class Z15 according to EN 10164 sm = 1,34 without quality classification

Figure 1 Tensile load perpendicular to plane of rolling Hence follow the limit design stresses, which are dependent on the material and the kind of stressing which are given in Table 2. 5.2.3 5.2.3.1 Limit design forces in bolt connections Shear and bearing connections

The resistance of a connection shall be determined by applying the limit forces of the individual connecting devices. The limit design shear force Fv,Rd per bolt and per shear plane shall be calculated by:

Fv , Rd =

with where

f yb A

Rb 3

(5)

R b = m sb

f yb

A

is the yield point (nominal value) of the bolt material is the cross-section of the bolt shank at the shear plane is the specific resistance factor for bolt connections

sb

sb = 1,0

16

for multiple shear plane connections

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

sb = 1,3

for single shear plane connections

See Table 6 for limit design shear forces as an example. Table 6 Limit design shear force Fv,Rd per fitted bolt and per shear plane for multiple shear plane connections Fv,Rd (kN) Fitted bolt material for Rb = 1,1 4.6

16,7 28,6 43,5 52,2 61,8 77,6 95,1

Fitted bolt

Hole diameter

Shank resp. hole section (mm )

133 227 346 415 491 616 755

2

(mm)

M12 M16 M20 M22 M24 M27 M30 13 17 21 23 25 28 31

5.6

20,9 35,7 54,4 65,3 77,3 97,0 111,8

8.8

44,6 76,2 116,2 139,4 164,9 206,9 253,6

10.9

62,8 107,2 163,2 196,0 231,9 291,0 356,6

12.9

75,4 128,6 196,1 235,2 278,3 349,2 428,0

The limit design bearing force Fb,Rd per bolt may be calculated by:

Fb, Rd =

with where

fy d t Rb

(6)

R b = m sb

e1 3 d 0

= Min

p1 1 3 d 0 4 f ub fu

1.0

e1 2,0 do e2 1,5 do p1 3,0 do p2 3,0 do (7)

17

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

Figure 2 Illustration for formula (7)

f ub fu

is the ultimate strength (nominal value) of the bolt (Table 5) is the ultimate strength (nominal value) of the basic material (Table 2) is the yield point (nominal value) of the basic material (Table 2) is the shank diameter of the bolt is the minimum of thicknesses of the basic material is the specific resistance factor for bolt connections

fy

d

sb

sb = 0,7 for multiple shear plane connections sb = 0,9 for single shear plane connections

5.2.3.2 Slip-resistant connections

The resistance of a connection shall be determined by applying the limit forces of the individual connecting devices. For slip-resistant connections the limit design slip force Fs,Rd per bolt and per friction interface shall be calculated by:

Fs , Rd =

with

( F p, d Ft ) Rs

(8)

Rs = m ss

where:

is the slip factor

= 0,50 for surfaces

blasted metallic bright with steel grit or sand, no unevennesses; blasted with steel grit or sand and aluminised; blasted with steel grit or sand and metallised with a product basing on zinc that causes a friction coefficient of min. 0,5

= 0,40 for surfaces

18

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3-1:2004 (E)

blasted with steel grit or sand and alkali-zinc-silicate coating of 50 m to 80 m thickness

= 0,30 for surfaces

cleaned metallic bright with wire brush or scarfing

= 0,20 for surfaces

cleaned of loose rust, oil and dirt

F p ,d

Ft

is the design preloading force. is an external tensile force in direction of the axis of the bolt (see Figure 3) It shall be ensured that the used preloading force is greater than or equal to the design preloading force.

ss

is the specific resistance factor for slip-resistant connections;

ss =1,14

See Table 7 for limit design slip forces using for example a design preloading force of

F p, d = 0,7 f yb As ,

where

f yb

As

is the yield point (nominal value) of the bolt material (Table 5) is the stress area of the bolt.

19

prCEN/TS 13001-3-1:2003 (E)

Table 7 Limit design slip force FS,Rd per bolt and per friction interface using a design preloading force F p, d = 0.7 f yb As Limit design slip force F s,Rd (kN) Bolt material 8.8 Slip factor :

12.9 63,7 119,0 185,0 229,0 267,0 347,0 424,0 618,0 146,0 117,0 87,8 58,6 206,0 165,0 100,0 80,3 60,2 40,2 141,0 113,0 82,4 65,9 49,4 33,0 116,0 92,5 69,4 84,7 124,0 63,2 50,6 37,9 25,3 88,8 71,0 53,3 54,4 43,5 32,6 21,8 76,4 61,1 45,8 30,6 35,5 46,2 56,5 82,4 44,0 35,2 26,4 17,6 61,6 49,3 37,0 24,6 28,1 22,5 16,9 11,2 39,6 31,6 23,7 15,8 15,1 12,1 9,1 6,0 21,2 17,0 12,7 8,5 25,5 47,6 74,0 91,6 107,0 139,0 170,0 247,0 0.50 0.40 0.30 0.20 0.50 0.40 0.30 0.20 0.50

Bolt

stress area 10.9 Slip factor : 12.9 Slip factor :

0.40 20,4 38,1 59,2 73,3 85,4 111,0 136,0 198,0 0.30 15,3 28,6 44,4 55,0 64,1 83,3 102,0 148,0

Design preloading force Fp,d (kN)

AS

Bolt material

(mm2)

8.8

10.9

0.20 10,2 19,0 29,6 36,6 42,7 55,5 67,8 98,9

M12

84,3

37,8

53,1

M16

157,0

70,3

98,9

M20

245,0

110,0

154,0

M22

303,0

136,0

191,0

M24

353,0

158,0

222,0

M27

459,0

206,0

289,0

M30

561,0

251,0

353,0

M36

817,0

366,0

515,0

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

20

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

5.2.3.3

Connections loaded in tension

The resistance of a connection shall be determined by applying the limit forces of the individual connecting devices. In principle the proof of competence has to take into account the stiffnesses of the bolt and the flanges to be connected (see Figure 3).

Fp

Preloading force in bolt Bolt elongation from preloading External force Additional elongation Tensile force in bolt additional force in bolt

p

Ft

:

Fb

Fb

Slope Kb Stiffness of bolt Slope Kc Stiffness of flanges

Figure 3 Force-elongation-diagram For simplification the limit design tensile force per bolt Ft,Rd may be calculated by:

Ft , Rd =

F p ,d

Rb

(9)

with Rb = m sb where

F p ,d

is the design preloading force. It shall be ensured that the used preloading force is greater than or equal to the design preloading force

sb

is the specific resistance factor for connections loaded in tension

sb = 1,0

See Table 8 for limit design tensile forces according to formula (9) using for example a design preloading force of

F p, d = 0,7 f yb As

where

21

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

f yb

As

is the yield point (nominal value) of the bolt material (Table 5) is the stress area of the bolt.

Table 8 Limit design tensile force Ft,Rd per bolt in direction of the bolt axis, using a design preloading force F p, d = 0,7 f yb As Limit design tensile force per bolt Ft,Rd (kN) for Rb = 1.1 Bolt material 8.8

M12 M16 M20 M22 M24 M27 M30 M36 84,3 157,0 245,0 303,0 353,0 459,0 561,0 817,0 37,8 70,3 110,0 136,0 158,0 206,0 251,0 366,0

stress area Bolt AS (mm )

2

Design preloading force Fp,d (kN) Bolt material 10.9

53,1 98,9 154,0 191,0 222,0 289,0 353,0 515,0

12.9

63,7 119,0 185,0 229,0 267,0 347,0 424,0 618,0

8.8

34,3 63,9 100,0 123,6 143,9 187,2 228,1 332,7

10.9

48,2 88,9 140,0 173,6 201,8 262,7 320,9 468,1

12.9

57,9 108,1 168,1 208,1 242,7 315,4 385,4 561,8

5.2.4

Limit design forces in pins

The pin of a pin connection shall be designed taking into account bending, shearing and bearing. Therefore the following simplified system may be assumed: For pins the following limit design loads shall be taken into account: Limit design bending moment

M Rd =

Wel f yp

Rp

(10)

with where

Rp = m sp

Wel

is the elastic section modulus of the pin is the yield point (nominal value) of the pin material is the specific resistance factor for pin connections bending moment sp = 1,0

f yp

sp

Limit design shear force per shear plane for pins

Fv ,Rd =

1 A f yp u 3 Rp

(11)

22

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

with where

Rp = m sp

u=

4 3

for solid pins

4 1+ v + v 2 u= 3 1 + v2

where

for hollow pins

=

Di DO

Di , DO

is the inner diameter of pin is the outer diameter of pin

is the cross-section of the pin is the specific resistance factor for pin connections shear force

sp

sp = 1,0 for multiple shear plane connections sp = 1,3 for single shear plane connections

Limit design bearing force

Fb, Rd =

d t fy Rp

(12)

with where

Rp = m sp

f yp f y = Min 1,0

23

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Figure 4 Pin connections

fy

d

is the yield point (nominal value) of basic material is the diameter of the pin is the minimum of thickness of the basic material is the specific resistance factor for pin connections bearing force

sp

sp = 0,7 for multiple shear plane connections sp = 0,9 for single shear plane connections

In case of significant movement between pin and bearing the limit bearing force shall be reduced in order to reduce wear. 5.2.5 Limit design stresses in welded connections

The limit design weld stress fw,Rd used for the design of a welded connection depends on: the parent metal to be welded; the type of the weld; the type of stress; the weld quality; the kind of welding process.

24

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

The limit design weld stress fw,Rd shall be calculated by:

f w, Rd =

with where

w f yk Rw

(13)

Rw = m sw

w is a factor given in Table 9 in dependence on the type of weld, the type of stress and the material

f yk is the minimal nominal value of the yield points of the parent and weld consumable materials in the

weld joint

sw is the specific resistance factor for welded connections sw = 1,0

Table 9 Factor w for limit weld stress

w

Direction of stress Penetration Type of stress fyk < 690 (N/mm)

Weld with full penetration or backwelded Stress across the weld direction Weld without full penetration Weld with/without full penetration Stress in weld direction Weld with/without full penetration Tension Compression Tension Compression Shear Tension/ Compression Shear 1,0 1,0 0,7 0,8 1/ 2

690 fyk < 960 (N/mm)

1,0 1,0 0,7 0,8 1/ 3

fyk 960 (N/mm)

0,93 0,93 0,65 0,74 0,54

1,0 1/ 3

1,0 1/ 3

0,93 0,54

5.3

5.3.1

Execution of the proof

Proof for structural members

For the structural member to be designed it shall be proven that:

Sd f Rd and Sd f Rd

where

(14)

Sd , Sd

f Rd

are the design stresses is the corresponding limit design stress according to 5.2.2.

25

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

In case of plane states of stresses it shall additionally be proven that:

Sd , x Sd , y Sd , x Sd , y Sd f Rd , x + f Rd , y f Rd , x f Rd , y + f Rd

where x, y

(15)

indicate the orthogonal directions of stresses

Spatial states of stresses may be reduced to the most unfavourable plane state of stress. 5.3.2 Proof for bolt connections

For the most unfavourably loaded element of a connection it shall be proven that:

FSd FRd

where

(16)

FSd FRd

is the design force of the element is the limit design force according to 5.2.3, in dependence on the type of the connection and its type of stress, i. e. limit design shear force Fv,Rd limit design bearing force Fb,Rd limit design slip force Fs,Rd limit design tensile force Ft,Rd

In particular for connections loaded in tension (see 5.2.3.3) the tensile force in the bolt Fb shall always satisfy:

Fb

5.3.3

f yb AS

(17)

Proof for pin connections

For pins, it shall be proven that:

M Sd M Rd Fv , Sd Fv , Rd Fbi ,Sd Fb ,Rd

where (18)

M Sd M Rd

is the design value of the bending moment in the pin is the limit design bending moment according to 5.2.4 is the design value of the shear force in the pin

Fv , Sd

26

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Fv , Rd Fbi ,Sd Fb, Rd

5.3.4

is the limit design shear force according to 5.2.4 is the decisive design value of the bearing force in the joining plate i of the pin connection is the limit design bearing force according to 5.2.4

Proof for welded connections

For the weld to be designed it shall be proven that:

w,sd and w, Sd f w, Rd

where

(19)

w,Sd , w, Sd

f w, Rd

are the design weld stresses (see annex D) is the corresponding limit design weld stress according to 5.2.5

In case of plane states of stresses in welded connections it shall additionally be proven that:

w, Sd , x f w, Rd , x

where x,y

w,Sd , y + f w, Rd , y

w, Sd , x w,Sd , y w, Sd + f w, Rd , x f w, Rd , y f w, Rd

1,1

(20)

indicate the orthogonal directions of stresses.

Spatial states of stresses may be reduced to the most unfavourable plane state of stress.

6

6.1

Proof of fatigue strength

General

The proof of fatigue strength prevents failure or formation of critical cracks of structural members or connections under cyclic loading. In general, the proof shall be executed by applying the load combinations A according to Table 10 of EN 13001-2, setting all partial safety factors p = 1, and the resistances (i. e. limit design stresses) according to 6.2. The stresses are calculated as nominal stress concept. A nominal stress is a stress in the parent material adjacent to a potential crack location, calculated in accordance with simple elastic strength of materials theory, excluding local stress concentration effects. Annex A and annex E contain the influences of constructional details and thus include the effects of: local stress concentrations due to the shape of the joint and the weld geometry; size and shape of acceptable discontinuities; the stress direction;

27

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

residual stresses; metallurgical conditions; in some cases, the welding process and post-weld improvement procedures. The effect of additional geometric stress concentration (global stress concentration) shall be estimated with appropriate methods. This standard does not use other methods like Hot Spot Stress Method. The bibliography gives information on literature about Hot Spot Stress Method. For the execution of the proof of fatigue strength the stress history parameters (see 4.3.4 of EN 13001-1) is needed. Values for this parameter can be determined by simulation, testing or using classes S (see 6.3). Thus the service conditions and their effect on the stressing of the structure are taken into account. Mean-stress influence, as presented in EN 13001-1, in structures in as-welded condition (without stress relieving) is negligible. Therefore the stress history parameter s is independent of the mean-stress and the fatigue strength is based on the stress range only. In non-welded details or stress relieved welded details, the effective stress range to be used in the fatigue assessment may be determined by adding the tensile portion of the stress range and 60 % of the compressive portion of the stress range or by special investigation (see 6.4). Uncertainties in assuming the fatigue strength and possible consequences of a damage shall be taken into consideration by a fatigue strength specific resistance factor Mf according to Table 10. Table 10 Fatigue strength specific resistance factor Mf Mf Inspection and access

Periodic inspection and maintenance Accessible joint detail Periodic inspection and maintenance Poor accessibility 1,15 1,25 1,35

Fail-safe components

Non fail-safe components without hazards with hazards for for persons persons

1,15 1,25

1,0

Fail-safe structural components are those with reduced consequences of failure, such that the local failure of one component does not result in failure of the structure or falling of loads. Non fail-safe structural components are those where local failure of one component leads rapidly to failure of the structure or falling of loads.

6.2

6.2.1

Limit design stresses

Characteristic values of the stress range

The limit design stress of a constructional detail stressed by fatigue is characterised by the characteristic value of the stress range c (notch condition). c represents the fatigue strength under 2 10

6

constant

stress range cycles and a probability of survival of Ps = 97,7 % (mean value minus double standard deviation), see Figure 5.

28

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

The several values c are arranged in a sequence of notch classes (NC) with the constant ratio of 1,125 between the classes (see annex C, first column). For shear stressing the above is also applicable and c is used instead of c . The characteristic values of the stress range c resp. c and the related inverse slopes m of the /Ncurve are given in annex A (normative) and annex E (informative) as follows: Table A.1: Table A.2: Table A.3: Table E.1: Basic material of structural members; Bolted members, connecting devices; Welded members; Values of inverse slope of the /N-curve m and permissible stress range c for connections and joints of hollow section girders; Values of inverse slope of the /N-curve m and permissible stress range c for lattice type connections of hollow section girders.

Table E.2:

The given values apply for the defined basic conditions. For deviating conditions an appropriate notch class (NC) shall be selected one or more notch classes above (+ 1 NC, + 2NC, ...) or below (- 1 NC, - 2 NC, ...) the basic reference class. The effects of several deviating conditions shall be summed up.

Principle figure above

Simplification (see EN 13001-1)

Key 1 2 Constant stress range fatigue limit Cut-off limit

Figure 5 Illustration of s/N-curve and ?s c

29

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

6.2.2

Weld quality

c -values in annex A and annex E depend on the quality level of the weld. Quality classes B, C, D shall be according to EN 25817. In annex E class C is assumed. Usage of lower quality levels than D is not allowed. For the purpose of this standard an additional quality level B* can be used. The requirements in addition to those of level B given hereafter define quality level B*.

Additional requirements for quality level B*: For the purpose of this standard 100 % NDT (non destructive testing) means inspection of the whole length of the weld with an appropriate method to ensure that the specified quality requirements are met. For butt welds: full penetration without initial points; both surfaces machined or flush ground down to plate surface; grinding in stress direction; the weld toe post-treated by grinding, remelting by TIG, plasma welding or by needle peening; eccentricity of the joining plates less than 5 % of thickness of greater plate; sum of lengths of concavities of weld less than 5 % of the total length of the weld; 100 % NDT. For parallel and lap joints: transition angle of the weld to the plate surface shall not exceed 25; the weld toe post-treated by grinding, remelting by TIG, plasma welding or by needle peening; 100 % NDT. All other joints: full penetration; transition angle of the weld to the web surface shall not exceed 25; the weld toe post-treated by grinding, remelting by TIG, plasma welding or by needle peening; 100 % NDT; eccentricity less than 10 % of thickness of greater plate. If TIG dressing is used as a post treatment of the potential crack initialisation zone of a welded joint in order to increase the fatigue strength, welds of quality class C for design purposes may be upgraded to quality class B for any joint configuration. 6.2.3 Effect of test loads

The characteristic value of stress range c respective c of a welded detail that was subjected to a test load (see EN 13001-2, 4.1.4.3) is higher than the value of that detail not subjected to a test load.

30

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

c values of annex A and annex E are related to details as test loaded. Therefore application of these

values requires test loads as given in EN 13001-2. 6.2.4 Requirements for fatigue testing

Details not given in annex A and annex E or consideration of mean stress influence require special investigation into c and m by tests. Requirements for such tests are: test specimen in real size (1:1); test specimen produced under workshop conditions; at least 7 tests per stress range level. Requirements for determination of m and c are:

c shall be determined from numbers of cycles based on mean value minus double standard deviation

in a log/log presentation;

at least one stress range level that results in a number of stress cycles to failure of less than 2104 cycles; at least one stress range level that results in a number of stress cycles to failure between 1,5106 and 2,5106 cycles. A simplified method for the determination of m and c may be used: m shall be set to m = 3; only stress range levels that result in a number of stress cycles to failure of less than 1105 cycles shall be used.

6.3

6.3.1

Classes S of stress history parameter s

Simplified method based on service conditions

Determination of the class S (see EN 13001-1) decisively depends on: the class U of working cycles; the class Q of the load spectrum; the factor 2 respective hoisting class HC. The structure or parts of the structure can be related to a class S according to Table 11 and Table 12 dependent on the classes U, Q and a parameter Gt/( 2 Q), under consideration of an average influence of the class Dlin and/or class Dang and class P, where

Gt

is the mass of the moving crane parts during a representative working cycle, such as:

31

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

for a bridge crane: Gt is the mass of the trolley and load lifting attachments; for slewing cranes: when considering load supporting slewing parts: Gt is the mass of the jib transformed to the load suspension point; when considering non slewing parts: Gt is the mass of the entire slewing parts, transformed to the load suspension point;

Q

2

is the mass of the maximum hoist load influencing the part under consideration; (i. e. if the hoist load is of no influence, Q is set to 0); is the dynamic factor (see EN 13001-2).

The derivation of Table 11 and Table 12 is based on the damage theory of Corten-Dolan and on the assumption that the average horizontal displacement of the load centre is about 2/3 of the span or 2/3 of the maximum working radius.

32

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Table 11 Class S for trolley frames and main girders between two supports, as well as for structures of wall and slewing cranes with constant working radius of the load centre Class of load spectrum

Gt 2 Q

0 0,25 S0 S0 S0 S0 S1 S1 S2 S0 S0 S0 S0 S1 S2 S3 S4 S5 S6 S7 S2 S3 S1 S3 S4 S2 S4 S5 S3 S5 S6 S4 S6 S7 S5 S7 S8 S6

Class of total number of working cycles U0 U1 U2 U3 U4

S0 S1

U5

S1 S2

U6

S2 S3

U7

S3 S4

U8

S4 S5

U9

S5 S6

Q0

0,5 1 2 0 0,25

Q1

0,5 1 2 0 0,25

S1

S2

S3

S4

S5

S6

S7

S8

S0 S0 S0 S1

S1

S2

S3

S4

S5

S6

S7

Q2

0,5 1 2 0 0,25

S2

S3

S4

S5

S6

S7

S8

Q3

0,5 1 2 0 0,25

S0

S0

S1

S2

S3

S4

S5

S6

S7

S8

Q4

0,5 1 2 0 0,25

S1 S0

S2

S3

S4

S5

S6

S7

S8

S9

S0

S1

S2

S3

S4

S5

S6

S7

S8

S1

S2

S3

S4

S5

S6

S7

S8

S9 S9

Q5

0,5 1 2 S1 S0 S0 S1 S2 S3 S4 S5 S6 S7 S2 S3 S4 S5 S6 S7 S8

S8

33

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Table 12 Class S for stringers, supports and parts of main girders project over the supports, as well as for structures of wall and slewing cranes with variable working radius of the load centre Class of load spectrum

Gt 2 Q

0 0,25 S0 S0 S0 S0 S1 S1 S2 S1 S2 S3 S0 S0 S0 S0 S0 S1 S1 S2 S0 S0 S1 S2 S3 S4 S5 S6 S7 S2 S3 S0 S1 S0 S0 S3 S4 S1 S2 S4 S5 S2 S3 S5 S6 S3 S4 S6 S7 S4 S5 S7 S8 S5 S6 S1

Class of total number of working cycles U0 U1 U2 U3 U4 U5 U6 U7 U8 U9

S0 S0 S1 S2 S3 S4 S1 S2 S1 S2 S3 S4 S5 S2 S3 S2 S3 S4 S5 S6 S3 S4 S3 S4 S5 S6 S7 S4 S5 S4 S5 S6 S7 S8 S5 S6

Q0

0,5 1 2 0 0,25

Q1

0,5 1 2 0 0,25

Q2

0,5 1 2 0 0,25

S1

S2 S0

S3 S1

S4 S2

S5 S3

S6 S4

S7 S5

S8 S6

Q3

0,5 1 2 0 0,25

S0 S0 S0 S1 S2 S3 S4 S5 S6 S7

S1 S0

S2 S1

S3 S2

S4 S3

S5 S4

S6 S5

S7 S6

S8 S7

Q4

0,5 1 2 0 0,25

S0

S0 S1 S2 S3 S4 S5 S6 S7 S8

Q5

0,5 1 2

S0

S0

S1

S2

S3

S4

S5

S6

S7

S8

34

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

6.3.2

Selection based on experience

The members of crane structures may be related to classes S due to experience. If a single class S is used for the whole structure the most severe class shall be used. Guidance is given in annex B.

6.4

Execution of the proof

For the detail under consideration it shall be proven that:

Sd Rd Sd = max min

where

(21) (22)

Sd

max, min

is the calculated maximum range of design stresses are the extreme values of design stresses resulting from load combinations A according to Table 10 of EN 13001-2, by applying P = 1 (compression stresses with negative sign). For design weld stress see annex D. For thermally stress relieved or non-welded structural members the compressive portion of the stress range may be reduced to 60 %. is the permissible stress range

Rd

Shear stresses are treated similarly. For each stress component where x,y indicate the orthogonal directions of stresses.

x , y and the proof shall be executed separately.

In case of non welded details, if the normal and shear stresses induced by the same loading event vary simultaneously, or if the plane of the maximum principal stress does not change significantly in the course of a loading event, the maximum principal stress range shall be used. In case of non welded details with independently varying ranges of normal and shear stresses it shall be proven that:

Sd , x m c, x

where

mx

s x ( mx )

Sd , y + c, y

my

s y( m y )

Sd + c

s ( m )

1.0 Mf

(23)

Sd , Sd c , c

s(m) m

are the calculated maximum ranges of design stresses are the characteristic values of stress range is the stress history parameter inverse slope of /N-curve (the maximum value of mx, my, m shall be taken as radical

35

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

index) x, y indicate the orthogonal direction of normal stresses indicate the respective shear stress

6.5

6.5.1

Determination of the permissible stress range

Applicable methods

The permissible stress ranges Rd for the detail under consideration shall be determined either by direct use of stress history parameter s(m) or simplified by use of class S. 6.5.2 Direct use of stress history parameter

The permissible stress range shall be calculated by:

Rd =

where

Mf m s(m )

(24)

Rd c , m

is the permissible stress range are the characteristic values of stress range and the respective inverse slope of the log /log N-curve (see annex A and annex E)

Mf

s (m)

is the fatigue strength specific resistance factor (see Table 10) is the stress history parameter (calculated according to the formula of 4.3.4 of EN 130011:1997)

*

NOTE When s(m) is obtained on the basis of m = 3, the permissible stress range may be calculated using k as shown in formula (26).

6.5.3 6.5.3.1

Use of class S Slope m

When the detail under consideration is related to a class S according to 6.3, the simplified determination of the permissible stress range is dependent on the (negative inverse) slope m of the log /log N-curve. 6.5.3.2 Slope m = 3

In dependence on the S-classes the values of the classified stress history parameter s (m = 3) are as follows: Table 13 s (m = 3) of classes S Class

s(m=3)

SO

0.008

S1

0.016

S2

0.032

S3

0.063

S4

0.125

S5

0.25

S6

0.5

S7

1.0

S8

2.0

S9

4.0

36

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

The permissible stress range shall be calculated by:

Rd =

where

Mf s(m = 3)

3

(25)

Rd

c

s(m=3)

is the permissible stress range; is the characteristic value of stress range of details with m = 3 (see annex A and annex E); is the classified stress history parameter (see Table 13); is the fatigue strength specific resistance factor (see Table 10).

Mf

For

Mf = 1,25 Annex C gives the values of Rd in dependence on the class S and c .

Slope m 3

6.5.3.3

If the negative inverse slope m of the log /log N-curve is not equal to 3, the permissible stress range is dependent on the class S and the stress spectrum factor k(m) (see 4.3.4 of EN 13001-1). The permissible stress range Rd shall be calculated by:

Rd = Rd ,1 k *

Rd ,1 = c

(26)

Mf m s ( m=3)

1

(27)

k*=m

where

k ( m = 3) k ( m)

(28)

Rd

is the permissible stress range is the permissible stress range for k* = 1 is the specific spectrum ratio factor are the characteristic values of stress range and the respective inverse slope of the log /log N-curve (see annex A and annex E)

Rd ,1

k*

c , m

s (m = 3)

is the classified stress history parameter (see Table 13) is the fatigue strength specific resistance factor (see Table 10)

Mf

37

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

k ( m = 3) k ( m)

k(m=3) and k(m)

is the stress spectrum factor based on m = 3 is the stress spectrum factor based on m of the detail under consideration shall be based on the same stress spectrum that is derived either from calculation or simulation

For

Mf = 1,25 and m = 5. Annex C gives the values of Rd in dependence on the class S and c .

Simplified method for slope m 3

6.5.3.4

As k* = 1 covers the most unfavourable stress spectra, Rd ,1 may be used as permissible stress range. The value of k* may be calculated for k(m=3) and k(m) from the stress spectrum estimated by experience.

Proof of static strength of hollow section girder joints

The proof of design strength of hollow section girder joints guards against failure due to: plasticising of the boom member flange; plasticising or instability of the boom member web; shearing of the boom member cross-section; punching-through of the boom member flange; tearing-off of the web member with effective cross-section; local bulging. The proof shall be executed according to the rules of Eurocode 3, ENV 1993-1-1:1993, annex K.

Proof of elastic stability

The proof of elastic stability prevents structural members from the loss of stability by lateral deformation (e. g. buckling, bulging).

NOTE This clause is still under consideration and will be given in a later revision. It is intended to follow the principles of DIN 18800 and applicable literature.

38

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Annex A (normative) Values of inverse slope of /N-curve m and permissible stress range c, c

Table A.1 Basic material of structural members

c

No.

c

(N/mm )

2

Constructional detail

Requirements

Rolled surfaces and edges, Surface condition according to EN 10163-A3/C3, No thermal cutting, No notches or geometrical notch effects (e. g. cutouts)

m=5 1 Plates, flat bars, rolled profiles under normal stresses 250 280 315 fy 275 275 < fy 355 355 < fy

2 m=5 Plates, flat bars, rolled profiles under normal stresses 200 225 fy 275 275 < fy

Flame cut edges, quality according to EN ISO 9013-IA No geometrical notch effects (e. g. cutouts)

39

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Table A.1 (concluded)

c

No.

c

(N/mm )

2

Constructional detail

Requirements

Nominal stress calculated for the net cross-section Holes not flame cut, Bolts may be present, when these are stressed

m=5 3

up to 20 % of their strength in shear/ bearing connections or

Holes in a plate under normal stresses

200 225

fy 275 275 < fy

up to 100 % of their strength in slip-resistant connections

m=5 4

Plates, flat bars, rolled profiles under shear stress 140 160 180 fy 275 275 < fy 355 355 < fy

40

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Table A.2 Bolted members, connecting devices

c

No.

c

(N/mm )

2

Constructional detail

Requirements

Double shear

Supported single-shear m=5 1 (example)

The proof of fatigue strength is not required for bolts of slip resistant bolt connections Nominal stress calculated for the net cross-section

Single-shear

Perforated parts in slip-resistant bolt connections under normal stresses 200 225 2 m=5 180 3 m=5 125 m=5 4 140 355 m=5 5 100 250 m=3 6 32 45 fy 275 275 < fy Perforated parts in shear/bearing connections under normal stresses double-shear and supported single-shear Normal stress Perforated parts in shear/bearing connections under normal stresses single-shear joints, not supported Normal stress Fitted bolts in double-shear or supported single-shear joints Shear stress ( c ) Bearing stress ( c ) Fitted bolts in single-shear joints, not supported Shear stress ( c ) Bearing stress ( c ) Threaded bolts loaded in tension Machined thread Rolled thread Uniform distribution of stresses is assumed Uniform distribution of stresses is assumed Nominal stress calculated for the net cross-section Nominal stress calculated for the net cross-section

calculated for the stress-area of the

bolt, using 5.2.3.3)

Fb

(see

41

Licenza d'uso concessa a ENEA CENTRO DI FRASCATI per labbonamento anno 2005. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

CEN/TS 13001-3.1:2004 (E)

Table A.3 Welded members

No.

c c 2 (N/mm )

Constructional detail

Requirements Basic conditions: symmetric plate arrangement fully penetrated weld Manual or partially mechanized welding Components with usual residual stresses Angular misalignment < 1 t1 = t2 or

m=3

slope <1:3 Symmetric butt joint, normal stress across the weld Special conditions: Components with considerable residual stresses (e. g. joint of components with restraint of shrinkage) - 1 NC - 2 NC

180

Butt weld, quality level B*

160

Butt weld, quality level B

- 4 NC

140

Butt weld, quality level C Basic conditions:

4 NC

symmetric plate arrangement fully penetrated weld Manual or partially mechanised welding Components with usual residual stresses Angular misalignment < 1 Components with considerable residual stresses (e. g. joint of components with restraint of shrinkage) -1 NC

m=3

Symmetric butt joint, normal stress across the weld

Special conditions:

90