Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Analisis Quimico Tuberia 1 12

Caricato da

CARLOS ROMEROTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Analisis Quimico Tuberia 1 12

Caricato da

CARLOS ROMEROCopyright:

Formati disponibili

WELD LOCATION RECORD and MATERIAL CERTIFICATE

www.jasonenergy.com

Yantai Jereh Petroleum Equipment &

Customer Technologies Co., Ltd Coiled Tubing No. 623349

Certificate No. JGC22070703 Size 1.500"×TAP

Product Name Coiled Tubing Grade TS-90

Manufacturer Jason Energy Technologies Co.,Ltd. Length 18314 ft

Spool Size Metal/128×72×70×62(in) Tubing Weight 38603 Lbs.

Package Size L×W×H:146×74×131(in) Total Weight 43674 Lbs.

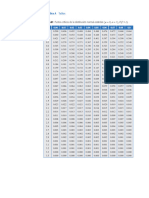

Mechanical Property Chemical Analysis,Wt %

Weld

Wall Length Weld

Strip No. Loc Coil No. Heat No. Yield Tensile

(in) (ft) Type Elongation Rockwell Hardness

(ft) Strength Strength C Mn P S Si Cr Mo Ni Cu Nb Ti

(%) Mat'l Weld

(psi)0.2% (psi)

1113685750108 0.125 394 394 BIAS 11136857501 11226708 97000 107000 23.0 98.5HRB 20.0HRC 0.14 0.78 0.011 0.001 0.31 0.57 0.17 0.16 0.30 0.015 0.015

2220177640104 0.125 1985 2379 BIAS 22201776401 22102236 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220177640105 0.125 1985 4364 BIAS 22201776401 22102236 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220177640106 0.125 1982 6346 BIAS 22201776401 22102236 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220177640107 0.125 1991 8337 BIAS 22201776401 22102236 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220177640108 0.125 1791 10128 BIAS 22201776401 22102236 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220219260101 0.134 1968 12096 BIAS 22202192601 22105630 0.14 0.75 0.012 0.001 0.33 0.59 0.14 0.15 0.30 0.014 0.017

2220177910103 0.134 558 12654 BIAS 22201779101 22113347 0.14 0.74 0.012 0.001 0.33 0.58 0.13 0.15 0.30 0.014 0.015

2220155330101 0.156 1539 14193 BIAS 22201553301 22102237 0.14 0.77 0.011 0.000 0.33 0.59 0.13 0.15 0.30 0.014 0.015

2220155330102 0.156 1542 15735 BIAS 22201553301 22102237 0.14 0.77 0.011 0.000 0.33 0.59 0.13 0.15 0.30 0.014 0.015

2220155330103 0.156 1001 16736 BIAS 22201553301 22102237 0.14 0.77 0.011 0.000 0.33 0.59 0.13 0.15 0.30 0.014 0.015

2120961310103 0.175 853 17589 BIAS 21209613101 21161022 0.13 0.75 0.009 0.001 0.34 0.60 0.13 0.14 0.29 0.013 0.016

2220215190308 0.175 725 18314 END 22202151903 22105632 98500 109000 23.0 21.0HRC 95.5HRB 0.14 0.78 0.011 0.001 0.35 0.61 0.14 0.15 0.29 0.014 0.017

UNION END (H/N:1830005 2″FIG 1502)

NDE Test Mechanical Test Hydrostatic Test

Flash-in Gauge Ball Nitrogen Freeze

X-Ray ET Tensile Test Flaring Test Flattening Test Hydrostatic Test Fluid PH

Remove Material / Size Purge&Wiped Proof

No Defect ASTM E309 ASTM A370 No Crack No Crack 12600 Psi 30 Minute 8.0 N/A Metal / 1.000 in Acceptable N/A

Product Specification JGC0119 A/1

We hereby certify that the material herein described has been manufactured, tested and inspected strictly in accordance with the full

Material Specification Ref.ASTM A606

requirements of the specification or applicable exceptions and the above records of test and inspections are true and accurate.

Quality Control /Date Jul. 7, 2022

Effective :14-09-26/ Rev:1218 Waste disposal should meet the local government's requirements.

Potrebbero piacerti anche

- Verifica Profilo Appoggio AppoggioDocumento4 pagineVerifica Profilo Appoggio AppoggiosbacchiNessuna valutazione finora

- Tiempos S10Documento6 pagineTiempos S10joseNessuna valutazione finora

- Giunti ElasticiDocumento3 pagineGiunti ElasticiMassimiliano VidoniNessuna valutazione finora

- Infrastrutture AeroportualiDocumento67 pagineInfrastrutture AeroportualiEdomrgNessuna valutazione finora

- 4-Geotecnica EA PDFDocumento44 pagine4-Geotecnica EA PDFDawsonNessuna valutazione finora

- Catalogo Generale: General CatalogueDocumento16 pagineCatalogo Generale: General CatalogueWilliam da Silva MarquesNessuna valutazione finora

- Analisis Sismico Sin RefDocumento33 pagineAnalisis Sismico Sin RefluzagredasNessuna valutazione finora

- 1 Ppto Analitico AMPLIACDocumento23 pagine1 Ppto Analitico AMPLIACp.rojasc3dNessuna valutazione finora

- Zapata Continua InicioDocumento1 paginaZapata Continua Iniciojeiser vasquez chNessuna valutazione finora

- Ensayo de Corte Directo Astm D 3080Documento1 paginaEnsayo de Corte Directo Astm D 3080GEO TAMBOPATANessuna valutazione finora

- Retencion en Linea - 12300100035Documento1 paginaRetencion en Linea - 12300100035Adrian MartinNessuna valutazione finora

- Direct ShearDocumento1 paginaDirect SheartitoalfaizanNessuna valutazione finora

- Serie Tayler TablaDocumento1 paginaSerie Tayler TablaLMVM927919Nessuna valutazione finora

- Ischebeck TitanDocumento4 pagineIschebeck Titanmoca89Nessuna valutazione finora

- Formato MercaderistaDocumento5 pagineFormato Mercaderistacarlos albertoNessuna valutazione finora

- Catalogo - Compensatori - SteelFlex 29Documento1 paginaCatalogo - Compensatori - SteelFlex 29lattie18728Nessuna valutazione finora

- Specifiche Tubi X Circuiti Oleodinamici (BENTELER)Documento12 pagineSpecifiche Tubi X Circuiti Oleodinamici (BENTELER)managerscribdNessuna valutazione finora

- Dati e Tabelle UtiliDocumento10 pagineDati e Tabelle Utilixojak31526Nessuna valutazione finora

- 10 Schede Tecniche Lamiere Grecate COPERALL PDFDocumento16 pagine10 Schede Tecniche Lamiere Grecate COPERALL PDFAlessio de IulisNessuna valutazione finora

- Diametri Sezioni e PortateDocumento1 paginaDiametri Sezioni e PortateRobNessuna valutazione finora

- 10 Schede Tecniche Lamiere Grecate COPERALL PDFDocumento16 pagine10 Schede Tecniche Lamiere Grecate COPERALL PDFAlessio de IulisNessuna valutazione finora

- Cross Real-Portico EquivalenteDocumento16 pagineCross Real-Portico Equivalentefernando mafaileNessuna valutazione finora

- Calculo Sismico DinamicoDocumento33 pagineCalculo Sismico DinamicoBrighitaNormaQuispeCatariNessuna valutazione finora

- Guias para Cilindros 09-05-03-02-Anelli - Guida - EDWRDocumento2 pagineGuias para Cilindros 09-05-03-02-Anelli - Guida - EDWRCarmelo ValenciaNessuna valutazione finora

- Induttanze In3 DV 4 Dimensioni e Dati Tecnici BT 2015 PDFDocumento2 pagineInduttanze In3 DV 4 Dimensioni e Dati Tecnici BT 2015 PDFCristian BandilaNessuna valutazione finora

- Filtro Ps AltoDocumento6 pagineFiltro Ps Altorifat2842003Nessuna valutazione finora

- Test Pile'3.5m'1st - 2 - TabDocumento5 pagineTest Pile'3.5m'1st - 2 - TabAbhinandan MazumderNessuna valutazione finora

- Anelli ElasticiDocumento26 pagineAnelli ElasticiMichele TrevisiolNessuna valutazione finora

- Norma Flanges PRFV PDFDocumento33 pagineNorma Flanges PRFV PDFAlvaro RiverosNessuna valutazione finora

- CATALOGO DE RODAMIENTOSsistemi T.I.B..cuscinetti PDFDocumento84 pagineCATALOGO DE RODAMIENTOSsistemi T.I.B..cuscinetti PDFArnaldo CabreraNessuna valutazione finora

- Libro 1Documento4 pagineLibro 1Grace ElizabethNessuna valutazione finora

- Tabelle Caratt-MaterialiDocumento6 pagineTabelle Caratt-MaterialiLorenzo MasottiNessuna valutazione finora

- Alinyemen ValDocumento4 pagineAlinyemen ValAnjasmara Pribadi BarlianNessuna valutazione finora

- Condotte in Pressione TabelleDocumento3 pagineCondotte in Pressione Tabellevirgus87Nessuna valutazione finora

- Tubi e Raccordi in PVCDocumento37 pagineTubi e Raccordi in PVCPedro Figueroa MartínezNessuna valutazione finora

- Catalogo COPPERCLAD ACS para TierrasDocumento7 pagineCatalogo COPPERCLAD ACS para TierrasDaniel NavasNessuna valutazione finora

- Caratteristiche Viti PDFDocumento1 paginaCaratteristiche Viti PDFCkaal74Nessuna valutazione finora

- 06 5911Documento1 pagina06 5911Shreyas IyengarNessuna valutazione finora

- Calculo Del Diametro Mas Economico - Con FormulasDocumento5 pagineCalculo Del Diametro Mas Economico - Con FormulasCarlos Neria Jimenez100% (1)

- Cartera Tramo 1Documento1 paginaCartera Tramo 1Jadith Villar BorreroNessuna valutazione finora

- TabellaProgettoMsemplice0 0667Documento3 pagineTabellaProgettoMsemplice0 0667David SmithNessuna valutazione finora

- ABB Technology LTD: ItscbDocumento2 pagineABB Technology LTD: ItscbMahyar MashayekhiNessuna valutazione finora

- Laminati MercantiliDocumento7 pagineLaminati MercantiliGiuseppe RainoneNessuna valutazione finora

- Master File Chamber-Non MacroDocumento82 pagineMaster File Chamber-Non MacroRudolfNessuna valutazione finora

- Caratteristiche Barre Filettate PDFDocumento1 paginaCaratteristiche Barre Filettate PDFClaudioNessuna valutazione finora

- Tablas A1-A4 z-chi-T-FDocumento5 pagineTablas A1-A4 z-chi-T-FFernanda JaramilloNessuna valutazione finora

- Sistema Di Drenaggio UrbanoDocumento15 pagineSistema Di Drenaggio UrbanoalessioNessuna valutazione finora

- Tabella-Di-Conversione durezza-ASTM-A370Documento1 paginaTabella-Di-Conversione durezza-ASTM-A370xojak31526Nessuna valutazione finora

- Graficas X-SDocumento6 pagineGraficas X-SRamón OchoaNessuna valutazione finora

- Wagner Acciaio TemprabileDocumento1 paginaWagner Acciaio TemprabileSilvia GaianiNessuna valutazione finora

- UNI 5933 DIN 7991: Viti A Testa Svasata Piana Con Cava Esagonale Passo GrossoDocumento1 paginaUNI 5933 DIN 7991: Viti A Testa Svasata Piana Con Cava Esagonale Passo GrossoEMMEVINessuna valutazione finora

- Viti TSEI UNI 5933 PDFDocumento1 paginaViti TSEI UNI 5933 PDFGNessuna valutazione finora

- CICSA Chains LH and MHDocumento1 paginaCICSA Chains LH and MHENTREGA RUBIALESNessuna valutazione finora

- UNI 5933 DIN 7991: Viti A Testa Svasata Piana Con Cava Esagonale Passo GrossoDocumento1 paginaUNI 5933 DIN 7991: Viti A Testa Svasata Piana Con Cava Esagonale Passo GrossoEMMEVINessuna valutazione finora

- Viti TSEI UNI 5933 PDFDocumento1 paginaViti TSEI UNI 5933 PDFGNessuna valutazione finora

- Ventas Flota Illimani Marzo 2017Documento7.275 pagineVentas Flota Illimani Marzo 2017Carla Miriam Soliz CostasNessuna valutazione finora

- Dati e Tabelle Utili 2015 - 2436341Documento12 pagineDati e Tabelle Utili 2015 - 2436341Francesco SpinellaNessuna valutazione finora