Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

EP2066171B1

Caricato da

Anonymous DxaBg8fUE0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni23 paginesang che 12

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentosang che 12

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

7 visualizzazioni23 pagineEP2066171B1

Caricato da

Anonymous DxaBg8fUEsang che 12

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 23

EP 2 066 171 B1

(19) )) a

(12)

(45) Date of publication and mention

ofthe grant ofthe patent:

28.07.2012 Bulletin 2012/0

(21) Application number: 06799771.8

(22) Date of fling: 16.10.2008,

(11) EP 2 066 171 B1

EUROPEAN PATENT SPECIFICATION

(61) Intel

ADIM 21/04.2800)

(86) Intamational application number:

PCT/SE2006/001171,

(87) Intemational publication number:

Wo 2008/039122 (03.04.2008 Gazette 2008/14)

(64) ADMINISTERING TREATMENT SUBSTANCE TO POROUS ELEMENTS

\VERABREICHUNG EINER BEHANDLUNGSSUBSTANZ AN POROSE ELEMENTE

ADMINISTRATION D'UNE SUBSTANCE DE TRAITEMENT A DES ELEMENTS POREUX

(84) Designated Contracting States:

AT BE BG CH CY CZ DE DK EE ES FIFR GB GR

HUJE IS IT LILTLU LV MC NL PL PT RO SE SI

SkTR

(80) Priority: 25.09.2006 SE 0601986

(43) Date of publication of application:

10.06.2009 Bulletin 2009724

(73) Proprietor: Merving, Hans A. K.

644 00 Torshalla (SE)

Hans A. K,

(Se)

(72) Inventor: Mervin

644 00 Torsha

(74) Representative: Hedman, Anders et al

Aros Patent AB

P.O, Box 1544

751 45 Uppsala (SE)

(68) Reterences cited

EP-At- 0 400 882

US-A-2970348

US-A- 4.208 689

US-A-5 207 021

US-A-5 505 021

Wo-A1-94/06276

US-A-2970 404

US-A- 4 905 021

US-A-5 408 781

Note: Within nine months ofthe publication of the mention ofthe grant of the European patent In the European Patent

Bulletin, any person may give notice to the European Patent Office of opposition to that patent, in accordance withthe

Implementing Regulations. Notice of opposition shall not be deemed to have been fled untl the opposition fee has been

paid. (Art. 99(1) European Patent Convention),

1 EP 2.066 171 B1 2

Description

TECHNICAL FIELD

[0001] The presentinvention concerns the administer.

ingoftreatment substance generally porous elements,

such as wood, and in particular to plants, trees etc. by

‘means of a capsule for delivering such substance to the

interior ofthe element

BACKGROUND

[0002] US. Patents 4,905,410, 5,485,698 and § 408

71 disclose tree treatment capsules Including aplug for

insertion into an end opening of an intemal cavity of a

container. The capsule is introduced into a bore formed

in tree, with aprotruding outer end of the plug engaging

bottom end ofthe bore. An impact forces then applied

to.a head element of the plastic container, outside the

tree, to move the head element towards the plug and

break a shank of the container. A chemical agent is re

leased from the internal cavity when the shanks broken

in this way. Generally, the use ofthese known capsules

has advantageous effects and provides good final re

cults, but involves rather time-consuming preparation

{due not only to the large number of bores required but

also to the comparatively strict requirement for appropri

ate dimensions, especially depth, ofthe bores formed in

the porous elements.

‘SUMMARY

[0003] tis a general object ofthe present invention to

provide an improved administering of treatment sub

stance to porous elements, specifically by facitating the

preparation work andlor by reducing the amount of such

preparation work

[0004] In particular itis an object of the invention to

suggest a convenient and cost effective method of ad-

‘ministering treatment substance to porous elements,

whereby in particular the preparation work on said ele

‘ments will be greatly facilitated

[0005] Another object of the invention isto provide @

‘capsule for use in administering treatment substance to

‘porous elementin accordance withthe basie principles

(ofthe invention,

[0006] These and other objects are met by the inven

tion as defined by the accompanying patent claims,

[0007] The invention generally relates to the adminis-

tering or supply of treatment substance to a porous ele-

‘ment by means of a capsule adapted for insertion into @

bore ofthe element and consisting ofa container having

closed and open ends and a shank portion connecting

sald ends and forming treatment substance cavity with

in said container, and a plug being partially fited into the

‘open endof the container, whereby treatment substance

is supplied to the element by driving the plug into the

cavity to break open the shank portion of the container.

~

»

Ithas been recognized that essentially improved etficien

‘oy may be achieved by allowing the capsule receiving

bores to be formed with optional depth. A basic idea is

to accomplish this by introducing the capsule with the

closed end of the container first, into the bore and by

‘supporting the container adjacent said open end thereof,

against an outer surface of the porous element prior to

arving the plug into the cavity,

[0008] According to a further aspect of the invention

an improved capsule for administering treatment sub

stance is provided that is adapted for use withthe inven-

tive method. The capsule includes @ container having

closed and open ends and a shank portion connecting

‘said ends and forminga treatment substance cavity with

in said container, and a plug being partially fited into the

‘open end of the container. A basic idea of this aspect is

toprovide a container wherein an outer support structure

is provided on the container, close tothe open endithere

ot

[0009] By tapering the shank of the container towards

the closed container end such that the shank portion has

its major circumferential dimension towards seid open

end a portion of the shank will be broken up by direct

‘contact withthe plug being criven down and insertion of

the capsule into the bore wil simultaneously be facili

ed.

[0010] In one embodiment that may be specifically

preferable for applications requiring multiple treatments,

the treatment substance cavity is divided into mutiple

‘compartments,

[0011] _Inanother embocimentthat may be particularly

preferable for use for the administering of fuid treatment

‘substances, the plugaandthe container are each provided

with complementary cooperating and eaengaging seal

ing means.

[0012] Advantages offered by the present invention, in

addition to those described above, wil be readly appre

ciated upon reading the below detalied description of em-

bodiments ofthe invention.

BRIEF DESCRIPTION OF THE DRAWINGS

[0013] The invention, together with further objects and

advantages thereot, willbe best understood by reference

to the following deseription taken together with the ac:

‘companying drawings, in which:

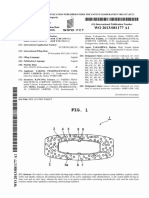

Fig. 1A is a party schematical exploded side view

ilustrating a first embodiment of a capsule

for administering treatment substance ac

cording to the invention:

Fig.18 is a side view of the assembled treatment

substance capsule of Fig. 1A;

Fig.2A isan exploded view corresponding that of

Fig. 14, illustrating the capsule ofthe inven:

tion in section;

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

Fig

28

2c

3A

38

sc

an

4B

ac

BA

86

10

3 EP 2.066 171 B1

is a view corresponding to that of Fig. 1B

illustrating the assembled capsule of the in

vention in section;

is a view corresponding to that of Fig. 28

illustrating the capsule ofthe invention with

treatment substance added to the cavity;

is a detalled side view of the container part

of the capsule of Fig. 18:

isa detalledbottom view ofthe containerpart

of the capsule of Fig. 1A:

is a detailed top view of the container part of

the capsule of Fig. 1A;

is a detailed side view ofthe plug part of the

capsule of Fig. 1A;

is a detailed bottom view of the plug part of

the capsule of Fig. 1A;

is a detaled top view of the plug part of the

ccapeule of Fig. 14;

isa schematical ilustration of steps I-IV of a

‘method accordingto the invention for admin

isteringtreatmentsubstance bymeans tthe

capsule of Figs 1A-B;

ilustrates a section through a second em

bodiment of the capsule for administering

treatment substance according to the inven

tion;

illustrates @ partial section through @ third

‘embodiment of the treatment substance ad-

‘ministering capsule according tothe inven

tion

is a schernatical top view of the container of

fa frst variant of the third capsule embod!

‘ment of Fig, 7;

is a schematical top view of the container of

‘second variant ofthe thtd capsule embod

iment of Fig. 7:

illustrates a sealed plug part for a treatment

substance administering capsule, in side,

top and bottom views;

illustrates an altemative embodiment of the

plug pat ofthe treatment substance admin

istering capsule according to the invention,

ina side view and in section;

~

»

Fig

Fig

Fig.

Fig

Fig

Fig.

Fig

Fig

Fig

Fig.

11,

ne

16a,

168

17

178

4

is an exploded side view, in section, ofa fur

ther altemative, forth embodiment of the

treatment substance administering capsule

‘according to the invention;

ilustrates the plug part ofthe forth embod

‘ment ofthe capsule, in side an top views,

llustrates alternative embodiments of the

closed bottom of the container part of the

treatment substance administering capsule

‘according to the invention;

ilystrates a practical application of the treat

‘ment substance administering capsule ac

cording to the invention;

ilystrates a further practical application of

the treatment substance administering cap-

sule according to the Invention;

Is a side view of a further embodiment of a

Container for a treatment substance admin

Istering capsule according to the invention,

especially sutable for use in the application

of Fig. 14

Is a side view of an alternative embodiment

cof a container fora treatment substance ad

ministering capsule according tothe inven

ton, being suitable for use in the application

of Fig. 14;

is anendview{romabove ofthe embodiment

of Fig, 164:

is @ side view, partially in section, of a fith

alternative embodiment of the trestment

substance administering capsule according

to the invention, in an assembled condition;

and

Is a side view corresponding to that of Fig,

17A, illustrating the fith embodiment of the

treatment substance administering capsule

‘according to the invention in an activating

phase,

DETAILED DESCRIPTION

[0014] The invention will now be explained with refer

ence to exemplitying embodiments thereot, which are

ilustrated in the accompanying drawing figures and

‘serve to exempiy the use ofthe principles of the inven:

tion in diferent applications for administering or supply:

Ing atreatment substance, such as a chemical agent,

the phloem layer of @ tree, The substance may be either

aherbicide or any other tre destroying agent ifthe treat

5 EP 2.066 171 B1 6

‘ments designed kil the tree, an insecticide ifthe treat-

‘mentis designed for noxious insect control, ora fertilizer,

fungicide or other medicant or nutrient the treatments

designed to cure the tree from a disease or a nutrient

deficiency. It shall be emphasized, though that the illus

trations ate forthe purpose of describing preferred em

bbodiments of the invention and are not intended to iit

the Invention to the details thereof. The invention may

therefore also be used for other applications such as the

delivery of dye or an impregnation agent in order to

change the color or other characteristics ofaplant tree

trunk, ether ving or felled, or any other porous element.

[0018] The prior art solutions ofthe iniially discussed

kind, for introducing treatment substance in @ porous el

‘ement such as atree trunk, are allbased on the insertion

‘of @ capsule into @ bore in the element with an open end

of a container first, said open end being temporary

closed by an installed plug. To achieve the desired func:

tion the capsule must be introduced into the bore until

the plug abuts the bottom of the bore, which requires the

formation of a bore with relatively narrow tolerance with

regartto its depth, Forming such bores with narrow tol

france is unnecessarily time consuming and undesira

ble.

[0016] | Thepresentinvention eliminates this shortcom-

ing in the prior at by suggesting a solution that allows

forthe formation of a capsule receiving bore having op

tional length, which wil make the work of forming bores

‘much quicker and more effective.

[0017] A first exemplifying embodiment ofthe inven

tion Is shown in Figs. 1-5, wherein the present invention

is embodied in a tree treatment capsule 1 that with ref

ference to Fig, 5 is adapted for insertion into a predriled

bore 34 formed in the trunk of a tree 20 to be treated,

‘Thebore extends through thebark 32 andintothe phioem

layer 31 of the tree 30, as will be described below, in

‘association with Fig. 5. The capsule 1 includes a con-

talner 2 having a closed end 4, an open end 5 and @

hollow shank portion & interconnecting the closed and

‘open ends 4 and 5, respectively. The shank portion 3 of

the container 2 forms an internal cavity 8 that Is open at

‘one end and closed at the other to receive a treatment

substance 20 therein in an assembled conaltion of the

capsule 1

[0018] The shank3 consists ofa first portion 2A taper:

ing towards the closed end 4 and a generally cylindrical

‘second portion 3B adjacent the open container end 5.

“The tapering frst shank portion 2A isin this embodiment

integral with @ bottom wall 10 forming said closed end of,

the container 3 and of sa internal treatment substance

cavity 8. For reasons to be described later, the tapering

first shank portion SA is atleast partially frangible so that

itmay be appropriately brokento allow thetreatmentsub-

stance to exit the cavity 8 and enter the bore 34. In the

illustrated embodiment, this isachievedby providingmul

tiple evenly spaced notches 7 around the circumference

of said fst shank portion 2A, extending along the first

shank portion towards the closed container end 4, These

~

»

notches 7 wil serve as crack initiating means when a

breaking force is applied to the container 8, as will be

explained below. The cylindrical second shank portion

‘3B is formed integral withthe open container end 5 that

is in tum formed integral with an outer stop flange 6 that

circumterentially surrounds said open end § for abutting

an outer surface of said tree 30 when the capsule isin

‘serted info sald bore 34, Therefore, the actual shank 3

has an outer diameter smaller than the diameter of the

bore 34 in the tree 30 but the stop flange has an outer

dlameter essentially exceeding the dlameter of the bore

34,

[0019] | TheopencontainerendShas aclreular opening

‘A for receiving a plug 18. The plug 16 is inserted into

the open container end 5 during assembly ofthe capsule

1, closing said open second end § and retaining said

treatment substance 20 in the internal cavity 8. The plug

16 is generally cylindrical in shape and has a diameter

slightly smaller than the inner diameter of the second

‘shank portion 3B and ofthe citeular opening 6A, to pro:

vide atghtitfor the fully installed plug 1Sinthe container

2, The plug 15 has a chamfered insertion end 17 to fa:

ciltate insertion into the open container end § and an

opposite end having a fat Impact surface 18 for applying

2 plug driving impact force F thereto during activation of

the treatment capsule 1

[0020] Referring specifically to Figures 2A-C and 4A.

G itis apparentthat the plug 1Smay preferably behollow,

with aseries of reinforcingribs 18A, 188 integrally formed

with and on the circumferential inner surface ofthe plug

416 to provide a lightweight and yet strongly reinforced

structure that wll be snugly received within the shank 3

when the capsule 1 is fully assembled, The ribs 188, 188

may preferably be arranged at equal circumferential

‘spacings extending crosswise over its full hollow interior

asin this frst embodiment, but may alternatively extend

only a limited distance into said hollow interior, as is

‘shown for the ribs 418A in the alternative embodiment

of Fig. 9. Theplug 16 is provided with a crcumferentially

protruding ridge 16 on the outer cylindrical surface there

of. The ridge 16 is preferably provided at a location ad

Jacent the chamfered end 17 of the plug 18. As will be

‘come clear, when capsule 1 is assembled, the ridge 16

of plug 18 interlocks witha recess 9 formedin the radially

Inner surface of the second cylindrical shank portion 3B,

to secure plug 16 in open end 5 of the container 2,

[0021] Inassembiingthe capsule 1, the treatment sub

stance is introduced into the cavity 8 of the container 2

and the plug 15 is then inserted into open end § of the

container 10. Plug 15 is forced into the open end until

ridge 16 snaps into engagement with and is completely

recelved in recess 9, as is shown in Fig. 20. The cylin

rica plug 15 tigntl fits inthe open end and cylindrical

‘shank portion 3B, Ridge 16 is completely received in and

tightly engaged with recess 9 to completely seal off te

‘open end 5 of container 2, An appropriate connection

between capsule parts, Le. container 2 and plug 16, is

therefore provided. Although a tight fit is normally ob-

7 EP 2.066 171 B1 8

tained between the plug 18 and the container 2 due to

the interengagement of ridge 16 and recess 9, itis pos

sible to adcitionaly apply an adhesive or alternatively a

sealing coating on the plug 18 andior container 2 and

specifically in the area of the ridge 16 and the recess 9

to further seal andlor secure the plug 15 in the open end

65 in order to provide a superior seal. The treatment sub

stance 20 may be of any of the above mentioned kinds,

being appropriate forthe application in question, such as

a herbicide or a fungicide, and in any appropriate form,

such as a tablet, a powder, a gel material, a pasty mate

fal, aliquid or even @ gas.

[0022] The method of applying the fully assembled

capsule 1 of the invention will now be described with ret

ferenceto Fig.6. In first step |, an appropriate tool, here

a dill 33, is employed to form a bore 4 ina tree 30, in

this case a tree trunk, through the bark $2 and into the

phloem layer 31 ofthe tree 30, According to the invention

the bores formedin he tree 30 having an optional depth

D exceeding the axial length L ofthe shank 3 ofthe cap.

sule container 2 from said closed 4 to sald open end 5.

‘The bore 34 is further dimensioned to have an internal

diameter sightly exceeding the outer diameter of the ac-

tual shank portion 3 and clearly smaller than the outer

diameter of the stop flange 6. In a second step Il the

‘assembled treatment eubstance containing capsule 1 is

then inserted into the prediilled bore 34 in the trunk of

the tree 30 to be treated. The capsule 1 is inserted into

the bore 34 ofthe tree 30 untithe container stop flange

6 abuts against the outer surface in the tree 30, in this

‘case the bark 22, Ina third step Illa driving foree, inthis

‘embodiment an impact force, is applied to the plug 15

such as by hammering in the direction shown by arrow

F in Fig, 5, causing the plug 15 to move further into the

shank portion 3 of the container 2 and into the cavity 20

such that the chamfered end 17 engages the tapered

shank portion SA and forces itto expand radially outward-

ly until the tapered shank portion 3A breaks along the

Weakening notches 7. Inthe first phase ofthis breaking

up of the tapered shank wall 3A, passages 208 are

formed through the wall at said notches 7 to permit the

treatment substance 20, atleast itis in gel-ike or liquid

form, to be released and mix with the sap 95 of the tree

0, oo permit the sap 35 ofthe tree 30, ifthe treatment

‘substance is in the form of a tablet or a powder, to per:

‘meate andmixwith the treatment substance 20, Because

passages 208 are located in the central part of shank,

they are more precisely aligned with the phloem layer of

tree 3. The substance 20 contained in the capsule 1 Is

therefore more precisely eleased into this phloem layer.

Due tothe expansion ofthe frst shank portion 3A by the

driven plug 15, a very tight fit will be obtained between

the container 2 of the capsule 1 and the bore 34 in the

tree 30 after the driving force F has been applied. This

causes the capsule 1 to be held firmly in the tree 20. in

a final phase IV of the application the plug 18 may be

tiven down so thatthe lower part of the tapered shank

portion 3A, together with the lowermost closed container

~

»

end 4 Is completely tom off from the remainder of the

container 2 to provide unrestricted aistribution of sub-

stance 20 and sap 36.

[0023] All or some portions of the capsule 1 may be

made of diferent formulations of plastic materials, such

as by injection molding or extrusion molding; polyvinyl

alcohol or starch materials, to faciltate dissolution of

parts of the shank walls upon contact with the sap of a

tree, the fuidin cut flower stems, or similar liquids; wood;

paperboard fibre; formulations of plaster; or metal. Al

parts may advantageously be made of a suitable biode:

gradable material. The container 2 shank: Is preferably

made of a brite, frangible material allowing etectve

breaking up of the tapered shank portion 3A by the con

tact with the driven plug 16 that may preferably be made

of a higher strength material. In an exemplary embodi

ment the container 2is made of polystyrene or polycar-

bonate and the plug 15 is made of polyethylene. Making

the container 2 and plug 16 of these different plastic ma:

terials enables the container 2 to be broken more easily

than plug 15.

[0024] "A second embodiment of a capsule 101 of the

invention is shown in Fig 6 Many elements ofthis second

embodiment are the same as corresponding elements

of the first embodiment and a repetitive descrigtion of

these elements isnot provided. The second embodiment

is intended for use in the same way as the first embodt

ment of Figs 1-5, butiffers therefrom essentially by the

‘act that the container 102 and the plug 116 are formed

as an integral unit, retained in relative position by the

attachment to each otherin a connection portion 111 that

will break when applying driving force to the plug 116.

Toallowriling ofthe cavity 108 with treatment substance,

the container 102 n this embodiment has a separate bo:

tom 110 forming the closed container end 104 and being

releasably attached to the tapered shank portion 103A

byaridge 110A andrecess 104Atypesnap-inconnection

similar to that forthe releasable connection between the

plug and container in the fist embodiment.

[0025] Inathirdembodiment ofthe capsule 201 shown

with variants in Figs. 7 and 8A-8B, the containers 202,

802 and 802%, respectively, are identical in all respects

to the container 2 of the first embodiment, except that

they include at least one diviging wall 212, 312, 31

respectively, within the cavity volume 208, 308, 208, re

spectively. In Fig. 7 is ilustrated a basic variant where

cone straight dividing wall 212 extends across the cavity

208 and separates sub-chambers 208A, 208B from each

other. One substance 20, such as an insecticide, may be

stored in one of the chambers 208A, while another sub-

stance 21, such asa fungicide, maybe storedin the other

chamber 2088. Figures 8A and 88 illustrate variants

where additional sub-chamivers 308A-C, S0BA'-D' may

be formed by including additional or alternatively config

ured dlviging walls 312, 312’ The dividing walls can be

formed of the same material as the container, as de-

seribed previously, and will break up when the plug is

driven down, to thereby release the containedsubstance,

9 EP 2.066 171 B1 10

[0026] In Fig, 9 Is lllustrated an alternative plug 415

providing excellent sealing between the plug and the

shank. In this case the plug 415 is formed with a recess,

not spectcally shown, in place of the ridge of the first,

‘embodiment, and in this recess is received a seal 416,

such as an O-ring, that in the fully assembled condition

will be received in the recess in the container shank to

provide a fluid tight seal for the substance in the cavity,

[0027] A further embodiment of the plug 515 is illus

trated in Fig. 10. Here, both ends 517A and 6178 of the

plug 515 are chamfered and provided with a retaining

ridge 616A, 5168. Such an embodiment will primarily fa

clitate assembly, specifically allowing for an automated

assembly.

[0028] | Inafurtherembodimentoftheinventivecapsule

601, ilustrated in Figs 11A and 11, the sealing of the

‘open end 05 of the container 602 and the retaining of

the plug 615 inthe fully assembled condition is achieved

by providing a retaining ridge 616 in the form of an ex:

ternal thread on the outer circumference of the plug 615

‘and a groove in the for of a complementary internal

thread 609 in the nner wall ofthe second shank portion

(6038. The threads 616, 609, may have an optional pitch

‘adapted to the spectic application, es indicated in Figs.

11A and 11B. In extreme cases they may also be addi-

tionally sealed with an appropriate coating. It will be un-

derstood that in this case the driving ofthe plug 615 into

the cavity 608 will be accomplished by applying a rotary

driving force F through a screw socket 619 in the plug

tend wall 618 and an appropriate too (not shown)

[0029] In Fig, 12 are shown alternative solutions for

Closing the container closed end. These alternative so

lutions may in applicable cases be used for al of the

previously described container embodiments 2-602, Of

these variants the first four comprise separate bottom

walls 10:1-10:4 that are attached to the container 2-206

prior to or ater filing the treatment substance cavity, de~

pending upon the capsule embodiment. Ofthese, bottom

wall 10:1 is atape thatis adheredto the bottom container

‘end; bottom wall 10:2 carries an external thread and is

sscrewedinto the container end, having an intemalthread

formed therein; bottom wall 10:3 inserted ito the con-

talner end and is secured thereto by an appropriate ad

hesive; and bottom wall 10:4 is secured to the container

by means of a type of bayonet lock. In the fith variant

the bottom wall 10:5 is made integral withthe container

2, having weakening notches formed at its edge to allow

breaking away of the bottom wall when driving down the

plug

[0030] In Fig. 13 is shown a further favourable ettect

‘ofthe optional bore $4’ depth D alowed according tothe

invention. In the ilustrted embodiment a bore 34’ is

formed from one side of a tree trunk 30' and extends

across the major portion of the trunk. When the container

of the capsule 1 has been broken up in the described

way, the treatment substance is distributed very advan

tageously across the trunk due to the extension of the

bore and the large amount of sap flowing into the bore

~

»

34’. This wil normally reduce the total number of bores

that wil have to be formed in the tre.

[0031] Fig. 14 shows a further variant with bores

34" formedina stump 30" ofatree. SeveralboresS4" are

distributed close to the outer circumference of the tree

‘stump and are formed at an angle to the upper surface

ofthe stump to provide excellent cistribution of treatment

substance in the stump,

[0032] In Fig. 15 is given an example of a container

702 design for the inventive capsule that is specifically

adapted for use in an application lke the one llustrated

In Fig. 14, where angled bores are formed in a tree ora

tree stump. In this example, the container carries a fixed

angled lange 706 on the outer circumference of the shaft

708, adjacent the open container end 706. In a modified

design, illustrated in Figs. 16A-B, of a container 802 in

‘tended for use ina similar application, the actual contain:

er 802 may be provided with a straight flange 806 that is

provided ata distance from the open end 805 ofthe con

tainer. In this embodiment the flange 806 is only locally

connected to, preferably integral with, the shaft 03

through narrow webs 8138, leaving gaps 813A separa

Ing the flange 806 from the shaft 803 around the major

portions of the outer circumference of the shaft. Due to

the flexibility ofthe container materia, the flange 806 will

in this case be automatically adjusted in position in rela

tion tothe angle of its associated bore, when the capsule

isinsertedandactivatedin he bore, Thisis schematically

illustrated in dash-dot lines in Fig. 16A.

[0033] Finally, Figs. 174-8 illustrate a further modified

variant ofthe ree treatment capsule 901 ofthe invention.

Here, the capsule 901 container 902 has a separate re

leasable bottom 910 fitted to or formed integral with the

closed end 904 ef the container, similar to the bottom

designs 10,10:3 or 10:5 as ilustrated in Fig. 12. This

‘separate bottom 910 is atts upper side, facing the cavity

908 forthe substance 20, provided with acentral rod 914

that extends along a mejor potion ofthe cavity 908, and

10.8 position close to the lower end of the plug 918, in its

assembled condition. The rod 914 may be formed inte

gral with or attached to the bottom. When driving force

is applied to the plug 915 and the plug engages the rod

914, the bottom 910 will be quickly pushed out or broken

off from the closed container end 904 so that the sub

stance 20 immediately leaves the cavity and cannot es:

cape upwardly past the plug 918 even when the sub-

stance is a highly viscous fui. In an alternative design

the central rod may be formed integral with or attached

to the bottom face of the plug instead, 60 thatthe plug

and container rod form @ unit that when bewing driven

cdown causes the bottom to be completely released from

the container.

[0034] Although the invention has been described and

ilustrated with specific reference to an application for a

‘ree trunk or stump, the invention isin no way restricted

touch applications, as indicated above. The basic prin:

ciples ofthe invention may be applied to treat other po:

fous elements by impregnation, dying ete

1" EP 2.066 171 B1 12

[0035] Theinvention hasbeen describedinconnection

with what is presently considered the most practical and

preferred embodiments, but it s to be understood that

the invention is notlimitedto the disclosed embodiments.

‘The invention is intended to cover various variations,

‘modifications and equivalent arrangements included

Within the scope of the appended claims.

Claims

1. A method of applying treatment substance (20) to

the interior of a porous element (30; 30; 30") com-

prising the steps of

+ providing a treatment substance capsule (1;

101; 201; 301; 601; 201) including a container

(@; 102; 202; 302; 602; 702; 802; 902) having =

closed end (4; 104; 204; 604; 904), an open end

(6; 105; 205; 605; 705; 805) anda shank (8; 103;

208; 603; 703; 803; 903) interconnecting said

closed and open ends, and having an internal

cavity (8; 108; 208; 308; 308'; 608; 908), treat

‘ment substance (20; 21) aisposed in sad inter

nal cavity, and a plug (15; 118; 215; 415; 815;

618;918)fitedinthe open end of said container,

sald pluginan assembled condition closing said

‘open end and retaining said treatment sub

stance in said internal cavity,

= forming at least one bore (94; 34” 94") into the

Interior of sald element; characterised in that

inserting an assembled tree treatment capsule

With said closed end first into sald bore or each

bore formedin the element so that an outer stop

flange (6; 106; 206; 606; 706; 806) at said open

tend of the capsule abuts an outer surface (31;

82) of said element, and

- applying driving force (F) to said plug to move

itthrough said open end, into the cavity, causing

at least a portion (BA; 108A; 208A; 603A; 10;

10:1; 10; 2; 10:3; 10:4; 10:5; 110; 910) of the

container to break, thereby releasing treatment

substance from saidintemaleavty by permiting

itto pass from said internal cavity and into said

bore.

2. Amethod according to claim 1, wherein a treatment

substance cepsule (1; 101; 201; 301; 601; 901) is

provided having a first shank portion (3A; 103A;

203A; 603A) tapering towards said closed container

fend (4; 104; 204; 604; 904) and wherein said plug

(18; 118; 215; 418; 615; 615; 915) Is forced through

ssald open end (5; 105; 205; 605; 705; 805) and said

cavity, into engagement withthe tapering shank por.

tion, breaking sald shank portion by direct contact

therewith

3, A method according to claim 1 oF 2, wherein the at

~

»

least one bore (84; 34’ 34°) is formed in sald porous

‘element (80; 30° 30") having 2 depth (0) being es:

sentially larger than an axial length (L) ofthe shank

(3; 103; 208; 603; 703; 803; 903) ofthe capsule (1

101; 201; 901; 601; 901) from said closed (4; 104;

204; 604; 904) to said open (6; 105; 205; 605; 705;

£205) end,

‘A method according to any of claims 1 - 3, wherein

‘eid driving force (F)s applied to said plug (615) by

‘a rotary manipulation thereof and by the mutual en-

‘gagement between external and internal threads

(616; 609) on the plug and the container (602), re

spectively,

‘A method according to any of claims 1 - 4, wherein

several different treatment substances (20; 21) are

simultaneously released from separate compart

‘ments (206A-B; 30BA-C; S0BA'-D)) of said internal

cavity (208; 308; 308') by the diving of sald plug

(216) into the cavity.

‘A capsule (1; 101; 201; 301; 601; $01) for insertion

into a bore (34; 34'; 34°) of a porous element (30;

20’, 30°) to apply treatment substance (20;21)to the

interior of the element, sad capsule comprising

+ a container (2; 102; 202; 302; 602; 702; 802;

902) havingaclosedend(4; 104;204; 604; 904),

an open end (5; 105; 205; 605; 705; 805) and a

shank (3; 109; 203; 603,703; 803; 903) intercon:

necting sald clased and open ends, and having

fan internal cavity (; 208; 308; 308’; 608; 908)

for receiving treatment substance therein,

a plug (18; 118; 216; 416; 515; 618; 915) for

insertion into the open end of said capsule, said

plug in an assembled condition closing sald

‘open end and retaining said treatment sub-

stance in said internal cavity; characterised in

that

+ an outer stop flange (6; 106; 206; 606; 706;

806) at said open end, for abutting an outer wall

(2;31")of said element when insertedinto said

bore.

A capsule (1; 101; 201; 301; 601; 901) according to

claim 6, wherein a first portion (3A; 103A; 200A;

{609A) ofthe shank (2; 103; 209; 603; 703; 803; 903)

is taperedtowards said closed end (4; 104; 204; 604;

904) and is manufactured trom a frangible material

andlor alternatively hes crack initiating notches (7)

formed therein to allow sald plug (15; 115; 216; 416;

5516; 615; 916) to be forced through said open end

(6; 106; 205; 605, 705; 805) and said cavity (8; 208;

308; 308’; 608; 908), into engagement with the ta:

pring frst shank portion, breaking sald shank por-

tion by drect contact therewith

13 EP 2.066 171 B1 14

Acapsule (1; 101; 201; 801; 601; 901) according to

claim 6 or 7, wherein attachment means (16, 9; 111;

416; 616, 608) are provided on the outer circumfer.

tence of the plug (18; 115; 415; 615; 915) and onthe

inner circumference ofa generally cylindtical second

shank portion (3B; 1098; 2038; 6098), respectively,

foreleasably retaining said plug (15; 115; 416; 615;

918) and container (2; 102; 602; 702; 802: 902) in a

‘mutually sealed assembled condition,

9. A-capsule (201) according to any of claims 6 - 8,

Wherein the container (202; 302; 302) comprises in-

temal dividing walls (212; 312; 812’) dividing the in-

nner cavity (208; 308; 308) into several sub-cham

bers (208A-B; 308A-C; S0BA-D)) each containing 2

separate treatment substance (20;21)in the assem

bled condition,

10. Acapsule (1; 101; 201; 301; 601; 901) according to

any of claims 6-9, wherein said closed end (4; 104;

204; 604; 904) of the container (2; 102; 202: 302;

(602; 702; 802; 902) comprises a bottom wall that is

(110; 10:1; 10:2; 10:3; 10:4; 910) releasably at-

tached to the shank (3; 103; 203; 603; 903) at sald

closed end (4; 104; 204; 604; 904) or thats (10; 10:

5) alternatively formed integral with the tapered first

shank portion (8A; 103A; 203A; 603A).

11. A capsule (901) according to any of claims 6-9,

wherein, in its assembled condition, a central rod

(914) extends along @ major portion of the cavity

(908) andi formedintegral with or attached either

‘a bottom wall (910) at said closed end (904) of the

container (902) or the plug (915).

Patentanspriiche

1. Verfahren zum Auforingen einer Behandlungssub-

stanz (20) auf das Innere eines pordsen Elementes

(G0; 30'; 80"), umfassend die Schrite:

- Berelstellen einer Behandlungssubstanzkep

sel (1; 191; 201; 301; 601; 901), beinhaltend et:

nen Behaiter (2; 102; 202; 302; 602; 702; 802;

902), der ein geschlossenes Ende (4: 104; 204:

604; 904), ein offenes Ende (5; 105; 208; 605:

705; 805) und einen Schaft (2; 103; 209; 603:

78; 803; 908) autweist, der die geschlossenen

Und offenen Enden miteinander verbindet, und

dereine innenliegende Kavitat(8; 108;208;308;

308’; 608; 908) autwelst, wobel die Behand-

lungssubstanz (20; 21) in der innenliegenden

Kavitat angeordnet ist, und einen Ver-

schlussstopten (18; 118; 215; 415; 516; 615:

918) aufweist, der in das offene Ende des Be

hlters eingepasst ist, wobel der Ver:

schlussstopfen in einem zusammengesetzten

~

»

Zustand das offene Ende verschilet und de

Behandungssubstanz in der innenliegenden

Kavitt halt,

= Ausblden mindestens eines Bobviochs (34;

34°, 34") in dem Inneren des Elementes,

gekennzeichnet durch

= Eingetzen einer zusammengesetzten Saum:

behandlungskapsel mit dem geschlossenen

Ende voran in das oder jedes in dem Element

ausgebildete Bohrloch derart, dass ein uBerer

Halteftansch 6; 106;206; 606; 706; 806) an dem

offenen Ende der Kapsel an einer auBeren

(Obertiéche (31; 32) des Elementes anliegt und

+ Autbringen einer Triebkraft (F) auf den Ver

schlussstopfen, um diesen durch das offene

Ende in die Kavtat hinein 2u bewegen, Bewir

ken, dass mindestens ein Tel (8A; 103A; 203A;

603A; 10; 10:1; 10:2; 10:3; 10:4; 10:5; 110; 910)

des Behaiters zerbricht, wodurch Behandlungs:

substanz aus der innenliegenden Kavitét aus:

‘gegeben wird, ndem zugelassen wird, dass die

'se von der innenliegenden Kavita in das Bohr-

loch hinein gelangt

2. Verfahren nach Anspruch 1, wobei eine Behand:

lungssubstanzkapsel (1; 101; 201; 801; 601; 901)

bereitgestellt wird, die einen ersten Schafttell (9A;

108A; 203A; 602A) aufweist, derin Richtung des ge

schlossenen Behalterendes (4; 104; 204; 604; 904)

konisch zulautt, und wobei der Verschlussstopfen

(15; 118; 218; 418; 518; 615; 915) durch das offene

Ende (6; 105; 205; 606; 705; 805) und die Kavitt in

Eingrf mit dem konisch zulaufenden Schattell ge

‘zwangt wird und den Schafitll durch ditekten Kon:

takt mit diesem zerbrcht

3. Verfahren nach Anspruch 1 oder 2, wobel das min-

Potrebbero piacerti anche

- CN104262073ADocumento16 pagineCN104262073AAnonymous DxaBg8fUENessuna valutazione finora

- EP2258159A2Documento18 pagineEP2258159A2Anonymous DxaBg8fUENessuna valutazione finora

- WO2001082864A2Documento74 pagineWO2001082864A2Anonymous DxaBg8fUENessuna valutazione finora

- US3279995ADocumento3 pagineUS3279995AAnonymous DxaBg8fUENessuna valutazione finora

- DE202012001243U1Documento8 pagineDE202012001243U1Anonymous DxaBg8fUENessuna valutazione finora

- US2117808ADocumento4 pagineUS2117808AAnonymous DxaBg8fUENessuna valutazione finora

- WO2006097612Documento20 pagineWO2006097612Anonymous DxaBg8fUENessuna valutazione finora

- Wo2013081177 Pamph 20130606 7631Documento73 pagineWo2013081177 Pamph 20130606 7631Anonymous DxaBg8fUENessuna valutazione finora

- US4929241ADocumento9 pagineUS4929241AAnonymous DxaBg8fUENessuna valutazione finora

- WO2014053401A2Documento104 pagineWO2014053401A2Anonymous DxaBg8fUENessuna valutazione finora

- US5344408ADocumento15 pagineUS5344408AAnonymous DxaBg8fUENessuna valutazione finora

- US5053017ADocumento9 pagineUS5053017AAnonymous DxaBg8fUENessuna valutazione finora

- US5973728ADocumento14 pagineUS5973728AAnonymous DxaBg8fUENessuna valutazione finora

- Us 4740417 ADocumento9 pagineUs 4740417 AAnonymous DxaBg8fUENessuna valutazione finora

- NL 1037664 CDocumento29 pagineNL 1037664 CAnonymous DxaBg8fUENessuna valutazione finora

- HDDK Sang Che 1Documento13 pagineHDDK Sang Che 1Anonymous DxaBg8fUENessuna valutazione finora

- EP2149656A1Documento6 pagineEP2149656A1Anonymous DxaBg8fUENessuna valutazione finora

- So Huu Cong Nghiep Sang CheDocumento16 pagineSo Huu Cong Nghiep Sang CheAnonymous DxaBg8fUENessuna valutazione finora