Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1.1.-CDA Serie CD3000S 1 Fase 15-110A SSR+HB

Caricato da

aco1970Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

1.1.-CDA Serie CD3000S 1 Fase 15-110A SSR+HB

Caricato da

aco1970Copyright:

Formati disponibili

USERS MANUAL

Rev. 01/2007

CD3000S-1PH

Thyristor Unit

Heater Break version

from 15A to 110A

CD Automation S.r.l.

Via Picasso 34/36 - 20025 Legnano (MI) ITALY

Tel +39 0331 577479 Fax +39 0331 579479

E-Mail: info@cdautomation.com - WEB: www.cdautomation.com

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Important warning for safety

Thyristor units are used in power industrial equipment.

The voltages used in the Thyristor unit can cause severe electrical shock, and could be lethal.

Don't remove the plastic cover.

Don't use this unit in aerospace and nuclear application.

Electric Shock Hazard (Risque the choque lectrique)

When thyristor unit has been connected to main supply voltage and is switched off, before to touch it be

secure that the unit is isolated and wait at least one minute to allow discharging internal capacitors. Thus

be secure that:

Access to thyristor unit is only permitted to specialised personnel;

The authorised personnel must read this manual before to have access to the unit;

The access to the unit must be denied to unauthorised personnel.

Important warnings(attention)

Local regulations regarding electrical installation should be rigidly observed.

Safety regulations must be rigidly observed.

Don't bend components to maintain insulation distances.

Protect the unit from high temperature humidity and vibrations.

Don't touch components to prevent electrostatic discharges on them.

Verify that all rating is in line with real needs.

If authorized personnel must measure voltage current etc. on units, take away rings and other jewels

from fingers and hands.

Authorized personnel working on thyristor unit under power supply voltage must work on insulated

board. Be secure that board is not connected to earth.

This listing does not represent a complete enumeration of all necessary safety cautions.

Protection(protection)

CD3000 thyristor unit has a polymeric plastic cover to compliance to International specification IP20.

To understand if IP20 protection is sufficient should be evaluated the installation place.

Open Type Equipment.

Earth(terre)

CD3000 family has isolated heatsink. For safety connect the heatsink to earth to avoid shocks in case that

circuit board or thyristor lose insulation. Earth impedance should be correspondent to local earth

regulation. Periodically the earth efficiency should be inspected.

Electronic supply (alimentation lectronique)

CD3000 family electronic circuit should be supplied by dedicated voltage supply for all electronic circuit

but not in parallel with contactors coil, solenoids and other inductive or capacitive loads.

Its recommended to use a shielded transformer.

Electromagnetic compatibility (compatibilit lectromagntique)

Our thyristor units have an excellent immunity to electromagnetic interferences if all suggestions

contained in this manual are respected. In respect to a good Engineering practice, all inductive loads like

solenoids contactor coils should have a filter in parallel.

Emissions (emission)

All thyristor switching at high speed generate some radiofrequency disturbance. CD3000 series

compliance with EMC rules for CE mark. In many installations near electronic devices have not been noted

problems. If radiofrequency devices at low frequency are used near the thyristor unit some precautions

should be taken like line Filters and shielded cables for input signal and for load cables.

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Quick Start

Attention: this procedure must be carried out by skilled people only.

If your CD3000M code is in line with what you really need, then the main configuration is already done by

CD Automation and you just need to do the following steps:

1. Verify CD3000S Sizing. Be sure that:

The load current is equal or less than the Max current of CD3000S.

The load voltage is equal or less than the Max voltage of CD3000S.

2. Verify the Order Code

3. Verify the Installation

4. Verify the Diagram of control connection:

All auxiliary connections must be done in line with wirings on this manual.

Verify that there isnt a short circuit on the load.

5. Supply the auxiliary voltage of the unit (see Order Code)

6. For size 110A, supply the Fan:

230VAC 15% 50/60Hz (standard)

110VAC 15% 50/60Hz (Optional)

7. Supply the Power unit

8. Make Calibration procedure.

The CD3000S is ready to start.

CD3000S Sizing

Wiring with resistive load

I=

P

V

V = Nominal load voltage

I = Nominal load current

P = Nominal load power

Order Code

CD3000S-1PH

Max

Current

Operating

Voltage

MAX

Volt

Aux

AC/DC

Input

Firing

15A

Write

240Vac

1224V

SSR

ZC

110v

Fan

25A

Operating

480Vac

010V

BF4

EP

35A

Voltage

600Vac

420mA

BF8

EF

45A

<=

BF16

NF

No fuses

60A

MAX Volt

ICT

internal CT

HB

Heater Break Alarm

90A

Options

Fan at 110Vac

External Protection IP20

for size 60110A

External fuses and

fuse holders

110A

Only for size from 35A to 110A

Only with Analog Input 010V or 420mA

Only for size 35A and 45A (Standard for 15A and 25A)

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Installation

Before to install the CD3000 unit examine for damages or

deficiencies. If any is found, notify the carrier immediately. Check

that the product features shown on CD3000 cover corresponds to

that ordered.

CD3000 unit should be always mounted in vertical position to

improve air cooling on heatsink.

Maintain minimum distances in vertical and in horizontal as

represented.

Don't install in proximity of hot elements and near units generating

electromagnetic interferences.

When more units are mounted in the same cabinet provide air

circulation as represented.

Sometimes it is necessary to provide a fan to have better air

circulation.

Dimensions and Fixing holes

110A

4,5mm

65 mm

4,5mm

110 mm

65 mm

120 mm

110 mm

120 mm

110 mm

52 mm

117 mm

ICT option

117 mm

159 mm

140 mm

120 mm

With

159 mm

120 mm

30 mm

140 mm

6090A

4,5mm

138

120 mm

3545A

4,5mm

110 mm

1525A

Environmental installation conditions

Ambient temperature

0-40C at nominal current.

Over 40C use the Derating Curve.

Stocking temperature

-25C to 70C

Installation place

Altitude

Humidity

Dont install at direct sun light, where there are

conductive dust, corrosive gas, vibration or water

and also in salty environmental.

Up to 1000 meter over sea level. For higher altitude

reduce the nominal current of 2% for each 100m

over 1000m

From 5 to 95% without condense and ice

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

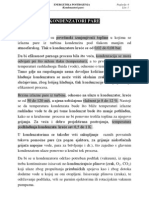

Diagram of control connection

1525A

3545A

60110A

L1

L1

L1

L1

L1

L1

L2/N

L2/N

L2/N

L2/N

L2/N

L2/N

LOAD

Fan Power Supply

(Only for size 110A)

H.B.

Alarm**

L1

L1

1 2 3 4 5

Ext. CAL

12-24Vdc

H.B.

Alarm**

1 2 3

Ext. CAL

12-24Vdc

6 7 8

T1

1 2 3 4 5 6 7 8

T1

- ++ -

-+

-+

Input:

FAN

C.T.

Input:

SSR

SSR

Aux:

12-24v

AC/DC

Aux:

12-24v

AC/DC

LOAD

H.B.

Alarm**

Ext. CAL

12-24Vdc

C.T.

Input:

SSR

LOAD

Aux:

12-24v

AC/DC

Note:

The user installation must be protecting by electromagnetic circuit breaker or by fuse isolator (*).

See par. HB alarm contact (**).

With ICT option, the Current Transformer (C.T.) must not be mounted.

Wiring instructions

CD3000S unit has isolated heatsink. For safety connect the heatsink to hearth using its terminal with

hearth symbol.

The CD3000S can be susceptible to airborne interferences from near equipment or from interferences on

main supply, so a number of precautions must be taken.

Contactors coils and chokes must have in parallel a RC filter and must be supplied with a different

voltage line.

All input/output signals must use screened bifilar wires.

Signal input and output must not route in same cable try and must not be parallel.

Local regulations regarding electrical installation should be rigidly observed.

Use copper cables and wires rated for use at 75 C only

Power cable torque (suggested)

Current

Connector

Type

Torque

Lb-in (N-m)

Wire Range

AWG/kcmil

Wire Terminal

UL Listed (ZMVV)

15A,25A,35A,45A

M5 Screw

26.6 (3.0)

Wire Pin

60A,90A, 110A

M6 Screw

70.8 (8.0)

Fork/Spade Terminal

Copper Tube Crimp. Lug

Load

Cable

Screw M

mm AWG

4

12

M5

6

10

M5

10

8

M5

10

8

M5

16

6

M6

35

3

M6

35

3

M6

Earth

Cable

Screw M

mm AWG

4

12

M5

4

12

M5

6

10

M5

6

10

M5

6

10

M5

6

10

M5

6

10

M5

Cable dimensions (suggested)

Current

15A

25A

35A

45A

60A

90A

110A

Supply

Cable

Screw M

mm AWG

4

12

M5

6

10

M5

10

8

M5

10

8

M5

16

6

M6

35

3

M6

35

3

M6

Auxiliary Supply

Cable

mm AWG

0,50

18

0,50

18

0,50

18

0,50

18

0,50

18

0,50

18

0,50

18

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Technical Specifications

Input features

General features

Cover and Socket

material:

PolymericV2

Logic input SSR:

4 30Vdc 5mA Max

(ON 4Vdc

OFF < 1Vdc)

Heat-sink:

Anodized aluminum

0 10Vdc (15K)

Delay switch ON time:

0.5 period Max

Analog Input:

(Standard)

Analog Input:

4 20mA (100)

Delay switch OFF time:

0.5 period Max

Heater Break Alarm

Auxiliary Voltage:

1224V dc/ac

(max 70mA)

Fan voltage:

(Only for size 110A)

230Vac 15% 14W

(110Vac opt.)

Is a microprocessor based circuit to diagnose

partial or total load failure and short circuit on

SCR and fuses failure.

Discrimination better than 20%.Latching alarm.

Relay Output:

0.5A at 125VAC

Power output features

Repetitive peak

reverse

Voltage

Latching

current.

Max peak

one cycle

Leakage

current

I2T value

thyristor

Frequency

range

Power loss

Isolation

Voltage

(V)

480V

600V

(mAeff)

(10ms) (A)

(mAeff)

tp=10msec

(Hz)

I=Inom

(W)

Vac

15A

24480

1200

1200

150

230

15

610

4770

18

2500

25A

24480

1200

1200

150

230

15

610

4770

30

2500

35A

24600

1200

1600

250

400

15

780

4770

42

2500

45A

24600

1200

1600

250

600

15

1800

4770

54

2500

60A

24600

1200

1600

450

1000

15

4750

4770

72

2500

90A

24600

1200

1600

450

2000

15

19100

4770

108

2500

110A

24600

1200

1600

450

1540

15

11300

4770

137

2500

Size

Voltage

range

(A)

Derating Curve

Led status and Alarms

The following events and alerts dont stop the

unit:

SCR Short Circuit

Heater Break

When one of these alarms is active, the HB relay

change status.

LED

ON

SC

HB

STATUS

DESCRIPTION

Load IS NOT Powered

Load IS Powered

SCR OK

SCR short circuit

Load OK

Load Fault

= OFF

= ON

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Heater break alarm and SCR short circuit

The Heater Break circuit to work properly must have at least an input of 25% of the nominal

current.

H.B. circuit read load current via a current transformer 25-50/0.05 or 100/0.05 depending on thyristor

size.

Minimum current is 30% of the current transformer sizes. If load current is below this value make two

turns or more around current transformer. H.B. circuit also diagnoses fuse failure.

HB alarm contact

CD3000S up to 25A is supplied with Heater Break (HB) alarm contacts normally opened (NO) and

normally closed (NC), for the other sizes instead, the contact standard of alarm is normally opened (NO):

In normal conditions (without alarm) and with auxiliary power supply, the contact to the terminals

has opened (relay coil energized).

In alarm condition or without auxiliary power supply the contact to the terminals is closed (relay coil

not energized).

if you wish to change the alarm contact put the jumper as shown:

3545A

60110A

JP1

C

B

A

JP1

ABC

Type

NO(standard)

NC

JP1

A-B

B-C

Heater break Calibration procedure

An automatic function sets the Heater Break Alarm.

The auto setting function can be activated using the CAL button on front unit, or supply with 12-24Vdc

the digital input "Cal Ext." (See Diagram of control connection).

The Heater Break calibration procedure is performed in this way:

CD3000S gives the maximum voltage output

all LEDS are on, this means that calibration procedure is active

The values of voltage and current are stored in memory

After a minute the CD3000S comes back to the initial situation

If load current decreases for partial or total load failure (sensitivity 20%) the yellow LED become ON and

alarm relay change status.

If CD3000 is still in conduction with no input signal (LED green OFF) it means that there is a short circuit

on thyristors and red LED (SC) become ON.

If the load has been changed the Heater Break calibration procedure must be done again.

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Firing setting

ZC firing mode is used with Logic Output from temperature controllers and the Thyristor operates like a

contactor. The Cycle time is performed by temperature controller. ZC minimizes interferences because the

Thyristor unit switches ON-OFF at zero voltage.

VOLTAGE SUPPLY (V)

LOAD VOLTAGE (V)

SSR from controller

Input setting

The input type is already configured in line with customer requirements that are defined in the complete

product code. However, verify that the jumper are set as below represented.

1525A

3545A

60110A

JP3

JP6

JP3 JP6

A

C

B JP2

B

C

A

JP6 JP3

C

C

JP2

B

B

A

A

CBA

JP2

CBA

Input

SSR

JP2

Open

JP3

B-C

JP6

A-B

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Fuses and Fuse holder

Warning: High speed fuses are only used for the thyristor protection and can not be used to

protect the installation.

CD3000S unit must be protected against short circuit by High speed fuses.

The Fuses must have It 20% less than thyristors It.

The warranty of thyristor is null if no proper fuses are used. See tab.

Fuses and Fuse Code for CE.

Fuse and Fuse holder

Size

CODE

15A

FFH1038/16A

25A

FFH1038/32A

35A

FFH1451/40A

45A

FFH1451/50A

60A

FFH2258/80A

90A

FFH2258/125A

110A

FFH2760/160A

Fuse Holder size

For size from 15A - 25A

For size from 60A - 90A

Fuse CODE

FU1038/16A

FU1038/32A

FU1451/40A

FU1451/50A

FU2258/80A

FU2258/125A

FU2760/160A

Current

(ARMS)

16

32

40

50

80

125

160

IT

(A sec.)

150

600

1650

2000

6550

14000

15000

For size from 35A - 45A

For size from 110A

CD Automation srl

CD3000S-1PH SSR-HB from 15A to 110A

Users manual

Maintenance

In order to have correct cooling, the user must clean the heatsink and the protective grill of the fans. The

frequency of this servicing depends on environmental pollution.

Also check periodically if the screw for the power cables and safety earth are tightened correctly

(See Diagram of control connection)

Trouble Shooting

Small problems sometimes can be solved locally with the help of the below tab of trouble shooting. If you

dont succeed, contact us or your nearest distributor.

Symptom

Indication on

front unit

Possible reasons of the

symptom

Actions

No voltage auxiliary power

Green LED (ON)

light off

No input signal

Reversed polarities of input

signal

Give auxiliary voltage supply

(See Diagram of connection)

Provide to give input signal

Reverse the input signal polarity

Green LED (ON)

light off

Fuse failure

Load failure

Load connection interruption

Thyristor faulty

Substitute the fuse

Check the load

Check the wiring

Substitute the faulty thyristor

Check the load wiring

Substitute the thyristor

Thyristor unit

doesnt go in

conduction with

input signal

The yellow led (HB) is light on

Load current

flows also with no

input signal

Green LED (ON)

is always light on

Current flows at

nominal value but

Yellow LED (HB)

is light on

Yellow LED (HB)

light on

Current flows at

nominal value but

Red LED (SC) is

light on

Red LED (SC)

light on

Thyristor unit

doesnt work

properly

Wrong wiring

Short circuit on thyristor

The red led (SC) is light on

HB circuit not tuned

Make HB calibration procedure

Current transformers not

properly wired

Control current transformers

wiring

HB circuit not tuned

Make HB calibration procedure

Auxiliary voltage supply out of

limits

Wrong input signal selection.

Wrong input signal calibration

(out of range)

Verify the auxiliary voltage

supply

Control input signal setting.

Repeat input calibration

procedure.

Warranty condition

CD Automation gives a 12 months warranty to its products. The warranty is limited

to repairing and parts substitution in our factory and does exclude products not

properly used and fuses.

Warranty does not include products with serial numbers deleted.

The faulty product should be shipped to CD Automation at customers cost and our

Service will evaluate if product is under warranty terms.

Substituted parts remain of CD Automation property

ENG CD3000S-1PH__15-110A_SSR-HB - 03.doc

Potrebbero piacerti anche

- The Organising Committee of The Third International Scientific Colloquium Mathematics and Children PersisDocumento597 pagineThe Organising Committee of The Third International Scientific Colloquium Mathematics and Children Persisaco1970100% (1)

- UserGuide PDFDocumento228 pagineUserGuide PDFjohnNessuna valutazione finora

- Eko Lab Pumps 417101774 - EMP - KKS - E60 - E-1Documento76 pagineEko Lab Pumps 417101774 - EMP - KKS - E60 - E-1aco1970Nessuna valutazione finora

- Eko Lab Pumps 417101774 - EMP - KKS - E60 - E-1Documento76 pagineEko Lab Pumps 417101774 - EMP - KKS - E60 - E-1aco1970Nessuna valutazione finora

- Load Cell PrimerDocumento62 pagineLoad Cell PrimerJohn HallowsNessuna valutazione finora

- Installers Manual ING 2010Documento161 pagineInstallers Manual ING 2010aco1970Nessuna valutazione finora

- 130508-100817-EVertical Multistage Centrifugal Electric Pumps Available in Various Versions: Cast Iron (EVMG), AISI 304 Stainless Steel (EVM), AISI 316 Stainless Steel (EVML) .VM - EngDocumento35 pagine130508-100817-EVertical Multistage Centrifugal Electric Pumps Available in Various Versions: Cast Iron (EVMG), AISI 304 Stainless Steel (EVM), AISI 316 Stainless Steel (EVML) .VM - Engaco1970Nessuna valutazione finora

- PLC InstallationDocumento153 paginePLC InstallationMN Titas TitasNessuna valutazione finora

- The constantly increasing demand in resources and energy of people and business leads to more and more bottle - necks and increasing costs in material procurement. For this reason, it is necessary to deal with materials and resources in an efficient manner for reasons of economy and sustainability. Process-Optimized These points are very important to Schmalz. Therefore the company has organized its processes to gain added value. The added-value system pursues aims such as lowest production and process costs, shortest processing times, low stocks and at the same time highest quality. The added-value system, together with the company’s modern workplaces, is the basis for efficient production and its ability to compete over the long term. At Schmalz state-of-the-art production and logistic concepts determine most of the everyday tasks in manufacturing. For example, Schmalz uses the one-piece flow concept whenever it is possible and makes sense to do so. With this concept, the vacuum speciDocumento716 pagineThe constantly increasing demand in resources and energy of people and business leads to more and more bottle - necks and increasing costs in material procurement. For this reason, it is necessary to deal with materials and resources in an efficient manner for reasons of economy and sustainability. Process-Optimized These points are very important to Schmalz. Therefore the company has organized its processes to gain added value. The added-value system pursues aims such as lowest production and process costs, shortest processing times, low stocks and at the same time highest quality. The added-value system, together with the company’s modern workplaces, is the basis for efficient production and its ability to compete over the long term. At Schmalz state-of-the-art production and logistic concepts determine most of the everyday tasks in manufacturing. For example, Schmalz uses the one-piece flow concept whenever it is possible and makes sense to do so. With this concept, the vacuum speciaco1970Nessuna valutazione finora

- VIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:Documento28 pagineVIP Red CatalogueIntroduction This catalogue will provide you with an idea of range, which now includes a huge selection of plumbing products and pumps to complement our already extensive engineering range. - our service is constantly reviewed and we aim to offer our customers excellence in all areas. About Us Formed in 1985, we have earned a reputation for setting standards in quality, service and reliability. We supply a wide range of industries including:aco1970Nessuna valutazione finora

- Rotork is the market leading actuator manufacturer and flow control company that operates in any market where the flow of gasses or liquids needs to be controlled. It has established manufacturing facilities, a global network of local offices and agents who can truly provide a worldwide service. You will be able to locally source Rotork's products, supported by life-of-plant maintenance, repair and upgrade services.Documento132 pagineRotork is the market leading actuator manufacturer and flow control company that operates in any market where the flow of gasses or liquids needs to be controlled. It has established manufacturing facilities, a global network of local offices and agents who can truly provide a worldwide service. You will be able to locally source Rotork's products, supported by life-of-plant maintenance, repair and upgrade services.aco1970Nessuna valutazione finora

- Solid Works PDFDocumento67 pagineSolid Works PDFaco1970Nessuna valutazione finora

- Omron SYSMAC C200HE - HX - HG - 2004 - W303-E1-09 - OPERATIONDocumento586 pagineOmron SYSMAC C200HE - HX - HG - 2004 - W303-E1-09 - OPERATIONaco1970Nessuna valutazione finora

- Minertia Motor J SeriesDocumento4 pagineMinertia Motor J Seriesaco1970Nessuna valutazione finora

- A/C-Heater System Uniform Inspection Guidelines Article TextDocumento19 pagineA/C-Heater System Uniform Inspection Guidelines Article Textaco1970Nessuna valutazione finora

- Thermostats and Dial ThermometersDocumento252 pagineThermostats and Dial Thermometersaco1970Nessuna valutazione finora

- Analytical MeasurementDocumento262 pagineAnalytical Measurementaco1970100% (1)

- Rodamientos SKFDocumento1.380 pagineRodamientos SKFSebastian Lobos OpitzNessuna valutazione finora

- ESPRIMO™ Mobile V5535 v5535Documento1 paginaESPRIMO™ Mobile V5535 v5535aco1970Nessuna valutazione finora

- ESPRIMO™ Mobile V5535 v5535Documento1 paginaESPRIMO™ Mobile V5535 v5535aco1970Nessuna valutazione finora

- Prirucnik Za TermodinamikuDocumento172 paginePrirucnik Za Termodinamikucevapcic10063% (8)

- Kondenzator PareDocumento8 pagineKondenzator PareIvan KorlevicNessuna valutazione finora

- Rhodium HTC WWE UM PDFDocumento264 pagineRhodium HTC WWE UM PDFaco1970Nessuna valutazione finora

- ESPRIMO™ Mobile V5535 v5535Documento1 paginaESPRIMO™ Mobile V5535 v5535aco1970Nessuna valutazione finora

- Solid Works Tutorial 2001Documento262 pagineSolid Works Tutorial 2001anurak.aun100% (9)

- Solidworks: Engineering Design ProjectDocumento55 pagineSolidworks: Engineering Design ProjectNikola Boskovic100% (1)

- Solid Works PDFDocumento67 pagineSolid Works PDFaco1970Nessuna valutazione finora

- Solid Works PDFDocumento67 pagineSolid Works PDFaco1970Nessuna valutazione finora

- Solid Works Tutorial 2001Documento262 pagineSolid Works Tutorial 2001anurak.aun100% (9)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- IndexDocumento35 pagineIndexCésar Cusi LazoNessuna valutazione finora

- Installation & Intial Line UpDocumento154 pagineInstallation & Intial Line UpWerberth MoreiraNessuna valutazione finora

- Micom C264/C264C: Bay ComputerDocumento732 pagineMicom C264/C264C: Bay ComputerBimMariusNessuna valutazione finora

- Programmable Graphic Display For Controlling Mobile MachinesDocumento2 pagineProgrammable Graphic Display For Controlling Mobile MachineskevNessuna valutazione finora

- Installation and Operation ManualDocumento161 pagineInstallation and Operation ManualmauricioNessuna valutazione finora

- Manual: Instant Recovery Electric Fryer SERIES 2006Documento42 pagineManual: Instant Recovery Electric Fryer SERIES 2006chjunaidchNessuna valutazione finora

- Wiring Diagrams 04 FABIADocumento494 pagineWiring Diagrams 04 FABIABaciu Nicolae71% (7)

- Service Manual For R330H Desktop POS PrinterDocumento35 pagineService Manual For R330H Desktop POS Printerawsam hanyNessuna valutazione finora

- MDF IndoorDocumento29 pagineMDF IndoorEhsan RohaniNessuna valutazione finora

- Manual Normafix EN 453030007 PDFDocumento31 pagineManual Normafix EN 453030007 PDFMostapha BenaliNessuna valutazione finora

- Center Mount Bicycle Motor Kit PlansDocumento47 pagineCenter Mount Bicycle Motor Kit PlansLiveFastMotors100% (2)

- 7XG22 2RMLG Catalogue SheetDocumento12 pagine7XG22 2RMLG Catalogue SheetS. M. Touhidur RahmanNessuna valutazione finora

- Dodge Nitro KA - 2007 - Audio VideoDocumento27 pagineDodge Nitro KA - 2007 - Audio VideoeephantomNessuna valutazione finora

- Parts Manual For Susie's Craftsman 18 HP OHV Riding MowerDocumento27 pagineParts Manual For Susie's Craftsman 18 HP OHV Riding MowermojarramanNessuna valutazione finora

- P0340Documento5 pagineP0340Freddie Kemp100% (1)

- Module Bar PTX1.6 PDFDocumento8 pagineModule Bar PTX1.6 PDFkumelachewbirre22Nessuna valutazione finora

- 3fe50796aaaa 01Documento104 pagine3fe50796aaaa 01ehoangvanNessuna valutazione finora

- As-9500 Quick Installation GuideDocumento1 paginaAs-9500 Quick Installation GuideJose Mario GarzonNessuna valutazione finora

- IPM Blood Pressure MonitorDocumento6 pagineIPM Blood Pressure MonitorRajo LangitNessuna valutazione finora

- Onderdelen AtmosDocumento50 pagineOnderdelen AtmosKlaske JellemaNessuna valutazione finora

- Pt303 Pt308 (Ashcroft)Documento4 paginePt303 Pt308 (Ashcroft)Serge LapointeNessuna valutazione finora

- Dkg-507-J Automatic Mains Failure UnitDocumento42 pagineDkg-507-J Automatic Mains Failure UnitElsad HuseynovNessuna valutazione finora

- D02601880 - Instruction ManualDocumento2 pagineD02601880 - Instruction ManualAsyraf BadaruddinNessuna valutazione finora

- Led TV: Service ManualDocumento68 pagineLed TV: Service ManualEtu100% (1)

- PWC Communication Tools and B.U.D.S. (Spark Series) - Shop Manual Supplement smr2016-108Documento6 paginePWC Communication Tools and B.U.D.S. (Spark Series) - Shop Manual Supplement smr2016-108Théo GousseyNessuna valutazione finora

- EE082-Fault Finding in Electrical Control Systems-Th-Inst PDFDocumento78 pagineEE082-Fault Finding in Electrical Control Systems-Th-Inst PDFSameera Kodikara100% (2)

- 2002 Buell Blast Service ManualDocumento400 pagine2002 Buell Blast Service Manualbztw6138Nessuna valutazione finora

- Ex-Link Cable For C - D - E Series and BD Players - SamyGODocumento11 pagineEx-Link Cable For C - D - E Series and BD Players - SamyGOsopteaNessuna valutazione finora

- Offers January 2013 PowerstormDocumento19 pagineOffers January 2013 PowerstormShannan MontgomeryNessuna valutazione finora

- Power ToolsDocumento8 paginePower ToolsMonica CarrollNessuna valutazione finora