Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Managerial Accounting'

Caricato da

Hassan Akhtar ChDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Managerial Accounting'

Caricato da

Hassan Akhtar ChCopyright:

Formati disponibili

HYDERI BREVAGES

BILAWAL AKHTAR CH MUHAMMAD FAIZAN ADIL QURESHI USMAN RIAZ AMAD SOHAIL RAZA ZAIDI

Haidri Beverages Group was set up in 1979 and is Pepsi's sole selling agent for District Rawalpindi and Islamabad. It is based in the CDA Industrial Triangle, Kahuta Road, Islamabad. It manages the supply for several wholesalers, retailers, restaurants, hotels and other such food outlets

MISSION STATEMENT We work to increase the value of our shareholders investment. We do this through sales growth, cost control and wise investment of resources. We believe that our commercial success depends upon offering quality and value to our customers. INDUSTRIAL OVERVIEW In Pakistan the beverage industry is not as competitive as compared to the beverage industry of the developed countries. In Pakistan Pepsi and Coca-Cola are the two major shareholders of the beverage industry. ORGANIZATION OVERVIEW Haidri Beverages primary functions are to conduct a systematic manufacturing and supply of the product without any tactical flaws.

7 Up Mountain Dew Pepsi

Haidri

Mirinda Slice

Aquafina

Sting

Corporate Strategy: Haidri corporate strategy is compromised of the following aspects: Gaining leadership in the concerned markets. Maintaining standards of production Efficiency and effectiveness OPERATIONS STRATEGY: The operations strategy of Haidri beverages is integrated with their corporate strategy. Minimizing cost No compromise on quality CORE COMPETENCY: The core competency of Haidri Beverages is its highly automated production plants. The organization ability to analyze the market trends.

Core process: The core process at Haidri Beverages is the Line Process because from the starting to the end product, every sub process is in line with the other and all the processes are interconnected. Each of the sub process adds value to the product. Like in the manufacturing of Pepsi Cans, Cans are unwrapped on stretch wrap through conveyer belts, and then they are passed on for rinsing and then filling and crowning. After that they are inverted on the inverted, which is

in line with the crowner. Then date coding is done and cans are again inverted from where they are passed on for packing. Similarly, in case of glass bottles and PET bottles, all the processes are in line with the other and each process is adding value to the other.

ECONOMIES OF SCALE: As Haidri produces few standardized products on a large scale; mass production; this spreads the overhead cost on more no of units thereby reducing the average per unit cost. This implies that Haidri has a high level of economies of scale. The production capacity of for each line process is mentioned below.

Returnable bottles Non returnable bottles

Glass line PET bottles Cans

600 bottles/min 200 bottles/min 600 cans/min

PREVENTIVE COSTS: Regular internal tests are carried to ensure that the bottles are meeting the pre-determined standards. Managers talk sporadic rounds to ensure that the manpower is being effectively utilized. Regular checks ensure the reduction of beverage, glass and plastic wastage. All the operators examine the machines theyre operating on a daily basis at the time of closing. Preventive maintenance is carried out in schedules which vary from machine to machine. APPRAISAL COSTS: Monthly audits and annual audits are carried out to maintain quality. Moreover, auditors from Beijing visit the plant annually to check the performance. Employees are motivated by placing them in their interested fields so that they remain vigilant in their work.

CAPACITY EFFECTIVE AND PEAK CAPACITY: The peak and effective capacities of bottles at Haidri Beverages are as follow:

Effective capacity Peak capacity

24000 bottles/hour i:e 400/min 21000 bottles/hour i:e 350/min

Basic Cost: Selling price of the Pet Bottles is Rs.28 Variable Cost is Rs. 22 How they do their analysis: Case 1: Suppose Haidri receives an order of 16,000 no. of bottles and the person who is ordering that he will give Rs.25 per bottle. First of all they check out what is variable cost per unit for producing more bottles which is also known as incremental costs. If this incremental cost is less than the selling price or that price which company is receiving (also known as incremental revenue), Haidri beverages accept the order and start working on it. Or if the incremental revenue is less than incremental cost than the company must refuse the order, either they have the capacity or not. So the INCREMENTAL COST is: (22*16,000 = 352,000Rs) And the INCREMENTAL REVENUE is: (25*16,000= 400,000Rs) Decision: Haidiri have the capacity to produce more units in routine with its normal capacity, and receiving 48,000Rs profits by accepting this project

Case 2:

Haidri receive an order of 10,000 pet bottles. The person who is ordering ready to give the 20 Rs per pet bottle. First of all Haidri analyses the cost of the order check out the incremental cost which occurs due to accepting a project which is: (22*10,000 = 220,000Rs) And the incremental revenue is: (20* 10,000 = 200,000Rs) Decision: Through cost analysis we came to know that if Haidri accepted that he has to face a loss of 20,000Rs and it is benefited for the company to reject it.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- (Manufacturing and Production Engineering) Fariborz Tayyari - Cost Analysis For Engineers and Scientists-CRC Press (2021)Documento231 pagine(Manufacturing and Production Engineering) Fariborz Tayyari - Cost Analysis For Engineers and Scientists-CRC Press (2021)Radar NhậtNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Presentasi AEO Indonesia (English)Documento15 paginePresentasi AEO Indonesia (English)Purnama JayaNessuna valutazione finora

- Pankhuri - Aditya BirlaDocumento7 paginePankhuri - Aditya BirlaAnkush JainNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Chapter (5) Auto Shop Safety (Myanmar)Documento10 pagineChapter (5) Auto Shop Safety (Myanmar)Bo GyiNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Students Satisfaction On The Services Provided by The School Canteens in Catanduanes State UniversityDocumento31 pagineStudents Satisfaction On The Services Provided by The School Canteens in Catanduanes State UniversityAnthony HeartNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Homework Practice CH 6 25th EdDocumento4 pagineHomework Practice CH 6 25th EdThomas TermoteNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Akademi Laut Malaysia ALAM Course Calendar 2015Documento6 pagineAkademi Laut Malaysia ALAM Course Calendar 2015Abraham Immanuel AdamNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Syk ResumeDocumento4 pagineSyk ResumeSurendra InnamuriNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Chapter 18-Process Cost Systems: True/FalseDocumento22 pagineChapter 18-Process Cost Systems: True/FalseROLANDO II EVANGELISTANessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Microsoft Power Point - Value Chain Analysis & Bench MarkingDocumento23 pagineMicrosoft Power Point - Value Chain Analysis & Bench MarkingDillip Khuntia100% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Madison FittingsDocumento27 pagineMadison FittingsMohamed AlkharashyNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Contract Law Assignment Name:p.v.n.s Ramya Topic: Invitation To Offer and Its Effects On Contract Law Batch-2021-2026 Submit:Manish Sir Amity Law School, Amity University, MaharastraDocumento3 pagineContract Law Assignment Name:p.v.n.s Ramya Topic: Invitation To Offer and Its Effects On Contract Law Batch-2021-2026 Submit:Manish Sir Amity Law School, Amity University, Maharastraishika pNessuna valutazione finora

- ATLAS COPCO HCS 3715 - ManualsDocumento246 pagineATLAS COPCO HCS 3715 - Manualsandre100% (5)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Operations Management Mms 1Documento355 pagineOperations Management Mms 1amithariaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- PROJECT REPORT taBLEAU 2 PDFDocumento12 paginePROJECT REPORT taBLEAU 2 PDFrahulsg0358Nessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- ISO 45001 Occupational Health & Safety Management Systems RequirementsDocumento18 pagineISO 45001 Occupational Health & Safety Management Systems RequirementsSead Zejnilovic100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Risk Management in Supply ChainDocumento2 pagineRisk Management in Supply Chaintuoyinopuo nobapuoNessuna valutazione finora

- Operation Costing, Just-In-Time System, and Backflush CostingDocumento15 pagineOperation Costing, Just-In-Time System, and Backflush CostingJeremy Cyrus TrinidadNessuna valutazione finora

- Delta Air Lines, Inc. Delta Air Lines, Inc.: Technical Operations Engine Maintenance OperationsDocumento13 pagineDelta Air Lines, Inc. Delta Air Lines, Inc.: Technical Operations Engine Maintenance Operationsalagu vairamuthuNessuna valutazione finora

- JSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.Documento3 pagineJSA 03 To Do Work On Concrete Mixer, Concrete Pump, Vibrator, De-Watering Pump.mehtab uddinNessuna valutazione finora

- Management: Paper: 09, Entrepreneurship Development & Project ManagementDocumento11 pagineManagement: Paper: 09, Entrepreneurship Development & Project ManagementDeepak Kumar PanigrahiNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Kra Eipl Qa 2020Documento36 pagineKra Eipl Qa 2020venkata rami reddyNessuna valutazione finora

- Talent Acquisition Assistant Manager - Sheila Pradesia SantosoDocumento2 pagineTalent Acquisition Assistant Manager - Sheila Pradesia SantosoDyah FanniNessuna valutazione finora

- CFZ Locators DirectoryDocumento96 pagineCFZ Locators DirectoryMhel BundalianNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Case Study Presented by Donald CrossDocumento13 pagineCase Study Presented by Donald CrossUmeshNessuna valutazione finora

- Prosci Change Management Takes Change Management Webinar Slides 2021Documento16 pagineProsci Change Management Takes Change Management Webinar Slides 2021Ervin Preg100% (1)

- Facilities Management Worksheet Module 1Documento5 pagineFacilities Management Worksheet Module 1haroonNessuna valutazione finora

- 4882-Article Text-21748-1-10-20220329Documento13 pagine4882-Article Text-21748-1-10-20220329Aldela AlipNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

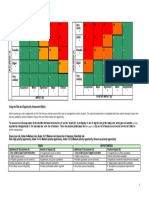

- Risk Assessment and Opportunity Assessment Matrix TableDocumento1 paginaRisk Assessment and Opportunity Assessment Matrix TableWin AsharNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)