Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Rodrigo Lameiras Joaquim Barros, Miguel Azenha and Isabel Valente

Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Rodrigo Lameiras Joaquim Barros, Miguel Azenha and Isabel Valente

Copyright:

Formati disponibili

SANDWICH STRUCTURAL PANELS COMPRISING THIN-WALLED STEEL FIBRE REINFORCED SELF-COMPACTING CONCRETE (SFRSCC) AND FIBRE REINFORCED POLYMER

(FRP) CONNECTOR

University of Minho School of Engineering ISISE, Departament of Civil Engineering

Institu for Sustainability and te Innovation in Structural Engineering

RODRIGO LAMEIRAS* Joaquim Barros, Miguel Azenha and Isabel Valente

* rmlameiras@civil.uminho.pt

Introduction

The main interest on using construction sandwich panels is related to the structural and thermal efficiency that can be achieved with this technology. Traditionally, these sandwich panels adopt two conventionally reinforced concrete layers (also known as wythes) and metallic connectors between both of them. Due to their high thermal conductivity, the metallic connectors in these insulated wall panels generally cause thermal bridges on the building envelope that increase heat flow.

Adhesively bonded

C

Embedded

L

Figure 5: Experimental setup for the pull-out tests and types of connectors studied. To increase the connection load capacity, circular holes were devised in embedded connectors.

Figure 3: Proposed load-bearing sandwich panel.

Optimization of the Sandwich Panel Concept

The optimization of sandwich panel concept was done by numerical modelling with recourse to linear FE analysis (FEMIX). Panels with 5,0m width and 2,5m tall were studied, with concrete layers represented by shell elements and the connectors by shell and beam elements.

Figure 4 : Initial optimization consisted in evaluating two solutions: (i) adopting ribbed wythes to minimize stress concentration along connectors; (ii) using either trusses or profiles as connectors. Figure 6 : Force versus slip diagrams for pull out tests performed with different types of connectors.

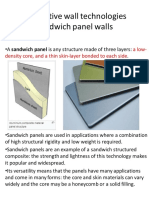

Figure 1: Typical sandwich panels and problems related to their use.

Aim

The present research work aims to propose an innovative thermally efficient prefabricated structural sandwich panel composed by external thin steel fibre reinforced self-compacting concrete (SFRSCC) layers, a lightweight thermally insulating core material, and fibre reinforced polymer (FRP) shear connectors.

Figure 7: Typical failure modes obtained for the adhesively bonded (C) and embedded connections (L, T and Y).

The results shown that the use of trusses as connectors leads to higher stress levels on the SFRSCC layers. Increasing the thickness of the concrete in the vicinity of the connections is an effective solution to reduce tensile stresses in the wythes, which provides wider safety margins for cracking.

Connections between FRP and SFRSCC Pull out tests

A preliminary experimental program was performed to compare the mechanical behaviour of several connector configurations through pull-out tests. One type of adhesively bonded (C) and 3 types of embedded connections (referred to as L, T and Y) were tested.

These preliminary tests evidence the possibility of attaining a pullout load that is considered enough for expected stress levels in the present application. Contrary for what is observed for the bonded connections, the embedded connections have shown a quite large ductility.

ACKNOWLEDGEMENTS

The first author would like to thank the FCT for financial support through the PhD grant SFRH/BD/64415/2009. The Authors acknowledge the support of the QREN research project number 5387.

Figure 2: Concrete sandwich panel components and their functions.

Uma Escola a Reinventar o Futuro Semana da Escola de Engenharia - 24 a 27 de Outubro de 2011

Potrebbero piacerti anche

- Sensing Complex Environments With Localization RequirementsDocumento1 paginaSensing Complex Environments With Localization RequirementsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Resource Complementarity in Activity NetworksDocumento1 paginaResource Complementarity in Activity NetworksSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Model of Integrated Management of Public Procurement: Guidance For The Development of Electronic Public Procurement Oriented To Public ValueDocumento1 paginaModel of Integrated Management of Public Procurement: Guidance For The Development of Electronic Public Procurement Oriented To Public ValueSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Automatic Detection and Segmentation of Cortical Lesions in Multiple SclerosisDocumento1 paginaAutomatic Detection and Segmentation of Cortical Lesions in Multiple SclerosisSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Cooling System Optimization in Polymer Injection MouldingDocumento1 paginaCooling System Optimization in Polymer Injection MouldingSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Decision Support System For The Intensive Care UnitDocumento1 paginaDecision Support System For The Intensive Care UnitSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Experimental Characterization of Commercially Available Grouts For Use in Masonry StructuresDocumento1 paginaExperimental Characterization of Commercially Available Grouts For Use in Masonry StructuresSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Design Software Systems From Business Process ModelingDocumento1 paginaDesign Software Systems From Business Process ModelingSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Improving Quality of Information in Health Records With Medical OnthologiesDocumento1 paginaImproving Quality of Information in Health Records With Medical OnthologiesSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Archetype Based Intelligent System For Healthcare InteroperabilityDocumento1 paginaArchetype Based Intelligent System For Healthcare InteroperabilitySemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- A Cognitive Impairment HelperDocumento1 paginaA Cognitive Impairment HelperSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Performance's Evaluation of Building's Envelope To EarthquakesDocumento1 paginaPerformance's Evaluation of Building's Envelope To EarthquakesSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Critical Knowledge Monitor System ModelDocumento1 paginaCritical Knowledge Monitor System ModelSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Semantic Interoperability and Health RecordsDocumento1 paginaSemantic Interoperability and Health RecordsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- UV Protection of Polyamide Fabrics With Polymeric NanocompositesDocumento1 paginaUV Protection of Polyamide Fabrics With Polymeric NanocompositesSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Assessing The Performance of Neonatology UnitsDocumento1 paginaAssessing The Performance of Neonatology UnitsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Articulation Between Information Systems and Quality Management SystemsDocumento1 paginaArticulation Between Information Systems and Quality Management SystemsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Hybridization of A Genetic Algorithm With A Pattern Search Augmented Lagrangian MethodDocumento1 paginaHybridization of A Genetic Algorithm With A Pattern Search Augmented Lagrangian MethodSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Social Signals Processing in Human-Computer InteractionDocumento1 paginaSocial Signals Processing in Human-Computer InteractionSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Application of Functional Textiles in The Healthcare AreaDocumento1 paginaApplication of Functional Textiles in The Healthcare AreaSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Implantable Flexible Sensor Based On Aligned-Carbon Nanotubes For Blood Pressure MonitoringDocumento1 paginaImplantable Flexible Sensor Based On Aligned-Carbon Nanotubes For Blood Pressure MonitoringSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Risk Characterization in Wood CompaniesDocumento1 paginaRisk Characterization in Wood CompaniesSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Fed-Batch Cultures of Pichia Pastoris Under Increased Air PressureDocumento1 paginaFed-Batch Cultures of Pichia Pastoris Under Increased Air PressureSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Gesture Dynamics With Skin Conductivity - A Multimodal Approach To Biometric AuthenticationDocumento1 paginaGesture Dynamics With Skin Conductivity - A Multimodal Approach To Biometric AuthenticationSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Assessment of The Post-Cracking Behaviour of SFRSCC by Flexural and Tensile TestsDocumento1 paginaAssessment of The Post-Cracking Behaviour of SFRSCC by Flexural and Tensile TestsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Butanol Production by Clostridium Pasteurianum Using Biodiesel-Derived Crude GlycerolDocumento1 paginaButanol Production by Clostridium Pasteurianum Using Biodiesel-Derived Crude GlycerolSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Knowledge Metamodel For Crowdsourcing Innovation IntermediariesDocumento1 paginaKnowledge Metamodel For Crowdsourcing Innovation IntermediariesSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- A Sustainable Index For Urban Expansion ManagementDocumento1 paginaA Sustainable Index For Urban Expansion ManagementSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- Surface Modification of Bacterial Cellulose by Plasma TreatmentsDocumento1 paginaSurface Modification of Bacterial Cellulose by Plasma TreatmentsSemana da Escola de Engenharia da Universidade do MinhoNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Alucobond TechnicalDocumento4 pagineAlucobond TechnicalMarco Ngawang KeelsenNessuna valutazione finora

- 4-Part-B Civil PDFDocumento65 pagine4-Part-B Civil PDFPratik GuptaNessuna valutazione finora

- Contents Sandwich Panels CalculationDocumento6 pagineContents Sandwich Panels CalculationAndrea BarbieriNessuna valutazione finora

- TR 45 150 Roof Wall Sandwich Panel Data SheetDocumento4 pagineTR 45 150 Roof Wall Sandwich Panel Data SheetanwarNessuna valutazione finora

- ETEM - 1. Etalbond - PE - FR - A2Documento24 pagineETEM - 1. Etalbond - PE - FR - A2Ivo AntonijevicNessuna valutazione finora

- Technical Catalog Sandwich Panels Paneltech 2020.1Documento88 pagineTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNessuna valutazione finora

- Welding Application in ShipbuildingDocumento9 pagineWelding Application in ShipbuildingUnaJuricNessuna valutazione finora

- Alstone ACP BrochureDocumento9 pagineAlstone ACP BrochuresinhaaksNessuna valutazione finora

- Rout and Return Dry-Seal - Full SetDocumento16 pagineRout and Return Dry-Seal - Full SetFacundo Garcia LlanosNessuna valutazione finora

- Vitracore G2 Product Introduction - FairviewDocumento12 pagineVitracore G2 Product Introduction - FairviewRichee Genesis TuasonNessuna valutazione finora

- Aluminium Composite Panel - Specification: Indian StandardDocumento14 pagineAluminium Composite Panel - Specification: Indian StandardSuman ChatterjeeNessuna valutazione finora

- Alucobond Plus Flyer 0905 01Documento2 pagineAlucobond Plus Flyer 0905 01Achmad SugiyonoNessuna valutazione finora

- XPS - Ravago Eu 00 005 Ravatherm Industry Brochure Ok3Documento36 pagineXPS - Ravago Eu 00 005 Ravatherm Industry Brochure Ok3SivarajSivaNessuna valutazione finora

- General Specifications 20190523 PDFDocumento4 pagineGeneral Specifications 20190523 PDFMuhammad Farhan GulNessuna valutazione finora

- TMPPHP 9 IahycDocumento164 pagineTMPPHP 9 IahycAgung TriyonoNessuna valutazione finora

- A1 Retail May 2015Documento84 pagineA1 Retail May 2015JohnNessuna valutazione finora

- Alternative Wall Technologies-Sandwitch PanelsDocumento14 pagineAlternative Wall Technologies-Sandwitch PanelsDiya MakanurNessuna valutazione finora

- Exhibitor List - WINDOWS DOORS & FACADES AND SAUDI GLASSDocumento13 pagineExhibitor List - WINDOWS DOORS & FACADES AND SAUDI GLASSAhmed RamzyNessuna valutazione finora

- Birla Aerocon Panel - Data CentersDocumento3 pagineBirla Aerocon Panel - Data Centersshahul hameed100% (1)

- Sound Transmission Characteristics of Sandwich Panels With A Truss Lattice CoreDocumento93 pagineSound Transmission Characteristics of Sandwich Panels With A Truss Lattice CoreKirandeep GandhamNessuna valutazione finora

- LPS1181 Part One 1.1Documento27 pagineLPS1181 Part One 1.1alex metalNessuna valutazione finora

- Sandwich PanelsDocumento25 pagineSandwich PanelsGajaraj GajapathiNessuna valutazione finora

- Aluminium Plastic Composite PanelDocumento9 pagineAluminium Plastic Composite PanelFrankie ChanNessuna valutazione finora

- The Only Non-Combustible Composite PanelDocumento6 pagineThe Only Non-Combustible Composite Paneltroyel99Nessuna valutazione finora

- Building FacadesDocumento10 pagineBuilding FacadesAnubhav GargNessuna valutazione finora

- ACP Tutorials PDFDocumento10 pagineACP Tutorials PDFPratik JoshiNessuna valutazione finora

- Sandwich Panel Details - ObornikiDocumento3 pagineSandwich Panel Details - ObornikiAnas MuhammadNessuna valutazione finora

- Esr 2653Documento9 pagineEsr 2653Uğur ErdoğanNessuna valutazione finora

- Alucobond Color ChartDocumento2 pagineAlucobond Color ChartwilliamsaminNessuna valutazione finora

- Signsfy Catalog 2020Documento56 pagineSignsfy Catalog 2020rakos omerorNessuna valutazione finora