Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Characterization of Powders, Porous Solids and Suspensions

Caricato da

Solmaz TaheriDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Characterization of Powders, Porous Solids and Suspensions

Caricato da

Solmaz TaheriCopyright:

Formati disponibili

Characterization of

Powders, Porous Solids

and Suspensions

Lecture 8

Main Characteristics of Powders

and Porous Solids

Particle size

Surface area

Porosity

Why We Care About Particle Size

and Surface Area

These characteristics control many properties of

materials:

Flowability;

Filter-ability

Viscosity-Reology;

Agglomeration;

Dusting tendency;

Settling rate;

Activity/Reactivity rate (e.g. of catalyst);

Dissolution rate (of pharmaceutical);

Gas absorption;

Hydration rate (of cement);

Moisture absorption;

Entry into lungs (shape dependency too);

Combustion rate (of fuel)

Etc

What is Particle Size?

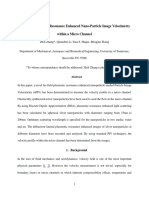

SEM of real ibuprofen particles

A Concept of Equivalent Sphere

Due to symmetry, size of sphere is

completely determined by only

one parameter its diameter

(radius)

Other properties of sphere are

easily computed from its size:

Sphere is just a convenient model!

This is why it is found throughout

the particle size analysis

3

6

1

d V t =

2

d S t =

3

6

d m t

=

Different Equivalent Spheres

Particle Size Measurement

Techniques

Direct observation (image analysis)

Sieving;

Sedimentation settling rate;

Coulter counter electrozone sensing;

Gas adsorption BET (SSA back extrapolation

to size);

Permeability (gas or liquid) e.g. Blaine, FSSS

Light scattering laser diffraction and Photon

Correlation Spectroscopy / Dynamic Light

Scattering

And What Do They Measure

Direct observation (image analysis) usually

some 2-D representation of a particle. Which

dimension is viable?;

Sieving combination of particle size and

shape;

Sedimentation settling rate. Stokes Law

(spheres, straight line settling);

Coulter counter electrozone sensing;

Gas absorption / Permeability surface area.

Extrapolate to average particle size only. BET

(SSA back extrapolation to size);

Light scattering equivalent scatterers;

Particle Size by Direct Observation

Google for

ImageJ

Dynamic Light Scattering (DLS)

DLS measures Brownian motion and relates this to the size of the

particles.

The larger the particle the slower the Brownian motion will be.

Smaller particles are kicked further by the solvent molecules and

move more rapidly.

The velocity of Brownian motion is defined by a property known as

the translational diffusion coefficient (D).

The size of a particle is calculated from the translational diffusion

coefficient by using the Stokes-Einstein equation:

d(H) hydrodynamic diameter, D translational diffusion coefficient, k

Boltzmanns constant, T temperature, - viscosity

D

kT

H d

tq 3

) ( =

What We Measure in DLS?

The diameter that is measured in

DLS is a value that refers to how a

particle diffuses within a fluid so it is

referred to as a hydrodynamic

diameter

The diameter that is obtained by this

technique is the diameter of a

sphere that has the same

translational diffusion coefficient as

the particle

The translational diffusion coefficient

will depend not only on the size of

the particle core, but also on any

surface structure, as well as the

concentration and type of ions in the

medium

Particle core

Shell formed by solvent particles,

ions etc. Low conductivity medium

will produce an extended double

layer of ions around the particle,

reducing the diffusion speed and

resulting in a larger, apparent

hydrodynamic diameter.

Thus, the measurements are

usually done in 10mM

NaCl (ISO13321 Part 8 1996)

How DLS Works

The dark spaces in the speckle pattern produced by light scattering are where the

phase additions of the scattered light are mutually destructive. The bright spots of

light in the speckle pattern are where the light scattered from the particles arrives

with the same phase and interfere constructively.

The observed signal depends on the phase addition of the scattered light falling

on the detector. In example A, two beams interfere and cancel each other out

resulting in a decreased intensity detected. In example B, two beams interfere

and enhance each other resulting in an increased intensity detected.

How DLS Works

For a system of particles undergoing Brownian motion, a speckle pattern is

observed where the position of each speckle is seen to be in constant

motion. This is because the phase addition from the moving particles is

constantly evolving and forming new patterns.

The rate at which these intensity fluctuations occur will depend on the size

of the particles. Figure above schematically illustrates typical intensity

fluctuations arising from a dispersion of large particles and a dispersion of

small particles.

The small particles cause the intensity to fluctuate more rapidly than the

large ones.

It is possible to directly measure the spectrum of frequencies contained in

the intensity fluctuations arising from the Brownian motion of particles, but it

is inefficient to do so. The best way is to use a device called a digital auto

correlator.

How an Auto Correlator Works

If the intensity of a signal is compared with itself at a particular point in time and a time

much later, then for a randomly fluctuating signal it is obvious that the intensities are not

going to be related in any way, i.e. there will be no correlation between the two signals.

However, if the intensity of signal at time t is compared to the intensity a very small time

later (t+t), there will be a strong relationship or correlation between the intensities of two

signals.

Perfect correlation is indicated by unity (1.00) and no correlation is indicated by zero

(0.00).

If the signals at t+2t, t+3t, t+4t etc. are compared with the signal at t, the correlation of

a signal arriving from a random source will decrease with time until at some time,

effectively t = , there will be no correlation.

If the particles are large the signal will be changing slowly and the correlation will persist

for a long time. If the particles are small and moving rapidly then correlation will reduce

more quickly.

Different Forms of Particle Size Distribution

Consider 2 populations of spherical particles of diameter 5nm and 50nm present in equal

numbers.

If a number distribution of these 2 particle populations is plotted, a plot consisting of 2 peaks

(positioned at 5 and 50nm) of a 1 to 1 ratio would be obtained.

If this number distribution was converted into volume, then the 2 peaks would change to a

1:1000 ratio (because the volume of a sphere is proportional to d

3

).

If this was further converted into an intensity distribution, a 1:1000000 ratio between the 2

peaks would be obtained (because the intensity of scattering is proportional to d

6

from

Rayleighs approximation).

In DLS, the distribution obtained from a measurement is based on intensity.

Schematics of Zetasizer Nano

Measurement of Porosity and

Specific Surface Area by

Gas Adsorption

F. Rouquerol, J. Rouquerol, K. S. W. Sing, Adsorption by Powders and Porous

Solids, Academic Press, 1-25, 1999

What are Porous Materials?

Non-porous solid

Low specific surface area

Low specific pore volume

Porous solid

High specific surface area

High specific pore volume

Porous materials have highly developed internal surface area that can be

used to perform specific function.

Almost all solids are porous except for ceramics fired at extremely high

temperatures

Measure of Porosity

Pore size and

its distribution

Specific Surface Area, m

2

/g =

Porosity

There are three parameters used as a measure of porosity; specific surface

area, specific pore volume or porosity, and pore size and its distribution.

Mass of the solid, g

Total surface area, m

2

Specific Pore volume, cm

3

/g

Mass of the solid, g

Total pore volume, cm

3

=

Porosity, % =

Volume of solid (including pores)

Volume of pores

X 100

Concept of Porosity: Open vs.

Closed Pores

Dead end

(open)

Closed

Inter-connected

(open)

Passing

(open)

F. Rouquerol, J. Rouquerol, K. S. W. Sing, Adsorption by Powders and Porous

Solids, Academic Press, 1-25, 1999

Open pores are accessible

whereas closed pores are

inaccessible pores. Open pores

can be inter-connected, passing

or dead end.

Size of Pores (IUPAC Standard)

2 nm 50 nm

Micropores

Mesopores Macropores

Zeolite,

Activated

carbon,

Metal organic

framework

Mesoporous silica,

Activated carbon

Sintered metals

and ceramics

Porous material are classified according to the size of pores: material with

pores less than 2 nm are called micropores, materials with pores between 2

and 50 nm are called mesopores, and material with pores greater than 50 nm

are macrospores

Sing, K. S. W. et al. Reporting Physisorption Data for Gas/Solid Systems. Pure & Appl. Chem. 57,

603-619 (1985).

Shapes of Pores

Conical

Interstices

Slits

Cylindrical

Spherical or

Ink Bottle

Pore

Shapes

F. Rouquerol, J. Rouquerol, K. S. W. Sing, Adsorption by Powders and Porous Solids, Academic

Press, 1-25, 1999

Experimental Techniques

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Can measure only open pores

Pore size : 0.4 nm 50 nm

Easy

Established technique

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Similar to gas

adsorption

Can measure only

open pores

Pore size >1.5 nm

Easy

Established technique

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Provide information

regarding pore

connectivity

Pore size can be

measured if the

materials contains

ordered pores

Rarely used for pore

analysis

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Pore size > 5nm

Rarely used for pore

analysis

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Any pore size

Open + Close

porosity

Techniques for Porosity Analysis

Mercury

porosimetry

TEM

SEM

Small angle

X-ray

scattering

Small

Angle

Neutron

scattering

Gas

adsorption

Techniques

Any pore size

Open & Close

porosity

Costly

Techniques for Porosity Analysis

Theory of Adsorption

Adsorption Process

Adsorption is brought by the forces acting between the solid and the

molecules of the gas. These forces are of two kinds: physical

(physiosorption) and chemical (chemisorption)

Adsorbent - the solid where adsorption takes place

Adsorbate - the gas adsorbed on the

surface of solids

Adsorptive - adsorbate before being adsorbed on the surface

PHYSISORPTION CHEMISORPTION

WEAK, LONG RANGE BONDING

Van der Waals interactions

STRONG, SHORT RANGE BONDING

Chemical bonding involved.

NOT SURFACE SPECIFIC

Physisorption takes place between all

molecules on any surface providing the

temperature is low enough.

SURFACE SPECIFIC

E.g. Chemisorption of hydrogen takes place on

transition metals but not on gold or mercury.

H

ads

= 5 .. 50 kJ mol-1 H

ads

= 50 .. 500 kJ mol

-1

Non activated with equilibrium achieved

relatively quickly. Increasing temperature

always reduces surface coverage.

Can be activated, in which case equilibrium can

be slow and increasing temperature can favour

adsorption.

No surface reactions. Surface reactions may take place:- Dissociation,

reconstruction, catalysis.

MULTILAYER ADSORPTION

BET Isotherm used to model adsorption

equilibrium.

MONOLAYER ADSORPTION

Langmuir Isotherm is used to model adsorption

equilibrium.

Physisorption vs Chemisorption

http://www.soton.ac.uk

Adsorption Process

1. Diffusion to adsorbent surface

2. Migration into pores of adsorbent

3. Monolayer builds up of adsorbate

1 2 3

Gas molecules admitted

under increasing pressure to

a clean, cold surface.

Data treatment techniques

find the quantity of gas that

forms the first layer.

1 2 3

S. Lowell & J. E. Shields, Powder Surface

Area and Porosity, 3rd Ed. Chapman & Hall,

New York, 1991

Adsorption Process

Adsorbent

Adsorbate

adsorptive of pressure saturated

adsorbate of pressure

where

: as written be can equation

above the constant, made are I and T, W, If

adsorbent. and adsorbate between n interactio

re; temperatu

adsorbate; the of pressure

adsorbent; of weight

adsorbed; gas of volume

where

) , , , (

=

|

|

.

|

\

|

=

=

=

=

=

=

=

p

p

p

p

f

I

T

P

W

P I T W f

o

o

V

V

V

a

a

a

Equation of adsorption

isotherm

S. Lowell & J. E. Shields, Powder Surface Area and

Porosity, 3rd Ed. Chapman & Hall, New York, 1991

Gas Sorption: Isotherm

Adsorption isotherm

Isotherm is a measure

of the volume of gas

adsorbed at a constant

temperature as a

function of gas

pressure.

Isotherms can be

grouped into six

classes.

adsorptive of pressure saturated

adsorbate of pressure

where

=

|

|

.

|

\

|

=

p

p

p

p

f

o

o

V

a

V

a

Desorption isotherm

p

p

o

Gas Sorption: Isotherm

V

a

1

P/P

o

Type I

or

Langmuir

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd Ed.

Chapman & Hall, New York, 1991

Concave to the P/P

o

axis

Exhibited by microporous

solids ( < 2nm )

1

P/P

o

Type II

Exhibited by nonporous or

macroporous solids ( > 50nm )

Unrestricted monolayer-multilayer

adsorption

Point B indicates the relative

pressure at which monolayer

coverage is complete

B

V

a

Gas Sorption: Isotherm

V

a

1

P/P

o

Type III

Convex to the P/P

o

axis

Exhibited by nonporous solids

V

a

1

P/P

o

Type IV

Exhibited by mesoporous

solids

Initial part of the type IV follows

the same path as the type II

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd Ed.

Chapman & Hall, New York, 1991

Gas Sorption: Isotherm

V

a

1

P/P

o

Type V

1

P/P

o

Type VI

Highly uncommon

Exhibited by mesoporous solids

Exhibited by nonporous solids

with an almost completely uniform

surface

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd Ed.

Chapman & Hall, New York, 1991

V

a

Gas Sorption: Hysteresis

Hysteresis indicates the presence of mesopores.

Hysteresis gives information regarding pore shapes .

Types I, II and III isotherms are generally reversible but type

I can have a hysteresis. Types IV and V exhibit hysteresis.

1

P/P

o

Hysteresis

V

a

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd Ed.

Chapman & Hall, New York, 1991

Gas Sorption: Hysteresis

V

a

1

P/P

o

Type A

Cylindrical Slits

Type B

1

P/P

o

1

P/P

o

Type C Type D

1

P/P

o

Type E

1

P/P

o

Conical

Bottle neck

Adsorption Theories: Langmuir

Adsorbate

Adsorbent

Assumptions:

homogeneous surface (all adsorption

sites energetically identical)

monolayer adsorption (no multilayer

adsorption)

no interaction between adsorbed

molecules

adsorbate. of pressure

and constant; empirical

monolayer; form to required gas of volume

; pressure at adsorbed gas of volume

where

1

=

=

=

=

+ =

P

b

V

P V

V

P

b V V

P

m

a

m m a

I. Langmuir The Constitution and Fundamental

Properties of Solids and Liquids. Part I. Solids.

J. Am. Chem. Soc., 1916, 38 (11), 2221-2295

Adsorption Theories: BET

adsorbate. of pressure relative

and layer); 1st of adsorption of energy to (related constant BET C

monolayer; form to required gas of volume

; pressure at adsorbed gas of volume

where

) 1 ( 1

) (

=

=

=

=

|

.

|

\

|

+ =

o

m

a

o

m m

o

a

P

P

V

P V

P

P

C V

C

C V P P V

P

Modification of Langmuir

isotherm

Both monolayer and multilayer

adsorption

Assumptions:

(a) gas molecules physically

adsorb on a solid in layers

infinitely;

(b) there is no interaction between

each adsorption layer;

(c) the Langmuir theory can be

applied to each layer.

Adsorbate

Adsorbent

S.Brunauer, P.Emmett, E.Teller Adsorption

of Gases in Multimolecular Layers, J. Am.

Chem. Soc., 1938, 60 (2), pp 309319

Specific Surface Area Calculation

C V P

P

C V

C

P P V

P

m

o

m

o

a

1 ) 1 (

) (

+

|

.

|

\

|

i mX Y + =

i m

V

m

+

=

1

P/P

o

1

V[(P

o

/P)-1]

0-1 0-2 0-3

At least three data points in the

relative pressure range 0.05 to 0.30

adsorbate of Weight

area surface Total

cs av m

A N V

=

sample of Weight

area surface Total

area) surface (Specific SSA =

Porosity Analyzer

Outgassing station

Analysis station

Liquid nitrogen

bath

Steps for Measurement

3. Interpretation

2. Adsorption Analysis

1. Sample Preparation

Sample Preparation (Outgassing)

Surface contamination is

removed by application

of:

Temperature

Flowing gas (helium or

nitrogen) or vacuum

Backfill can be done

using helium or adsorbate

gas.

According to IUPAC

standards, materials

should be outgassed for

at least 16 hours.

Adsorbate

Helium

Vacuum

P

o

Outgassing

station

Analysis station

Sample

Cell

Adsorption Analysis

Adsorbate (nitrogen,

argon, carbon dioxide,

krypton)

Analysis temperature

(liquid nitrogen, liquid

argon, 0

o

C)

Quantity of sample (1

mg sample is sufficient)

Number of points

(single point, five

points, seven points,

eleven points, full

analysis)

Adsorbate

Helium

Vacuum

P

o

Outgassing

station

Analysis station

Sample

Cell

Interpretation

Points P/P

o

Volume

adsorbed

1

2

3

Weight of sample

Pore shape

Specific

surface area

Pore volume

Pore size

&

distribution

Results

Common Adsorbates

Gas Temperature Cross sectional

area (nm

2

)

N

2

-195.8

o

C (liquid nitrogen)

-183

o

C (liquid argon).

0.162

Ar -183

o

C (liquid argon).

-195.8

o

C (liquid nitrogen)

0.142

CO

2

-78

o

C, -25

o

C, 0

o

C 0.195

CO -183

o

C (liquid argon) 0.163

Kr -195.8

o

C (liquid nitrogen) 0.205

O

2

-183

o

C (liquid argon) 0.141

C

4

H

10

0

o

C, 25

o

C 0.469

Choice of Adsorptive

N

2(g)

in N

2(l)

is the most

commonly used

adsorbate.

Not completely inert.

Dipole movement and

thus can have

localized adsorption.

Cross-sectional area of

0.162 nm

2

is

questionable.

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd

Ed. Chapman & Hall, New York, 1991

Quantachrome Autosorb-I Operational Manual

O

x

y

g

e

n

A

r

g

o

n

N

i

t

r

o

g

e

n

C

a

r

b

o

n

m

o

n

o

o

x

i

d

e

C

a

r

b

o

n

d

i

o

x

i

d

e

K

r

y

p

t

o

n

n

-

b

u

t

a

n

e

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

C

r

o

s

s

-

s

e

c

t

i

o

n

a

l

a

r

e

a

,

n

m

2

O

x

y

g

e

n

A

r

g

o

n

N

i

t

r

o

g

e

n

C

a

r

b

o

n

m

o

n

o

o

x

i

d

e

C

a

r

b

o

n

d

i

o

x

i

d

e

K

r

y

p

t

o

n

n

-

b

u

t

a

n

e

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

C

r

o

s

s

-

s

e

c

t

i

o

n

a

l

a

r

e

a

,

n

m

2

Choice of Adsorptive

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd

Ed. Chapman & Hall, New York, 1991

Quantachrome Autosorb-I Operational Manual

Ar

(g)

in Ar

(l)

is preferable

but because of

unavailability of Ar

(l)

(87K),

N

2(l)

(77 K) is used.

Ar can reach to somewhat

smaller pores than N

2

.

Accurate measurement of

micropores is possible

using Ar.

O

x

y

g

e

n

A

r

g

o

n

N

i

t

r

o

g

e

n

C

a

r

b

o

n

m

o

n

o

o

x

i

d

e

C

a

r

b

o

n

d

i

o

x

i

d

e

K

r

y

p

t

o

n

n

-

b

u

t

a

n

e

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

C

r

o

s

s

-

s

e

c

t

i

o

n

a

l

a

r

e

a

,

n

m

2

Choice of Adsorptive

S. Lowell & J. E. Shields, Powder Surface Area and Porosity, 3rd

Ed. Chapman & Hall, New York, 1991

Quantachrome Autosorb-I Operational Manual

In case of activated

carbon, CO

2

is often

the most preferred

adsorbate.

Adsorption analysis of

CO

2

takes less time.

Limited to micropore

analysis.

Shape of Microporous Materials

V

a

1

P/Po

Type I

or

Langmuir

Type I isotherms dont have

hysteresis.

Pore shape cannot be

determined by isotherm.

As various methods for pore

size calculation are based on

shape of pores, reliability of pore

size calculation is questionable.

F. Rouquerol, J. Rouquerol, K. S. W. Sing, Adsorption by Powders and Porous

Solids, Academic Press, 439-446, 1999

2 nm

50 nm

Micropores

Mesopores Macropores

Methods

Assumption

Pore Shape Based on ..

Brunauer MP method Cylindrical or Slit shaped de Boers t-method

Dubinin-Astakhov method - Polanyi potential

theory

Independent of

Kelvin equation

HK (Horvath-Kawazoe) method Slit Everett and Powl

method

Independent of

Kelvin equation

Saito-Foley method Cylindrical HK method

Choice of Method

P. A. Webb, C. Orr, Analytical Methods in Fine Particle Technology, Micromeritics, 53

152, 1997

Quantachrome Autosorb-I Operational Manual

2 nm 50 nm

Micropores

Mesopores Macropores

Methods

Assumption

Pore Shape Based on ..

BJH (Barrett, Joyner and

Halenda) method

Cylindrical, Slit-shaped Kelvin equation

DH (Dollimore Heal) method

Cylindrical t-method

Choice of Method

P. A. Webb, C. Orr, Analytical Methods in Fine Particle Technology, Micromeritics, 53

152, 1997

Quantachrome Autosorb-I Operational Manual

2 nm

50 nm

Micropores

Mesopores Macropores

Methods

Assumption

Pore Shape Based on ..

NLDFT (Non Local Density

Functional Theory) and Monte

Carlo simulation method

Cylindrical and slit Statistical

thermodynamics

Choice of Method

P. A. Webb, C. Orr, Analytical Methods in Fine Particle Technology, Micromeritics, 53

152, 1997

Quantachrome Autosorb-I Operational Manual

Potrebbero piacerti anche

- MATE 280 Characterization of Powders and Porous MaterialsDocumento65 pagineMATE 280 Characterization of Powders and Porous MaterialsAnissa Adiwena100% (1)

- MATE 280 Characterization of Powders and Porous MaterialsDocumento57 pagineMATE 280 Characterization of Powders and Porous MaterialsBogdan NedelcuNessuna valutazione finora

- MRK656-01 DLS in 30 MinutesDocumento8 pagineMRK656-01 DLS in 30 MinutesQilu ZhangNessuna valutazione finora

- Optical Properties of ColloidsDocumento17 pagineOptical Properties of ColloidsEduardo Montealegre LopezNessuna valutazione finora

- Inggit Dwi Wismoyowati (52134120 Fitiyatun Nur Jannah (5213412006) Nur Rofiah (52134120 Siti Nur Afifah (52134120Documento31 pagineInggit Dwi Wismoyowati (52134120 Fitiyatun Nur Jannah (5213412006) Nur Rofiah (52134120 Siti Nur Afifah (52134120Rin Ririn MahmudatiNessuna valutazione finora

- DTS Nano Series Training Course Size DayDocumento98 pagineDTS Nano Series Training Course Size DayDerya KöseNessuna valutazione finora

- PGSF21 421Documento22 paginePGSF21 421Cheryl LeeNessuna valutazione finora

- Laser Tissue InteractionsDocumento16 pagineLaser Tissue InteractionsDuchung TranNessuna valutazione finora

- Turbidimetry and Nephelometry SDDocumento9 pagineTurbidimetry and Nephelometry SDCamilo Varela VegaNessuna valutazione finora

- Dust Particle Formation and CharacteristicsDocumento34 pagineDust Particle Formation and CharacteristicsJoao MinhoNessuna valutazione finora

- Liquid Glass Transition: A Unified Theory From the Two Band ModelDa EverandLiquid Glass Transition: A Unified Theory From the Two Band ModelNessuna valutazione finora

- Physics 2Documento32 paginePhysics 2Pika WabblesNessuna valutazione finora

- Theory: Infrared Spectroscopy (IR Spectroscopy) Is TheDocumento37 pagineTheory: Infrared Spectroscopy (IR Spectroscopy) Is TheAnkit KhuranaNessuna valutazione finora

- Moire Interferometria PDFDocumento4 pagineMoire Interferometria PDFLuis RcNessuna valutazione finora

- Nano Particle Tracking AnalysisDocumento11 pagineNano Particle Tracking AnalysisprabhatNessuna valutazione finora

- Zetasizer DLSDocumento10 pagineZetasizer DLSmontero73Nessuna valutazione finora

- Far-Field Plasmonic Resonance Enhanced Nano-Particle Image Velocimetry Within A Micro ChannelDocumento16 pagineFar-Field Plasmonic Resonance Enhanced Nano-Particle Image Velocimetry Within A Micro ChannelANessuna valutazione finora

- Particle Size Measurement: Dynamic Light Scattering (DLS) or Photon Correlation Spectroscopy (PCS)Documento24 pagineParticle Size Measurement: Dynamic Light Scattering (DLS) or Photon Correlation Spectroscopy (PCS)Aakshi JairathNessuna valutazione finora

- Particle Size Measurement: Dynamic Light Scattering (DLS) or Photon Correlation Spectroscopy (PCS)Documento24 pagineParticle Size Measurement: Dynamic Light Scattering (DLS) or Photon Correlation Spectroscopy (PCS)Aakshi JairathNessuna valutazione finora

- Mech. Operations-Particle TechnologyDocumento475 pagineMech. Operations-Particle TechnologyEshwar Iyer100% (3)

- Theoretical Analysis of Gold NanoparticlesDocumento7 pagineTheoretical Analysis of Gold NanoparticlesSurinder SinghNessuna valutazione finora

- Dynamic Light Scattering: An Introduction in 30 Minutes: DH KT DDocumento8 pagineDynamic Light Scattering: An Introduction in 30 Minutes: DH KT DajaysingodiyaNessuna valutazione finora

- 3MS: Multiphase Systems: DR Daniele Vigolo - Chemical Engineering Email: D.vigolo@bham - Ac.uk Tel: 0121 415 8694Documento36 pagine3MS: Multiphase Systems: DR Daniele Vigolo - Chemical Engineering Email: D.vigolo@bham - Ac.uk Tel: 0121 415 8694Tom BombadilNessuna valutazione finora

- Material Science: Prof. Satish V. KailasDocumento7 pagineMaterial Science: Prof. Satish V. Kailasanupam_kayalNessuna valutazione finora

- Size Analysis of Solid Particles Using Laser Diffraction and Sieve AnalysisDocumento10 pagineSize Analysis of Solid Particles Using Laser Diffraction and Sieve AnalysisTatiana Monroy MoraNessuna valutazione finora

- RFDC SputteringDocumento4 pagineRFDC Sputteringसुरेन्द्र वशिष्ठNessuna valutazione finora

- CHE572 Chapter 2 Particle Size Characterization PDFDocumento18 pagineCHE572 Chapter 2 Particle Size Characterization PDFMuhd FahmiNessuna valutazione finora

- Partical TechnologyDocumento54 paginePartical TechnologyEhtisham ZiaNessuna valutazione finora

- AMIE AD 302 Study MaterialsDocumento12 pagineAMIE AD 302 Study MaterialsKaruppusamy MariNessuna valutazione finora

- Geophysical Research Letters - 2020 - Claudepierre - Empirically Estimated Electron Lifetimes in The Earth S RadiationDocumento9 pagineGeophysical Research Letters - 2020 - Claudepierre - Empirically Estimated Electron Lifetimes in The Earth S RadiationCH YNessuna valutazione finora

- Particulate Morphology: Mathematics Applied to Particle AssembliesDa EverandParticulate Morphology: Mathematics Applied to Particle AssembliesNessuna valutazione finora

- Letters: Ale Vy Flight For LightDocumento4 pagineLetters: Ale Vy Flight For LightThakur Jitender PundirNessuna valutazione finora

- Milling PDFDocumento5 pagineMilling PDFHaroon RahimNessuna valutazione finora

- Material ReportDocumento42 pagineMaterial ReportOmar ElsayedNessuna valutazione finora

- IRDocumento8 pagineIRbudinganjukNessuna valutazione finora

- A Non-Standard Statistical Approach To The Silo Discharge: T E P JDocumento8 pagineA Non-Standard Statistical Approach To The Silo Discharge: T E P JA94leo14hsetmaNessuna valutazione finora

- Experiment-4: Aim: Synthesis and Characterization of Carbon Nanotube/Polypyrrole Requirements: Formula Used: TheoryDocumento4 pagineExperiment-4: Aim: Synthesis and Characterization of Carbon Nanotube/Polypyrrole Requirements: Formula Used: TheoryTush RohNessuna valutazione finora

- Surface Plasmon ResonanceDocumento37 pagineSurface Plasmon ResonancepraveenNessuna valutazione finora

- Dynamic Light Scattering (DLS)Documento13 pagineDynamic Light Scattering (DLS)Ahalallala LololalaNessuna valutazione finora

- Experimental Evidence of An Effective Medium Seen by Diffuse Light in Turbid ColloidsDocumento8 pagineExperimental Evidence of An Effective Medium Seen by Diffuse Light in Turbid ColloidsvespacthNessuna valutazione finora

- 57-Dynamic Light ScatteringDocumento9 pagine57-Dynamic Light ScatteringNastase EduardNessuna valutazione finora

- Alexander Dreischuh Et Al - Observation of Attraction Between Dark SolitonsDocumento4 pagineAlexander Dreischuh Et Al - Observation of Attraction Between Dark Solitons23213mNessuna valutazione finora

- Multiple Scattering As A Diffusion Process: Discrete OrdinatesDocumento2 pagineMultiple Scattering As A Diffusion Process: Discrete OrdinatesAmra IbrahimovicNessuna valutazione finora

- Malvern Zetasizer LSDocumento132 pagineMalvern Zetasizer LSwinsonecNessuna valutazione finora

- Particulate TechnologyDocumento38 pagineParticulate TechnologyTamoor TariqNessuna valutazione finora

- Effective Gradients in Porous Media Due To Susceptibility DifferencesDocumento9 pagineEffective Gradients in Porous Media Due To Susceptibility DifferencesDaksh ParasharNessuna valutazione finora

- Laboratory Report 3Documento3 pagineLaboratory Report 3api-3864822Nessuna valutazione finora

- PIV Tracer-SeedingDocumento12 paginePIV Tracer-SeedingKaffelNessuna valutazione finora

- Characterization of Single ParticleDocumento29 pagineCharacterization of Single ParticlePiyush RajNessuna valutazione finora

- Dark Matter, Unified Field Theory, and Ufo’S, Are Understandable and Achievable.Da EverandDark Matter, Unified Field Theory, and Ufo’S, Are Understandable and Achievable.Nessuna valutazione finora

- Diffusion in Catalyst PelletsDocumento10 pagineDiffusion in Catalyst PelletsAnonymous JvnjUlEHNessuna valutazione finora

- Characterization of NanoparticlesDocumento16 pagineCharacterization of NanoparticlesPrasun SarkarNessuna valutazione finora

- Artigo 7Documento11 pagineArtigo 7Letícia SerrouNessuna valutazione finora

- Question Bank Mass Transfer IDocumento4 pagineQuestion Bank Mass Transfer Imohanraj1990100% (1)

- Brownian Motion HandoutDocumento23 pagineBrownian Motion HandoutSehrelilNessuna valutazione finora

- Assignment Ir SpectrosDocumento10 pagineAssignment Ir SpectrosHumayun ArshadNessuna valutazione finora

- RT Read Before Class MPDVDocumento16 pagineRT Read Before Class MPDVphantomsNessuna valutazione finora

- Oxygen Diffusion in Pores of Iron-Ore PelletsDocumento3 pagineOxygen Diffusion in Pores of Iron-Ore PelletsKrol PrietoNessuna valutazione finora

- The Impacts of Isola 370HR in PCB FabricationDocumento5 pagineThe Impacts of Isola 370HR in PCB FabricationjackNessuna valutazione finora

- Properties of SteamDocumento27 pagineProperties of SteamVishal DhimanNessuna valutazione finora

- Mcat Organic ChemistryDocumento3 pagineMcat Organic Chemistryhussai7Nessuna valutazione finora

- 5. nhũ dịch, hỗn dịchDocumento6 pagine5. nhũ dịch, hỗn dịchTrần Thị NhungNessuna valutazione finora

- Time Resolved Pulsed Laser Photolysis Study of The Rate Constant and Reaction Mechanism For Ru (Bpy) 32+ Phosphorescence Quenching by O2Documento10 pagineTime Resolved Pulsed Laser Photolysis Study of The Rate Constant and Reaction Mechanism For Ru (Bpy) 32+ Phosphorescence Quenching by O2kjg51163824Nessuna valutazione finora

- Power PlantDocumento3 paginePower PlantVictor John PingkianNessuna valutazione finora

- Termo PRDocumento99 pagineTermo PRSapnaNessuna valutazione finora

- 1450 81090702169R PDFDocumento16 pagine1450 81090702169R PDFdevoydouglasNessuna valutazione finora

- 3BM3 Lecture 1 To 8Documento64 pagine3BM3 Lecture 1 To 8Sheila KwokNessuna valutazione finora

- GC Methode Development RestekDocumento71 pagineGC Methode Development RestekbenyNessuna valutazione finora

- Preparation of Cyclohexene From CyclohexanolDocumento7 paginePreparation of Cyclohexene From CyclohexanolDumile Nombasa100% (5)

- Shipborne Meteorological InstrumentsDocumento59 pagineShipborne Meteorological InstrumentsJayson CandelariaNessuna valutazione finora

- Explanation To Report in RACDocumento2 pagineExplanation To Report in RACPaulDenver Villafuerte DoloresNessuna valutazione finora

- δ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationDocumento6 pagineδ-Bi2O3 thin films prepared by reactive sputtering - Fabrication and characterizationrafael pimentelNessuna valutazione finora

- Biochem Practical 12Documento21 pagineBiochem Practical 12Sayanta BeraNessuna valutazione finora

- ManufacturersDocumento96 pagineManufacturersSilenceNessuna valutazione finora

- The Smoking Gun Sem Afm BTBPDocumento17 pagineThe Smoking Gun Sem Afm BTBPEkabudiNessuna valutazione finora

- Mahatma Gandhi University: Model Question PaperDocumento4 pagineMahatma Gandhi University: Model Question PaperaNessuna valutazione finora

- Heat Transfer ActivityDocumento4 pagineHeat Transfer ActivityMark Angelo UyNessuna valutazione finora

- Soal HysysDocumento99 pagineSoal HysysHengky PrasetyoNessuna valutazione finora

- Science 9 Quarter 2 Week 1Documento5 pagineScience 9 Quarter 2 Week 1Leslie Darwin DumasNessuna valutazione finora

- Electronics Cooling Final PresentationDocumento37 pagineElectronics Cooling Final PresentationManoj KumarNessuna valutazione finora

- Fermentation - ChE 135Documento8 pagineFermentation - ChE 135continentalflossNessuna valutazione finora

- Karakteristik FononDocumento15 pagineKarakteristik FononNiken Rahayu PutriNessuna valutazione finora

- #The Exudation Test For "Bleeding" in Bituminous RoofingDocumento3 pagine#The Exudation Test For "Bleeding" in Bituminous RoofingMa JamieNessuna valutazione finora

- General Chemistry I - Q2 M6.2 Electron Configuration of AtomsDocumento17 pagineGeneral Chemistry I - Q2 M6.2 Electron Configuration of Atomseli100% (1)

- 1331 - Chapter 11 Questions IGNORE QUESTIONS 3, 10, 37 Onwards Intermolecular ForcesDocumento5 pagine1331 - Chapter 11 Questions IGNORE QUESTIONS 3, 10, 37 Onwards Intermolecular ForcesDaevy Toribio AmdosNessuna valutazione finora

- Boiler Efficiency Improvement Through Analysis of Losses PDFDocumento5 pagineBoiler Efficiency Improvement Through Analysis of Losses PDFTambun BerdikariNessuna valutazione finora

- Unit 1 Module 3 Period 3 and Group II Elements WorksheetDocumento2 pagineUnit 1 Module 3 Period 3 and Group II Elements WorksheetFrank MassiahNessuna valutazione finora

- 2011 H2 Chemistry Paper 3 Suggested SolutionsDocumento7 pagine2011 H2 Chemistry Paper 3 Suggested SolutionsLee Jun Hui0% (1)