Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Finite Element Analysis of Electric Machines - The Solver and Its Application

Caricato da

Harshan ArumugamDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Finite Element Analysis of Electric Machines - The Solver and Its Application

Caricato da

Harshan ArumugamCopyright:

Formati disponibili

Finite Element Analysis of Electric Machines

------The Solver and Its Application

Danhong Zhong

Department of Electrical Engineering

The Pennsylvania State University

Motivation

Steady-state finite element solver

Low rotor loss permanent magnet

machine design

Summary and future work

Outline

Electric Machines in New Technologies

Flywheel for frequency regulation for

renewable and distributed generation

(Credit: Beacon Power)

How do we design a machine that

suits our need?

Flywheel energy storage system

Motor/Generator test setup for flywheel system

Design Objectives

Flywheel motor/generator for

small satellite application

Power level of 100W

Ultrahigh speed operation

(150-300krpm)

High frequency

electromagnetics

Continuously charging and

discharging

Thermal Constraints important

Electrical losses

Rotor

losses

Design Methods

Rules-of-thumb, empirical tables, design equations, a designers

intuition are all valuable

Classic Way----prototyping

Large-scale numerical simulation

Magnetic excitation is supplied by high-energy permanent magnet

No power loss is associated

with machine field excitation

High power/weight ratio

----Popular choice for

high-speed motor/generator

applications

Synchronous Permanent Magnet (PM) Machines

Rotor losses

Rotor exposed to high electrical frequency harmonics

Heat generated

Rotor spins in vacuum, supported by magnetic bearings

Only method of heat transfer is through blackbody

radiation, which is a relatively poor heat transfer mechanism

Temperature dependence of Neodymium Iron Boron

The properties of many

materials in the flywheel rotor will

degrade with increasing

temperature

E.g., the intrinsic coercivity of

Neodymium-Iron-Boron decreases

significantly with temperature,

creating a risk of demagnetization

It is therefore important to

minimize rotor losses in this

application

Change of intrinsic coercivity of

Neodymium Iron Boron

with respect to temperature

(courtesy Dexter Magnetics)

Solver overview

Programmed in MATLAB environment

2-D finite element analysis

Software capable of:

model building

mesh generation

steady-state solution solving (time stepping)

rotor losses calculation

Uses GMRES method to speed up steady-state solution

Allows study of rotor losses when insulating barriers exist

in the 2-D plane of the rotor (e.g., segmenting permanent

magnets)

Road Map

1) Maxwells equation --The governing Partial

Differential Equation(PDE) of the problem

2) PDE - Finite Element Equations

3) Main techniques used in achieving the steady state

solution.

Mathematical model

Maxwells equations:

t

B

E

J H

B

c

c

= V

= V

= V 0

Constitutive Laws:

M H B

B v E J

0 0

) (

o

+ =

+ =

Governing Partial Differential Equation (PDE)

(1)

Finite Element Method

The object is divided into Finite

Element mesh

A simple relationship is used to

represent the variables anywhere in

the element by variables on the

nodes of the element.

Within the element, approximate

functions in terms of nodal values

are then derived from the PDE

Mesh (16761 points 33232 elements)

element

The method of weighted residuals

Define a residual function:

(1)

The solution of the PDE should satisfy that, for a given weight function w,

(2)

(3)

Finite Element Formulation

The finite element formulation is given as:

Where

D, K :global matrix decided by material properties and element shape

IM, AM : represents magnetization in ferromagnetic materials or

permanent magnets, can be a nonlinear function of x

I s : forced current flowing in stator windings

(4)

(

(

(

=

(

(

(

A + I

A + I

(

(

(

V

(

(

(

+

(

(

(

V

(

(

(

(

(

E

s y s x s

y r x r

s

r

ss rs

sr rr

s

r rr

I M M

M M

a

a

K K

K K

s

a

a S 0

0 0

0

3

~

0 0

0 0 0

0 0

0

~

3

1

0

|

o

|

(5)

Steady-State Analysis

Under steady-state assumptions, after one period T we wish to achieve

the same primary variables, i.e.

If we define the nonlinear state transition function as , this becomes:

) (- +

(6)

Steady-State Solution Techniques

The state transition function in (6) is determined by (5)

To achieve the steady-state solutions, we used the following numerical

techniques:

o Backward Euler Integration

o Shooting-Newton Algorithm

o Matrix-free GMRES

(5)

(6)

Shooting Newton Method

Modify

NO

Time integration of the differential equation

YES

Initial Value Final Value

Error < Tolerance?

Target Value (=Initial Value) End Iteration

Calculate

Modification

The steady-state solution in the time domain is obtained by

using a shooting Newton method:

Applying the Newton-Raphson method, we get:

Where J

+

is the Jacobian of the nonlinear state transition function

(8)

In our solver we define

(7)

Matrix-free GMRES Method

Generalized minimum residual method (GMRES) :

A Krylov-subspace method

When solving Ax=b, no direct access of matrix A is used, A only

need to be accessible via a subroutine that returns y=Az

The Jacobin

1

1

1

) 0 (

) (

) , 0 , ) 0 ( (

+

c

c

=

j

j

j

x

T x

T x J

can not be explicitly written

(8)

A

x b

Efficiency Improvement

By using GMRES, the computation time of the shooting-Newton

method is dramatically reduced.

Flux Density Distribution

Rotor Loss Distribution

Harmonic analysis

0 20 40 60 80 100

0

0.05

0.1

0.15

0.2

0.25

harmonics

r

o

t

o

r

l

o

s

s

e

s

(

w

)

After we achieve the steady-state solution, we perform a Discrete Fourier

Transform of x(t) and calculate the eddy current rotor losses for each

harmonic.

Rotor Loss Design Study

Design parameters are changed to study the effect

on rotor losses

The stator current peak is adjusted to maintain

constant steady-state mechanical power

Segmenting the PM poles

Other Rotor Design Aspect

Laminated backiron

Different permanent magnet materials

Stator Design: 36 Stator Slots

Stator Design: Open Slot vs. Closed Slot

open slot

closed slot

0 20 40 60 80 100

0

0.05

0.1

0.15

0.2

0.25

harmonics

l

o

s

s

(

w

)

Techniques for Reducing Rotor Losses

Laminating rotor backiron

Segmenting the Permanent magnet poles

Increasing slot number

Closing the stator slots

Summary

Purpose of Finite element analysis for electric machines

The flywheel energy storage system

The steady-state nonlinear finite element solver

Its application

Further research into numerical modeling of electric

machines

Special machine design and analysis

Future Work

2011 Chevrolet Volt Propulsion System

(Credit: GM)

Thank you!

This work has been supported by NASA Grant NAG3-2598

Currents flowing in permanent magnet are eddy currents. In machine

design, magnets can be electrically insulated from each other and the

rotor backiron.

Eddy currents meet large impedance at the

end of the machine, surface charge will

accumulate and electric potential is built

across the magnet

Permanent Magnets

) (

1

2

0

A M A

t

A

V + V = V

c

c

| o

o

Electric Scalar Potential Dynamics

| o o V

c

c

=

t

A

J

eddy

(2)

s

ds J

s

eddy

c

}

= o

c

o

|

c

= V

ds

t

A S

s

V +

c

c

= V

}

) ( | |

o

c

The charge relaxation time constant c/o is extremely small in

permanent magnets, and so our system consists of a set of fast

dynamics (electric scalar potential) and slow dynamics (magnetic

vector potential). Therefore, singular perturbation techniques can

be used to analyze the system.

Singular Perturbation Analysis Techniques

Under singular perturbation theory, when analyzing the fast

dynamics, the slow variables can be assumed to be essentially

constant

If the fast dynamics are stable under this condition, the fast

variables will converge to a quasi-steady-state value, which is a

function of the slow variables

When analyzing the slow dynamics, it can be assumed that the

fast variables have converged to their quasi-steady-state value

discussed above.

0 = V

c

c

}

| S ds

t

A

S

m

n

R z z t z t z x g z

R x x t x t z x f x

e = =

e = =

, ) ( ), , , , (

, ) ( ), , , , (

0

0

0

0

c c

c

c

small

) , 0 ,

~

,

~

( 0 t z x g =

(3)

ds

t

A S

s

V +

c

c

= V

}

) ( | |

o

c

Applying Finite Element Method

To solve the Partial Differential Equations

use 2D finite element method

Primary variable : A and V|

Element type : triangular

Shape functions : linear

Procedure used : weighted residuals

Error distribution principle :

Galerkins method

Boundary conditions:

0 =

I z

A

Newton-Raphson Method

Applying the Newton-Raphson method, we get:

Where J

+

is the Jacobian of the nonlinear state transition function

) ( ) (

1 1

1

=

c

c

j j j

x

x f x x

x

f

j

Define : and its called the Jacobian of

j

x

f

x

f

J

c

c

=

) (x f

(5)

In our solver we define

For a nonlinear equation, the Newton-Raphson Method provides the

following iterative procedure to solver for x:

0 ) ( = x f

Equation solving

Now we look closely at the steady state iterative equation :

1

1

1

) 0 (

) (

) , 0 , ) 0 ( (

+

c

c

=

j

j

j

x

T x

T x J

In (5), is not known explicitly but is determined

through Backward Euler Integration. Thus:

1 1

) ( ) , 0 , ) 0 ( (

= +

j j

T x T x

(5)

can not be explicitly written either and would have to be calculated using a

form of numerical integration

Equation solving (2)

One way of solving for the Jacobian is to differentiate both sides of (4)

with respect to

+

J

Where and are matrices derived from (4). can then be computed by

repeatedly solving (6) starting from the initial condition

f

C

p

C

+

J

Computation load analysis of this method:

Matrix-Matrix multiplication on the right side and LU-factorization on the left

side. If the vector has components, the computation work per time step is

of at least order

N

2

N

The Backward Euler Integration Method calculate y at step

n+1 implicitly by :

Backward Euler Integration

Consider the problem:

) ( ) (

2

1 1

h O y hf y y

n n n

+ =

+ +

In the solver we separate the period T into a number of time

steps h. Provided a solution at time t1, x(t1), we then can

compute the solution x(t1+h) at time t1+h, by applying the

backward Euler integration to (5) over the time interval h:

(5)

(7)

Application of the GMRES

Computation load analysis of this method:

Now we consider solving the problem using GMRES method. By using

GMRES method, we dont need to provide explicitly. Instead, we only need

to provide . We apply the procedure (6) to a vector

+

J

Matrix-vector multiplication on the right side and LU-factorization on the left

side. Typically the number of iterations required by GMRES to achieve a

sufficiently low relative error is substantially smaller than problem size. So by

using GMRES, the numerical efficiency is improved.

The eddy currents in rotor are :

Post-processing:

rotor loss calculation

After we achieve the steady-state solution at time 0, the entire response

x(t) can be calculated by integrating (5) for one period. We perform a

Discrete Fourier Transform of x(t) and calculate the eddy current rotor

losses for each harmonic in each element.

}

}

V =

=

Se

i i i s

Se

i e

s

ei

dS A j l

dS J

l

P

2

2

) ( ) (

) (

e | e e o

e

o

u V

c

c

= o o

t

A

J

Potrebbero piacerti anche

- German Language CourseDocumento210 pagineGerman Language Course42099% (71)

- CFD NotesDocumento155 pagineCFD NotesAjit ChandranNessuna valutazione finora

- (Tabatabaian, Mehrzad) COMSOL5 For Engineers (B-Ok - Xyz)Documento335 pagine(Tabatabaian, Mehrzad) COMSOL5 For Engineers (B-Ok - Xyz)Aeyrton Oliver Baez Martínez100% (2)

- Advanced Engineering Mathematics 3rd Edition PDFDocumento775 pagineAdvanced Engineering Mathematics 3rd Edition PDFLeangHeySeyNessuna valutazione finora

- (Fluid Mechanics and Its Applications 110) Roelof Vos, Saeed Farokhi (Auth.) - Introduction To Transonic Aerodynamics-Springer Netherlands (2015) PDFDocumento561 pagine(Fluid Mechanics and Its Applications 110) Roelof Vos, Saeed Farokhi (Auth.) - Introduction To Transonic Aerodynamics-Springer Netherlands (2015) PDFAugusto C. Campagnon100% (2)

- Airfoil SectionDocumento3 pagineAirfoil SectionHarshan ArumugamNessuna valutazione finora

- Introduction To Finite Element Methods PDFDocumento34 pagineIntroduction To Finite Element Methods PDFThirumalaimuthukumaranMohanNessuna valutazione finora

- Differential Forms on Electromagnetic NetworksDa EverandDifferential Forms on Electromagnetic NetworksValutazione: 4 su 5 stelle4/5 (1)

- Handbook of Power Systems Engineering with Power Electronics ApplicationsDa EverandHandbook of Power Systems Engineering with Power Electronics ApplicationsNessuna valutazione finora

- Ode Ie Cov Balwan SirDocumento229 pagineOde Ie Cov Balwan SirRrq HolitosNessuna valutazione finora

- Earthquake EngineeringDocumento79 pagineEarthquake EngineeringLuis MontoyaNessuna valutazione finora

- Aircraft Structural Analysis Full VersionDocumento20 pagineAircraft Structural Analysis Full Versionpradeephit100% (1)

- Infinitiv Präteritum (Preterite) Perfekt (Past Participle) : AnfangenDocumento3 pagineInfinitiv Präteritum (Preterite) Perfekt (Past Participle) : AnfangenHarshan ArumugamNessuna valutazione finora

- Industrial Training ReportDocumento30 pagineIndustrial Training ReportHarshan ArumugamNessuna valutazione finora

- SAP Materials Management Question BankDocumento66 pagineSAP Materials Management Question BankHarshan ArumugamNessuna valutazione finora

- From Skinny To MuscularDocumento114 pagineFrom Skinny To MuscularIonut AdrianNessuna valutazione finora

- From Skinny To MuscularDocumento114 pagineFrom Skinny To MuscularIonut AdrianNessuna valutazione finora

- Simulation of Electric Machines and Drive Systems Using Matlab and SimulinkDocumento11 pagineSimulation of Electric Machines and Drive Systems Using Matlab and SimulinkmdpkishoreNessuna valutazione finora

- Plates and ShellsDocumento106 paginePlates and ShellsMadhu Kiran KolatiNessuna valutazione finora

- 4528 R451 01 (Fundamentals - 1) PDFDocumento238 pagine4528 R451 01 (Fundamentals - 1) PDFMikhail TarabrinNessuna valutazione finora

- Design & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Documento58 pagineDesign & Analysis Project BY INDIAN STUDENT (ANSYS CATIA MATLAB)Vaibhav Soni100% (1)

- Harmonic Elimination in Three-Phase Voltage Source Inverters by Particle Swarm OptimizationDocumento8 pagineHarmonic Elimination in Three-Phase Voltage Source Inverters by Particle Swarm Optimizationfade2548Nessuna valutazione finora

- Motoranalysis-Pm: Design and Analysis of Permanent Magnet MachinesDocumento107 pagineMotoranalysis-Pm: Design and Analysis of Permanent Magnet Machineslupillorivera9981Nessuna valutazione finora

- An Introduction To Electrostatic ActuatorDocumento32 pagineAn Introduction To Electrostatic Actuatormujeeb.abdullah2830Nessuna valutazione finora

- Motoranalysis-Pm v1.1 ManualDocumento110 pagineMotoranalysis-Pm v1.1 ManualName24122021Nessuna valutazione finora

- A Novel Preconditioner Based On CSL Operator For Solving The Helmholtz EquationsDocumento3 pagineA Novel Preconditioner Based On CSL Operator For Solving The Helmholtz EquationssinsecticideNessuna valutazione finora

- Model Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationDocumento19 pagineModel Predictive Control of A Permanent Magnet Synchronous Motor With Experimental ValidationAlimamy KoromaNessuna valutazione finora

- Bifurcation in The Dynamical System With ClearancesDocumento6 pagineBifurcation in The Dynamical System With Clearancesklomps_jrNessuna valutazione finora

- Power Flow Calculation by Combination of Newton-Raphson Method and Newton's Method in OptimizationDocumento4 paginePower Flow Calculation by Combination of Newton-Raphson Method and Newton's Method in OptimizationAbdulrahmanNessuna valutazione finora

- Fault Detection of PM Synchronous Motor Via Modulating FunctionsDocumento6 pagineFault Detection of PM Synchronous Motor Via Modulating Functionsjithesh87Nessuna valutazione finora

- Control of DC Electric MotorDocumento16 pagineControl of DC Electric MotorNa ChNessuna valutazione finora

- Robust Position Control of A DC Motor by Sliding ModeDocumento10 pagineRobust Position Control of A DC Motor by Sliding ModeDuy TrươngNessuna valutazione finora

- EMFT Challenging ExperimentsDocumento15 pagineEMFT Challenging ExperimentsMaile Sachin KumarNessuna valutazione finora

- Solution To The Schrodinger Equation For A Linear 1 D PotentialDocumento12 pagineSolution To The Schrodinger Equation For A Linear 1 D PotentialbobNessuna valutazione finora

- Mohsin RiazDocumento5 pagineMohsin RiaznohuggermuggerNessuna valutazione finora

- Elec/Tele/Phtn 4123 Electrical/Telecommunications Design Proficiency Lab2Documento11 pagineElec/Tele/Phtn 4123 Electrical/Telecommunications Design Proficiency Lab2Joseph NguyenNessuna valutazione finora

- ps5 Thermal GuideDocumento6 pagineps5 Thermal GuideSundaramNessuna valutazione finora

- 2004 CSAcoust SimDocumento6 pagine2004 CSAcoust SimberndNessuna valutazione finora

- Application of Dynamic Programming To Optimization of Running Profile of A TrainDocumento10 pagineApplication of Dynamic Programming To Optimization of Running Profile of A Trainbasardeniz87Nessuna valutazione finora

- Dyn Sim ModelDocumento5 pagineDyn Sim ModelJojo KawayNessuna valutazione finora

- L4 FemDocumento10 pagineL4 FemPrem KumarNessuna valutazione finora

- Resonancia SubsincronaDocumento16 pagineResonancia SubsincronaSheyla Elizabeth Santamaria RoqueNessuna valutazione finora

- Symmetry and Bandwidth: AE and Bars 3, 4, 5, and 6Documento11 pagineSymmetry and Bandwidth: AE and Bars 3, 4, 5, and 6Hilary WatsonNessuna valutazione finora

- Lab Manual FEM 19th JanDocumento54 pagineLab Manual FEM 19th Janabhishek ranjanNessuna valutazione finora

- FEM SlidesDocumento31 pagineFEM SlidesAnya CooperNessuna valutazione finora

- Finite Element 3D Magnetic Field ComputationDocumento6 pagineFinite Element 3D Magnetic Field Computationant7dotcomNessuna valutazione finora

- Antenna Azimuth and Its Simulation by Lab View Program: School of Electrical and Electronoic EngineeringDocumento25 pagineAntenna Azimuth and Its Simulation by Lab View Program: School of Electrical and Electronoic EngineeringKenneth CastroNessuna valutazione finora

- ECE 422/522 Power System Operations & Planning/Power Systems Analysis II: 7 - Transient StabilityDocumento35 pagineECE 422/522 Power System Operations & Planning/Power Systems Analysis II: 7 - Transient StabilityMohEladibNessuna valutazione finora

- EEE 471 Transient StabilityDocumento31 pagineEEE 471 Transient StabilityFrew FrewNessuna valutazione finora

- LambertDocumento24 pagineLambertpclaudeNessuna valutazione finora

- Examples (Partial Differential Equation Toolbox)Documento5 pagineExamples (Partial Differential Equation Toolbox)أبو كعب علاء الدينNessuna valutazione finora

- A Simple Control Arithmetic of Step Wave Cascaded Multilevel Inverter With Different Voltage StepDocumento5 pagineA Simple Control Arithmetic of Step Wave Cascaded Multilevel Inverter With Different Voltage StepSumit HarwaniNessuna valutazione finora

- FYP PresentationDocumento81 pagineFYP PresentationTarek Bmr100% (1)

- Simulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab MethodsDocumento4 pagineSimulation and Analysis Calculation of PMBLDCM Based On Time-Stepping Finite Element and Matlab Methodsபொன்னியின் செல்வன்Nessuna valutazione finora

- 2 Symposium On Lift and Escalator TechnologiesDocumento12 pagine2 Symposium On Lift and Escalator TechnologiesfreddyjoertyNessuna valutazione finora

- Internal ModelDocumento15 pagineInternal ModelDiego RamirezNessuna valutazione finora

- Homework # 3Documento2 pagineHomework # 3eniNessuna valutazione finora

- Constrained Predictive Control of A Servo-Driven Tracking TurretDocumento6 pagineConstrained Predictive Control of A Servo-Driven Tracking TurretVu Duc TruongNessuna valutazione finora

- Introduction To Time Domain Electromagnetic Methods: Yanjie Zhu Yinchao Chen Paul G. Huray 12/03/2004Documento40 pagineIntroduction To Time Domain Electromagnetic Methods: Yanjie Zhu Yinchao Chen Paul G. Huray 12/03/2004Ashish VermaNessuna valutazione finora

- Feedback Control Systems: Dr. Basil Hamed Electrical Engineering Islamic University of GazaDocumento43 pagineFeedback Control Systems: Dr. Basil Hamed Electrical Engineering Islamic University of GazaSalmaanCadeXaajiNessuna valutazione finora

- Paper 5Documento9 paginePaper 5Aisha ShaikhNessuna valutazione finora

- Draft UAS DINAMIKA SISTEM 2022Documento6 pagineDraft UAS DINAMIKA SISTEM 2022skiperkresNessuna valutazione finora

- Comparison of Different FE Calculation Methods For The Electromagnetic Torque of PM MachinesDocumento8 pagineComparison of Different FE Calculation Methods For The Electromagnetic Torque of PM Machinesmlkz_01Nessuna valutazione finora

- Bound States, Open Systems and Gate Leakage Calculation in Schottky BarriersDocumento70 pagineBound States, Open Systems and Gate Leakage Calculation in Schottky BarriersRahul RoyNessuna valutazione finora

- Project Report DCSDocumento51 pagineProject Report DCSEngr XamirNessuna valutazione finora

- Magnetostatics - MATLAB & Simulink PDFDocumento5 pagineMagnetostatics - MATLAB & Simulink PDFNguyễn Thành CôngNessuna valutazione finora

- Modal FRA With NastranDocumento13 pagineModal FRA With Nastran5colourbalaNessuna valutazione finora

- Dynamics and VibrationsDocumento19 pagineDynamics and Vibrationsadhi2796Nessuna valutazione finora

- Sun 2013Documento5 pagineSun 2013Dr. Ulaganathan.M, AP /EEENessuna valutazione finora

- EP-Based Optimisation For Estimating Synchronising and Damping Torque CoefficientsDocumento7 pagineEP-Based Optimisation For Estimating Synchronising and Damping Torque CoefficientsSaddam HussainNessuna valutazione finora

- Modeling of Dynamic SystemsmesinDocumento19 pagineModeling of Dynamic SystemsmesinRifqi Bustanul FaozanNessuna valutazione finora

- Calculation and Measuring of Low-Frequency Magnetic Field of 10 (20) /0,4 KV Transformer Station PrefaceDocumento11 pagineCalculation and Measuring of Low-Frequency Magnetic Field of 10 (20) /0,4 KV Transformer Station Prefaceh_salkicNessuna valutazione finora

- Factorization of Boundary Value Problems Using the Invariant Embedding MethodDa EverandFactorization of Boundary Value Problems Using the Invariant Embedding MethodNessuna valutazione finora

- Difference Equations in Normed Spaces: Stability and OscillationsDa EverandDifference Equations in Normed Spaces: Stability and OscillationsNessuna valutazione finora

- The Not So Short Introduction To LATEXDocumento171 pagineThe Not So Short Introduction To LATEXMa BuNessuna valutazione finora

- Lctr-Notes634 BOOK TurbulenceDocumento179 pagineLctr-Notes634 BOOK TurbulenceAaron JacksonNessuna valutazione finora

- A Perspective On Life at 25Documento4 pagineA Perspective On Life at 25Harshan ArumugamNessuna valutazione finora

- Ex 6Documento4 pagineEx 6Mohamed ArifNessuna valutazione finora

- Notes On Materials Science and Engineering: Unit: IiiDocumento10 pagineNotes On Materials Science and Engineering: Unit: IiiAnandVasuNessuna valutazione finora

- Composite MaterialDocumento37 pagineComposite MaterialHarshan ArumugamNessuna valutazione finora

- I Do Like CFD Vol1 - 2ed - v00Documento299 pagineI Do Like CFD Vol1 - 2ed - v00ipixunaNessuna valutazione finora

- Aircraft Structural Analysis Notes 1Documento20 pagineAircraft Structural Analysis Notes 1Harshan ArumugamNessuna valutazione finora

- Ucf Sap Ib SC QBDocumento39 pagineUcf Sap Ib SC QBHarshan ArumugamNessuna valutazione finora

- MH 2013Documento16 pagineMH 2013sadiksnmNessuna valutazione finora

- FEA Tutorial PDFDocumento7 pagineFEA Tutorial PDFHarshan ArumugamNessuna valutazione finora

- MM Sap 1Documento10 pagineMM Sap 1Harshan ArumugamNessuna valutazione finora

- SAP MM Basic TcodesDocumento3 pagineSAP MM Basic TcodesHarshan ArumugamNessuna valutazione finora

- A Guide To Writing Scientific EssaysDocumento4 pagineA Guide To Writing Scientific EssaysGunawan Johan LimNessuna valutazione finora

- Profession & ProfessionalismDocumento15 pagineProfession & ProfessionalismHarshan ArumugamNessuna valutazione finora

- Introduction To Finite Element ModelingDocumento5 pagineIntroduction To Finite Element Modelingmastura_rahim_3Nessuna valutazione finora

- Kinematic Synthesis of MechanismsDocumento25 pagineKinematic Synthesis of MechanismsHarshan Arumugam75% (4)

- Engineering As Social ExperimentationDocumento18 pagineEngineering As Social ExperimentationHarshan ArumugamNessuna valutazione finora

- MH 2010Documento10 pagineMH 2010Ashish MahapatraNessuna valutazione finora

- MH 2010Documento10 pagineMH 2010Ashish MahapatraNessuna valutazione finora

- Seq Sub Speciality IsbnDocumento76 pagineSeq Sub Speciality IsbnalfredomedardoNessuna valutazione finora

- SNAKE 2catalogo Completo BassaDocumento146 pagineSNAKE 2catalogo Completo BassaCarlos FreundNessuna valutazione finora

- Previous Year Question Bank ExademyDocumento21 paginePrevious Year Question Bank ExademyAyush RanjanNessuna valutazione finora

- Mathematics 2009Documento20 pagineMathematics 2009jitendra jhaNessuna valutazione finora

- Algebraic Equations PDFDocumento56 pagineAlgebraic Equations PDFAnonymous LLsXddLvtmNessuna valutazione finora

- Anna University 1st Year 2017 Regulation Engineering Notes For All Department, 1st, 2nd Semester - BrainkartDocumento143 pagineAnna University 1st Year 2017 Regulation Engineering Notes For All Department, 1st, 2nd Semester - BrainkartM.V. TVNessuna valutazione finora

- TT XXDocumento5 pagineTT XXAsees SachdevNessuna valutazione finora

- 209 - 2017 Regulation SyllabusDocumento107 pagine209 - 2017 Regulation SyllabussivakumarNessuna valutazione finora

- DiffyqsDocumento466 pagineDiffyqsSahil MalikNessuna valutazione finora

- Unit - Iii-2Documento28 pagineUnit - Iii-2SUJIN JOHNSONNessuna valutazione finora

- 95 Undergrad GD 2014-2015Documento69 pagine95 Undergrad GD 2014-2015alfeusmartiusNessuna valutazione finora

- Scheme of Studies For BS MathematicsDocumento17 pagineScheme of Studies For BS MathematicsanamNessuna valutazione finora

- (Lecture Notes in Control and Information Sciences 423) Vladimir L. Kharitonov (Auth.), Rifat Sipahi, Tomáš Vyhlídal, Silviu-Iulian Niculescu, Pierdomenico Pepe (Eds.)-Time Delay Systems_ Methods, AppDocumento444 pagine(Lecture Notes in Control and Information Sciences 423) Vladimir L. Kharitonov (Auth.), Rifat Sipahi, Tomáš Vyhlídal, Silviu-Iulian Niculescu, Pierdomenico Pepe (Eds.)-Time Delay Systems_ Methods, Appfsilassie8012Nessuna valutazione finora

- Mth102 Differential EquationDocumento3 pagineMth102 Differential EquationPraveen Kumar SinghNessuna valutazione finora

- Dupiere Discrete ModelDocumento14 pagineDupiere Discrete Modelabhiu1991Nessuna valutazione finora

- 00 Introducción e Historia CFDDocumento8 pagine00 Introducción e Historia CFDInés PetrinaNessuna valutazione finora

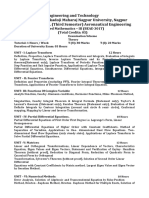

- Engineering and Technology Rashtrasant Tukadoji Maharaj Nagpur University, Nagpur Syllabus For B.E. (Third Semester) Aeronautical EngineeringDocumento85 pagineEngineering and Technology Rashtrasant Tukadoji Maharaj Nagpur University, Nagpur Syllabus For B.E. (Third Semester) Aeronautical Engineeringprabhat ranjan mishraNessuna valutazione finora

- Special FunctionsDocumento35 pagineSpecial FunctionsdimitriNessuna valutazione finora

- Ggsipu CatalogueDocumento76 pagineGgsipu CatalogueMohammed AbbasNessuna valutazione finora

- Hydrogen Atom: Numerical MethodsDocumento11 pagineHydrogen Atom: Numerical MethodsBryan HarterNessuna valutazione finora

- Exam Timetable Report Room Wise Session WiseDocumento228 pagineExam Timetable Report Room Wise Session WiseANANT KUMARNessuna valutazione finora

- Soln 01Documento6 pagineSoln 01Anshu Kumar GuptaNessuna valutazione finora

- Lecture Notes On Problem Discretization Using Approximation TheoryDocumento73 pagineLecture Notes On Problem Discretization Using Approximation TheorychandrahasNessuna valutazione finora