Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Polymer Memory

Caricato da

Ram VBITDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Polymer Memory

Caricato da

Ram VBITCopyright:

Formati disponibili

SUBMITTED BY www.tricksworld.net.

tc

Polymer memory, the memory device made of plastic. Plastic is not only an insulator, but it also a conductor, Heeger et al proved it. Polymer memory is a digital memory with advance technology. Imagine a time where mobiles need a memory of GBs and PCs with TBs. It is not possible with silicon based memory in less space, but it is possible with polymer memory.

The current memory technologies have a lot of limitations. DRAM is volatile and difficult to integrate, RAM is high cost and volatile. Flash has lesser number of write/erase cycles compared to others. Expansion is possible only in two dimensional space. Hence industry is searching for Holy Grail future memory technologies. Next generation memories are trying a tradeoffs between size and cost .

Large number of memory technologies were emerged. They include MRAM, FeRAM, Polymer Memory and Ovonics Unified Memory. The most important one among them is polymer. Polymer memory is the leading technology among them. It is mainly because of their expansion capability in three dimensional spaces.

Comparison:

C o s t >

Semi cond uctor s

Polymer memory

Disc drives

Read/write time(faster>)

The fundamental idea of all these technologies is the bistable nature which is due to their internal dipole moment. Eg: FeRAM works on the basis of the bistable nature of the centre atom of selected crystalline material. Why Polymer memory is called PFRAM? In Polymer memory the crystalline substance used is polymers. Polymers just as ferroelectric crystals set up local dipoles within them when electric field is applied.

Polymers are organic materials consisting of long chains of single molecules. Electrons were removed, or introduced, ithen the structure becomes electrically conductive. Thin Film Electronics has developed a specific group of polymers that are bistable and non-volatile memory. . This polymer is "smart", to the extent that functionality is built into the material itself, like switchability, and charge store. This opens up tremendous opportunities in the electronics world, where tailor-made memory materials represent unknown territory.

Coatues chip an electric field draws ions up through the polymer increasing the conductivity. Difference in conductivity represents bits of data. Coatue fabricates each memory cell as a polymer sandwiched between two electrodes.

Coatue's multi-state polymer memory cells can be switched between on and off states, representing 1's and 0's.

The basic principle of Polymer based memory is the dipole moment. The intensity of dipole moment depend applied electric field intensity. Memory cells are defined by the physical overlap of the electrode crossings and selected by applying voltage. The polymer memory layers are just 1/10,000 of a millimeter or less in thickness.

Expanding memory capability is simply a matter of coating a new layer on top of an existing one. This means that the new technology is not just for saving space, but also the option of using software architectures. The driver circuitry, comprising column and row decoders, sense amplifiers, is located entirely outside. Examples: The equivalent of 400,000 CDs, or 60,000 DVDs, may be stored on a polymer memory chip the size of a credit card.

The holographic technique packs data so tightly that one 12-centimeter disk could eventually hold a terabyte. What's more, holographic storage opens the possibility of reading and writing data a million bits at a time.

That means we could duplicate an entire DVD movie in mere seconds.

Polymer memory layers can be stacked , This enable to achieve very high storage capacity. Memory is Nonvolatile. Fast read and write speeds. Very low cost/bit, high capacity per dollar. Low power consumption. Easy manufacture ,use ink-jet printers to spray liquidpolymer circuits onto a surface. Thin Film system requires about 0.5 million transistors per gigabit, Traditional silicon-based system would require between 1.5 to 6.5 billion transistors.

But turning polymer memory into a commercial product wont be easy. Memory technologies compete not only on storage capacity but on speed, energy consumption and reliability Cost per MB will here become so low that true disposable memory chips can be envisaged. One report says that this technology could take flash card prices to 10 per cent of what they are today.

Future

The fundamental strength, i.e. The stacking of memory layers which yields maximum storage capacity is the main reason why Polymer memory is highly preferred. The non volatileness and other features are in built in molecular level and offers very high advantages in terms of cost. Polymers ,which are once considered to be the main reason for pollution has found a new area of utilization.

Many miles to go..

Potrebbero piacerti anche

- Polymer Memory PPT 451Documento19 paginePolymer Memory PPT 451Sri SiluNessuna valutazione finora

- Polymer MemoryDocumento26 paginePolymer MemoryVidyasagar KatariNessuna valutazione finora

- Polymer MemoryDocumento22 paginePolymer Memoryakkamahadevi_m_b67% (3)

- Polychloroprene ProductionDocumento1 paginaPolychloroprene ProductionBramJanssen76Nessuna valutazione finora

- Sheet Lamination Additive ManufacturingDocumento2 pagineSheet Lamination Additive ManufacturingYeabsraNessuna valutazione finora

- Nano Composites PDFDocumento17 pagineNano Composites PDFmkrajasekarNessuna valutazione finora

- Shimadzu AutoTestingDocumento8 pagineShimadzu AutoTestingewfsdNessuna valutazione finora

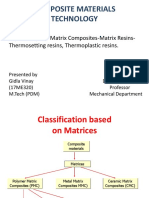

- Polymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic ResinsDocumento27 paginePolymer Matrix Composites - Matrix Resins - Thermosetting Resins, Thermoplastic Resinsgidlavinay100% (1)

- Mit PDFDocumento80 pagineMit PDFHIRA SHABBIRNessuna valutazione finora

- Shape Memory PolymersDocumento2 pagineShape Memory PolymersSaurav Kumar0% (1)

- Composites GrooverDocumento32 pagineComposites GrooverhilaldemirNessuna valutazione finora

- Problems in Compos Mater Questions PG PDFDocumento15 pagineProblems in Compos Mater Questions PG PDFJimmyFigueroaANessuna valutazione finora

- Fortegra 100Documento3 pagineFortegra 100Gunjan GadodiaNessuna valutazione finora

- Investigation On Tensile and Flexural Strength of KOH Treated Ridge Gourd Fiber-Polyester Resin CompositeDocumento4 pagineInvestigation On Tensile and Flexural Strength of KOH Treated Ridge Gourd Fiber-Polyester Resin CompositeEditor IJRITCCNessuna valutazione finora

- Polypropylene Matrix Composites Reinforced With Coconut FibersDocumento6 paginePolypropylene Matrix Composites Reinforced With Coconut FibersIsmove MvNessuna valutazione finora

- Carbon Fibre PDFDocumento13 pagineCarbon Fibre PDFmarianaNessuna valutazione finora

- Composite Report For Ajith PrabhakaranDocumento44 pagineComposite Report For Ajith PrabhakaranSanthosh Nagaraja100% (1)

- Organic Light-Emitting DiodesDocumento17 pagineOrganic Light-Emitting DiodesSuresh KumarNessuna valutazione finora

- Finite Element Modeling and Simulation For BendingDocumento5 pagineFinite Element Modeling and Simulation For BendingAnand RasNessuna valutazione finora

- Handbook of Polymeric Foams and Foam Technology: HanserDocumento10 pagineHandbook of Polymeric Foams and Foam Technology: Hanserfreidor0% (2)

- Smart StructuresDocumento19 pagineSmart Structuresxyz333447343Nessuna valutazione finora

- IV I Mech Mems (Open Elective-R13)Documento2 pagineIV I Mech Mems (Open Elective-R13)Aboobakker SidhiqueNessuna valutazione finora

- Handbook Adhesive TechnologyDocumento29 pagineHandbook Adhesive TechnologyVansala GanesanNessuna valutazione finora

- Polymer Electronics - Fancy or The Future of Electronics: Karlheinz Bock, Rolf Aschenbrenner, Jan FelbaDocumento6 paginePolymer Electronics - Fancy or The Future of Electronics: Karlheinz Bock, Rolf Aschenbrenner, Jan FelbaAnandhu C100% (1)

- Eliminating Constraints in Plastic Injection MoldingDocumento8 pagineEliminating Constraints in Plastic Injection MoldingpatrickNX9420Nessuna valutazione finora

- Binders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsDocumento13 pagineBinders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsPranav KumarNessuna valutazione finora

- Selection of Polymers With Functional Groups For Daytime Radiative CoolingDocumento5 pagineSelection of Polymers With Functional Groups For Daytime Radiative CoolingEdgar Emmanuel Ochoa ValdezNessuna valutazione finora

- Unit 1 PDFDocumento109 pagineUnit 1 PDFrajath bhatNessuna valutazione finora

- Industrial SelectorGuide PDFDocumento9 pagineIndustrial SelectorGuide PDFMaxime DelburyNessuna valutazione finora

- Ybco Superconductor Characterization Under Shear StrainDocumento4 pagineYbco Superconductor Characterization Under Shear StrainRiddhesh PatelNessuna valutazione finora

- Touch Screen Tech Seminar OverviewDocumento39 pagineTouch Screen Tech Seminar Overviewmd rizwanNessuna valutazione finora

- SEMINAR On Laminated CompositesDocumento15 pagineSEMINAR On Laminated CompositesPraveengouda PatilNessuna valutazione finora

- How Rheological Properties Affect Fine-Line Screen Printing - of Pastes - A Combined Rheological and High-Speed Video Imaging - StudyDocumento12 pagineHow Rheological Properties Affect Fine-Line Screen Printing - of Pastes - A Combined Rheological and High-Speed Video Imaging - StudyAmar KasbeNessuna valutazione finora

- Recent Development in 2D Materials Beyond GrapheneDocumento83 pagineRecent Development in 2D Materials Beyond GrapheneYunzhe DuNessuna valutazione finora

- POY Spinning of Polyester - New Technologies To Improve ProductivityDocumento8 paginePOY Spinning of Polyester - New Technologies To Improve ProductivitySteve Jenkins100% (1)

- Plasticizers 1.1. Historical OverviewDocumento6 paginePlasticizers 1.1. Historical Overviewmuhammad umairNessuna valutazione finora

- Composite Materials Literature Review For Car Bumber: August 2016Documento12 pagineComposite Materials Literature Review For Car Bumber: August 2016meita alviraNessuna valutazione finora

- SEMINAR On NanocompositesDocumento30 pagineSEMINAR On NanocompositesRama GaurNessuna valutazione finora

- A Critical Review On The Fabrication Processes and Applications of Microwave Dielectric Ceramics Ba6-3Xnd8+2Xti18O54Documento24 pagineA Critical Review On The Fabrication Processes and Applications of Microwave Dielectric Ceramics Ba6-3Xnd8+2Xti18O54TJPRC Publications100% (1)

- Pojet PPT 1Documento39 paginePojet PPT 1Tushar JainNessuna valutazione finora

- Triton-Ocean Bottom Seismometer-001Documento2 pagineTriton-Ocean Bottom Seismometer-001Furio RuggieroNessuna valutazione finora

- Biaxial Testing MachineDocumento1 paginaBiaxial Testing MachineAshok MacheNessuna valutazione finora

- An Overview of Computer Graphics Industry Standards.Documento12 pagineAn Overview of Computer Graphics Industry Standards.Pallavi PatilNessuna valutazione finora

- Nano Electro Mechanical System NemsDocumento26 pagineNano Electro Mechanical System NemsAnaMilerNessuna valutazione finora

- Dolfyn CFDDocumento3 pagineDolfyn CFDFortes100% (1)

- Mechanical and Water Absorption Behavior of Sisal and Banana Fiber CompositesDocumento49 pagineMechanical and Water Absorption Behavior of Sisal and Banana Fiber CompositesKutty AravindNessuna valutazione finora

- 2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingDocumento9 pagine2011 - Sage - Natural Fiber-Based Reinforcements in Epoxy Composites Processed by Filament WindingECE IV YearNessuna valutazione finora

- Synthesis and Applications of Electrospun NanofibersDa EverandSynthesis and Applications of Electrospun NanofibersNessuna valutazione finora

- Durosan 03 Matt Exterior (Azad Jotun)Documento3 pagineDurosan 03 Matt Exterior (Azad Jotun)AzadAhmadNessuna valutazione finora

- 5 ThinFilmSolarDocumento18 pagine5 ThinFilmSolarnomyisNessuna valutazione finora

- PSN College Aeronautical Engineering CurriculumDocumento78 paginePSN College Aeronautical Engineering CurriculumNambi RajanNessuna valutazione finora

- Composite ReportDocumento78 pagineComposite ReportSanthosh NagarajaNessuna valutazione finora

- 3 DYNAmore InfoComposites DIGIMAT LieboldDocumento54 pagine3 DYNAmore InfoComposites DIGIMAT LieboldOat GT100% (1)

- Journal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TDocumento15 pagineJournal of The European Ceramic Society: Vincenzo Buscaglia, Clive A. Randall TAryan Singh LatherNessuna valutazione finora

- A Study On The Effect of Hardener On The Mechanical Properties of Epoxy ResinDocumento150 pagineA Study On The Effect of Hardener On The Mechanical Properties of Epoxy ResinarunmythreyeeNessuna valutazione finora

- The Effect of Fiber Volume Fraction On Filament Wound - 2001 - Composites Part B PDFDocumento17 pagineThe Effect of Fiber Volume Fraction On Filament Wound - 2001 - Composites Part B PDFAhmed HassanNessuna valutazione finora

- Composite Materialslab Text BookDocumento49 pagineComposite Materialslab Text BookSHAHBAZ PNessuna valutazione finora

- Preparation and Studies of Nitrile Rubber Nanocomposites With MMT NanoparticlesDocumento13 paginePreparation and Studies of Nitrile Rubber Nanocomposites With MMT NanoparticlesAnish KumarNessuna valutazione finora

- Polymer MemoryDocumento15 paginePolymer Memorymanimaran014234100% (1)

- Le401 Surface ComputingDocumento36 pagineLe401 Surface ComputingRam VBITNessuna valutazione finora

- 450 Night Vision TechnologyDocumento19 pagine450 Night Vision TechnologyRam VBITNessuna valutazione finora

- Le402 Cellphone JammersDocumento19 pagineLe402 Cellphone JammersRam VBIT100% (2)

- Le402 Cellphone JammersDocumento40 pagineLe402 Cellphone JammersRam VBITNessuna valutazione finora

- 450 Night Vision TechnologyDocumento29 pagine450 Night Vision TechnologyRam VBITNessuna valutazione finora

- 456 Bio SensorsDocumento31 pagine456 Bio SensorsRam VBITNessuna valutazione finora

- 460 RoboticsDocumento26 pagine460 RoboticsRam VBITNessuna valutazione finora

- Le401 Surface ComputingDocumento29 pagineLe401 Surface ComputingRam VBITNessuna valutazione finora

- 460 RoboticsDocumento21 pagine460 RoboticsRam VBITNessuna valutazione finora

- 454 4g Wireless SystemDocumento14 pagine454 4g Wireless SystemRam VBITNessuna valutazione finora

- 458 Military RobotsDocumento29 pagine458 Military RobotsRam VBITNessuna valutazione finora

- 446 Wi-Max TechnologyDocumento15 pagine446 Wi-Max TechnologyRam VBITNessuna valutazione finora

- 458 Military RobotsDocumento29 pagine458 Military RobotsRam VBITNessuna valutazione finora

- 456 Bio SensorsDocumento14 pagine456 Bio SensorsRam VBITNessuna valutazione finora

- 453 Light Emitting PolymersDocumento14 pagine453 Light Emitting PolymersRam VBITNessuna valutazione finora

- 453 Light Emitting PolymersDocumento23 pagine453 Light Emitting PolymersRam VBITNessuna valutazione finora

- 444 Sixth Sense TechnologyDocumento25 pagine444 Sixth Sense TechnologyRam VBITNessuna valutazione finora

- 452 Internet Protocol TelivisionDocumento22 pagine452 Internet Protocol TelivisionRam VBITNessuna valutazione finora

- 443 Remote Access ServiceDocumento22 pagine443 Remote Access ServiceRam VBITNessuna valutazione finora

- 444 Sixth Sense TechnologyDocumento17 pagine444 Sixth Sense TechnologyRam VBITNessuna valutazione finora

- 445 Face Recognition TechnologyDocumento19 pagine445 Face Recognition TechnologyRam VBITNessuna valutazione finora

- 446 Wi-Max TechnologyDocumento29 pagine446 Wi-Max TechnologyRam VBITNessuna valutazione finora

- 445 Face Recognition TechnologyDocumento27 pagine445 Face Recognition TechnologyRam VBITNessuna valutazione finora

- 442 Intel IntiumDocumento24 pagine442 Intel IntiumRam VBITNessuna valutazione finora

- 441 Parking Gate Usin Infra RedDocumento13 pagine441 Parking Gate Usin Infra RedRam VBITNessuna valutazione finora

- 442 Intel IntiumDocumento28 pagine442 Intel IntiumRam VBITNessuna valutazione finora

- 441 Parking Gate Usin Infra RedDocumento18 pagine441 Parking Gate Usin Infra RedRam VBITNessuna valutazione finora

- 439 Security Features of ATMDocumento21 pagine439 Security Features of ATMRam VBIT100% (2)

- 439 Security Features of ATMDocumento20 pagine439 Security Features of ATMRam VBIT100% (11)

- Vidya Bharathi Institute of Technology: Smart AntennaDocumento15 pagineVidya Bharathi Institute of Technology: Smart AntennaRam VBITNessuna valutazione finora

- Ac Ac ConverterDocumento56 pagineAc Ac ConverterPutri Hanifah SNessuna valutazione finora

- Questions PV Design 2023Documento8 pagineQuestions PV Design 2023Mutaz M BanatNessuna valutazione finora

- GTG Control Description E1A2026115Documento36 pagineGTG Control Description E1A2026115Sudhir Joshi100% (2)

- Microcontroller Based Home Automation SystemDocumento4 pagineMicrocontroller Based Home Automation Systemagr512Nessuna valutazione finora

- IGCSE Physics Revison Question BankDocumento43 pagineIGCSE Physics Revison Question BankSyed Waqas Ahmed100% (4)

- Tutorial 04 (07022019)Documento9 pagineTutorial 04 (07022019)Devansh GuptaNessuna valutazione finora

- 1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECDocumento61 pagine1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECRobert RocafuerteNessuna valutazione finora

- PH 531: Electromagnetic Theory IDocumento1 paginaPH 531: Electromagnetic Theory ISaif IshtiaqueNessuna valutazione finora

- Lesson 3 Electric FieldsDocumento7 pagineLesson 3 Electric FieldsRachel LaserNessuna valutazione finora

- Screenshot 2024-01-25 at 11.47.33 AMDocumento46 pagineScreenshot 2024-01-25 at 11.47.33 AM8b6m8fvnrvNessuna valutazione finora

- Ic F3022SDocumento36 pagineIc F3022SEfren.galNessuna valutazione finora

- Resume Prof. S.K.JoshiDocumento15 pagineResume Prof. S.K.JoshiPriyank PatelNessuna valutazione finora

- Cacat Yang Umum Terdapat Pada PipaDocumento10 pagineCacat Yang Umum Terdapat Pada PipaAntrasit CoffeeNessuna valutazione finora

- E-Z Command InstructionsDocumento8 pagineE-Z Command InstructionsSebas CheeNessuna valutazione finora

- TWM 220 N Yoke - Operating Manual - Apr18Documento7 pagineTWM 220 N Yoke - Operating Manual - Apr18Michael LloydNessuna valutazione finora

- PSOC Question BankDocumento17 paginePSOC Question Bankiamketul6340Nessuna valutazione finora

- Technical Data Sheet ML90FB 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocumento4 pagineTechnical Data Sheet ML90FB 220-240V 50Hz 1 R404A: Compressor Model Voltage Refrigerantoscar rene rodriguez rojasNessuna valutazione finora

- Fabrication Techniques of A PN Junction DiodeDocumento5 pagineFabrication Techniques of A PN Junction DiodeNida Amber100% (3)

- LABLABDocumento14 pagineLABLABRuellynne Barberan BonifacioNessuna valutazione finora

- Two Resistor Model For Thermal Simulation-EDocumento5 pagineTwo Resistor Model For Thermal Simulation-EILikeScribd5050Nessuna valutazione finora

- 89543-REV - NEW: Current To Pressure ConvertorDocumento44 pagine89543-REV - NEW: Current To Pressure ConvertorErick FalconiNessuna valutazione finora

- Datasheet Reg-Da en 2016Documento28 pagineDatasheet Reg-Da en 2016Weber HahnNessuna valutazione finora

- Capacitive Type Surface-Micromachined Silicon Accelerometer With Stiffness Tuning CapabilityDocumento8 pagineCapacitive Type Surface-Micromachined Silicon Accelerometer With Stiffness Tuning CapabilityminhibtNessuna valutazione finora

- 2 - EE - Intro - Electronics Pg. 28-41 Op Amp-Merged PDFDocumento402 pagine2 - EE - Intro - Electronics Pg. 28-41 Op Amp-Merged PDFAdelin IonutNessuna valutazione finora

- Manual Usuario EspañolDocumento144 pagineManual Usuario EspañolNarda TiconaNessuna valutazione finora

- Lesson PlanDocumento5 pagineLesson PlanLM AlboNessuna valutazione finora

- SIS-Preventive Maintenance For BatteriesDocumento2 pagineSIS-Preventive Maintenance For BatteriesmkNessuna valutazione finora

- Magnetic Components Design and ApplicationsDocumento354 pagineMagnetic Components Design and Applicationseugene50% (2)

- 10 Dollar Phone Patch PDFDocumento2 pagine10 Dollar Phone Patch PDFblesk2hotNessuna valutazione finora

- Odi-065r15mjjjj02-Q-Ru V1 DS 1-Ru-0Documento4 pagineOdi-065r15mjjjj02-Q-Ru V1 DS 1-Ru-0Иван КадигробNessuna valutazione finora