Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 05 Avi

Caricato da

anton_deocampoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 05 Avi

Caricato da

anton_deocampoCopyright:

Formati disponibili

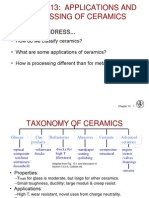

Chapter 5-

ISSUES TO ADDRESS...

How does diffusion occur?

Why is it an important part of processing?

How can the rate of diffusion be predicted for

some simple cases?

1

How does diffusion depend on structure

and temperature?

CHAPTER 5:

DIFFUSION IN SOLIDS

Chapter 5- 2

Glass tube filled with water.

At time t = 0, add some drops of ink to one end

of the tube.

Measure the diffusion distance, x, over some time.

Compare the results with theory.

DIFFUSION DEMO

Chapter 5- 3

Interdiffusion: In an alloy, atoms tend to migrate

from regions of large concentration.

Initially After some time

100%

Concentration Profiles

0

Adapted from

Figs. 5.1 and

5.2, Callister

6e.

DIFFUSION: THE PHENOMENA (1)

Chapter 5- 4

Self-diffusion: In an elemental solid, atoms

also migrate.

Label some atoms After some time

A

B

C

D

DIFFUSION: THE PHENOMENA (2)

Chapter 5- 5

Substitutional Diffusion:

applies to substitutional impurities

atoms exchange with vacancies

rate depends on:

--number of vacancies

--activation energy to exchange.

DIFFUSION MECHANISMS

Chapter 5- 6

Simulation of

interdiffusion

across an interface:

Rate of substitutional

diffusion depends on:

--vacancy concentration

--frequency of jumping.

(Courtesy P.M. Anderson)

DIFFUSION SIMULATION

Chapter 5- 7

(Courtesy P.M. Anderson)

Applies to interstitial

impurities.

More rapid than

vacancy diffusion.

Simulation:

--shows the jumping of a

smaller atom (gray) from

one interstitial site to

another in a BCC

structure. The

interstitial sites

considered here are

at midpoints along the

unit cell edges.

INTERSTITIAL SIMULATION

Chapter 5-

Case Hardening:

--Diffuse carbon atoms

into the host iron atoms

at the surface.

--Example of interstitial

diffusion is a case

hardened gear.

Result: The "Case" is

--hard to deform: C atoms

"lock" planes from shearing.

--hard to crack: C atoms put

the surface in compression.

8

Fig. 5.0,

Callister 6e.

(Fig. 5.0 is

courtesy of

Surface

Division,

Midland-

Ross.)

PROCESSING USING DIFFUSION (1)

Chapter 5-

Doping Silicon with P for n-type semiconductors:

Process:

9

1. Deposit P rich

layers on surface.

2. Heat it.

3. Result: Doped

semiconductor

regions.

silicon

silicon

Fig. 18.0,

Callister 6e.

PROCESSING USING DIFFUSION (2)

Chapter 5-

Flux:

10

Directional Quantity

Flux can be measured for:

--vacancies

--host (A) atoms

--impurity (B) atoms

MODELING DIFFUSION: FLUX

Chapter 5-

Concentration Profile, C(x): [kg/m

3

]

11

Fick's First Law:

Concentration

of Cu [kg/m

3

]

Concentration

of Ni [kg/m

3

]

Position, x

Cu flux Ni flux

The steeper the concentration profile,

the greater the flux!

Adapted from

Fig. 5.2(c),

Callister 6e.

CONCENTRATION PROFILES & FLUX

Chapter 5-

Steady State: the concentration profile doesn't

change with time.

12

Apply Fick's First Law:

Result: the slope, dC/dx, must be constant

(i.e., slope doesn't vary with position)!

J

x

= D

dC

dx

dC

dx

|

\

|

.

|

left

=

dC

dx

|

\

|

.

|

right

If J

x

)

left

= J

x

)

right

, then

STEADY STATE DIFFUSION

Chapter 5-

Steel plate at

700C with

geometry

shown:

13

Q: How much

carbon transfers

from the rich to

the deficient side?

Adapted from

Fig. 5.4,

Callister 6e.

EX: STEADY STATE DIFFUSION

Chapter 5-

Concentration profile,

C(x), changes

w/ time.

14

To conserve matter: Fick's First Law:

Governing Eqn.:

NON STEADY STATE DIFFUSION

Chapter 5-

Copper diffuses into a bar of aluminum.

15

General solution:

"error function"

Values calibrated in Table 5.1, Callister 6e.

C

o

C

s

position, x

C(x,t)

t

o

t

1

t

2

t

3

Adapted from

Fig. 5.5,

Callister 6e.

EX: NON STEADY STATE DIFFUSION

Chapter 5-

Copper diffuses into a bar of aluminum.

10 hours at 600C gives desired C(x).

How many hours would it take to get the same C(x)

if we processed at 500C?

16

Result: Dt should be held constant.

Answer:

Note: values

of D are

provided here.

Key point 1: C(x,t

500C

) = C(x,t

600C

).

Key point 2: Both cases have the same C

o

and C

s

.

PROCESSING QUESTION

Chapter 5- 17

The experiment: we recorded combinations of

t and x that kept C constant.

Diffusion depth given by:

C(x

i

, t

i

) C

o

C

s

C

o

= 1 erf

x

i

2 Dt

i

|

\

|

.

|

|

= (constant here)

DIFFUSION DEMO: ANALYSIS

Chapter 5-

Experimental result: x ~ t

0.58

Theory predicts x ~ t

0.50

Reasonable agreement!

18

DATA FROM DIFFUSION DEMO

Chapter 5-

Diffusivity increases with T.

Experimental Data:

D has exp. dependence on T

Recall: Vacancy does also!

19

D

interstitial

>> D

substitutional

C in o-Fe

C in -Fe

Al in Al

Cu in Cu

Zn in Cu

Fe in o-Fe

Fe in -Fe

Adapted from Fig. 5.7, Callister 6e. (Date for Fig. 5.7 taken from E.A.

Brandes and G.B. Brook (Ed.) Smithells Metals Reference Book, 7th

ed., Butterworth-Heinemann, Oxford, 1992.)

DIFFUSION AND TEMPERATURE

Chapter 5- 20

Diffusion FASTER for...

open crystal structures

lower melting T materials

materials w/secondary

bonding

smaller diffusing atoms

cations

lower density materials

Diffusion SLOWER for...

close-packed structures

higher melting T materials

materials w/covalent

bonding

larger diffusing atoms

anions

higher density materials

SUMMARY:

STRUCTURE & DIFFUSION

Chapter 5-

Reading:

Core Problems:

Self-help Problems:

0

ANNOUNCEMENTS

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Chemistry - The Molecular Nature of Matter and ChangeDocumento25 pagineChemistry - The Molecular Nature of Matter and ChangeJennifer SiuNessuna valutazione finora

- Mass Transfer PartDocumento29 pagineMass Transfer Partoctoviancletus100% (5)

- College of Engineering, Architecture, Fine Arts & Computing SciencesDocumento2 pagineCollege of Engineering, Architecture, Fine Arts & Computing Sciencesanton_deocampoNessuna valutazione finora

- Introduction To Data CommunicationDocumento21 pagineIntroduction To Data Communicationanton_deocampoNessuna valutazione finora

- Chapter 02 AviDocumento19 pagineChapter 02 Avianton_deocampoNessuna valutazione finora

- Chapter 22: Materials Selection: Economic, Environ., & Design IssuesDocumento17 pagineChapter 22: Materials Selection: Economic, Environ., & Design Issuesanton_deocampoNessuna valutazione finora

- Chapter 21 AviDocumento13 pagineChapter 21 Avianton_deocampoNessuna valutazione finora

- Chapter 18 AviDocumento16 pagineChapter 18 Avianton_deocampoNessuna valutazione finora

- Chapter 20 AviDocumento11 pagineChapter 20 Avianton_deocampoNessuna valutazione finora

- Chapter 13 AviDocumento18 pagineChapter 13 Avianton_deocampoNessuna valutazione finora

- Chapter 16 AviDocumento12 pagineChapter 16 Avianton_deocampoNessuna valutazione finora

- UntitledDocumento11 pagineUntitledhihiNessuna valutazione finora

- DiagnosticsDocumento8 pagineDiagnosticsNORBERTUS KRISNU PRABOWONessuna valutazione finora

- PV Physical Pharmaceutics 4th SemDocumento82 paginePV Physical Pharmaceutics 4th SemSejal ShirgaveNessuna valutazione finora

- Solids Liquids and Gases TMIDDocumento37 pagineSolids Liquids and Gases TMIDBen PassmoreNessuna valutazione finora

- Particles of MatterDocumento7 pagineParticles of MatterFatema KhatunNessuna valutazione finora

- Analysis of Diffusion in Macroporous Media in Terms of A Porosity, A Tortuosity and A Constrictivity FactorDocumento11 pagineAnalysis of Diffusion in Macroporous Media in Terms of A Porosity, A Tortuosity and A Constrictivity FactorsamityNessuna valutazione finora

- Solution Smuth Cap 5Documento32 pagineSolution Smuth Cap 5Joyce Caroline Lima Nunes100% (1)

- Chemkin TheoryDocumento273 pagineChemkin TheoryAhmad Syihan AuzaniNessuna valutazione finora

- The Drying of Granular FertilizersDocumento16 pagineThe Drying of Granular FertilizersnataliamonteiroNessuna valutazione finora

- Diffusion of Solids in LiquidsDocumento8 pagineDiffusion of Solids in LiquidselonNessuna valutazione finora

- BookOfAbstracts 15thWORKSHOP PDFDocumento392 pagineBookOfAbstracts 15thWORKSHOP PDFkillermonkeyNessuna valutazione finora

- Unit Number 1: GAS ABSORPTIONDocumento22 pagineUnit Number 1: GAS ABSORPTIONISAAC STANLYNessuna valutazione finora

- Astm C 1556-03Documento7 pagineAstm C 1556-03Kaleeswari GNessuna valutazione finora

- 2.2.solidification, Imperfection (Defect) in Solids, and DiffusionDocumento22 pagine2.2.solidification, Imperfection (Defect) in Solids, and Diffusionjun005Nessuna valutazione finora

- Chemical EngineeringDocumento44 pagineChemical EngineeringAjitsingh JagtapNessuna valutazione finora

- J. Electrochem. Soc.-2017-Monroe-E3547-51Documento5 pagineJ. Electrochem. Soc.-2017-Monroe-E3547-51Geovanny JaenzNessuna valutazione finora

- Dimensionless Analysis of Swelling of Hydrophilic Glassy Polymers With Subsequent Drug Release From Relaxing StructuresDocumento12 pagineDimensionless Analysis of Swelling of Hydrophilic Glassy Polymers With Subsequent Drug Release From Relaxing StructuresfarzadsadeghzadNessuna valutazione finora

- Int. J. Miner. Process.: Vida Safari, Gilnaz Arzpeyma, Fereshteh Rashchi, Navid Mostou FiDocumento5 pagineInt. J. Miner. Process.: Vida Safari, Gilnaz Arzpeyma, Fereshteh Rashchi, Navid Mostou FiDanielle BarkerNessuna valutazione finora

- Floating Matrix Tablets Based On Low Density Form Powder Effects of Formulation and Processing Parameters On Drug ReleaseDocumento9 pagineFloating Matrix Tablets Based On Low Density Form Powder Effects of Formulation and Processing Parameters On Drug ReleaseCesar Rodolfo Angulo DelgadoNessuna valutazione finora

- Kinetics Thermodynamics and Process Parameter Impact On Solvent Extraction of Oil From Colocynthis Vulgaris Shrad Melon SeedsDocumento22 pagineKinetics Thermodynamics and Process Parameter Impact On Solvent Extraction of Oil From Colocynthis Vulgaris Shrad Melon SeedsCharles OrakwueNessuna valutazione finora

- Extraction Liquid - SolidDocumento13 pagineExtraction Liquid - SolidHalkawt G MuhammadNessuna valutazione finora

- Gases: Behavior & PropertiesDocumento35 pagineGases: Behavior & PropertiesAdelia SetianingsihNessuna valutazione finora

- 6 Limitations of The Axis Translation TechniqueDocumento10 pagine6 Limitations of The Axis Translation TechniqueJaime Musso HottNessuna valutazione finora

- Catalytic Converter CFD Using COMSOLDocumento10 pagineCatalytic Converter CFD Using COMSOLKulaNessuna valutazione finora

- Intrinsic Kinetics of MTBE Synthesis From Methanol and Isobutene Using A Synthesised MFI Type ZeoliteDocumento7 pagineIntrinsic Kinetics of MTBE Synthesis From Methanol and Isobutene Using A Synthesised MFI Type ZeolitetungksnbNessuna valutazione finora

- Electrode Kinetics For Chemists Chemical Engineers and Materials Scientists PDFDocumento313 pagineElectrode Kinetics For Chemists Chemical Engineers and Materials Scientists PDFrosendo rojas barragan100% (2)

- PERMIT Ion Migration Test: For The Measurement of Chloride Diffusivity of Concrete Cover in SituDocumento4 paginePERMIT Ion Migration Test: For The Measurement of Chloride Diffusivity of Concrete Cover in SituLakhwant Singh KhalsaNessuna valutazione finora

- CHMT 3005 - Lecture Notes - 2018 - SAKAI - Lecture 1 - 2 PDFDocumento66 pagineCHMT 3005 - Lecture Notes - 2018 - SAKAI - Lecture 1 - 2 PDFSidney MakololoNessuna valutazione finora