Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Quality

Caricato da

Shobitha UchilDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Quality

Caricato da

Shobitha UchilCopyright:

Formati disponibili

1

Chapter 10

Quality Control

2

Phases of Quality Assurance

Acceptance

sampling

Process

control

Continuous

improvement

Inspection

before/after

production

Corrective

action during

production

Quality built

into the

process

The least

progressive

The most

progressive

3

Inspection: Appraisal of good/service quality

How Much (sample size) /How Often (hourly, daily)

C

o

s

t

Optimal

Amount of Inspection

Cost of

inspection

(appraisal and

Prevention cost)

Cost of

passing

defectives

(failure cost)

Total Cost

4

Inspection

Where/When

Raw materials

Finished products

Before a costly operation, PhD comp. exam before candidacy

Before an irreversible process, firing pottery

Before a covering process, painting, assembly

Centralized vs. On-Site, my friend checks quality at cruise lines

Inputs Transformation Outputs

Acceptance

sampling

Process

control

Acceptance

sampling

5

Examples of Inspection Points

Type of

business

Inspection

points

Characteristics

Fast Food Cashier

Counter area

Eating area

Building

Kitchen

Accuracy

Appearance, productivity

Cleanliness

Appearance

Health regulations

Hotel/motel Parking lot

Accounting

Building

Main desk

Safe, well lighted

Accuracy, timeliness

Appearance, safety

Waiting times

Supermarket Cashiers

Deliveries

Accuracy, courtesy

Quality, quantity

6

Statistical Process Control (SPC)

SPC: Statistical evaluation

of the output of a process during production

The Control Process

Define

Measure

Compare to a standard

Evaluate

Take corrective action

Evaluate corrective action

7

Statistical Process Control

Shewharts classification of variability:

common cause vs. assignable cause

Variations and Control

Random variation: Natural variations in the

output of process, created by countless minor

factors, e.g. temperature, humidity variations.

Assignable variation: A variation whose source

can be identified. This source is generally a

major factor, e.g. tool failure.

8

Mean and Variance

Given a population of numbers, how to

compute the mean and the variance?

o

= =

= =

=

=

=

deviation Standard

) (

Variance

Mean

} ,..., , { Population

1

2

2

1

2 1

N

x

N

x

x x x

N

i

i

N

i

i

N

9

Statistical Process Control

From a large population of goods or

services (random if possible) a sample is

drawn.

Example sample: Midterm grades of BA3352

students whose last name starts with letter R

{60, 64, 72, 86}, with letter S {54, 60}

Sample size= n

Sample average or sample mean=

Sample range= R

Standard deviation of sample means=

x

population the of deviation Standard : where o

o

o

n

x

=

10

Sampling Distribution

Sampling distribution

Variability of the average scores of

people with last name R and S

Process distribution

Variability of the scores

for the entire class

Mean

Sampling distribution is the distribution of sample means.

Grouping reduces the variability.

11

Normal Distribution

Mean

3o 2o +2o +3o

95.44%

99.74%

x

at x. cdf normal ) 1 , _ , , ( normdist : functions l statistica Excel

at x. pdf normal ) 0 , _ , , ( normdist : functions l statistica Excel

dev st mean x

dev st mean x

normdist(x,.,.,0)

Probab

normdist(x,.,.,1)

12

Cumulative Normal Density

) _ , , ( norminv : prob" " at cdf of function Inverse

) 1 , _ , , ( normdist : at x (cdf) function Cumulative

: functions l statistica Excel

dev st mean prob

dev st mean x

0

1

x

normdist(x,mean,st_dev,1)

prob

norminv(prob,mean,st_dev)

13

Normal Probabilities: Example

If temperature inside a firing oven has a

normal distribution with mean 200

o

C and

standard deviation of 40

o

C, what is the

probability that

The temperature is lower than 220

o

C

=normdist(220,200,40,1)

The temperature is between 190

o

C and 220

o

C

=normdist(220,200,40,1)-normdist(190,200,40,1)

14

Control Limits

Sampling

distribution

Process

distribution

Mean

LCL

Lower

control

limit

UCL

Upper

control

limit

Process is in control if sample mean is between control limits.

These limits have nothing to do with product specifications!

15

Setting Control Limits:

Hypothesis Testing Framework

Null hypothesis: Process is in control

Alternative hypothesis: Process is out of control

Alpha=P(Type I error)=P(reject the null when it is true)=

P(out of control when in control)

Beta=P(Type II error)=P(accept the null when it is false)

P(in control when out of control)

If LCL decreases and UCL increases what happens to

Alpha ?

Beta?

Not possible to target alpha and beta simultaneously,

control charts target a desired level of Alpha.

16

Type I Error=Alpha

Mean

LCL UCL

o/2 o/2

o = Probability

of Type I error

st_dev) mean, /2, - norminv(1 UCL

st_dev) mean, /2, norminv( LCL

o

o

=

=

17

Control Chart

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

UCL

LCL

Sample number

Mean

Out of

control

Normal variation

due to chance

Abnormal variation

due to assignable sources

Abnormal variation

due to assignable sources

18

Observations from Sample Distribution

Sample number

UCL

LCL

1 2 3 4

19

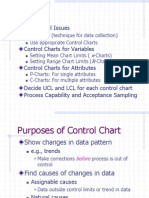

Control Charts

Control charts for variables (measurable

quantities), e.g. length, temperature

Mean control charts

To check mean

Range control charts

To check variability

Control charts for attributes, e.g. fit, defective

p-charts

To check proportion of defectives (occurrences)

c-charts

To check the number of defectives (occurrences)

20

Mean control chart

deviation standard of multiple a minus mean grand

deviation standard of multiple a plus mean grand

= =

= + =

=

x

x

z x LCL

z x UCL

x of average x mean Grand

o

o

x

x

x

) , x /2, - norminv(1

z

o

o o

o

x x UCL

=

=

Most often z is set to 2 or 3.

If the standard deviation of the sample means is not known,

use the average of sample ranges to get the limits:

ranges sample of average the of multiple a minus mean grand

ranges sample of average the of multiple a plus mean grand

R ranges sample of average

2

2

= =

= + =

=

R A x LCL

R A x UCL

R

Multiplier A_2 depends on n and is available in Table 10-2.

21

Range Control Chart

ranges sample of average the of multiple A

ranges sample of average the of multiple A

3

4

= =

= =

R D LCL

R D UCL

Multipliers D_4 and D_3 depend on n and are available in Table 10-2.

EX: In the last five years, the range of GMAT scores of incoming PhD class is

88, 64, 102, 70, 74. If each class has 6 students, what are UCL and LCL for

GMAT ranges?

0 79.6 * 0 159.2 79.6 * 2

. 0 D , 2 D 6, n For . 6 . 79 5 / ) 74 70 102 64 88 (

3 4

3 4

= = = = = =

= = = = + + + + =

R D LCL R D UCL

R

Are the GMAT ranges in control?

22

Mean and Range Charts: Which?

UCL

LCL

UCL

LCL

R-chart

x-Chart

Detects shift

Does not

detect shift

(process mean is

shifting upward)

Sampling

Distribution

23

Mean and Range Charts: Which?

UCL

LC

L

LC

L

R-chart

Reveals increase

x-Chart

UCL

Does not

reveal increase

(process variability is increasing)

Sampling

Distribution

24

Use of p-Charts

p=proportion defective, assumed to be known

When observations can be placed into two categories.

Good or bad

Pass or fail

Operate or dont operate

Go or no-go gauge

before as ,

) 1 (

LCL

z

n

p p

where

z p z p UCL

p

p p

=

= + =

o

o o

25

Use of c-Charts

c=number of occurrences per unit

Use only when the number of occurrences per

unit can be counted.

Scratches, chips, dents, or errors per item

Cracks or faults per unit of distance

Breaks or Tears per unit of area

Bacteria or pollutants per unit of volume

Calls, complaints, failures per unit of time

c average the use known, not is c if

LCL c z c c z c UCL = + =

26

C-chart Example

While the nuclear submarine Kursk was being raised in the

Barents sea (between Svalbard, No and Novaya Zemlya, Ru),

which took 15 hours, engineers took a reading of number of

Geiger counts per hour to detect any increase in radiation

levels. Should they have stopped before 5

th

or 10

th

hour given

3-sigma control and the readings data: 42, 48, 50, 45, 52, 66,

64, 84, 92, 76.

At the 5

th

hour, average number of counts=47.4, stdev of counts=6.88,

UCL=47.4+3*6.88=68.05, LCL=47.4-3*6.88=26.75. Do not stop.

At the 10

th

hour, average number of counts=61.9, stdev of counts=7.87,

UCL=61.9+3*7.87=85.51, LCL=61.9-3*7.87=38.29. Stop, 9

th

reading is

out of control.

27

Up and Down Run Charts

If all readings are in control, is the process

really in control?

There could be trends in readings even

when they are in control.

Counting Up/Down Runs (r=8 runs)

U U D U D U D U U D

28

Up and Down Run Charts

samples of Number K

90

29 16

and

3

1 - 2K

E(r)

runs of stdev of multiple a minus runs Expected ) (

runs of stdev of multiple a plus runs Expected ) (

=

= =

= =

= + =

K

z r E LCL

z r E UCL

r

r

r

o

o

o

EX: What are 3-sigma UCL and LCL for the number of runs in 50 samples?

2.92 * 3 - 33 ) (

2.92 * 3 33 ) (

92 . 2

90

29 16

and 33

3

1 - 2K

E(r) 50, K

= =

+ = + =

=

= = = =

r

r

r

z r E LCL

z r E UCL

K

o

o

o

29

Tolerances/Specifications

Requirements of the design or customers

Process variability

Natural variability in a process

Variance of the measurements coming from the process

Process capability

Process variability relative to specification

Capability=Process specifications / Process variability

Process Capability

30

Process Capability:

Specification limits are not control chart limits

Lower

Specification

Upper

Specification

Process variability matches

specifications

Lower

Specification

Upper

Specification

Process variability well within

specifications

Lower

Specification

Upper

Specification

Process variability exceeds

specifications

Sampling

Distribution

is used

31

Process Capability Ratio

When the process is centered, process capability ratio

Upper specification lower specification

6o

Cp =

A capable process has large Cp.

Example: The standard deviation, of sample averages of the

midterm 1scores obtained by students whose last names start

with R, has been 7. The SOM management requires the

scores not to differ by more than 50% in an exam. That is the

highest score can be at most 50 points above the lowest

score. Suppose that the scores are centered, what is the

process capability ratio?

Answer: 50/42

32

Process Capability Ratio

When the process is not centered, process capability ratio

Min{Process mean - lower spec , Upper spec - Process mean}

3o

Cpk=

When the process is not centered, the closest spec to mean determines

the capability of the process because that spec is likely to be

more of a limiting factor than the other.

Example: Suppose that the process is not centered in the previous example

and the SOM wants all the scores to fall within 50% and 100%. What is the

Capability ratio if the average score was 70?

Answer: From the lower limit, we have (70-50)/21

From the upper limit, we have (100-70)/21

Then the ratio is 20/21

33

Process

mean

Lower

specification

Upper

specification

+/- 3 Sigma

+/- 6 Sigma

3 Sigma and 6 Sigma Quality

34

Chapter 10 Supplement

Acceptance

Sampling

35

Acceptance Sampling

Acceptance sampling: Is a lot of N products good

if a random sample of n (n<N) products contain

only c defects?

For example take a sample of 10(=n) milk bottles out

of every 100(=N). If 1(=c) or more bottles do not fit

specifications, reject the entire lot of 100 bottles.

c is determined to balance type I and type II

errors.

This is a smart compromise between 100%

inspection and no inspection.

Generally used for input/output inspection.

36

Why not to emphasize

Acceptance Sampling (AS)

AS plans have no clearly stated economic objective.

They target some levels of type I and II errors.

AS incorporate an attitude of punishment by

rejecting entire lots after examining small samples.

This feeds the mistrust between supplier and the

customer.

AS does not attempt to find the root cause of

defectives. It merely detects defectives. Real

problem is actually finding the root cause. Some

people say that:

AS provides elegant solutions to balance type I and II

errors by making a type III error: solving the wrong

problem.

Potrebbero piacerti anche

- Statistic ProcessDocumento39 pagineStatistic ProcessxredjokerxNessuna valutazione finora

- Statistical Quality ControlDocumento82 pagineStatistical Quality ControlShahmirBalochNessuna valutazione finora

- Statistical Quality Control PDFDocumento82 pagineStatistical Quality Control PDFInshal KhanNessuna valutazione finora

- SPC: Statistical Process ControlDocumento53 pagineSPC: Statistical Process ControlSaoloan NaiborhuNessuna valutazione finora

- Statistical Quality Control (SQC) FinalDocumento47 pagineStatistical Quality Control (SQC) FinalSagar DhageNessuna valutazione finora

- Quality and Operations Management: Process Control and Capability AnalysisDocumento16 pagineQuality and Operations Management: Process Control and Capability AnalysisjayNessuna valutazione finora

- Introduction SPCDocumento28 pagineIntroduction SPCmixarimNessuna valutazione finora

- Process Capability and SPC : Operations ManagementDocumento43 pagineProcess Capability and SPC : Operations ManagementRahul KhannaNessuna valutazione finora

- Process Capability & SQCDocumento37 pagineProcess Capability & SQCNirav Solanki0% (1)

- QUALITY CONTROLDocumento23 pagineQUALITY CONTROLPrithiviraj RajasekarNessuna valutazione finora

- Statistical Quality Control 2Documento34 pagineStatistical Quality Control 2Tech_MXNessuna valutazione finora

- Statistical Quality ControlDocumento13 pagineStatistical Quality ControlsekelanilunguNessuna valutazione finora

- Operations MGMT 15Documento82 pagineOperations MGMT 15Umar Khalid MalhiNessuna valutazione finora

- Statistics For Business and Economics: Bab 20Documento43 pagineStatistics For Business and Economics: Bab 20balo100% (1)

- Statistical Quality Control ComponentsDocumento31 pagineStatistical Quality Control ComponentssingharvindkumarNessuna valutazione finora

- Statistical Quality Control: Simple Applications of Statistics in TQMDocumento57 pagineStatistical Quality Control: Simple Applications of Statistics in TQMHarpreet Singh PanesarNessuna valutazione finora

- Statistical Process Control for Quality ImprovementDocumento21 pagineStatistical Process Control for Quality ImprovementNikhil PandeyNessuna valutazione finora

- Statistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626Documento38 pagineStatistical Quality Control (S.Q.C.) Presented By-: Nikhil Garg ROLL NO-0129626jolaakNessuna valutazione finora

- Technical Note 8: Process Capability and Statistical Quality ControlDocumento46 pagineTechnical Note 8: Process Capability and Statistical Quality ControlVipin NairNessuna valutazione finora

- SPC FOR MONITORING LOG LENGTHSDocumento17 pagineSPC FOR MONITORING LOG LENGTHSHarris ChackoNessuna valutazione finora

- SPCDocumento62 pagineSPCSagar KansalNessuna valutazione finora

- Statistical Process Control (SPC) ExplainedDocumento53 pagineStatistical Process Control (SPC) ExplainedShubham AggarwalNessuna valutazione finora

- Partial Least Squares A TutorialDocumento12 paginePartial Least Squares A TutorialGutama Indra GandhaNessuna valutazione finora

- 6.FQA-QUALITY CONTROL-Presentation1Documento23 pagine6.FQA-QUALITY CONTROL-Presentation1grace mwenjeNessuna valutazione finora

- Lecture On C - ChartDocumento20 pagineLecture On C - Chart191329Nessuna valutazione finora

- 7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationDocumento55 pagine7 QC Tools: Check-Sheet Cause and Effect Pareto Histogram Control Chart Scatter Plot StratificationNilesh RathoreNessuna valutazione finora

- Total Quality Management, Statistical Process ControlDocumento11 pagineTotal Quality Management, Statistical Process ControlElmer GatchalianNessuna valutazione finora

- Statistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New MexicoDocumento68 pagineStatistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New Mexicoenzo atsituabNessuna valutazione finora

- Statistical Quality Control and SPC ChartsDocumento57 pagineStatistical Quality Control and SPC ChartsJigar NagvadiaNessuna valutazione finora

- 02 Statistical Process ControlDocumento68 pagine02 Statistical Process ControlacantillanapNessuna valutazione finora

- 6.4 Process CapabilityDocumento13 pagine6.4 Process CapabilitychuszNessuna valutazione finora

- LTPDDocumento20 pagineLTPDPradeepNessuna valutazione finora

- Inspection Because It Affects The Quality of The Product That Leaves TheDocumento2 pagineInspection Because It Affects The Quality of The Product That Leaves TheMatheus RossiNessuna valutazione finora

- Operations Management POMG2710: Chapter (10) Quality ControlDocumento37 pagineOperations Management POMG2710: Chapter (10) Quality Controlالف تاتNessuna valutazione finora

- Statistical Quality ControlDocumento3 pagineStatistical Quality ControlHunson Abadeer100% (1)

- Statistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaDocumento40 pagineStatistical Quality Control: by 4Th Edition © Wiley 2010 Powerpoint Presentation by R.B. Clough - Unh M. E. Henrie - UaaInderpreet SinghNessuna valutazione finora

- Statistical Process ControlDocumento52 pagineStatistical Process ControlKanupriya ChaturvediNessuna valutazione finora

- Statistical Process ControlDocumento42 pagineStatistical Process ControlErick Bok Cang YeongNessuna valutazione finora

- Quality Assurance Cheat SheetDocumento2 pagineQuality Assurance Cheat SheetluvfearNessuna valutazione finora

- Quality ControlDocumento13 pagineQuality ControlEuniceChungNessuna valutazione finora

- Variables Control ChartDocumento22 pagineVariables Control Chartbobby510Nessuna valutazione finora

- Quality ManagementDocumento10 pagineQuality ManagementTifarie Luesas33% (3)

- Class 3 NotesDocumento209 pagineClass 3 NotesJason FischerNessuna valutazione finora

- Statistical Quality ControlDocumento15 pagineStatistical Quality ControlMoniruzzaman MoNirNessuna valutazione finora

- Quality control charts: Detect process issuesDocumento30 pagineQuality control charts: Detect process issuesLibyaFlowerNessuna valutazione finora

- STAT 525 Diagnostics and Remedial Measures Chapter SummaryDocumento28 pagineSTAT 525 Diagnostics and Remedial Measures Chapter SummaryDash CorderoNessuna valutazione finora

- NTU OM 03162022-SlidesDocumento31 pagineNTU OM 03162022-SlidesDaniel WangNessuna valutazione finora

- Chapter 5. Control Charts For VariablesDocumento38 pagineChapter 5. Control Charts For VariablesJigar Patel's100% (2)

- Quality INSPECTION Sampling Plans and Control ChartsDocumento27 pagineQuality INSPECTION Sampling Plans and Control ChartsArshath MutholiMaranNessuna valutazione finora

- Statistical Process Control Exercise For Exam TwoDocumento4 pagineStatistical Process Control Exercise For Exam TwoHassan Abdulrahman OmarNessuna valutazione finora

- Experimentation, Validation, and Uncertainty Analysis for EngineersDa EverandExperimentation, Validation, and Uncertainty Analysis for EngineersNessuna valutazione finora

- Two-Degree-of-Freedom Control Systems: The Youla Parameterization ApproachDa EverandTwo-Degree-of-Freedom Control Systems: The Youla Parameterization ApproachNessuna valutazione finora

- A New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeDa EverandA New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeNessuna valutazione finora

- Hamiltonian Monte Carlo Methods in Machine LearningDa EverandHamiltonian Monte Carlo Methods in Machine LearningNessuna valutazione finora

- Mistakes in Quality Statistics: and How to Fix ThemDa EverandMistakes in Quality Statistics: and How to Fix ThemNessuna valutazione finora

- Practical Design of Experiments (DOE): A Guide for Optimizing Designs and ProcessesDa EverandPractical Design of Experiments (DOE): A Guide for Optimizing Designs and ProcessesNessuna valutazione finora

- Rasi CalculatorDocumento1 paginaRasi CalculatorShobitha UchilNessuna valutazione finora

- Describe Four Activities Performed by The Operations ManagerDocumento4 pagineDescribe Four Activities Performed by The Operations ManagerShobitha Uchil50% (4)

- International Year of ForestsDocumento6 pagineInternational Year of ForestsShobitha UchilNessuna valutazione finora

- Water CycleDocumento7 pagineWater CycleShobitha UchilNessuna valutazione finora

- Convert Decimal To Binary Sunday ClassDocumento14 pagineConvert Decimal To Binary Sunday ClassLaila HammadNessuna valutazione finora

- Installation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Documento62 pagineInstallation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Madelaine Velasquez Blacutt100% (1)

- Signal and Telecommunication - 1Documento83 pagineSignal and Telecommunication - 1srinathNessuna valutazione finora

- Mech Vi Non Traditional Machining (10me665) NotesDocumento45 pagineMech Vi Non Traditional Machining (10me665) Notesnikhil0% (1)

- Akvola Technologies MicroGas S Technical Specifications - Web PDFDocumento2 pagineAkvola Technologies MicroGas S Technical Specifications - Web PDFHardik VavdiyaNessuna valutazione finora

- Project PPTDocumento47 pagineProject PPTIshant KumawatNessuna valutazione finora

- Diebold ManualDocumento2 pagineDiebold Manualjoseperezlopes069Nessuna valutazione finora

- PHYSICS O-LEVEL PAST PAPER QUESTIONS ON MOMENTSDocumento7 paginePHYSICS O-LEVEL PAST PAPER QUESTIONS ON MOMENTSelty TanNessuna valutazione finora

- Training Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Documento51 pagineTraining Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Ankita BharadwajNessuna valutazione finora

- Surveying - Traverse Surveying - TraverseDocumento13 pagineSurveying - Traverse Surveying - Traversebills100% (1)

- AAL1 and Segmentation and Reassembly LayerDocumento18 pagineAAL1 and Segmentation and Reassembly Layeroureducation.inNessuna valutazione finora

- FETs DatabookDocumento189 pagineFETs DatabookTito Titon0% (1)

- Teaching NLTK NorwegianDocumento68 pagineTeaching NLTK NorwegianRamesh AkulaNessuna valutazione finora

- CH1 The Foundations - Logic and ProofsDocumento106 pagineCH1 The Foundations - Logic and ProofsMOHAMED BACHARNessuna valutazione finora

- Spe 58987 Propped Fracturing in Gas Carbonate Formations MexicoDocumento12 pagineSpe 58987 Propped Fracturing in Gas Carbonate Formations MexicoJose Gregorio FariñasNessuna valutazione finora

- Add Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDocumento32 pagineAdd Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDaniel Ernesto EspitiaNessuna valutazione finora

- Service Manual New Sigma-Control 2Documento132 pagineService Manual New Sigma-Control 2gil_bar_t0% (3)

- The Power of TQM: Analysis of Its Effects On Profitability, Productivity and Customer SatisfactionDocumento15 pagineThe Power of TQM: Analysis of Its Effects On Profitability, Productivity and Customer SatisfactionAbid Ahasan100% (1)

- Mebs7014 2223 03Documento78 pagineMebs7014 2223 03Yuki ChanNessuna valutazione finora

- 01 - Lesson Plan - Fractions - Decimal - PercentDocumento4 pagine01 - Lesson Plan - Fractions - Decimal - PercentAnthony MontoyaNessuna valutazione finora

- MSCS) (V4.12.10) MSC Server Hardware DescriptionDocumento148 pagineMSCS) (V4.12.10) MSC Server Hardware DescriptionDeepak JoshiNessuna valutazione finora

- Smart AntennasDocumento40 pagineSmart AntennasMeeraNessuna valutazione finora

- Analysis of Excessive Hydrogen Generation in TransformersDocumento8 pagineAnalysis of Excessive Hydrogen Generation in TransformersandikaubhNessuna valutazione finora

- TIMO Mock 2019 卷P3fDocumento9 pagineTIMO Mock 2019 卷P3fDo Yun100% (1)

- Putzmeister Pump TrucksDocumento17 paginePutzmeister Pump Truckslwin_oo243575% (4)

- Measuring AssignmentDocumento3 pagineMeasuring AssignmentArnab BhattacharyaNessuna valutazione finora

- ECI Symposium Proceedings Optimizes Fouling Mitigation DesignDocumento6 pagineECI Symposium Proceedings Optimizes Fouling Mitigation DesignJoseAndresCarreñoNessuna valutazione finora

- Monico Gen. 2 Gateway Datasheet PDFDocumento2 pagineMonico Gen. 2 Gateway Datasheet PDFRicardo OyarzunNessuna valutazione finora

- ACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinDocumento658 pagineACL Injuries in The Female Athlete: Causes, Impacts, and Conditioning Programs Frank R. Noyes Sue Barber-WestinluizamgoNessuna valutazione finora

- Maths Class VIII: Chapter As Per NCERT LessonsDocumento1 paginaMaths Class VIII: Chapter As Per NCERT Lessonsabhijeet_sangwanNessuna valutazione finora