Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Metro

Caricato da

Vipul RathiDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Metro

Caricato da

Vipul RathiCopyright:

Formati disponibili

Training under

DNRC

/6ut Pr6ect: /6ut Pr6ect:

]aipur Netro Rail is proposed to be setup ]aipur Netro Rail is proposed to be setup

on Public Private Partnership (DBFOT) on Public Private Partnership (DBFOT)

model. The project is going to have two model. The project is going to have two

corridors, one running from East to West corridors, one running from East to West

and the other running from North to and the other running from North to

South. The total length is around 3S Km. South. The total length is around 3S Km.

Najor portion of the East West corridor, Najor portion of the East West corridor, i.e i.e

3.2S Km out of total length of 11.S Km, is 3.2S Km out of total length of 11.S Km, is

already under construction by the already under construction by the

Corporation Corporation

East EastWest Corridor West Corridor Nansarovar, New Nansarovar, New Aatish Aatish

Narket, Narket, vivek vivek vihar vihar, , Shyam Shyam Nagar, Ram Nagar, Nagar, Ram Nagar,

Civil Lines, ]aipur Railway Station, Sindhi Camp Civil Lines, ]aipur Railway Station, Sindhi Camp

Bus Stand, Bus Stand, Chandpole Chandpole, , Choti Choti Chaoupar Chaoupar and and Badi Badi

Chaoupar Chaoupar. .

East EastWest Corridor West Corridor Nansarovar Nansarovar, New , New Aatish Aatish

Narket, Narket, vivek vivek vihar vihar, , Shyam Shyam Nagar, Ram Nagar, Nagar, Ram Nagar,

Civil Lines, ]aipur Railway Station, Sindhi Camp Civil Lines, ]aipur Railway Station, Sindhi Camp

Bus Stand, Bus Stand, Chandpole Chandpole, , Choti Choti Chaoupar Chaoupar and and Badi Badi

Chaoupar Chaoupar. .

The East The EastWest corridor of the Netro in West corridor of the Netro in Phase 1 Phase 1

is expected to cost Rs is expected to cost Rs 12S0 cr6re 12S0 cr6re. .

East EastWest Corridor West Corridor Nansarovar, New Nansarovar, New Aatish Aatish

Narket, Narket, vivek vivek vihar vihar, , Shyam Shyam Nagar, Ram Nagar, Nagar, Ram Nagar,

Civil Lines, ]aipur Railway Station, Sindhi Camp Civil Lines, ]aipur Railway Station, Sindhi Camp

Bus Stand, Bus Stand, Chandpole Chandpole, , Choti Choti Chaoupar Chaoupar and and Badi Badi

Chaoupar Chaoupar. .

The East The EastWest corridor of the Netro in West corridor of the Netro in Phase 1 Phase 1

is expected to cost Rs is expected to cost Rs 12S0 cr6re 12S0 cr6re. .

The Phase 2 is expected to cost Rs 7000 crore The Phase 2 is expected to cost Rs 7000 crore

ere are some facts about the ]aipur: ere are some facts about the ]aipur:

- Number of lines in ]aipur Netro Railways: 2 - Number of lines in ]aipur Netro Railways: 2

- Number of stations : 12 (phase 1) - Number of stations : 12 (phase 1)

- Daily ridership: roughly 6 lacks (one way). - Daily ridership: roughly 6 lacks (one way).

- Operation Began: 2010 (line 1) - Operation Began: 2010 (line 1)

- System length: 32.S kilometers - System length: 32.S kilometers

- Track gauge: 1,43S mm (4 ft 8+1 - Track gauge: 1,43S mm (4 ft 8+1''2 in) 2 in)

- Electrification: 2S kv, S0 AC through - Electrification: 2S kv, S0 AC through

overhead overhead

- Average speed: 33 km/h (21 mph) - Average speed: 33 km/h (21 mph)

- Top speed: 80 km/h (S0 mph) - Top speed: 80 km/h (S0 mph)

- - aipur metr6 rail start date aipur metr6 rail start date: Around ]une : Around ]une

2013. 2013.

Delhi Netro Rail Corporation Delhi Netro Rail Corporation

!TRODUCTO! !TRODUCTO!

For implementation and subsequent For implementation and subsequent

operation of Delhi NRTS, a company operation of Delhi NRTS, a company

under the name DEL NETRO RAL under the name DEL NETRO RAL

CORPORATON was registered on 03 CORPORATON was registered on 030S 0S

3S under the Companies Act, 13S6. DNRC 3S under the Companies Act, 13S6. DNRC

has equal equity participation from CO has equal equity participation from CO

and CNCTD. and CNCTD.

Pile F6undati6n

Construction of Construction of Pile F6undati6n Pile F6undati6n of of

the elevated structure for the transition the elevated structure for the transition

of of Netr6 Rail Netr6 Rail S also for the S also for the Netr6 Netr6

Stati6ns Stati6ns. .

ndian Standards 6n Piles ndian Standards 6n Piles

S 2311 : Part 1 : Sec 1 : 1373 Driven cast in S 2311 : Part 1 : Sec 1 : 1373 Driven cast insitu concrete situ concrete

piles piles

S 2311 : Part 1 : Sec 2 : 1373 Bored cast S 2311 : Part 1 : Sec 2 : 1373 Bored castin insitu piles situ piles

S 2311 : Part 1 : Sec 3 : 1373 Driven precast concrete piles S 2311 : Part 1 : Sec 3 : 1373 Driven precast concrete piles

S 2311 : Part 1 : Sec 4 : 1384 Bored precast concrete piles S 2311 : Part 1 : Sec 4 : 1384 Bored precast concrete piles

S 2311 : Part 2 : 1380 Timber piles S 2311 : Part 2 : 1380 Timber piles

S 2311 : Part 3 : 1380 Under reamed piles S 2311 : Part 3 : 1380 Under reamed piles

S 2311 : Part 4 : 138S Load test on piles S 2311 : Part 4 : 138S Load test on piles

Pile foundations are adopted generally in the following Pile foundations are adopted generally in the following

situation situation

- Low Bearing Capacity of soil. - Low Bearing Capacity of soil.

- Non availability of proper bearing stratum at shallow - Non availability of proper bearing stratum at shallow

depths. depths.

- eavy loads from the super structure for which - eavy loads from the super structure for which

shallow foundation may not be economical or shallow foundation may not be economical or

feasible. feasible.

Pile Foundations

Classification of Piles : Classification of Piles :

Based on material Based on material

Concrete Concrete

Steel Steel

Timber Timber

Classification of Piles : Classification of Piles :

Based on material Based on material

Concrete Concrete

Steel Steel

Timber Timber

Based on method of construction/installation.: Based on method of construction/installation.:

Driven /Displacement Pre cast Piles Driven /Displacement Pre cast Piles

Driven/Displacement Cast in Situ Piles Driven/Displacement Cast in Situ Piles

Bored/ Replacement Pre cast piles Bored/ Replacement Pre cast piles

Bored/ Replacement Cast in situ piles Bored/ Replacement Cast in situ piles

Classification of Piles : Classification of Piles :

Based on material Based on material

Concrete Concrete

Steel Steel

Timber Timber

Based on method of construction/installation.: Based on method of construction/installation.:

Driven /Displacement Pre cast Piles Driven /Displacement Pre cast Piles

Driven/Displacement Cast in Situ Piles Driven/Displacement Cast in Situ Piles

Bored/ Replacement Pre cast piles Bored/ Replacement Pre cast piles

Bored/ Replacement Cast in situ piles Bored/ Replacement Cast in situ piles

Based on Load transfer mechanism: Based on Load transfer mechanism:

Friction/Floating piles Friction/Floating piles

Bearing cum Friction piles Bearing cum Friction piles

Based on sectional area : Based on sectional area :

Circular Circular

Square Square

H Shape H Shape

Octagonal Octagonal

Tubular Tubular

Based on sectional area : Based on sectional area :

Circular Circular

Square Square

H Shape H Shape

Octagonal Octagonal

Tubular Tubular

Based on size: Based on size:

Micro piles Dia. < 150 mm Micro piles Dia. < 150 mm

Small dia. Pile Dia. > 150 mm and Dia. < 600 mm Small dia. Pile Dia. > 150 mm and Dia. < 600 mm

Large Dia. Piles Dia. > 600 mm Large Dia. Piles Dia. > 600 mm

SOFT SOIL

PILES

e used Friction Piles in Metro

Foundation

f the firm soil is at a considerable

depth, it may be very expensive to

use end bearing piles. n such

situations, the piles are driven

through the penetrable soil for some

distance. The piles transmit the load

of structure to the penetrable soil by

means of skin friction between the

soil.

Neth6d F6r Neth6d F6r

The C6nstructi6n The C6nstructi6n Of Of Pile F6undati6n Pile F6undati6n

The following steps were observed in the The following steps were observed in the

construction: construction:

SETTNC OUT SETTNC OUT

DRvNC OF TENPORARY CASNC DRvNC OF TENPORARY CASNC

Boring Boring

RENFORCENENT CACE LOWERNC RENFORCENENT CACE LOWERNC

RENFORCENENT COvER BLOCK RENFORCENENT COvER BLOCK

FLUSNC OPERATON FLUSNC OPERATON

CONCRETNC CONCRETNC

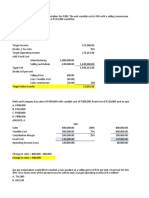

S.No. DESCRIPTION TYPE CAPACITY

1. Pilling Rig Mait HR 130 130 KN

2. Crane TATA 320

3. Excavator JCB .25 cum

4. Dumpers TATA/AL 4 cum

5. Batching Plant M1 30 cum/hr

6. Transit Mixers 6/4 cum

7. Welding Generator 400 Amps

8. Tremie Pipe 250 mm dia 25-35 mt

9. Hopper

CONSTRUCTION EQUIPMENTS

Soil Bucket Soil Bucket

Light weight Light weight

Large storage Large storage

capacity capacity

Durable Durable

Reliable Reliable

Tremie Pipes Tremie Pipes

quick disconnect quick disconnect

couplings couplings

O ring seals for easy O ring seals for easy

installation installation

leak proof leak proof

connections connections

various lengths can various lengths can

be provided be provided

NETHODOLOCY NETHODOLOCY

SETT!C OUT: SETT!C OUT:

Necessary survey was conducted and pile Necessary survey was conducted and pile

points were marked. The pile location was set points were marked. The pile location was set

out with respect to the control points by out with respect to the control points by

suitable pin marked at location and checked suitable pin marked at location and checked

by Engineer's representative. by Engineer's representative.

DR!C OF TENPORRY CS!C: DR!C OF TENPORRY CS!C:

W Rotating drilling rig fitted with

suitable tool (soil boring tool) to

be positioned at the premarked

pile point and boring was started

W On completion of boring up to

about 1m casing pipe was

installed in position using special

attachment to the rotary head

W Diameter of the cutting tool was

diameter of the pile minus 7Smm

Naterial Used Naterial Used: :

Bent6nite: Bent6nite:

used to stabilie the sides of used to stabilie the sides of

the pile borehole. the pile borehole.

Bentonite was saturated for Bentonite was saturated for

24hrs and then used. 24hrs and then used.

Frequency test: 24hrs after Frequency test: 24hrs after

mixing, prior to concreting. mixing, prior to concreting.

The properties of bentonite slurry met The properties of bentonite slurry met

at the site were: at the site were:

S.n6. Type 6f test Required

alue

Equipment t6 /e

used

1. Nud density 1.0S g/cc ydrometer

2. viscosity prior to concrete 30 - 40 second Narsh cone

3. p value 3.S to 12 p meter

4. Sand content 1 Sieve Analysis

S. Liquid limit 400 Casagranda

C6ncrete: C6ncrete:

Crade of concrete: N3S Crade of concrete: N3S

Slump of concrete: 1S0 to 200 mm Slump of concrete: 1S0 to 200 mm

The maximum sie of Coarse aggregate The maximum sie of Coarse aggregate

was 20mm was 20mm

The cement used for pilling work as per The cement used for pilling work as per

S:4SS specification for Portland slag S:4SS specification for Portland slag

cement. cement.

Ninimum cement content for the design Ninimum cement content for the design

mix was not kept less than 400kg/m mix was not kept less than 400kg/m

33

Reinf6rcement Steel: Reinf6rcement Steel:

TNT bars were used. TNT bars were used.

C. wires were used for binding C. wires were used for binding

reinforcement. reinforcement.

Bending of reinforcement was as per S: Bending of reinforcement was as per S:

2S021363. 2S021363.

The reinforcement was extended to the full The reinforcement was extended to the full

length of the pile and was projected 60 length of the pile and was projected 60

times diameter above the cut times diameter above the cutoff level. off level.

BOR!C BOR!C

nitial Boring of nitial Boring of

1.S meters was 1.S meters was

done by using done by using

auger auger

temporary casing temporary casing

was installed in was installed in

the borehole the borehole

Bentonite suspension was then filled in the Bentonite suspension was then filled in the

borehole for stabilising sides before borehole for stabilising sides before

starting boring below bottom of temporary starting boring below bottom of temporary

slurry slurry

The level of bentonite was always kept 1.S The level of bentonite was always kept 1.S

meters above the bottom of casing during meters above the bottom of casing during

grabbing grabbing

Further boring was done using soil bucket Further boring was done using soil bucket

till the required depth was reached till the required depth was reached

Once the bore has depth has reached to Once the bore has depth has reached to

the desired depth, the bottom of the bore the desired depth, the bottom of the bore

was cleaned by Bentonite flushing was cleaned by Bentonite flushing

RE!FORCENE!T CCE RE!FORCENE!T CCE

LOWER!C LOWER!C

The reinforcement was cut and bent to required The reinforcement was cut and bent to required

shape and sie shape and sie

The reinforcement cage was fabricated at the The reinforcement cage was fabricated at the

fabrication yard and was transported to the site fabrication yard and was transported to the site

Specified cover blocks were provided to the Specified cover blocks were provided to the

reinforcement cage for the pile reinforcement cage for the pile

The cage was lowered in 3 pieces or more The cage was lowered in 3 pieces or more

depending upon the length of pile. depending upon the length of pile.

Bottom cage was lowered inside the borehole Bottom cage was lowered inside the borehole

and temporarily supported on the casing pipe and temporarily supported on the casing pipe

top, keeping the dowel length projecting above top, keeping the dowel length projecting above

and second cage lifted and lapped by welding. and second cage lifted and lapped by welding.

The minimum lap length was 60d. elical was The minimum lap length was 60d. elical was

tied more closely at the welding one then the tied more closely at the welding one then the

whole cage length. whole cage length.

The whole cage then lowered inside the The whole cage then lowered inside the

bore hole. the reinforcement was bore hole. the reinforcement was

projected 60 times bar diameter above the projected 60 times bar diameter above the

cut off level. cut off level.

RE!FORCENE!T COER RE!FORCENE!T COER

BLOCK BLOCK

Circular cover blocks of 1S0mm diameter Circular cover blocks of 1S0mm diameter

was made with the same grade of was made with the same grade of

concrete as that of pile concrete and fixed concrete as that of pile concrete and fixed

to helical. to helical.

The cover block was provided at The cover block was provided at

approximately 2m intervals and suitably approximately 2m intervals and suitably

staggered. staggered.

FLUSH!C OPERTO! FLUSH!C OPERTO!

Before concreting the borehole was flushed again with Before concreting the borehole was flushed again with

fresh bentonite suspension. mmediately after lowering fresh bentonite suspension. mmediately after lowering

of the cage. of the cage.

Tremie pipes of 2S0mm diameter of length 1.Sm length Tremie pipes of 2S0mm diameter of length 1.Sm length

were joined together and lowered into the bore and the were joined together and lowered into the bore and the

bentonite was pumped through the pipe. bentonite was pumped through the pipe.

During flushing, contaminated bentonite from bottom of During flushing, contaminated bentonite from bottom of

the pile was collected in the tank through Tremie outlet the pile was collected in the tank through Tremie outlet

S fresh bentonite was pumped to maintain the bentonite S fresh bentonite was pumped to maintain the bentonite

at required level. at required level.

Flushing was continued till the density of the return mud Flushing was continued till the density of the return mud

was less then 1.2gm/cc. was less then 1.2gm/cc.

CO!CRET!C CO!CRET!C

W The concrete was

placed in the bore

through the tremie pipe.

W The bottom of the

tremie was 300mm

above the bottom of the

bore.

W During concreting the

care was taken to keep

the tremie pipe 1.Sm

embedded in the

concrete.

On completion of concreting to the On completion of concreting to the

required level elevation, temporary casing required level elevation, temporary casing

was withdrawn either by the crane or was withdrawn either by the crane or

drilling rig. drilling rig.

The grade of concrete used in the pile was The grade of concrete used in the pile was

N3S. N3S.

Workability of concrete and concrete Workability of concrete and concrete

cubes were prepared to check the cubes were prepared to check the

strength of concrete after 7 and 28 days. strength of concrete after 7 and 28 days.

Cast in Situ Replacement Pile Cast in Situ Replacement Pile

Advantage Disadvantages

Less noise or vibration problem Concrete cannot be inspected aIter

installation

Equipment can break up practically all

kinds oI obstructions

Liable to squeezing or necking

Can be installed in a very long length Raking bored pile are diIIicult to

construct

No ground heave Drilling a number oI pile groups may

cause ground loss and settlement oI

adjacent structures

Depth and diameter can varied easily Cannot be extended above ground

level without special adaptation

UNDERCROUND NETRO UNDERCROUND NETRO

STATON AT CANDPOLE STATON AT CANDPOLE

CENERAL ABOUT TE PRO]ECT FOR CENERAL ABOUT TE PRO]ECT FOR

UNDERCROUND NETRO STATON UNDERCROUND NETRO STATON

SCOPE SCOPE Construction of guide wall, trench Construction of guide wall, trench

excavation under bentonite, placing of excavation under bentonite, placing of

reinforcement cage and concreting of diaphragm reinforcement cage and concreting of diaphragm

wall. wall.

OWNER OWNER DNRC DNRC

CONTRACTOR CONTRACTOR TD Cementation ndia Ltd. TD Cementation ndia Ltd.

TOTAL COST TOTAL COST 102Cr(approx) 102Cr(approx)

LST OF NA]OR PLANTS AND LST OF NA]OR PLANTS AND

EQUPNENTS EQUPNENTS

S

!O.

Plant/Equipment Type !um/er

1. 7St Capacity Crawler Excavation

Crane/(Service)

2

2. ydraulic and/or Rope Crabs 1

3. Bentonite Facility and Equipment 1(set)

4. Stopend System As

required

Continue . Continue .

S !O. Plant/Equipmen

t Type

!um/er

S. Stopend Chisel As required

6. Tremie Pipe

System(2S0mmdia

) inc opper

2

7. Welding Sets 4

NETODOLOCY FOR TE NETODOLOCY FOR TE

CONSTRUCTON OF DAPRACN WALL CONSTRUCTON OF DAPRACN WALL

The following steps were observed in the The following steps were observed in the

construction: construction:

1. 1. Cuide Wall Cuide Wall

2. 2. Bentonite Nixing Bentonite Nixing

3. 3. Excavation Excavation

CONTNUE . CONTNUE .

4. 4. nstallation Of Stopened And Waterstopened nstallation Of Stopened And Waterstopened

S. S. Reinforcement S Concreting Reinforcement S Concreting

CUDE WALL CUDE WALL

t is temporary structure constructed prior t is temporary structure constructed prior

to excavation of diaphragm wall. to excavation of diaphragm wall.

Purpose of guide wall: Purpose of guide wall:

To ensure the stability and prevent the To ensure the stability and prevent the

collapsing of the soil strata. collapsing of the soil strata.

To provide temporary support for the To provide temporary support for the

reinforcement cage. reinforcement cage.

To provide the supports to Stopend. To provide the supports to Stopend.

STRUCTURAL DETALS OF CUDE STRUCTURAL DETALS OF CUDE

WALL WALL

Crade of concrete Crade of concrete N1S N1S

Thickness of Cuide wall Thickness of Cuide wall 1S0mm 1S0mm

Depth of Cuide wall Depth of Cuide wall 1S00mm 1S00mm

Continue. Continue.

Clear cover Clear cover 2Smm 2Smm

Dia. of steel used Dia. of steel used 10mm S 8 mm at a 10mm S 8 mm at a

distance of 2S0mm center to center. distance of 2S0mm center to center.

Clear distance between inner faces of Clear distance between inner faces of

guide wall guide wall600mm(diaphragm 600mm(diaphragm

wall)+S0mm wall)+S0mm

Cuide wall Cuide wall

BENTONTE NNC BENTONTE NNC

Nixing unit was erected on impermeable base to Nixing unit was erected on impermeable base to

check spillage. check spillage.

Kept in storage tank for 24hrs to hydrate. Kept in storage tank for 24hrs to hydrate.

Continuously agitated using vertical pump. Continuously agitated using vertical pump.

Daily bentonite test that were conducted Daily bentonite test that were conducted

1. ph 1. ph 8.3 8.3(3to11.S as S code3SS6 (3to11.S as S code3SS61380) 1380)

2. Density 2. Density 1.11 1.11(1.06to1.12 as s code 3SS6 (1.06to1.12 as s code 3SS61380) 1380)

Bent6nite Bent6nite

3. Sand Content 3. Sand Content

fresh(2) S fresh(2) S

contaminate contaminate

d(3){7 d(3){7

as per s as per s

code 3SS6 code 3SS6

1380} 1380}

4. viscosity 4. viscosity

4Ssec(32 4Ssec(3230 30

sec as per s sec as per s

code code3SS6 3SS6

1380) 1380)

Nixing Tank for Bentonite

DAPRCAN WALL ECAvATON DAPRCAN WALL ECAvATON

Wall is located between Cuide wall. Wall is located between Cuide wall.

The trench was excavated using ydraulic The trench was excavated using ydraulic

Drilling Rig . Drilling Rig .

Stopened with water stopened was then Stopened with water stopened was then

lowered into the trench. lowered into the trench.

Excavation was done in three Excavation was done in three

panel(primary, secondary S closing). panel(primary, secondary S closing).

Excavation was done with bentonite filled Excavation was done with bentonite filled

to top level. to top level.

Diaphrgam wall Diaphrgam wall

RENFORCENENT S CONCRETNC RENFORCENENT S CONCRETNC

Crade of steel Crade of steel FeS00 FeS00

Crade of concrete Crade of concrete N3S N3S

Dia of steels used Dia of steels used 3Smm S 2Smm 3Smm S 2Smm

Continue . Continue .

Ninimum clear cover Ninimum clear cover 7Smm 7Smm

Shape of cover blocks Shape of cover blocks Circular Circular

oriontal distance of cover blocks oriontal distance of cover blocks 1S00mm 1S00mm

W vertical distance of cover blocks 2000mm

W Dia of tremie pipe 2S0mm

W Length to which pipe was dipped inside

the concrete 2m

W Concreting was done to 1m above the

cut off level.

Concreting of Diaphrgam wall Concreting of Diaphrgam wall

Slump Test Slump Test

The test is an empirical test that measures The test is an empirical test that measures

the workability of fresh concrete. Nore the workability of fresh concrete. Nore

specifically, it measures consistency specifically, it measures consistency

between batches. The test is popular due between batches. The test is popular due

to the simplicity of apparatus used and to the simplicity of apparatus used and

simple procedure. The slump test is used simple procedure. The slump test is used

to ensure uniformity for different batches to ensure uniformity for different batches

of similar concrete under field conditions. of similar concrete under field conditions.

Types of slump Types of slump

Continue. Continue.

C6llapse Shear True

n a collapse slump the

concrete collapses

completely.

|2]

n a shear slump the top

portion of the concrete

shears off and slips

sideways.

|2]

n a true slump the

concrete simply

subsides, keeping more

or less to shape.

|2]

Slump Test Slump Test

1,.| ;oc 1,.| ;oc

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Modulus of Subgrade Reaction KsDocumento1 paginaModulus of Subgrade Reaction KsmohamedabdelalNessuna valutazione finora

- DEFCON ManualDocumento13 pagineDEFCON Manualbuyvalve100% (1)

- English 8-Q3-M3Documento18 pagineEnglish 8-Q3-M3Eldon Julao0% (1)

- Recommended lubricants and refill capacitiesDocumento2 pagineRecommended lubricants and refill capacitiestele123Nessuna valutazione finora

- UKBM 2, Bahasa InggrisDocumento10 pagineUKBM 2, Bahasa InggrisElvi SNessuna valutazione finora

- CVP Solution (Quiz)Documento9 pagineCVP Solution (Quiz)Angela Miles DizonNessuna valutazione finora

- ThesisDocumento18 pagineThesisapi-29776055293% (15)

- CH 4 - Consolidated Techniques and ProceduresDocumento18 pagineCH 4 - Consolidated Techniques and ProceduresMutia WardaniNessuna valutazione finora

- Library Management System (Final)Documento88 pagineLibrary Management System (Final)Ariunbat Togtohjargal90% (30)

- Lab 2 ReportDocumento9 pagineLab 2 Reportsherub wangdiNessuna valutazione finora

- 20220720-MODIG-Supply Chain Manager (ENG)Documento2 pagine20220720-MODIG-Supply Chain Manager (ENG)abhilNessuna valutazione finora

- Equity AdvisorDocumento2 pagineEquity AdvisorHarshit AgarwalNessuna valutazione finora

- Triblender Wet Savoury F3218Documento32 pagineTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- DS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDocumento2 pagineDS 20230629 SG3300UD-MV SG4400UD-MV Datasheet V16 ENDragana SkipinaNessuna valutazione finora

- PaySlip ProjectDocumento2 paginePaySlip Projectharishgogula100% (1)

- S0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFDocumento6 pagineS0231689H02-B01-0001 Rev 02 Code 1 General Arrangement Drawing For 44 Kva Diesel Generator PDFAnonymous AfjzJdnNessuna valutazione finora

- NH School Employee Criminal Record Check FormDocumento2 pagineNH School Employee Criminal Record Check FormEmily LescatreNessuna valutazione finora

- Entrepreneurship and EconomicDocumento2 pagineEntrepreneurship and EconomicSukruti BajajNessuna valutazione finora

- RF Power Measurements Basic PrinciplesDocumento27 pagineRF Power Measurements Basic PrinciplesHector Velasco100% (1)

- KL Wellness City LIvewell 360 2023Documento32 pagineKL Wellness City LIvewell 360 2023tan sietingNessuna valutazione finora

- Air Cycle Refrigeration:-Bell - Coleman CycleDocumento21 pagineAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Axtraxng™: Networked Access Control Management Software V27.XDocumento2 pagineAxtraxng™: Networked Access Control Management Software V27.XChiluvuri VarmaNessuna valutazione finora

- Cantilever Retaining Wall AnalysisDocumento7 pagineCantilever Retaining Wall AnalysisChub BokingoNessuna valutazione finora

- Ridge Regression: A Concise GuideDocumento132 pagineRidge Regression: A Concise GuideprinceNessuna valutazione finora

- 2011 Mid America - WebDocumento156 pagine2011 Mid America - WebFaronNessuna valutazione finora

- NVH Analysis in AutomobilesDocumento30 pagineNVH Analysis in AutomobilesTrishti RastogiNessuna valutazione finora

- Ielts Band 9 Sample Essay NoDocumento5 pagineIelts Band 9 Sample Essay NoNhã NguyễnNessuna valutazione finora

- Racial and Ethnic Challenges in the UAE vs UKDocumento16 pagineRacial and Ethnic Challenges in the UAE vs UKATUL KORINessuna valutazione finora

- AutocadDocumento8 pagineAutocadbrodyNessuna valutazione finora

- RCA - Mechanical - Seal - 1684971197 2Documento20 pagineRCA - Mechanical - Seal - 1684971197 2HungphamphiNessuna valutazione finora