Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fluid Flow in Rocket Nozzles

Caricato da

Venkat Akella0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

379 visualizzazioni24 pagineMain aim of the project is to analyze the flow of the fluid(propellants) inside a rocket nozzle. A procedure is outlined for calculating the maximum changes in the exhaust velocity of gases.

Descrizione originale:

Copyright

© Attribution Non-Commercial (BY-NC)

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoMain aim of the project is to analyze the flow of the fluid(propellants) inside a rocket nozzle. A procedure is outlined for calculating the maximum changes in the exhaust velocity of gases.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

379 visualizzazioni24 pagineFluid Flow in Rocket Nozzles

Caricato da

Venkat AkellaMain aim of the project is to analyze the flow of the fluid(propellants) inside a rocket nozzle. A procedure is outlined for calculating the maximum changes in the exhaust velocity of gases.

Copyright:

Attribution Non-Commercial (BY-NC)

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 24

Project Report on

Analysis of Fluid Flow in Rocket

Nozzles BY

A.Venkat (07311A0353)

Under the guidance of

Mr. V. Vasudeva Rao

Principal

Sree Nidhi Institute Of Science and Technology

CONTENTS

Abstract

Introduction to Fluid Flow

Parameters governing the Fluid Flow

Brief Introduction to Rocket Nozzles

Criterion for 1-D gas flow in Rocket Nozzles

Design Of rocket Nozzles based on Nozzle

performance

Conclusion

References

Abstract

The main aim of the project is to analyze the flow

of the fluid(propellants) inside a rocket nozzle. A

procedure is outlined for calculating the maximum

changes in the exhaust velocity of gases which

can be introduced during flow through a rocket

nozzle as the result of vibrational time lags.

Introduction to Fluid Flow

Fluid flow Fluids (liquids and gases) are a form of

matter that cannot achieve equilibrium under an

applied shear stress but deform continuously, or

flow, as long as shear stress is applied. The fluid

flow means the movement of materials through

certain bounded regions (pipe). The study of fluid

flow can be divided in to :

Fluid Statics : it deals with fluid at rest in

equilibrium.

Fluid dynamic s: it deals with fluid in motion.

Types of Fluid Flows

Steady Flow : In steady flow the velocity of the

fluid particles at any point is constant as time

passes.

Unsteady Flow : Unsteady flow exists whenever

the velocity at a point in the fluid changes as time

passes.

Turbulent Flow : Turbulent flow is characterized

by the irregular movement of particles of the fluid.

There is no definite frequency as there is in wave

motion. The particles travel in irregular paths with

no observable pattern and no definite layers. The

flow becomes irregular exceeds a certain velocity

any condition that causes abrupt changes in

velocity Eddy currents are a characteristic of

Streamline Flow : When the flow is steady,

streamlines are often used to represent the

trajectories of the fluid particles. A streamline is a

line drawn in the fluid such that a tangent to the

streamline at any point is parallel to the fluid

velocity at that point. Steady flow is often called

streamline flow.

Reynolds Number

The flow regime (either laminar or turbulent) is

determined by evaluating the Reynolds number of the

flow .The Reynolds number, based on studies of

Osborn Reynolds, is a dimensionless number

comprised of the physical characteristics of the flow.

where: Re = Reynolds number (unit less) V = average

velocity (ft/sec) D = diameter of pipe (ft) μ = absolute

viscosity of fluid (lbf-sec/ft2) For practical purposes, if

the Reynolds number is less than 2100, the flow is

laminar. If it is greater than 4000, the flow is turbulent.

Flows with Reynolds numbers between 2100 and

4000 are sometimes referred to as transitional flows.

Most fluid systems in nuclear facilities operate with

turbulent flow.

Significance of Reynolds Number

If the Reynolds number is less than 2100, the

flow is laminar. If it is greater than 4000, the flow

is turbulent.

Flows with Reynolds numbers between 2100 and

4000 are sometimes referred to as transitional

flows.

The fluid in the middle of the pipe will be moving

faster than the fluid next to the walls.

At constant velocity fluid can change from laminar

to turbulent if pipe diameters increased. Decrease

in viscosity due to temperature change may also

show similar effects.

Velocity Distribution

The velocity increases from zero at wall to max at

the axis of the tube. For Streamline flow .

The graph of velocity Vs Distance from the wall is

parabola, sharply pointed at middle. Ave. V = ½

Vmax.

For turbulent flow The graph is some what

flattened in the middle and Ave. V =0.8 Vmax.

Velocity profile for turbulent flow Velocity profile if

flow were laminar everywhere

Velocity profile inside a pipe

Bernoulli’s Theorem

Bernoulli's principle states that for an inviscid

flow, an increase in the speed of the fluid occurs

simultaneously with a decrease in pressure or a

decrease in the fluid's potential energy.

Bernoulli's principle can be applied to various

types of fluid flow, resulting in what is loosely

denoted as Bernoulli's equation.

Simplified form of Bernoulli’s

Equation

In many applications of Bernoulli's equation, the

change in the ρ g z term along the streamline is so

small compared with the other terms it can be

ignored. For example, in the case of aircraft in flight,

the change in height z along a streamline is so small

the ρ g z term can be omitted. This allows the above

equation to be presented in the following simplified

form:

where p0 is called total pressure, and q is dynamic

pressure. Many authors refer to

the pressure p as static pressure to distinguish it from

total pressure p0 and dynamic pressure q.

The simplified form of Bernoulli's equation can be

summarized in the following memorable word equation:

static pressure + dynamic pressure = total pressure Every

point in a steadily flowing fluid, regardless of the fluid

speed at that point, has its own unique static

pressure p and dynamic pressure q. Their sum p + q is

defined to be the total pressure p0. The significance of

Bernoulli's principle can now be summarized as total

pressure is constant along a streamline.

If the fluid flow is irrotational, the total pressure on every

streamline is the same and Bernoulli's principle can be

summarized as total pressure is constant everywhere in

the fluid flow. It is reasonable to assume that irrotational

flow exists in any situation where a large body of fluid is

flowing past a solid body. Examples are aircraft in flight,

and ships moving in open bodies of water. However, it is

important to remember that Bernoulli's principle does not

apply in the boundary layer or in fluid flow through

long pipes.

Compressible flow in fluid

dynamics

For a compressible fluid, with a barotropic equation of state, and

under the action of conservative forces, (constant along a

streamline)where:

p is the pressure ρ is the density , v is the flow speed ,Ψ is the

potential associated with the conservative force field, often

the gravitational potential. In engineering situations, elevations

are generally small compared to the size of the Earth, and the

time scales of fluid flow are small enough to consider the

equation of state as adiabatic. In this case, the above equation

becomes

(constant along a streamline)where, in addition to the terms listed

above:

γ is the ratio of the specific heats of the fluid, g is the

acceleration due to gravity ,z is the elevation of the point above a

reference plane. In many applications of compressible flow,

changes in elevation are negligible compared to the other terms,

so the term g and z can be omitted. A very useful form of the

equation is then:

where:

p0 is the total pressure

ρ0 is the total density

Introduction to Rocket Nozzles

A rocket engine nozzle is a propelling

nozzle usually of the de Laval type used in

a rocket engine to expand and accelerate the

combustion gases, from burning propellants, so

that the exhaust gases exit the nozzle

at hypersonic velocities.

Figure showing a simple de Laval nozzle

Criterion for 1-D gas flow in rocket

nozzles

Combustion gas is assumed to be IDEAL GAS.

Gas flow is

ISENTROPIC,FRICTIONLESS,ADIABATIC.

Gas flow is constant.

Gas flow is along a straight line from gas inlet to

exhaust gas outlet.(i.e. along the nozzle’s axis of

geometry)

Gas flow behavior is compressible since the flow is at

very high velocities

Design of Nozzles based on Nozzle

performance

As the combustion gas enters the rocket nozzle, it is

traveling at subsonic velocities. As the throat

contracts down the gas is forced to accelerate until at

the nozzle throat, where the cross-sectional area is

the smallest, the linear velocity becomes sonic. From

the throat the cross-sectional area then increases, the

gas expands and the linear velocity becomes

progressively more supersonic.

The linear velocity of the exiting exhaust gases can

be calculated using the following equation

where: Ve= Exhaust velocity at nozzle exit,

m/sT= absolute temperature of inlet gas, K

R= Universal gas law constant = 8314.5 J/(kmol·K)

M= the gas molecular mass, kg/kmol (also known

as the molecular weight)

k= cp / cv = isentropic expansion factor

cp= specific heat of the gas at constant pressure

cv= specific heat of the gas at constant volume

Pe= absolute pressure of exhaust gas at nozzle

exit, Pa

P= absolute pressure of inlet gas, Pa

Some typical values of the exhaust gas velocity Ve for

rocket engines burning various propellants are:

1.7 to 2.9 km/s (3800 to 6500 mi/h) for

liquid monopropellants

2.9 to 4.5 km/s (6500 to 10100 mi/h) for

liquid bipropellants

2.1 to 3.2 km/s (4700 to 7200 mi/h) for solid

propellants

As a note of interest, Ve is sometimes referred to as

the ideal exhaust gas velocity because it based on the

assumption that the exhaust gas behaves as an ideal

gas.

Specific Impulse

Thrust is the force which moves a rocket through

the air, and through space. Thrust is generated by

the propulsion system of the rocket through the

application of Newton's third law of motion: "For

every action there is an equal and opposite

reaction". A gas or working fluid is accelerated out

the rear of the rocket engine nozzle and the

rocket is accelerated in the opposite direction.

The thrust of a rocket engine nozzle can be

defined as

F

and for perfectly expanded nozzles, this reduces to:

F

The specific impulse, Isp, is the ratio of the amount of

thrust produced to the weight flow of the propellants.

It is a measure of the fuel efficiency of a rocket

engine.

It is observed exhaust velocity which is the most

prominent factor which governs the design of a

nozzle depends on four major factors.

1.Pressure

2.Temperature

3.Friction/Air drag

4.Nozzle geometry

Conclusions

I would like to conclude saying that altering

physical parameters like pressure and

temperature would enhance the working of a

nozzle and thereby also provides a better nozzle

efficiency.

Better optimization of the physical parameters is

a must for the proper working and safety of the

nozzle as well as the engine also.

Potrebbero piacerti anche

- Asymptotic Theory of Supersonic Viscous Gas FlowsDa EverandAsymptotic Theory of Supersonic Viscous Gas FlowsVladimir NeylandNessuna valutazione finora

- Computational Fluid Mechanics: Selected PapersDa EverandComputational Fluid Mechanics: Selected PapersNessuna valutazione finora

- Differential Transformation Method for Mechanical Engineering ProblemsDa EverandDifferential Transformation Method for Mechanical Engineering ProblemsNessuna valutazione finora

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsDa EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNessuna valutazione finora

- One-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesDa EverandOne-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesNessuna valutazione finora

- Space Technology Section-A, Module -1, Lecture-2 Class 2Documento7 pagineSpace Technology Section-A, Module -1, Lecture-2 Class 2Sid Siddapa SidhuNessuna valutazione finora

- Practical Chemical Thermodynamics for GeoscientistsDa EverandPractical Chemical Thermodynamics for GeoscientistsNessuna valutazione finora

- Transition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980Da EverandTransition and Turbulence: Proceedings of a Symposium Conducted by the Mathematics Research Center, the University of Wisconsin–Madison, October 13–15, 1980Nessuna valutazione finora

- Lid Driven Cavity Flow OK Final EldwinDocumento33 pagineLid Driven Cavity Flow OK Final Eldwineldwin_dj7216Nessuna valutazione finora

- Introduction To Convective Heat Transfer Analysis Chapter 8 PDFDocumento84 pagineIntroduction To Convective Heat Transfer Analysis Chapter 8 PDFhenrengNessuna valutazione finora

- Lecture Notes On Fluid MechanicsDocumento16 pagineLecture Notes On Fluid Mechanicssakura9999Nessuna valutazione finora

- Ehlen Fluent DeutschlandDocumento43 pagineEhlen Fluent DeutschlandAhmed AhmedovNessuna valutazione finora

- A Review of Heat Transfer and Pressure Drop Correlations For Laminar Flow in Curved Circular DuctsDocumento26 pagineA Review of Heat Transfer and Pressure Drop Correlations For Laminar Flow in Curved Circular DuctsRiddhesh PatelNessuna valutazione finora

- Fluid DynamicsDocumento53 pagineFluid DynamicsMuaz MushtaqNessuna valutazione finora

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationDa EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNessuna valutazione finora

- Potential FlowsDocumento13 paginePotential FlowsJuan Gonzalez100% (1)

- Boundary Layer and Flow Control: Its Principles and ApplicationDa EverandBoundary Layer and Flow Control: Its Principles and ApplicationNessuna valutazione finora

- Mae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsDocumento28 pagineMae 4262: Rockets and Mission Analysis: Combustion Overview For Rocket ApplicationsmibarjanNessuna valutazione finora

- Gas Dynamics and Jet PropulsionDocumento317 pagineGas Dynamics and Jet PropulsionVinoth RajaguruNessuna valutazione finora

- Venturi, Orifice, RotameterDocumento34 pagineVenturi, Orifice, RotameterVinod VadithyaNessuna valutazione finora

- Thermal engineering A Clear and Concise ReferenceDa EverandThermal engineering A Clear and Concise ReferenceNessuna valutazione finora

- Motion of Particles in FluidDocumento26 pagineMotion of Particles in FluidSubakti HungNessuna valutazione finora

- Initial-Boundary Value Problems and the Navier-Stokes EquationsDa EverandInitial-Boundary Value Problems and the Navier-Stokes EquationsNessuna valutazione finora

- Introduction To Computational Fluid Dynamics: Course Notes (CFD 4)Documento24 pagineIntroduction To Computational Fluid Dynamics: Course Notes (CFD 4)Amine Abd AlahNessuna valutazione finora

- Annular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsDocumento9 pagineAnnular Condensation CFD Models For The Water-Steam in The Heat Pipe SystemsRashed KaiserNessuna valutazione finora

- Shock Response Spectrum at Low FrequenciesDocumento10 pagineShock Response Spectrum at Low FrequenciesjackNessuna valutazione finora

- Flow Analysis in A Convergent-Divergent Nozzle Using CFDDocumento9 pagineFlow Analysis in A Convergent-Divergent Nozzle Using CFDsaradhi198Nessuna valutazione finora

- Thermoviscous Flow ReportDocumento20 pagineThermoviscous Flow ReportSoham SahaNessuna valutazione finora

- Factorization Methods for Discrete Sequential EstimationDa EverandFactorization Methods for Discrete Sequential EstimationNessuna valutazione finora

- Drag Force ReportDocumento8 pagineDrag Force ReportMateus RodriguesNessuna valutazione finora

- 312H Project - FinalDocumento39 pagine312H Project - Finalpmd5102100% (3)

- Bernoulli Chapter 3 PDFDocumento45 pagineBernoulli Chapter 3 PDFMirrovshan SagdullaevNessuna valutazione finora

- Transient Compressible Flow Inside Convergent Divergent NozzleDocumento45 pagineTransient Compressible Flow Inside Convergent Divergent NozzlelitonNessuna valutazione finora

- Turbomolecular PumpDocumento10 pagineTurbomolecular PumpMustafa SayyedNessuna valutazione finora

- Measure Lift and Drag on an AirfoilDocumento11 pagineMeasure Lift and Drag on an AirfoilFanis VlazakisNessuna valutazione finora

- Kinematics of Fluid Flow Its ApplicationDocumento26 pagineKinematics of Fluid Flow Its ApplicationProf. Avinash Mahale50% (2)

- Axial Fan NotchDocumento3 pagineAxial Fan NotchhahasiriusNessuna valutazione finora

- Experiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsDocumento10 pagineExperiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsAbdullah Alshihri100% (1)

- Nasa TN D-8431Documento234 pagineNasa TN D-8431HarryjoshiNessuna valutazione finora

- Experimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsDa EverandExperimental Thermodynamics: Experimental Thermodynamics of Non-Reacting FluidsB. Le NeindreNessuna valutazione finora

- Mechanics of Liquids and Gases: International Series of Monographs in Aeronautics and Astronautics: Division II: AerodynamicsDa EverandMechanics of Liquids and Gases: International Series of Monographs in Aeronautics and Astronautics: Division II: AerodynamicsNessuna valutazione finora

- Drag Coefficient and Settling Velocity For Particles of Cylindrical ShapeDocumento9 pagineDrag Coefficient and Settling Velocity For Particles of Cylindrical ShapekubacrNessuna valutazione finora

- Bourdon Tube: Prepared ByDocumento20 pagineBourdon Tube: Prepared BySaptarshi Panda100% (6)

- Achieving static and dynamic balanceDocumento13 pagineAchieving static and dynamic balanceTuanbk NguyenNessuna valutazione finora

- ORIFICEMETER + ROTAMETERDocumento19 pagineORIFICEMETER + ROTAMETERZaidNessuna valutazione finora

- Effi Cient Liquid CoolingDocumento44 pagineEffi Cient Liquid CoolingHavana AveiroNessuna valutazione finora

- Principles of Flight Easa Part-Fcl - PPL (A)Documento28 paginePrinciples of Flight Easa Part-Fcl - PPL (A)Helder AlvesNessuna valutazione finora

- Reverse OsmosisDocumento53 pagineReverse Osmosisanabloom100% (2)

- Kombi F - V4 BLC GP16 - ENGDocumento12 pagineKombi F - V4 BLC GP16 - ENGradi firmandaniNessuna valutazione finora

- Time Table: Semest Er Subject Name Subject Code Exam Date SessionDocumento79 pagineTime Table: Semest Er Subject Name Subject Code Exam Date SessionRachel DelgadoNessuna valutazione finora

- Lect7 Mechanical PropertiesDocumento44 pagineLect7 Mechanical PropertieskaranNessuna valutazione finora

- A Theoretical Justification For The Application of The Arrhenius Equation To Kinetics of Solid State Reactions (Mainly Ionic Crystals)Documento12 pagineA Theoretical Justification For The Application of The Arrhenius Equation To Kinetics of Solid State Reactions (Mainly Ionic Crystals)Mwengei MutetiNessuna valutazione finora

- SC4379-461-02 Fo Transfer SystemDocumento13 pagineSC4379-461-02 Fo Transfer SystemChandni JhaNessuna valutazione finora

- Porosity and Permeability Lab WorksheetDocumento3 paginePorosity and Permeability Lab Worksheetapi-318680005100% (1)

- Thermal Engineering Steam Nozzle NotesDocumento18 pagineThermal Engineering Steam Nozzle Notesgopi100% (1)

- Tesla R32 Heat Pump Air To Water TGTP-8HMDA1 Spec 2023 ENGDocumento1 paginaTesla R32 Heat Pump Air To Water TGTP-8HMDA1 Spec 2023 ENGAnonymous LDJnXeNessuna valutazione finora

- SB41Documento1 paginaSB41bhaaskarNessuna valutazione finora

- Catalogo Secadores Spray - GEA (Niro)Documento9 pagineCatalogo Secadores Spray - GEA (Niro)San ApolonioNessuna valutazione finora

- WeirDocumento12 pagineWeirBabylyn Austria100% (1)

- Reliable Vertical Pump for Chemical ApplicationsDocumento8 pagineReliable Vertical Pump for Chemical ApplicationsMehmet ArvasiNessuna valutazione finora

- Chemical EORDocumento56 pagineChemical EORAugusto Viera ZapataNessuna valutazione finora

- UCK351E Fall2012 M1QsDocumento2 pagineUCK351E Fall2012 M1QsEser GülNessuna valutazione finora

- Technical Information: Loop Flushing ValveDocumento8 pagineTechnical Information: Loop Flushing ValveanandsubbiahNessuna valutazione finora

- Chapter 4 - PermeabilityDocumento44 pagineChapter 4 - PermeabilityAfnan HamimiNessuna valutazione finora

- 2013-'14 TE-II Schedule, Question Bank & Bit BankDocumento26 pagine2013-'14 TE-II Schedule, Question Bank & Bit BankHerbert DeepakNessuna valutazione finora

- Ten Misconceptions On Rotary PD Pumps: Practice + OperationsDocumento3 pagineTen Misconceptions On Rotary PD Pumps: Practice + Operationssushant_jhawerNessuna valutazione finora

- Principles and Practice of Flow Meter Engineering - L K SpinkDocumento231 paginePrinciples and Practice of Flow Meter Engineering - L K SpinkAlberto Marsico33% (3)

- The Design and Testing of A Winglet Airfoil For Low-Speed AircraftDocumento11 pagineThe Design and Testing of A Winglet Airfoil For Low-Speed AircraftJulio Herrera VenegasNessuna valutazione finora

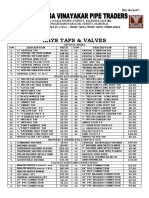

- Rays Taps & Valves: Sell The Best! Buy The Best!!Documento3 pagineRays Taps & Valves: Sell The Best! Buy The Best!!annamalaicvNessuna valutazione finora

- Improved Steam Condenser Gas Removal SystemDocumento7 pagineImproved Steam Condenser Gas Removal Systemtfernandes.x18Nessuna valutazione finora

- PARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGDocumento26 paginePARTIAL CONDENSER DESIGN CHEMICAL ENGINEERINGsegunju50% (2)

- Tyre PyrolysisDocumento6 pagineTyre PyrolysisHande CambazNessuna valutazione finora

- Stormwater Worksheet ConnorDocumento2 pagineStormwater Worksheet Connorapi-507049229Nessuna valutazione finora

- 2020.09.24 OLV & MSV Lead Piping DiscussionDocumento11 pagine2020.09.24 OLV & MSV Lead Piping DiscussionAswindana Ibnu SenaNessuna valutazione finora