Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

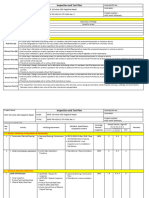

Unit V Energy Conservation Opportunities

Caricato da

Rajesh Bhaskarla0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni25 pagineConservation opportunities in boilers and chillers

Titolo originale

UNIT V

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoConservation opportunities in boilers and chillers

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni25 pagineUnit V Energy Conservation Opportunities

Caricato da

Rajesh BhaskarlaConservation opportunities in boilers and chillers

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 25

UNIT V

Energy Conservation Opportunities

Chilled Water Plants

Central Air conditioning system

Potential Energy Conservation Opportunities in Chilled Water

Plants and Central Air-conditioning systems

• Chiller retrofits

• Cooling tower retrofits

• Check expansion and compression tank sizes

• Replacements of air conditioning and heating units with heat pumps

• Replacement of inefficient window air conditioners with SEER >9.0

seasonal energy efficiency ratio (SEER) which is defined by the

Air Conditioning, Heating, and Refrigeration Institute in its 2008 standard

AHRI 210/240

• Resizing of chillers

• Retrofit with higher cop equipment

• Stain of multiple chillers

• Utilize gas absorption chillers

• Refrigerator replacement with high efficiency units

• Install cold storage system

• Install thermal energy storage systems

Water Heater

Potential Energy Conservation opportunities in Water Heaters

• Install decentralized water heaters

• Install ground water source heat pumps

• Install water heater blankets on water heaters

• Preheat feed water with reclaimed waste heat to reduce hot water heating system losses

• replace forced heaters with radiant heaters

• Use energy efficient system by analysing its efficiency

• Use heat pump water heaters

• Use of absorption to reduce electric demand

• Heat recovery for water heating

• Reclaim heat from waste water, steam condensate, incirnator heat

• Solar domestic hot water

• Installation of water meter

• install cleaning equipment for rinsing and cleaning

• Install hot water supply temperature reset control system

• Install duty cycle control system

• Reduce hot water consumption

Energy conservation opportunities in water coolers

• Install economizer cooling systems

• Install evaporative precooling on 100% make up air

• Install evaporative cooled or water cooled condensors.

• Evaporative cooling systems – install submeters

• Install double bundle chillers

• Equipment cooling, cool air compressors with closed loop system

• Repair existing equipment- evaporative cooling systems

• Install softeners, sub meters for make up water

• Plating and metal finishing – treat rinse water

• Rinsing and cleaning- install ultrasonic cleaning equipment, water saving

technologies, flow reduction devices, less water use, install timers and tamper

proof conductivity controllers to control quality of water in rinses.

• Clean evaporator and condensator equipment

• Lower cooling temperature set points.

• Install duty cycling control systems

• Install chilled water supply temperature reset control system

Compressor / Fan

Compressor Fans

Potential Energy Conservation opportunities in Compressors and Fans

• Create air movement with fans

• Duty cycle demand control

• Replacement of fans and pump

• Free cooling injector cycle

• Heat recovery from cooling oil, de super heating

• Insulation of low side refrigerant lines

• Investigate use of gas engine driven chillers

• Isolate offline chillers and cooling system

• Reduce system flow rate when not required

• Reducing compressor speed in over capacity system

• Reduction of non condensable gases in the system

• Variable speed drivers for fans and pumps

• Installation of compressed air metering

• Installation of gas meters

• Reduce excessive line air pressure losses, line air pressure

• Replace existing compressors with more efficient once.

• Use energy efficient air blow off nozzles, air drying systems, air intake filters

• Use outside intake air for air compressors.

Heat Pump

Potential Conservation opportunities in

Heat Pumps and Cooling systems

• Install booster pumps on hot water systems

• Install add on heat pumps

• Install roof spray cooling systems

• Install secondary pumping systems

Reference:

Energy Engineering and Management by Amlan

Chakrabarti, PHI Learning Private Ltd

We have completed our discussion on…

Energy conservation checklist, Energy conservation

opportunities in boilers, Heat pumps and cooling

systems, chilled water Plants and Central air-

conditioning systems, Water Heaters and coolers,

Compressors and Fans.

1. Exhaust rate adjustment

2. Heat Recovery and reheating system

3. Humidity control system

4. Use of insulation

5. Openings of seal oven

6. Variable speed recirculation fan

7. Idle mode

8. Maintenance of equipment

9. Installation of new/automated equipment

1. Exhaust rate adjustment

2. Heat Recovery system

3. Humidity control system

4. Use of insulation

5. Openings of seal oven

6. Variable speed recirculation fan

7. Idle mode

8. Maintenance of equipment

9. Installation of new/automated equipment

Opportunities in Boilers, Heaters, Heat

Pumps,

Improving insulation

Checking fouling, scaling inside boilers

Converting hard water to soft water

Installation of steam meters

Installation of boiler retrofits

Installation of condensator lines/pipes

Controlling evapouration

Controlling heat rate

Controlling exhaust / flue gases

Installation of variable duty cycle in the operation of boiler

Reducing steam leakage

Remove scales from watert

Optimising boiler steam pressure

Using closed loop sontril systems

Installing energy efficient bnoiler systesm

Closing the valvues at appropriate time

Maintaining feed water

Using preheating of water

Reheating

Superheater

Instal new boilers

Idle mode

Opportunities in cooling systems- chillers,

water coolers, Central Air conditioners

• Maintaining psycometric properties

• Checking temperature, humidity

• Shutting down when not in use

• Heat recovery

• Reduce frost formation

• Mainatainance of pipes evaporation and condensation

• Installation of cold storage systems

• Retrofits

• Install submeters

• Multiple compressors

• Monitoring the cooling systems

• Replacing with good thermodynamic refrigirent

• Insulation protection

• Detecting leakages

• Checking the gas pressure

• Installing gas pressure meters

• Closed loop controller

• Variable duty cycle operation

• Idle mode operation

Potrebbero piacerti anche

- Heat PumpDocumento60 pagineHeat PumpAitazaz Ahsan100% (1)

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewDa EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNessuna valutazione finora

- Unit I Basic Principles of Energy Audit: Prepared by Mr.B.Rajesh Assistant Professor, Department of EEE, VjitDocumento43 pagineUnit I Basic Principles of Energy Audit: Prepared by Mr.B.Rajesh Assistant Professor, Department of EEE, VjitRajesh Bhaskarla100% (1)

- Thyssen Krupp Synergy-Elevator PDFDocumento16 pagineThyssen Krupp Synergy-Elevator PDFAgnelo FernandesNessuna valutazione finora

- Terminal Report OJT MTTDocumento4 pagineTerminal Report OJT MTTJun MichaelNessuna valutazione finora

- Chiller OperationDocumento15 pagineChiller OperationThars ShanNessuna valutazione finora

- Air Conditioning SystemsDocumento19 pagineAir Conditioning SystemskatherinewingettNessuna valutazione finora

- Dcb20053 - Topic 2Documento51 pagineDcb20053 - Topic 2Margerath TiongNessuna valutazione finora

- Hvac System and Fire Sprinkerler SystemsDocumento14 pagineHvac System and Fire Sprinkerler SystemsTatheer ZahraNessuna valutazione finora

- HVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerryDocumento29 pagineHVAC Equipment: MAE 406 Energy Conservation in Industry Stephen TerrySuresh KumarNessuna valutazione finora

- Energy Conservation MeasuresDocumento22 pagineEnergy Conservation MeasuresGritty VimalNessuna valutazione finora

- Unit 3 Energy ConservationnDocumento77 pagineUnit 3 Energy ConservationnAgent SmithNessuna valutazione finora

- Objective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutDocumento5 pagineObjective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutSuraj KumarNessuna valutazione finora

- Module 4 - Cooling TowerDocumento15 pagineModule 4 - Cooling Towermadan karkiNessuna valutazione finora

- Meg 5-LF-35-36 Aux Steam SystemDocumento23 pagineMeg 5-LF-35-36 Aux Steam SystemAkash KandwalNessuna valutazione finora

- MEBS6008 Heat PumpDocumento60 pagineMEBS6008 Heat Pumphvactrg1Nessuna valutazione finora

- Unit 22 CondensersDocumento42 pagineUnit 22 CondenserssprotkarNessuna valutazione finora

- CH2. Hot Water SupplyDocumento13 pagineCH2. Hot Water SupplyPubudu KalpageNessuna valutazione finora

- Career Point University Power Engineering AssignmentDocumento19 pagineCareer Point University Power Engineering AssignmentNaman SharmaNessuna valutazione finora

- Presentation On: Heating Ventilation and Air CondtioningDocumento36 paginePresentation On: Heating Ventilation and Air Condtioningaishwarya903100% (2)

- Solar AC (Compatibility Mode)Documento41 pagineSolar AC (Compatibility Mode)Jeniwer BimroNessuna valutazione finora

- HVAC ControlsDocumento24 pagineHVAC ControlsKunal DeshmukhNessuna valutazione finora

- Boiler Operation On DcsDocumento4 pagineBoiler Operation On Dcsarif100% (2)

- Presentation For Mechanical EngineeringDocumento31 paginePresentation For Mechanical EngineeringShashi Bhushan KumarNessuna valutazione finora

- Thermal Energy ManagementDocumento8 pagineThermal Energy ManagementlucasNessuna valutazione finora

- Air Conditioning SystemDocumento46 pagineAir Conditioning SystemNurFarahinZakariahNessuna valutazione finora

- 2434 Chapter 2Documento25 pagine2434 Chapter 2Nagwa MansyNessuna valutazione finora

- Plumbing Systems - Hot Water Heating Keyword(s)Documento1 paginaPlumbing Systems - Hot Water Heating Keyword(s)Ann NambiaparambilNessuna valutazione finora

- Lecture 5 - Compression Refrigeration Systems 1Documento19 pagineLecture 5 - Compression Refrigeration Systems 1santiago ValleNessuna valutazione finora

- Building Services - Iv: Heating Ventilation and Air Conditioning Asst. Prof. EMIE B. FAIRDocumento16 pagineBuilding Services - Iv: Heating Ventilation and Air Conditioning Asst. Prof. EMIE B. FAIRKrishnapriya KNessuna valutazione finora

- Unit 22 CondensersDocumento26 pagineUnit 22 CondensersDebapratim Debnath0% (1)

- B7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallDocumento30 pagineB7.2KENNEDYKILTECHIDEA Presentation Miami June 2013smallSMBEAUTYNessuna valutazione finora

- Process UtilityDocumento13 pagineProcess UtilityAnupam Manoj100% (1)

- Operation and Maintenance of Chillers: TopicsDocumento10 pagineOperation and Maintenance of Chillers: TopicsMohammed AbbasNessuna valutazione finora

- The Facility Files 1 12Documento1 paginaThe Facility Files 1 12sajuhereNessuna valutazione finora

- Hot Water Heating SystemsDocumento36 pagineHot Water Heating SystemsSanju YallaNessuna valutazione finora

- Fluidos Termicos y Circuitos de CalentamientoDocumento38 pagineFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNessuna valutazione finora

- Hot Water SupplyDocumento21 pagineHot Water Supplybabita_gadbail21Nessuna valutazione finora

- Steam Jet Refrigeration SystemDocumento9 pagineSteam Jet Refrigeration SystemHenok GhidayNessuna valutazione finora

- Solar Water Heating & Solar Power SystemDocumento15 pagineSolar Water Heating & Solar Power SystemShivang KumarNessuna valutazione finora

- Module 3 - Chiller SystemDocumento45 pagineModule 3 - Chiller Systemmadan karkiNessuna valutazione finora

- Energy Efficiency in Thermal UtilitiesDocumento14 pagineEnergy Efficiency in Thermal UtilitiesJoeb DsouzaNessuna valutazione finora

- 2009-08 EMOs For Cooling SystemsDocumento4 pagine2009-08 EMOs For Cooling Systemsnikola ilicNessuna valutazione finora

- HVAC and Refrigeration SystemDocumento36 pagineHVAC and Refrigeration Systemranveer100% (1)

- AHA Fact Sheet 4. HEATING VENTILATION PDFDocumento5 pagineAHA Fact Sheet 4. HEATING VENTILATION PDFEnyinnayaOnwubikoNessuna valutazione finora

- Chapter 2 - Air Conditioning System - Part 2Documento23 pagineChapter 2 - Air Conditioning System - Part 2khairul izzudinNessuna valutazione finora

- Geothermal Heat Pump Systems PresentationDocumento33 pagineGeothermal Heat Pump Systems Presentationsolowe988Nessuna valutazione finora

- Air CycleDocumento30 pagineAir CycleSalokya KhandelwalNessuna valutazione finora

- Steam Generators 2Documento33 pagineSteam Generators 2gbharathreddysNessuna valutazione finora

- Modern Solutions For Boilers-"Walls" Integrated Units.: o o o o oDocumento13 pagineModern Solutions For Boilers-"Walls" Integrated Units.: o o o o oMacovei AlinNessuna valutazione finora

- RefrigerantsDocumento33 pagineRefrigerantsArun Raj.MNessuna valutazione finora

- Chilled - Water Systems - EMERSONDocumento32 pagineChilled - Water Systems - EMERSONInventor Solidworks100% (1)

- Air ConditioningDocumento22 pagineAir ConditioningEmmanuel BuhwaNessuna valutazione finora

- BoilerDocumento10 pagineBoilerkanbouchNessuna valutazione finora

- Chapter 1. BoilersDocumento74 pagineChapter 1. BoilersJms LebronNessuna valutazione finora

- Refrigeration Equipment: Heat Recovery 239Documento2 pagineRefrigeration Equipment: Heat Recovery 239Rohit ShresthaNessuna valutazione finora

- ChillersDocumento7 pagineChillersaldz5100% (1)

- Lecture 7Documento13 pagineLecture 7Shubham SinghNessuna valutazione finora

- Solar Heating: Solar Energy Can Be Used For - Solar Water Heating - Solar Space Heating - Solar Pool HeatingDocumento31 pagineSolar Heating: Solar Energy Can Be Used For - Solar Water Heating - Solar Space Heating - Solar Pool HeatingThiaga RajanNessuna valutazione finora

- Air PanassDocumento10 pagineAir PanassSyaza FieqaNessuna valutazione finora

- Cooling Water BasicsDocumento163 pagineCooling Water BasicsTin Aung Kyi94% (16)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesDa EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNessuna valutazione finora

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDa EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNessuna valutazione finora

- Hybrid Vehicles Transmission DiagramsDocumento25 pagineHybrid Vehicles Transmission DiagramsRajesh BhaskarlaNessuna valutazione finora

- Unit I-EvhvDocumento98 pagineUnit I-EvhvRajesh BhaskarlaNessuna valutazione finora

- EVHV20 IntroductionDocumento19 pagineEVHV20 IntroductionRajesh BhaskarlaNessuna valutazione finora

- Bimbhra Power ElectronicsDocumento596 pagineBimbhra Power ElectronicsRajesh BhaskarlaNessuna valutazione finora

- PE Question BankDocumento4 paginePE Question BankRajesh BhaskarlaNessuna valutazione finora

- Eac Unit Ii PFDocumento32 pagineEac Unit Ii PFRajesh BhaskarlaNessuna valutazione finora

- Power System Planning: PGPEPS204T Elective IIIDocumento2 paginePower System Planning: PGPEPS204T Elective IIIRajesh BhaskarlaNessuna valutazione finora

- Unit I-EvhvDocumento49 pagineUnit I-EvhvRajesh BhaskarlaNessuna valutazione finora

- 710713RA Solenoid ValvesDocumento2 pagine710713RA Solenoid ValvesEDUARDOMTZNessuna valutazione finora

- Data Center Construction MarketDocumento13 pagineData Center Construction MarketHarsh mishraNessuna valutazione finora

- Lift Maintenance Outcome GuidebookDocumento44 pagineLift Maintenance Outcome GuidebookKayeyera LawrenceNessuna valutazione finora

- James StirlingDocumento30 pagineJames StirlingRajniNessuna valutazione finora

- FUS ON: Experiencing Fusion Site PlanDocumento1 paginaFUS ON: Experiencing Fusion Site PlanNikola Dredge TristaniNessuna valutazione finora

- B V DoshiDocumento30 pagineB V DoshiJeeva Z FedricoNessuna valutazione finora

- Noise Guide For Local GovernmentDocumento187 pagineNoise Guide For Local GovernmenttertfgdfgdfgdfgdggdNessuna valutazione finora

- Design and Analysis of G+3 Building by Using Staad Pro: Mini ProjectDocumento10 pagineDesign and Analysis of G+3 Building by Using Staad Pro: Mini ProjectsaikirankasivojjulaNessuna valutazione finora

- Steel QB With SolutionDocumento64 pagineSteel QB With SolutionShazNessuna valutazione finora

- Structural Investigation of Historic Buildings - David C FischettiDocumento10 pagineStructural Investigation of Historic Buildings - David C FischettiMohammad Javad AarabiNessuna valutazione finora

- Professor Joe Greene Csu, ChicoDocumento15 pagineProfessor Joe Greene Csu, ChicoTushar Prakash ChaudhariNessuna valutazione finora

- Tailift FBT18-20 Displ Zapi GrandeDocumento203 pagineTailift FBT18-20 Displ Zapi Granderodrigo aguilarNessuna valutazione finora

- Nmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)Documento8 pagineNmif-pip-Ado-cl-itp-p-001 Rev. 0 - (16 Inches Ado Cargoline Repair)parangkilalakitaNessuna valutazione finora

- Main Villa GF Arc Window Schedule 02Documento1 paginaMain Villa GF Arc Window Schedule 02MiteshSuneriyaNessuna valutazione finora

- Workplace Inspection Checklist TemplateDocumento5 pagineWorkplace Inspection Checklist Templatemyo lwinNessuna valutazione finora

- An Experimental Casting of Light Transmitting Concrete Panel Using Optical Fibres To Check Strength CriteriaDocumento6 pagineAn Experimental Casting of Light Transmitting Concrete Panel Using Optical Fibres To Check Strength CriteriaIJAMTESNessuna valutazione finora

- Maintenance of Chiksan Valves and Swivel JointsDocumento4 pagineMaintenance of Chiksan Valves and Swivel JointsTg TarroNessuna valutazione finora

- Conpipe - CementlingDocumento43 pagineConpipe - Cementlingויליאם סן מרמיגיוס50% (2)

- 32 Samss 007Documento38 pagine32 Samss 007sanketNessuna valutazione finora

- JKR Standard TilingDocumento3 pagineJKR Standard TilingEzumi HarzaniNessuna valutazione finora

- Offshore Platform Installation PDFDocumento25 pagineOffshore Platform Installation PDFdndudc100% (1)

- Addendum To Standard Bidding Document Procurement of Civil WorksDocumento29 pagineAddendum To Standard Bidding Document Procurement of Civil WorksvivekNessuna valutazione finora

- Axle ShaftsDocumento13 pagineAxle ShaftsankitsarvaiyaNessuna valutazione finora

- HORMANN Industrial Sectional Doors Depth 42 MM enDocumento3 pagineHORMANN Industrial Sectional Doors Depth 42 MM enAndonie Alina CristinaNessuna valutazione finora

- Avoiding Danger From Overhead Power Lines: Guidance Note GS6 (Fourth Edition)Documento12 pagineAvoiding Danger From Overhead Power Lines: Guidance Note GS6 (Fourth Edition)Shahir IbrahimiNessuna valutazione finora

- 9 TH Plate (Sub)Documento12 pagine9 TH Plate (Sub)hemantNessuna valutazione finora

- (Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Documento168 pagine(Msia) Guide To Sewer Selection and Installation (Dec2006) - VC Pipe pg17Rachael Hoo100% (7)