Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CP Inspection

Caricato da

khanhtruongTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CP Inspection

Caricato da

khanhtruongCopyright:

Formati disponibili

CATHODIC PROTECTION

SERVICES FOR

UNDERGROUND

PIPELINES

January 15th, 2020

Bureau Veritas Vietnam

01 02

Cathodic Protection Pinpoint Target

Systems Customers

03 04

Overall Pipeline Personnel

Mappings Requirements

05 06

Equipment Competitors

Requirements

Agenda

© - Copyright Bureau Veritas 2

CATHODIC PROTECTION SYSTEMS

1. What Is Cathodic Protection?

Cathodic protection (CP) is a technique used

to control the corrosion of a metal surface by

making it the cathode of an electrochemical cell.

A simple method of protection connects the

metal to be protected to a more easily corroded

"sacrificial metal" to act as the anode.

2. How Does It Work?

The Cathodic Protection System serves as a

backup to the corrosion coating system. If the

corrosion coating system begins to fail, the

cathodic protection system should take over the

job of corrosion protection in the area of failure.

© - Copyright Bureau Veritas 3

CATHODIC PROTECTION SYSTEMS

Corrosion Control Techniques

The steel nails immersed in saline

Steel nails fixed to dry battery

water

terminals

1. The nail at +ve terminal

Corrodes

2. The nail at –ve terminal

remains Uncorroded

© - Copyright Bureau Veritas 4

CATHODIC PROTECTION SYSTEMS

CORROSION CONTROL METHODS

CATHODIC

PROTECTION

SYSTEMS

SACRIFICIAL IMPRESSED

ANODE CURRENT

© - Copyright Bureau Veritas 5

CATHODIC PROTECTION SYSTEMS

SACRIFICIAL ANODE SYSTEM IMPRESSED CURRENT SYSTEM

© - Copyright Bureau Veritas 6

CATHODIC PROTECTION SYSTEMS

© - Copyright Bureau Veritas 7

PINPOINT TARGET CUSTOMERS

There are three major domestic clients with large scale underground pipeline

networks that can enable our business growth in Cathodic Protection services;

1. NAM CON SON PIPELINE COMPANY

2. PETROVIETNAM GAS SOUTH EAST TRANSMISSION COMPANY

3. PETROVIETNAM GAS CA MAU COMPANY

© - Copyright Bureau Veritas 8

PINPOINT TARGET CUSTOMERS

1. Nam Con Son Pipeline

The Nam Con Son Pipeline (NCSP) is operating:

The two condensate storage tanks (T3005 and T3006) located within the NCSP Terminal at

Dinh Co – Ba Ria – Vung Tau, Vietnam.

The approx. 9km, 26” onshore gas/condensate pipeline from the Long Hai landfall, Ba Ria –

Vung Tau, to the NCSP Terminal.

The approx. 29km, 30” onshore gas pipeline from the NCSP Terminal to the Gas Distribution

Center (GDC), operated by Petro Vietnam Gas Company (PV Gas), at Phu My – Ba Ria –

Vung Tau.

The approx. 0.8km, 6” NCSP condensate pipeline from the NCSP Terminal to the Gas

Processing Plant (GPP), operated by PV Gas, at Dinh Co – Ba Ria – Vung Tau.

The cathodic protection systems designed to provide external corrosion control to these

structures. The pipelines run parallel in the shared pipeline corridor that basically begins at the

Long Hai landfall to the Phu My GDC.

© - Copyright Bureau Veritas 9

PINPOINT TARGET CUSTOMERS

1. Nam Con Son Pipeline

Scope of work:

Measure and record the “as found” DC output of each rectifier.

Measure and record the On/Off structure-to-soil potentials at each test station.

Measure and record the instant-off potentials of the polarized coupons installed in the NCSP test stations.

Interrupt the rectifiers and conduct instant off potential measurement for the tanks.

Interrupt the rectifiers and conduct interference testing of foreign structures and earthing system (at section from

KP28+100 to Phu My GDC, at NCS Terminal, and Long Hai Valve Station).

Adjust the DC output of the rectifiers and resistor junction boxes (if necessary) to achieve full protection to the

structures.

Check the calibration of the DC meters.

Check the effectiveness of insulating joints.

Inspect Transformer-Rectifier Unit for any damage, rusting and oxidation of terminals. Clean the units if required.

Inspect interior, exterior, terminals, cables, resistors and shunts of junction boxes and test posts for any damage,

oxidation or tightened. Clean junction boxes, test posts and terminal connections, re-fix cable tag names or tighten

terminal connections if required. Grease terminal connections.

© - Copyright Bureau Veritas 10

PINPOINT TARGET CUSTOMERS

1. Nam Con Son Pipeline

Scope of work:

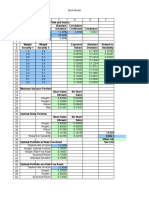

No. Scope of Work Descriptions Start day Finish day Days Quantity No. Scope of Work Descriptions Start day Finish day Days Quantity

Inspect all Transformer- 7 AC Current Attenuation Survey (PCM)

Rectifier Units at NCS 7.1 500m of 26’’ Inlet at Dinh Co

1 5 TRUs

Terminal, Phuoc Hoa Station

and GDC Phu My 7.2 300m of 30’’ Outlet at Dinh Co

Measure 'ON/OFF Tank to 7.3 500m of 30’’ Inlet at Phu My GDC

2.55km

2 soil and As Found potentials 2 Tanks KP 26+820 to KP 27+320 of 30’’ Gas

for two tanks 7.4

Pipeline

Check the effectiveness of all 750m of 6’’ Condensate Pipeline from

7.5

3 insulating joints ( MIJs and 7 MIJs and 30 IFs NCS to GPP Dinh Co

IFs) 8 Close Interval Potential Survey (CIPS)

Measure ON/OFF pipe to soil 26” onshore gas/condensate pipeline

8.1 9 km

and As-found potentials for 68 from Long Hai - NCS Terminal

Test Stations 30” onshore gas pipeline from the

8.2 29 km

4 + 37 Test Stations of NCS 68 TPs NCSP Terminal to GDC Phu My

pipeline 6” NCSP condensate pipeline from

+ 31 Test Stations of PVGas 8.3 0.8 km

the NCSP Terminal to GPP Dinh Co

SE Pipeline 9 Direct Current Voltage Gradient (DCVG)

Check condition/performance 26” onshore gas/condensate pipeline

5 protection of all sacrificial 13 Anodes 9.1 9.2 km

from Long hai - NCS Terminal

anodes 30” onshore gas pipeline from the

9.2 29 km

NCSP Terminal to GDC Phu My

Check condition/performance

6 protection of all Anode 82 Anodes 6” NCSP condensate pipeline from

Groundbeds 9.3 0.8 km

the NCSP Terminal to GPP Dinh Co

© - Copyright Bureau Veritas 11

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

PVGas SE currently operates three onshore pipeline systems at the south of Viet Nam:

Line 16A: the approximately 9 km 16-inch gas pipeline system from Long Hai to Dinh Co

Line 16B1: the approximately 7 km 16-inch gas pipeline system from Dinh Co to GDS Ba Ria

Line 16B2: The approximately 22 km 17-inch gas pipeline system from GDS Ba Ria to GDS Phu My;

Line 6A/6B/6C: the approximately 23 km 3-line x 6-inch liquid pipeline system from GPP to Thi Vai Terminal;

Line 22A; the approximately 38 km 22-inch gas pipeline system from Phu My to Hiep Phuoc;

The approximately 0.3 km 16-inch gas pipeline system from SDV X- 805 (16 inches) to SDV-803 (10 inches)

in GDS Ba Ria;

The approximately 1 km 12-inch gas pipeline system from GDC Nhon Trach to Nhon Trach Power Plant 1

The approximately 2 km 16-inch gas pipeline system from GDC Nhon Trach to Nhon Trach Power Plant 2

The approximately 1.5 km 12-inch gas pipeline system from GDS Hiep Phuoc to Hiep Phuoc Power Plant

The approximately 0.1 km 18-inch gas pipeline from Monolithic insulation joint MIJ-3304 to Monolithic

Insulation joint MIJ-3305 inside GDS Nhon Trach.

© - Copyright Bureau Veritas 12

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

Scope of Work

Direct Current Voltage Gradient (DCVG) survey and aid in identifying (interference, shorted casings, areas of

electrical or geologic current shielding, contact with other metallic structures and defective electrical insulation

joints, etc.

Inspection of electrical isolation flange, spark gap.

Inspection of the anode beds.

Soil resistivity at all the test station along the pipeline.

With some section of the pipeline run under road/track, it shall be surveyed with a suitable method to detect the

coating defects (ACVG, PCM).

Interrupt the rectifiers and conduct instant off potential measurements for all the test stations prior to performing the

DCVG survey.

Adjust the DC output of the rectifiers and resistor junction boxes (if necessary) to achieve full protection to the

structures.

Check the calibration of the DC meters.

Check the effectiveness of insulating joints.

Inspect Transformer-Rectifier Unit for any damage, rusting and oxidation of terminals. Clean the units if required.

Inspect interior, exterior, terminals, cables, resistors and shunts of junction boxes and test posts for any damage,

oxidation or tightened. Clean junction boxes, test posts and terminal connections, re-fix cable tag names or tighten

terminal connections if required. Grease terminal connections.

Interpretation of survey data and evaluate the status of pipeline coating (defect/location/sizing).

© - Copyright Bureau Veritas 13

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

Scope of Work

Finish Finish

No. Scope of Work Descriptions Start day Days Scope No. Scope of Work Descriptions Start day Days Scope

day day

Inspect Transformer-Rectifier Unit for any

6 Direct Current Voltage Gradient (DCVG) Survey

1 damage, rusting and oxidation of terminals. 08

Clean the units if required. 16-inch gas pipeline from Long Hai to Dinh

6.1 9km

Check the effectiveness of all insulating Co.

2 42 16-inch gas pipeline from Dinh Co Station to

joints (MIJs and IFs) 6.2 7km

Measure ON/OFF pipe to soil potentials for Ba Ria Station.

3 62

all Test Stations 17-inch gas pipeline from Ba Ria Station to

6.3 22km

Measure all soil resistivities at all Phu My GDC.

4 62

requirement locations 3x6inches liquid pipelines from Dinh Co GPP

6.4 23km

5 Close Interval Potential Survey (CIPS) to Thi Vai Station.

Measure ON/OFF potentials of 22-inch gas pipeline from Phu My GDC to

6.5 38km

5.1 3(6A/6B/6C) liquid pipelines from KP0+000 0.5km Hiep Phuoc Station.

to KP0+500. 16-inch gas pipeline from SDV X-805 to 10-

Measure ON/OFF potentials of 16-inch gas 6.6 inch gas pipeline SDV X-803 located inside 0.3km

5.2 1.95km

pipeline from KP0+000 to KP1+950. the GDC Nhon Trach.

Measure ON/OFF potentials of 17-inch gas 12-inch gas pipeline from GDC Nhon Trach to

6.7 1km

5.3 pipeline from KP30+745 to KP32+000 and 3.0km NMD Nhon Trach 1.

from KP36+260 to KP37+960. 16-inch gas pipeline from GDC Nhon Trach to

6.8 2km

Measure ON/OFF potentials of 12-inch gas NMD Nhon Trach 2.

5.4 pipeline from the flange of GDC Nhon 1km 12-inch gas pipeline from GDS Hiep Phuoc to

6.9 1.5km

Trach to the flange of NMD Nhon Trach 1. NMD Hiep Phuoc.

Measure ON/OFF potentials of 16-inch gas 18-inch gas pipeline from Monolithic Isolation

5.5 pipeline from the flange of GDC Nhon 2km 6.10 Joints(MIJ-3304) to MIJ-3305 located inside 0.1km

GDC Nhon Trach.

Trach to the flange of NMD 2.

© - Copyright Bureau Veritas 14

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

PVGas SE currently operates one onshore pipeline system at the North of Viet Nam:

The approximately 5.8km 12-inch gas pipeline system from Landfall Tien Hai to GDC Tien Hai in Ham Rong

– Thai Binh Province.

© - Copyright Bureau Veritas 15

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

Scope of work

To survey, gather and review all documents, data, information, operation parameters of PV Gas pipelines system related

to work.

To perform general cathodic protection inspection of all CP system components, including transformer rectifier units,

anode junction box, test post station, and bond boxes, anode grounds, etc.

To perform Direct Current Voltage Gradient (DCVG) survey.

To perform the Close Interval Potential Survey (CIPS) survey.

To perform Pipe Current Mapping (PCM) survey.

To perform Alternating Current Voltage Gradient (ACVG) survey.

To perform soil resistivity measurement at all test stations and coating defect locations along the pipeline.

To perform soil pH measurement at all test stations along the pipeline.

To perform a survey at the sources of possible AC/DC stray current.

To return the cathodic protection system operating with the good condition after the surveys.

To perform a survey and define pipe segments by construction and similar characteristics: materials, soil, and

construction.

To perform a root cause analysis shall there be any corrosion is found.

To produce preliminary and final reports based on the findings of the surveys.

To supply manpower, tools, equipment, etc. to excavate minimum 1 location shall there be any coating defect no 3 or no

4 as specified in NACE SP0502 standard.

© - Copyright Bureau Veritas 16

PINPOINT TARGET CUSTOMERS

2. Petrovietnam Gas South East Transmission Company

Scope of work

No. Scope of Work Descriptions Start day Finish day Days Quantity

Direct Current Voltage Gradient (DCVG) Survey from KP0+000 to

1 KP5+800. 5.8km

2 Close Interval Potential Survey (CIPS) from KP0+000 to KP5+800. 5.8km

Alternating Current Voltage Gradient (ACVG) Survey from KP0+000 to

3 KP5+800. 5.8km

4 Pipe Current Mapping (PCM) Survey from KP0+000 to KP5+800. 5.8km

5 Overall CP System Inspection

- Measure and record the “as found” DC output of each rectifier.

- Inspect Transformer-Rectifier Unit for any damage, rusting and

5.1 oxidation of terminals. Clean the units if required. 1 TRU

- Adjust the DC output of the rectifiers and resistor junction boxes (if

necessary) to achieve full protection to the structures.

5.2 Check the effectiveness of all insulating joints (MIJs and IFs). 3 MIJs

5.3 Check condition/performance protection of all Anode Groundbeds. 2

Measure ON/OFF pipe to soil potentials and AC potentials at all Test

5.4 7 TPs

Stations.

5.5 Measure all soil resistivities at all test station locations. 7 TPs

5.6 pH measurement at all test station locations 7 TPs

Mark and record all defect locations found which is identified in

5.7

category #3 and #4 at site.

© - Copyright Bureau Veritas 17

PINPOINT TARGET CUSTOMERS

3. Petrovietnam Gas Ca Mau Company

PVGas Ca Mau currently operates one onshore pipeline system:

The approximately 28km 18-inch gas pipeline system from Landfall Station to GDC Ca Mau.

The 16 &14 inches gas pipeline from GDC Ca Mau to GPP Ca Mau approximately 250m.

© - Copyright Bureau Veritas 18

PINPOINT TARGET CUSTOMERS

3. Petrovietnam Gas Ca Mau Company

Scope of work

Inspection of Groundbeds operating condition.

Inspection of Isolation Flange.

Soil resistivity, pH and other environmental characteristics surveys.

Carry out DCVG, CIPS, and PCM for 18", 14" and 16" gas pipelines from GDC CA MAU to Landfall Station.

Matching defect locations found in the DCVG survey with the previous surveys.

© - Copyright Bureau Veritas 19

PINPOINT TARGET CUSTOMERS

3. Petrovietnam Gas Ca Mau Company

Scope of work

Scope of Work Scope of Work

No. Start day Finish day Days Quantity No. Start day Finish day Days Quantity

Descriptions Descriptions

Measure"as-found" all the 7 Close Interval Potential Survey (CIPS)

1 test stations for Landfall to 69 TPs

GPP 18" gas pipeline from

7.1 28km

Landfall to GDC

Measure pH along the the

2 pipeline route from Landfall 69 TPs

to GPP 14" & 16" gas pipeline from

7.2 2km

GDC to GPP

Check the effectiveness of

3 all insulating joints ( MIJs 7 MIJs 8 AC Current Attenuation Survey (PCM) & ACVG

and IFs)

Check 18" gas pipeline from

8.1 28km

condition/performance Landfall to GDC

4 32 TPs

protection of all sacrificial

anodes 14" & 16" gas pipeline from

8.2 2km

GDC to GPP

Measure ON/OFF pipe to

soil potentials for 69 Test 9 Direct Current Voltage Gradient (DCVG)

Stations

5 + 67 Test Stations from 68 TPs 18" gas pipeline from

Landfall to GDC 9.1 28km

Landfall to GDC

+ 2 Test Stations from GDC

to GPP

14" & 16" gas pipeline from

Soil resistivity 9.2 2km

6 35 TPs GDC to GPP

measurement

© - Copyright Bureau Veritas 20

PINPOINT TARGET CUSTOMERS

Summary of underground pipeline systems

No Company Pipeline name Unit Quantity Period of inspection Remarks

1 Nam Con Son Pipeline • 30-inch gas pipeline - Annual inspection

• 26-inch gas pipeline km Approx.: 40 - 3 yearly inspection

• 6-inch gas pipeline

2 Petrovietnam Gas • 16-inch gas pipeline

South East • 16/17-inch gas 2 yearly inspection or

Transmission pipeline less than 2 years( it

Company • 3x6-inch liquid km Approx.: 110 depends on the

pipelines inspection results)

• 22-inch gas pipeline

• 12-inch gas pipeline

• 10 & 18-inches gas

pipelines

3 Petrovietnam Gas Ca • 18-inch gas pipeline 2 yearly inspection or

Mau Company • 14 & 16-inches gas km Approx.:28.5 less than 2 years( it

pipelines depends on the

inspection results)

Total underground pipeline lengths are under km Approx.: 178

Cathodic Protection System

© - Copyright Bureau Veritas 21

OVERALL PIPELINE MAPPINGS

Maps of NCS and PVGas pipelines from Long Hai – Hiep Phuoc

© - Copyright Bureau Veritas 22

OVERALL PIPELINE MAPPINGS

Maps of NCS and PVGas pipelines from Long Hai – Hiep Phuoc

© - Copyright Bureau Veritas 23

OVERALL PIPELINE MAPPINGS

Map of 18-inch gas pipeline in Ca Mau

© - Copyright Bureau Veritas 24

OVERALL PIPELINE MAPPINGS

Map of 12” gas pipeline in Ham Rong – Thai Binh

© - Copyright Bureau Veritas 25

PERSONNEL REQUIREMENTS

1. 01 Team Leader

• Team leader of the survey team at site shall be at least NACE certified Senior Corrosion or CP Technologist(CP

L3).

• Site team leader should have at least 10-year experience in CP design, installation and survey and done at

least 5 CIPS works, 5 DCVG works and 3 Current Mapping Works.

2. 02 CP Technicians

• 02 Team members should have at least 3-year experiences in CP survey and done at least 3 CIPS, 3 DCVG

and 1 Current Mapping works.

© - Copyright Bureau Veritas 26

EQUIPMENT REQUIREMENTS

No. Equipment Description QTY Remarks

Equipment:

1 Radio Frequency (Insulation tester) 1

2 Data Logger Model: DCVG Quantum Data Logger Meter 1

DCVG Equipment

3 1

Model: Maximus DCVG Digital Meter & Analogue Meter

4 Soil Resistivity Meter 1

5 Current Mapping tools (full package) 1

6 GPS synchronized current interrupter 5

7 High impedance Multimeter 1

8 10A portable current supply 1

9 Survey probe 1

10 Portable Cu/CuSO4 electrodes 2

11 Current clamp-on Ammeter 2

12 Portable GPS 1

Tools:

1 Cu/CuSO4 Pent hydrate Bottle 1

2 Copper trailing wire 1

3 Portable current supply 1

4 Camera 1

6 Water container 1

8 Car battery 3

9 Toolbox 1

10 Connecting cables and Clamps Lot

11 Power inverter 1

12 Pick-up Car 1

© - Copyright Bureau Veritas 27

COMPETITORS

1. TRUNG TIN A CHAU COMPANY ( TTA COMPANY)

2. VELOSI COMPANY

3. JST COMPANY

4. PVD TRAINING COMPANY

© - Copyright Bureau Veritas 28

© - Copyright Bureau Veritas 29

Potrebbero piacerti anche

- Porch Noun - DefinitionDocumento1 paginaPorch Noun - DefinitionkhanhtruongNessuna valutazione finora

- Bolted JointDocumento9 pagineBolted JointkhanhtruongNessuna valutazione finora

- Cipl Cat Survey Requirements PDFDocumento8 pagineCipl Cat Survey Requirements PDFkhanhtruongNessuna valutazione finora

- CBT Inspector Qualification Guidance - External - Rev-0 PDFDocumento10 pagineCBT Inspector Qualification Guidance - External - Rev-0 PDFkhanhtruong100% (1)

- CBT Inspector Qualification Guidance - External - Rev-0 PDFDocumento10 pagineCBT Inspector Qualification Guidance - External - Rev-0 PDFkhanhtruong100% (1)

- NDT Procedure Kiln Support Roller BinhfaDocumento4 pagineNDT Procedure Kiln Support Roller BinhfakhanhtruongNessuna valutazione finora

- Guided Wave Testing For Touch Point CorrosionDocumento7 pagineGuided Wave Testing For Touch Point CorrosionkhanhtruongNessuna valutazione finora

- HT DCVG ProductsDocumento4 pagineHT DCVG ProductskhanhtruongNessuna valutazione finora

- Casing InspectionDocumento18 pagineCasing InspectionkhanhtruongNessuna valutazione finora

- CP Procedure For Ncs PipelineDocumento16 pagineCP Procedure For Ncs PipelinekhanhtruongNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Handout Module6Documento69 pagineHandout Module6Oana MirceaNessuna valutazione finora

- Water Quality Index Determination of Malathalli LakeDocumento16 pagineWater Quality Index Determination of Malathalli Lakeajay kumar hrNessuna valutazione finora

- Lesson 49Documento2 pagineLesson 49Андрій ХомишакNessuna valutazione finora

- E-Kabin - O Series - Monoblock Enclosure - ENGDocumento12 pagineE-Kabin - O Series - Monoblock Enclosure - ENGCatalina CocoşNessuna valutazione finora

- B - Cracked Tooth SyndromeDocumento8 pagineB - Cracked Tooth SyndromeDavid TaylorNessuna valutazione finora

- As Level Chemistry Practical Paper 3 - GCE GuideDocumento1 paginaAs Level Chemistry Practical Paper 3 - GCE GuideJamal AldaliNessuna valutazione finora

- Microsoft Security Intelligence Report Volume 21 EnglishDocumento180 pagineMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoNessuna valutazione finora

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDocumento34 pagine220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMNessuna valutazione finora

- ContinueDocumento2 pagineContinueNeal ReppNessuna valutazione finora

- Classification of Nanostructured Materials: June 2019Documento44 pagineClassification of Nanostructured Materials: June 2019krishnaNessuna valutazione finora

- Overall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Documento6 pagineOverall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Ganapathi RajNessuna valutazione finora

- Aluminium - Hull Structure in Naval ApplicationsDocumento6 pagineAluminium - Hull Structure in Naval ApplicationsStefano CostaNessuna valutazione finora

- PulpectomyDocumento3 paginePulpectomyWafa Nabilah Kamal100% (1)

- Recommended Standards For Newborn ICU DesignDocumento39 pagineRecommended Standards For Newborn ICU DesignAlbert SekarNessuna valutazione finora

- Industries Visited in Pune & LonavalaDocumento13 pagineIndustries Visited in Pune & LonavalaRohan R Tamhane100% (1)

- BKM 10e Ch07 Two Security ModelDocumento2 pagineBKM 10e Ch07 Two Security ModelJoe IammarinoNessuna valutazione finora

- An Energy Saving Guide For Plastic Injection Molding MachinesDocumento16 pagineAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNessuna valutazione finora

- Biology 1st Term PaperDocumento2 pagineBiology 1st Term PapershrirahulambadkarNessuna valutazione finora

- AA-036322-001 - Anchor Bolt DetailsDocumento1 paginaAA-036322-001 - Anchor Bolt DetailsGaurav BedseNessuna valutazione finora

- Ancon Tension Systems March 2008Documento16 pagineAncon Tension Systems March 2008Slinky BillNessuna valutazione finora

- Schedule NDocumento3 pagineSchedule Nmittal kelaNessuna valutazione finora

- Brochure - ILLUCO Dermatoscope IDS-1100Documento2 pagineBrochure - ILLUCO Dermatoscope IDS-1100Ibnu MajahNessuna valutazione finora

- Constantino V MendezDocumento3 pagineConstantino V MendezNīc CādīgālNessuna valutazione finora

- Manual of GardeningDocumento812 pagineManual of GardeningPrakash PatelNessuna valutazione finora

- UgpeDocumento3 pagineUgpeOlety Subrahmanya SastryNessuna valutazione finora

- Практичне 25. Щодений раціонDocumento3 pagineПрактичне 25. Щодений раціонAnnaAnnaNessuna valutazione finora

- 10 Chapter 3 Occupancy Classification AnDocumento10 pagine10 Chapter 3 Occupancy Classification AnMatt BaronNessuna valutazione finora

- L Addison Diehl-IT Training ModelDocumento1 paginaL Addison Diehl-IT Training ModelL_Addison_DiehlNessuna valutazione finora

- Roto Fix 32 Service ManualDocumento31 pagineRoto Fix 32 Service Manualperla_canto_150% (2)

- (Engine International Air Pollution Prevention) : EIAPP CertificateDocumento2 pagine(Engine International Air Pollution Prevention) : EIAPP CertificateTan DatNessuna valutazione finora