Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Air Pollution Control

Caricato da

Yogesh0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni17 pagineBrief description of air pollution

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoBrief description of air pollution

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni17 pagineAir Pollution Control

Caricato da

YogeshBrief description of air pollution

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 17

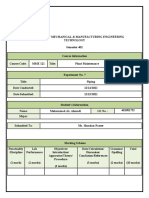

Presented by :

Particulate Control Equipments

Gravitational Settling Chamber

Cyclone Separator

Electrostatic Precipitator

Scrubber

Choice of equipments

Prevention of nuisance

Prevention of physical damage to property

Elimination of health hazards to plant

personnel

Recovery of valuable waste product

Minimization of economic losses

Improvement of product quality

Used to remove particles with size greater

than 50 μm.

Velocity of flue gas reduced in large

chamber.

Particles settle under gravitational force.

Vs= hV/ L ----------- (i)

L= length of chamber V= horizontal velocity of carrier gas

Vs= settling velocity of particulates h= height through

which particulates travel.

By stokes law Vs= g(ρ’ - ρ)D2/18μ -------

-- (ii) D= dia of particle g= acceleration due to gravity ρ’=

density of particle ρ = density of gas μ= viscosity of gas

From eq- i and ii D= [18Vhμ/ Lg (ρ’ -

ρ)]1/2 D = minimum size of particle that can be

removed in a settling chamber

Industrial application is limited

Used widely for removal of large solid

particulates from draft furnace, kilns.

Sometimes used in process industry, food

and metallurgical industry.

Used as pre-cleaners for high efficiency

collectors.

Centrifugal force is utilized to separate the

particulate matter.

It can remove 10 to 50 μm particle size.

Used mostly in industries

Design factor having greatest effect on

collection efficiency is cyclone diameter.

For smaller diameter, higher is efficiency,

because centrifugal action increase with

decreasing radius of rotation.

OPERATING PROBLEMS:

Erosion

Corrosion

Material build up

Control gas borne particulates from

industries like cement, feed and grain

processing, food and beverage processing,

mineral processing, paper and textile

industries and wood working industries.

Used in recovery of catalyst ducts in

petroleum industry and reduction of fly ash

emission.

Gas stream passed two electrodes and

high potential difference is

maintained.

Out of two electrodes, one is

discharging other collecting and

potentials of 100 kv are used.

Ionization creates active glow zone

called “corona”.Gas ionization is

As particulates pass through field, they get

charged and migrate to oppositely charged

electrode.

Particles deposited on collecting electrodes,

lose charge and removed mechanically by

rapping., vibration or washing to a hopper.

Application:

Cement factories, Pulp and paper mills ,Steel

plants , Non- ferrous metal industry , Chemical

industry ,Petroleum industry Carbon black

industry , Electric power industry

Particulate matters are incorporated into

liquid droplets and removed from the gas

stream.

Flue gas made to push up against a down

falling water current.

Particulate matter mix up with water thus

falls down and gets removed.

Spray towers

Venturi scrubbers

Cyclone scrubbers

Packed scrubbers

Mechanical scrubbers

Cyclones:- cheap to install, power consumption

moderate, maintenance cost normal.

Filters:- expensive to install, power

consumption moderate. Maintenance cost high.

Electrostatic precipitators:- most expensive

regarding installation, power consumption

moderate to low as pressure drops.

Maintenance cost moderate

Scrubbers :- installation cost moderate,

maintenance cost not high, high rate of power

consumption.

1. Particulate size

2. Particulate loading

3. Efficiency required

4. Properties of carrier gas

5. Flow characteristics of carrier gas

6. Specific property of contaminant

7. Allowable pressure drop

8. Contaminate disposal

9. Capital and operating cost of equipment

10. Ease of maintenance and reliability Economical

aspects

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- BS en Iso 1833-12-2010Documento12 pagineBS en Iso 1833-12-2010EmkFataAliraqNessuna valutazione finora

- ACI 318M-19 - Minimum ReinforcementDocumento1 paginaACI 318M-19 - Minimum ReinforcementahlanNessuna valutazione finora

- DissertationDocumento55 pagineDissertationYogeshNessuna valutazione finora

- Human Settlement Planning - Module 1Documento24 pagineHuman Settlement Planning - Module 1YogeshNessuna valutazione finora

- Module 5Documento20 pagineModule 5YogeshNessuna valutazione finora

- City Structure 1Documento31 pagineCity Structure 1YogeshNessuna valutazione finora

- Town Planning 1Documento34 pagineTown Planning 1YogeshNessuna valutazione finora

- UEEP MO22 09.14 UE Soil VegetationDocumento15 pagineUEEP MO22 09.14 UE Soil VegetationYogeshNessuna valutazione finora

- UEEP MO22 09.19 Climate UHI+Ecozones of IndiaDocumento9 pagineUEEP MO22 09.19 Climate UHI+Ecozones of IndiaYogeshNessuna valutazione finora

- Ueep Mo22 - 10.26 - Above + Eia-1Documento24 pagineUeep Mo22 - 10.26 - Above + Eia-1YogeshNessuna valutazione finora

- UEEP MO22 - 10.19 - Resilience, Ecosystem Services, Robustness, Layers of Info, GISDocumento17 pagineUEEP MO22 - 10.19 - Resilience, Ecosystem Services, Robustness, Layers of Info, GISYogeshNessuna valutazione finora

- UEEP MO22 - 10.10 - Complexity, Heterogeneity, Dynamic Nature, Resilience, Assam FloodsDocumento8 pagineUEEP MO22 - 10.10 - Complexity, Heterogeneity, Dynamic Nature, Resilience, Assam FloodsYogeshNessuna valutazione finora

- JHi 5 SJ 8 Oa FQTSMJ W8 L RFM 2 JJ 9 P MK VK7 I LNMM Ko Hy 7 G NCDocumento1 paginaJHi 5 SJ 8 Oa FQTSMJ W8 L RFM 2 JJ 9 P MK VK7 I LNMM Ko Hy 7 G NCYogeshNessuna valutazione finora

- Irctcs E-Ticketing Service Electronic Reservation Slip (Agent)Documento1 paginaIrctcs E-Ticketing Service Electronic Reservation Slip (Agent)YogeshNessuna valutazione finora

- CS 5150 So (Ware Engineering: System Architecture: Introduc OnDocumento65 pagineCS 5150 So (Ware Engineering: System Architecture: Introduc OnYogeshNessuna valutazione finora

- Progress Card HUMSSDocumento35 pagineProgress Card HUMSSwiljhon sunioNessuna valutazione finora

- Artificial Rocks, NaturallyDocumento2 pagineArtificial Rocks, NaturallyMichael BrownNessuna valutazione finora

- Welding Engineer Exam SyllubusDocumento2 pagineWelding Engineer Exam SyllubuskapsarcNessuna valutazione finora

- CSR Vol-1 PDFDocumento317 pagineCSR Vol-1 PDFmuhammad75makeNessuna valutazione finora

- Amendment No. 3 June 2018 TO Is 3597: 1998 Concrete Pipes - Methods of TestDocumento5 pagineAmendment No. 3 June 2018 TO Is 3597: 1998 Concrete Pipes - Methods of TestPratik KharmateNessuna valutazione finora

- Ankral RNT PDFDocumento1 paginaAnkral RNT PDFmahreza189Nessuna valutazione finora

- Ultimate Ceramic Veneers: A Laboratory-Guided Preparation Technique For Minimally Invasive RestorationsDocumento17 pagineUltimate Ceramic Veneers: A Laboratory-Guided Preparation Technique For Minimally Invasive RestorationsAlfred OrozcoNessuna valutazione finora

- Effect of The Addition of Polypropylene Fiber On Concrete PropertiesDocumento27 pagineEffect of The Addition of Polypropylene Fiber On Concrete PropertiesSantu PatraNessuna valutazione finora

- Is 2190 Fire Extinguishers PDFDocumento23 pagineIs 2190 Fire Extinguishers PDFPuspesh GiriNessuna valutazione finora

- Surface Protective Systems: Oxydur VE-ARDocumento3 pagineSurface Protective Systems: Oxydur VE-ARfrancisca ferrerNessuna valutazione finora

- Bearing Insulation Updates With SKF-1Documento3 pagineBearing Insulation Updates With SKF-1Shyam KumarNessuna valutazione finora

- Ep Lap MCQ CivilDocumento4 pagineEp Lap MCQ CivilBhavani MurugesanNessuna valutazione finora

- MNS LabDocumento4 pagineMNS LabLyracism UguumurNessuna valutazione finora

- Lab 7 PipingDocumento6 pagineLab 7 PipingAtif AbbasNessuna valutazione finora

- Manufacture of Alum PDFDocumento450 pagineManufacture of Alum PDFKimberly ConleyNessuna valutazione finora

- Cryogenic (Imperial)Documento28 pagineCryogenic (Imperial)Rahul LavandNessuna valutazione finora

- Extraction and Uses of Metals 1 QP PDFDocumento12 pagineExtraction and Uses of Metals 1 QP PDFAngus AnizNessuna valutazione finora

- Specific Gravity ChartDocumento2 pagineSpecific Gravity ChartApril Trish Albaña0% (1)

- Vci MBDocumento23 pagineVci MBAyeshaNessuna valutazione finora

- The Price List Is Valid From 03/05/2021Documento22 pagineThe Price List Is Valid From 03/05/2021Roxana RotaruNessuna valutazione finora

- PDFDocumento16 paginePDFĐặng HươngNessuna valutazione finora

- OPC Vs PPC - Difference Between OPC and PPC Cement - Civil LeadDocumento12 pagineOPC Vs PPC - Difference Between OPC and PPC Cement - Civil Leaddhan singhNessuna valutazione finora

- Victaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsDocumento2 pagineVictaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsRobson Custódio de SouzaNessuna valutazione finora

- Chemistry - Ionic Equilibrium DPPDocumento6 pagineChemistry - Ionic Equilibrium DPPmy missionNessuna valutazione finora

- Proyecto InglesDocumento8 pagineProyecto InglesGody StifmasterNessuna valutazione finora

- P S CL K Ca: F3 First Term RevisionDocumento6 pagineP S CL K Ca: F3 First Term Revisionjonas hoNessuna valutazione finora

- Hi-Temp 1027 Application GuideDocumento7 pagineHi-Temp 1027 Application Guidemehdi millwalaNessuna valutazione finora

- PU and EPS Prefab Sandwich Panel Technical SpecificationDocumento14 paginePU and EPS Prefab Sandwich Panel Technical SpecificationMohammed AffrozeNessuna valutazione finora