Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

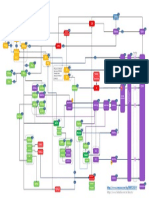

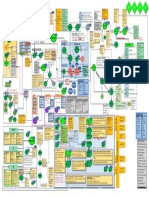

SAP PP Certification Overview (Mindmap Edition)

Caricato da

Yong BenedictTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAP PP Certification Overview (Mindmap Edition)

Caricato da

Yong BenedictCopyright:

Formati disponibili

SAP PP Concepts / Processes

Internal Procurement Strategy

MM03 OPPS Industry

MMR Strategy Discrete Process

Planned Indep Reqt (PIR) •Assemble to new Thing •Mix to new Stuff, Co-Prdt

•Easier to reverse •Difficult to reverse For Lean Manufacturing

Customer Indep Reqt (CIR) •Electronics, Aero/Auto •Chemical, F&B

Other settings OPP3

1. Mxed MRP Ind. MTS – base on forecast (ie PIR) MTO – base on S/O (ie CIR) •BOM/Operation/WC •Recipe/Phase/Resource •Backflush

2. Consupt. Mode •Parts-number •Batch number Repetitive (REM) REM Prof •MovTyp

3. Indiv/Coll Ind [10] Make-to-Stock (MTS) [20] Make-to-Order (MTO) AAC=E

•Tcode: CO01 •Tcode: COR1 •Discrete Ind. (typical) Assign at FG level

[11] MTS - Gross Reqt [21] MTO with PS (ETO) AAC=D •Period/Qty Base

OVZG

ReqClass [40] MTS net of PIR/CIR [25] MTO with VC AAC=M •Simple routing

•Periodic backflush KKF6N

•A/C Assign Cat •Order Type [70] Assembly-to-Stock [50] Assembly-to-Order AAC=M •Periodic cost control Product Cost

(Consupt Post, (either PP / PS) Collector

(selective list only) Assign at OrdTyp level

Spec.Stock) •Settle Profile

•RA Key

OVZI – can override ReqClass search rule for MTO

“Scenario” OME9

Order Type KOT2 Forecasting

E: MTO, SD Cost, SD-Stk IBP SO&P Manual

PP/PP-PI/PM PS Network Sales

M: MTO, PP Cost, SD-Stk [MD61] •MRP (PD)

(OrdCat: 10,40,30) (OrdCat: 20) Flex Plan Order

B: MTS, SD Cost, Coll-Stk MRP Prof •DDMRP (D1)

Q: ETO, PS Cost, PS-Stk •Reorder Point (VB)

D: ETO, PS Cost, SD-Stk •Forecast (VV)

CBP

G: MTS, PS Cost, Coll-Stk •Time-phased (R1)

PIR CIR

MRP Type

MD15 PR/SA

Demand Mgmt

Production Version OrdTyp Selection Pln Order MD04

Adv Planning MRP (Classic) MD01N

1.ProdSchd Prof [OPKP]

CS03 2.ProdScheduler‘s -> (PP/DS) MRP Live MRP Run CO41 MF Order

BOM ProdSchdProf [OPJ9] •Fixed PO Receipt

3.MRPGrp/Plnt [OPPE] OPU3

OrdSchd •Firmed PlnOrd

4.MRPGrp Para [OPPR] •Firmed PR CM21

5.Plant Para [OPPQ] Para •Lot Size Capacity Mgmt

CA03 OPL8

OPJK OPJH

Routing Ord/Plnt OrdTyp

•Oper Default MTO Shopfloor

VA01 •Order Level

•Ctrl Key Mat Staging Backflushing

•Batch Determ •MMR Level

•WC MD50 •WC Level

•StdVal •InspTyp Sales Order •MRP

OKO7 + Auto GR at Ctrl Key •OrdTyp Cnf [OPK4]

•Kanban

Settle

Profile PREL DLV TECO

KL03 COR1 (PI) COOISPI (PI) KSB1 (CC)

CN08 KOB1 (IO)

ActTyp CO01 QE51N MIGO CO11N MIGO COOIS KVBI (SOitm)

CJ20N CJI3 (WBS)

MF Order QM GI (to Order) CNF GR PP Reports CO Reports

MF Order Project/WBS MD51 InspTyp 03

QM Chk Back

•Capacity ATP

CR03 InspTyp 04 Flush

•Schedule Work

•Cost Center

(Formula) OPJ8

Operations Ctrl Key Costing

Plan

Prelim Cost

KS03 Cost

Cost Dir. Material Dir. Labour

Center

Direct Actual

Simul Cost

Cost Cost

KB21N

KGI2

Period

OH Sett Cost

Cost Settings

•DefRule Sett (PP1/2)

•RA Key (WIP) RA Key WIP KKAX WIP

•Def CostVar (Plan)

CO88

•Def CostVar (Act) OKV6

•Cost Collector Flag TCV VAR Period Sett Zero the WIP

Settings in OVZG will Scrap KKAX

supersede DefRule Sett if MTO

KSZ2 KKS2 VAR

CostSht OH

CO88 •MAT (if MTS)

Final Sett •CO Objects

(SOitm, WBS)

•COPA

VAR Key ‘MTO’: SOitm->COPA [KKA3+VA88]

‘ETO’: WBS->COPA [KKA2+CJ88]

https://www.linkedin.com/in/benytx/

Potrebbero piacerti anche

- SAP S/4HANA Retail: Processes, Functions, CustomisingDa EverandSAP S/4HANA Retail: Processes, Functions, CustomisingValutazione: 5 su 5 stelle5/5 (1)

- SAP Asset Accounting in 1-PagerDocumento1 paginaSAP Asset Accounting in 1-PagerYong Benedict100% (2)

- SAP S/4 HANA FI 1610 Overview (Mindmap Edition)Documento2 pagineSAP S/4 HANA FI 1610 Overview (Mindmap Edition)Yong Benedict100% (3)

- Mcdonald'S Corporation Vrio & Vrin Analysis, Table (Resource-Based View)Documento7 pagineMcdonald'S Corporation Vrio & Vrin Analysis, Table (Resource-Based View)Fakta NegeriNessuna valutazione finora

- SAP S4 HANA CO 1709 Overview (Mindmap Edition)Documento2 pagineSAP S4 HANA CO 1709 Overview (Mindmap Edition)Yong Benedict100% (2)

- ABAP/4 Mindmap!! - For Busy Functional ConsultantsDocumento1 paginaABAP/4 Mindmap!! - For Busy Functional ConsultantsYong Benedict100% (3)

- SAP CIF Complete GuideDocumento69 pagineSAP CIF Complete GuideKaruparthi Kuber100% (4)

- Sap MM Standard Business ProcessDocumento65 pagineSap MM Standard Business ProcessRahul Jagdale67% (3)

- SAP MRP Strategy ParameterDocumento1 paginaSAP MRP Strategy ParameterJagan KilariNessuna valutazione finora

- SAP S - 4HANA MM Mindmap by Benedict YongDocumento1 paginaSAP S - 4HANA MM Mindmap by Benedict Yongtucu23456100% (1)

- RicefwDocumento8 pagineRicefwanilks27Nessuna valutazione finora

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesDa EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNessuna valutazione finora

- ABAP/4 Mindmap!! - For Busy Functional ConsultantsDocumento1 paginaABAP/4 Mindmap!! - For Busy Functional ConsultantsYong Benedict100% (3)

- SAP S4 Hana CloudDocumento1 paginaSAP S4 Hana CloudYong Benedict100% (2)

- Conceptual Enterprise Asset Management For Plant Construction ProcessDocumento25 pagineConceptual Enterprise Asset Management For Plant Construction ProcessYong Benedict100% (1)

- SCM244 ProductionPlanningPartII (SAPR3 MRP)Documento315 pagineSCM244 ProductionPlanningPartII (SAPR3 MRP)krushi123Nessuna valutazione finora

- SAP PP ImpDocumento13 pagineSAP PP ImpRajRSaravananNessuna valutazione finora

- 7 SAP Core Modules (SDMM, FICO, PP, PS, HR) Mindmaps - All-in-One Deck!Documento7 pagine7 SAP Core Modules (SDMM, FICO, PP, PS, HR) Mindmaps - All-in-One Deck!Yong Benedict100% (1)

- ProductionDocumento563 pagineProductionShine KaippillyNessuna valutazione finora

- LO305 Basic Data For Process ManufacturingDocumento449 pagineLO305 Basic Data For Process Manufacturingdinhlap237Nessuna valutazione finora

- Vishal Gajjar - Sap PM SD MM ConsultantDocumento4 pagineVishal Gajjar - Sap PM SD MM ConsultantvgopalmmNessuna valutazione finora

- Fiori AppsDocumento43 pagineFiori AppsSudhakara VarmaNessuna valutazione finora

- IS Oil - DownstreamDocumento1 paginaIS Oil - DownstreamtalebiNessuna valutazione finora

- Orgunit / Concepts / Processes: MaterialDocumento1 paginaOrgunit / Concepts / Processes: MaterialPrakash Praky100% (1)

- SAP PP Training Material: ConfidentialDocumento13 pagineSAP PP Training Material: ConfidentialMahesh Kamdey100% (1)

- PPDS S4 FeaturesDocumento21 paginePPDS S4 FeaturesSrini DonapatiNessuna valutazione finora

- SAP PS Certification Overview (Mindmap Edition)Documento1 paginaSAP PS Certification Overview (Mindmap Edition)Yong Benedict100% (3)

- CIF Monitoring Guideline V3Documento48 pagineCIF Monitoring Guideline V3giampiero_gallarateNessuna valutazione finora

- #1 Service Desk Software: What Is SAP Production PlanningDocumento3 pagine#1 Service Desk Software: What Is SAP Production PlanningAnonymous IpnRP293100% (1)

- Archiving Process in Sales DistributionDocumento26 pagineArchiving Process in Sales DistributionkishorepanchakarlaNessuna valutazione finora

- A) Environments For SAP ERPDocumento15 pagineA) Environments For SAP ERPChristian Hope MubairaNessuna valutazione finora

- Flexible Planning in SAPDocumento24 pagineFlexible Planning in SAPharinikrishnaNessuna valutazione finora

- Integrating RFID Technology and ERP Systems - V2Documento59 pagineIntegrating RFID Technology and ERP Systems - V2Sorin IonescuNessuna valutazione finora

- First Steps in Sap Production Processes PPDocumento6 pagineFirst Steps in Sap Production Processes PPMichael Platt OlabodeNessuna valutazione finora

- RC SCM310 ProductionOrdersDocumento327 pagineRC SCM310 ProductionOrdersRRROMANCANessuna valutazione finora

- SAP PP - DemoDocumento61 pagineSAP PP - DemoChaitanyaARAvasarala100% (2)

- 3 SAP SD Level-1 TrainingDocumento38 pagine3 SAP SD Level-1 TrainingkalykumNessuna valutazione finora

- ABAP 1.o PDFDocumento320 pagineABAP 1.o PDFanilNessuna valutazione finora

- How To Understand The BOM - Bill of Material in APODocumento8 pagineHow To Understand The BOM - Bill of Material in APOAvrinz AvrinzNessuna valutazione finora

- All User ExitsDocumento100 pagineAll User ExitsShaffiullahNessuna valutazione finora

- APO Technical InformationDocumento12 pagineAPO Technical InformationNilesh Panchal100% (1)

- PP Sap TableDocumento4 paginePP Sap Tableganesh100% (1)

- SAP Model Company For AgribusinessDocumento1 paginaSAP Model Company For AgribusinesssergioNessuna valutazione finora

- PP Pi BookDocumento106 paginePP Pi BookShailendra Rane50% (2)

- SAP: PP Notes: Order Based ProductionDocumento4 pagineSAP: PP Notes: Order Based Productionsdm2124Nessuna valutazione finora

- Shopfloor Configuratrion SAP PPDocumento14 pagineShopfloor Configuratrion SAP PPSantosh Pavan100% (3)

- SAP Basic COPA OverviewDocumento1 paginaSAP Basic COPA OverviewYong BenedictNessuna valutazione finora

- Sap - List of BapisDocumento70 pagineSap - List of Bapisdaisy.ngNessuna valutazione finora

- Class 10 SCM300 REM PP PI PDFDocumento250 pagineClass 10 SCM300 REM PP PI PDFManiSekhar100% (3)

- Vim Cheat Sheet For Programmers PrintDocumento1 paginaVim Cheat Sheet For Programmers PrintBenjamin ShinwaNessuna valutazione finora

- Test SAP Solution Manager: Document CategoriesDocumento6 pagineTest SAP Solution Manager: Document CategoriesDinesh BabuNessuna valutazione finora

- Kraft QM DesignDocumento91 pagineKraft QM DesignPramod ShettyNessuna valutazione finora

- Sap Workcenter-Resource ViewsDocumento20 pagineSap Workcenter-Resource ViewsanjitachinkiNessuna valutazione finora

- SD - Business Process: Activity Organizational Unit TransactionDocumento15 pagineSD - Business Process: Activity Organizational Unit TransactionGaurav Harimitter100% (2)

- Apo220 PDFDocumento427 pagineApo220 PDFashahmednNessuna valutazione finora

- Steps in Implementing SAP PPDocumento10 pagineSteps in Implementing SAP PPlopezramon2111Nessuna valutazione finora

- IDocs - A Guide For New DevelopersDocumento56 pagineIDocs - A Guide For New DevelopersGhassan Abdul Gafoor100% (1)

- SAP PP TablesDocumento87 pagineSAP PP TablesKundan B0% (1)

- DP and PPDS Without SNPDocumento14 pagineDP and PPDS Without SNPJagannadh BirakayalaNessuna valutazione finora

- 1.S4 MM Flow DetailedDocumento1 pagina1.S4 MM Flow DetailedPrakash Praky100% (1)

- PP401 - MRP: FG: Production PlanningDocumento3 paginePP401 - MRP: FG: Production PlanningYong BenedictNessuna valutazione finora

- SmartForms - ConceptualDocumento32 pagineSmartForms - ConceptualYong Benedict100% (2)

- SAP Enhancement Framework GuideDocumento22 pagineSAP Enhancement Framework GuideYong Benedict100% (2)

- SAP Integration With Excel - Basic GuideDocumento19 pagineSAP Integration With Excel - Basic GuideYong Benedict100% (2)

- SAP Account Determination DiagramDocumento1 paginaSAP Account Determination DiagramYong Benedict100% (1)

- SAP S4 HANA InnovationsDocumento1 paginaSAP S4 HANA InnovationsYong Benedict100% (3)

- SAP PS Certification Overview (Mindmap Edition)Documento1 paginaSAP PS Certification Overview (Mindmap Edition)Yong Benedict100% (3)

- SAP MTS-To-COPA Flow DiagramDocumento1 paginaSAP MTS-To-COPA Flow DiagramYong BenedictNessuna valutazione finora

- SAP S4 HANA SD CertificationDocumento1 paginaSAP S4 HANA SD CertificationYong Benedict80% (5)

- SAP Basic COPA OverviewDocumento1 paginaSAP Basic COPA OverviewYong BenedictNessuna valutazione finora

- SAP S4 HANA MM CertificationDocumento1 paginaSAP S4 HANA MM CertificationYong Benedict100% (4)

- TechnipFMC PART P554583UDocumento2 pagineTechnipFMC PART P554583UDeepak HoleNessuna valutazione finora

- Assignment 1Documento2 pagineAssignment 1Ceres TheaNessuna valutazione finora

- 7 Cleaning & Surface TreatmentsDocumento70 pagine7 Cleaning & Surface Treatmentssakali ali100% (1)

- Airasia Project PresentationDocumento52 pagineAirasia Project Presentationlens00700100% (3)

- Case Presentation - Group1: Srinivas Bhattiprolu Falk Scherzer Georg WieningerDocumento19 pagineCase Presentation - Group1: Srinivas Bhattiprolu Falk Scherzer Georg WieningerAshutosh VikramNessuna valutazione finora

- Pertemuan 3. Business Motivations and Drivers For Big Data AdoptionDocumento16 paginePertemuan 3. Business Motivations and Drivers For Big Data AdoptionMuhammad alifakbarNessuna valutazione finora

- MKTGChapter 4 Digital Marketing and Social Media Living in The Connected WorldDocumento111 pagineMKTGChapter 4 Digital Marketing and Social Media Living in The Connected WorldGeorge BushNessuna valutazione finora

- Group 5 Diesel Case StudyDocumento6 pagineGroup 5 Diesel Case Studyabdullah mughalNessuna valutazione finora

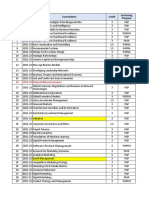

- Electives ListDocumento6 pagineElectives ListMadhusudhan KmsNessuna valutazione finora

- Directory Information For Product Like ''Documento1.024 pagineDirectory Information For Product Like ''san dipNessuna valutazione finora

- Philip BDocumento13 paginePhilip Bman319Nessuna valutazione finora

- Emily Joy A.Documento1 paginaEmily Joy A.Emily Joy Bretania AnduyanNessuna valutazione finora

- QAQC Procedure For Fabrication - Flare KOD Rev ADocumento9 pagineQAQC Procedure For Fabrication - Flare KOD Rev ARajesh K Pillai100% (1)

- What Is Pega Introduction To Pega PRPC - HKRDocumento7 pagineWhat Is Pega Introduction To Pega PRPC - HKRsridhar varmaNessuna valutazione finora

- Tuv Training Calendar - N-d-2017 - r0Documento1 paginaTuv Training Calendar - N-d-2017 - r0SudhagarNessuna valutazione finora

- Multiple Choice Question Ch-20 B) Financial StandardDocumento2 pagineMultiple Choice Question Ch-20 B) Financial StandardSourabh MandalNessuna valutazione finora

- Walastic: "Paper Packaging Using Banana Peel and Egg Shells"Documento5 pagineWalastic: "Paper Packaging Using Banana Peel and Egg Shells"Charles ManggaNessuna valutazione finora

- SIM OverviewDocumento77 pagineSIM Overviewtam_tim8757Nessuna valutazione finora

- Smed Class 2Documento108 pagineSmed Class 2Dennis Greer100% (2)

- Layout Planning, Logistics in Garment IndustryDocumento13 pagineLayout Planning, Logistics in Garment IndustryPRIYANKA GADENessuna valutazione finora

- Tensao Limite Hertz v02Documento4 pagineTensao Limite Hertz v02Jayce GreenfelderNessuna valutazione finora

- Payments ModernizationDocumento10 paginePayments ModernizationLuis YañezNessuna valutazione finora

- Avinash Kumar Resume AK1Documento2 pagineAvinash Kumar Resume AK1Avinash KumarNessuna valutazione finora

- Strategy and Roadmap For Solution Manager Session 3 PDFDocumento32 pagineStrategy and Roadmap For Solution Manager Session 3 PDFmaster_sodhi19Nessuna valutazione finora

- Rekap Finger Bulan Juni 2019Documento6 pagineRekap Finger Bulan Juni 2019Tahir TayoNessuna valutazione finora

- Chapter 12Documento32 pagineChapter 12Samuel AritonangNessuna valutazione finora

- Sha 2Documento51 pagineSha 2sprasadn66Nessuna valutazione finora

- Sap PM Online Training ClassesDocumento12 pagineSap PM Online Training Classesexpertisesignin1Nessuna valutazione finora

- Last Name, First Name: - UMD Directory IDDocumento8 pagineLast Name, First Name: - UMD Directory IDYealshaday BirhanuNessuna valutazione finora