Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Basics of Lean

Caricato da

Piter Kiiro0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni21 pagineTitolo originale

Basics_of_Lean

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

15 visualizzazioni21 pagineBasics of Lean

Caricato da

Piter KiiroCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 21

Basics of Lean

How to See and Eliminate Waste

Slides courtesy of Doug Fingles, MERC

Concept

“Lean” is not an acronym

It means to do more with less waste

Most processes in North America are

95% waste

Actual hands-on time is only 5%

The largest production gains will be

made in reducing the waste in a

process

Why Lean?

Competition is world-wide and growing

Companies that meet customer needs

and are more efficient than their

competitors will survive

“You can have any color you want, as

long as it’s black” is a dead philosophy

History of Lean

Henry Ford

Taiichi Ohno and the Toyota Production

System

“The Machine that Changed the World”

“Lean Thinking”

Automotive industry

Aerospace industry

…And beyond

8 types of waste

Injuries

Defects

Inventory

Overproduction

Waiting time

Motion

Transportation

Processing

5 Key Principles

Value

Value Stream

Flow

Pull

Perfection

What is Value?

Specific product that meets a

customer’s needs at a specific price and

specific time

What is important to the customer

What the customer is willing to pay for

Put yourself in the customer’s shoes

Use the customer’s words to describe

the product

What is the Value Stream?

Set of specific actions required to bring

a specific product through 3 critical

management tasks of all businesses

Problem Solving task (design, engineering)

Information Management task (order

taking, scheduling, planning)

Physical Transformation task (from raw

material to finished product)

What is Flow?

Parts “flow” through a Value Stream

Upstream is the beginning or “head” of the

flow

Downstream is the “mouth” of the flow,

where the part is pulled by the customer

Materials and parts are the “parts” in

manufacturing

Customer’s needs are the “parts” in service

industry

Same for administration

What is Pull?

“It has become a matter of course for

customers, or users, each with a different

value system, to stand in the frontline of the

marketplace and, so to speak, pull the goods

they need, in the amount and at the time

they need them.”

Taiichi Ohno, “Toyota Production System”

“…Nothing is produced by the upstream

provider until the downstream customer

signals a need”

Womack and Jones, “Lean Thinking”

What is Perfection?

The complete elimination of all waste,

so that all activities along a value

stream add value to the product

Ideal State Map

Lean Tools

Value Stream Analysis

6S

Cells

Standard Work

Rapid Improvement Events

Value Stream Analysis

Use Value Stream Analysis as a planning tool

Break down the Value Stream in manageable

sections

Communicate the “flow” with maps

Information

Material

Use Value Stream Analysis to create 3 maps

Current

Ideal

Future (near time-within a year)

Develop action plan from the Future map

6S

Often confused with Lean, because you

are “doing” something

Second step, after Value Stream

Analysis

6S

A tool to organize the workplace

Sort—Keep what you need, get rid of the

rest

Straighten—Organize what’s left

Scrub—A clean workplace is more efficient

Safety—Without our people, nothing gets

done

Standardize—Find a best way and have

everyone do it that way

Sustain—Don’t let up

Cells

Natural groups of parts or steps that

add value to a product

Single piece flow inside the cell

One at a time

If possible, one operator per cell

U-shaped to maximize human efficiency

Multi-skilled people required

Layout is based on the flow steps

Standard Work

The precise description of each work

activity specifying cycle time, takt time,

the work sequence of specific tasks,

and the minimum inventory of parts on

hand to conduct the activity

Everyone knows what they are

supposed to do at any moment in time

Rapid Improvement Events

A seven week cycle of preparation,

action, and follow-up to improve one

area or fix a problem

People: work leaders, mechanics,

workers, supervisor, and a Lean Change

Agent

Led by the supervisor or work leader

Guided by the Lean Change Agent

Review

Concept

History and reasons why

Principles

Value, Value Stream, Flow, Pull, Perfection

Tools

Value Stream Analysis, 6S, Cells, Standard

Work, Rapid Improvement Events

Acknowledgements

“Lean Thinking” by James Womack and

Daniel Jones

“Toyota Production System” by Taiichi

Ohno

Simpler Business System,

www.simpler.com

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Cover Letter For Addendum NO.3Documento31 pagineCover Letter For Addendum NO.3AbelNessuna valutazione finora

- Mendarda-2 - 105 - ReportDocumento12 pagineMendarda-2 - 105 - ReportBolt SankhaniNessuna valutazione finora

- SIP - Warehouse Flow ChartDocumento10 pagineSIP - Warehouse Flow ChartkrishnatejanitdgpNessuna valutazione finora

- Marsh Ellen Ar10342 PDFDocumento1 paginaMarsh Ellen Ar10342 PDFEllie MarshNessuna valutazione finora

- Quotation BestrackDocumento3 pagineQuotation BestrackRescos KasarachiNessuna valutazione finora

- Catalog Steel Grating Type 2016-10-01Documento12 pagineCatalog Steel Grating Type 2016-10-01Kho Chin NganNessuna valutazione finora

- 3S Structural Engineering Design Manual - Revision 5 - Pgs 1 To 52Documento52 pagine3S Structural Engineering Design Manual - Revision 5 - Pgs 1 To 52Barrasons Engineers TeamNessuna valutazione finora

- Ajay Goyal - HSS Bridge Over Chenan BridgeDocumento8 pagineAjay Goyal - HSS Bridge Over Chenan BridgemalevolentNessuna valutazione finora

- Specification For Drainage & Infrastructure WorksDocumento33 pagineSpecification For Drainage & Infrastructure WorkskhuanozNessuna valutazione finora

- Method StatementDocumento31 pagineMethod StatementMuneeb KhanNessuna valutazione finora

- Gravel and Sand SupplyDocumento3 pagineGravel and Sand SupplyPhilip Dyaguit BaguhinNessuna valutazione finora

- Impcops Price List 01.09.2018Documento33 pagineImpcops Price List 01.09.2018Dawood Batcha0% (1)

- Price Adjustment Calculation SheetDocumento12 paginePrice Adjustment Calculation SheetsandipNessuna valutazione finora

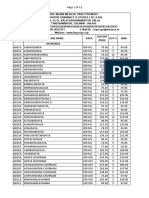

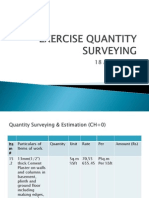

- Quantity Surveying & Estimation-3Documento17 pagineQuantity Surveying & Estimation-32449492100% (1)

- Cable Anchors: 11.1 GENERALDocumento1 paginaCable Anchors: 11.1 GENERALஅம்ரு சாந்திவேலுNessuna valutazione finora

- Chapter 1 5Documento34 pagineChapter 1 5Necee may lee ChuaNessuna valutazione finora

- Technology in The Construction IndustryDocumento5 pagineTechnology in The Construction IndustryGiancarlo GonzagaNessuna valutazione finora

- Basic Cost Terms and ConceptsDocumento8 pagineBasic Cost Terms and Conceptstegegn mogessieNessuna valutazione finora

- Mining Operations Plan DADocumento91 pagineMining Operations Plan DAGuizi Paleta Vasquez RojasNessuna valutazione finora

- 3.5 X 18 Redlam™ LVL 2.0E: This Product Meets or Exceeds The Set Design Controls For The Application and Loads ListedDocumento1 pagina3.5 X 18 Redlam™ LVL 2.0E: This Product Meets or Exceeds The Set Design Controls For The Application and Loads ListedbaoNessuna valutazione finora

- Steel Shop Drawing-ModelDocumento1 paginaSteel Shop Drawing-ModelAli MoazNessuna valutazione finora

- UNE S315MC - Chemical Composition, Properties, Heat Treatment, Steel EquivalentDocumento2 pagineUNE S315MC - Chemical Composition, Properties, Heat Treatment, Steel EquivalentJèManziNessuna valutazione finora

- Tower Base DesignDocumento5 pagineTower Base Designhabibur Rahman KhanNessuna valutazione finora

- Heydar Aliyev Cultural Center: Structu Ral Buil Ding Ma TerialsDocumento3 pagineHeydar Aliyev Cultural Center: Structu Ral Buil Ding Ma TerialsJasmin AzizNessuna valutazione finora

- Evolution of Skyscraper (For Powerpoint)Documento2 pagineEvolution of Skyscraper (For Powerpoint)Mar Kenneth Dela CruzNessuna valutazione finora

- Box-Culvert Design (Longitudinal Section)Documento1 paginaBox-Culvert Design (Longitudinal Section)Ruben Dario Posada BNessuna valutazione finora

- Bolted Connections PDFDocumento56 pagineBolted Connections PDFÃvēđÆñ ŤhåķųřNessuna valutazione finora

- Ansi+asse+a10 31-2013Documento64 pagineAnsi+asse+a10 31-2013Guillermo Mahecha Aponte100% (1)

- Survey QuestionnaireDocumento9 pagineSurvey QuestionnaireViele Antonette NaranjoNessuna valutazione finora

- Railway USSORDocumento123 pagineRailway USSORPrincipal DPWTCNessuna valutazione finora