Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Solutions Sharing Template - GSD2019

Caricato da

apoorv shrivastava0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaTitolo originale

Solutions Sharing Template - GSD2019.pptx

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaSolutions Sharing Template - GSD2019

Caricato da

apoorv shrivastavaCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Name: Santosh Swamy

Safety Solutions Sharing SESA ID: 450545

Region : Team leader

#GSD2019 #S.A.F.E. First

BEFORE: AFTER:

We have set high standards in 2019 when it Safe, Smart, Innovative Solutions Implementation Steps:

comes to Safety at Schneider Electric. Soft ware protection Monitoring will ensure • Test process includes safety interlock to

Having in mind our zero injuries goal and current ,voltage, timing & SMS notification. isolate employee from electrical conductors

the permanent concern for the safety of all Electrical protection will endure over • The concern is failure of the mechanical

our employees, this year already started current, leakage current & thermal. interlock which could expose employees to live

with big enhancements: we have updated Mechanical Protection will ensure voltage

most of our Safety Directives and Guidance Biometrics, inter lock, smoke dedicator, • The solution is external verification of Zero

Documents. tripping devices. Energy State prior to connecting/disconnecting

Test bench was running 8 to 10 hrs/Per day Test bench will run 24X7hrs with all safety electrical test leads on units

In case of failure time ,money & property will Increased testing efficiency of 60% For 90 % of equipment's installed Safety kit in

loss to organization GIGA lab

Picture: Failure mode Picture: Resources/Costs:

80000 thousand INR per kit.

Implemented by GIGA lab Bangalore .

Value added

1. It can detect heat changes in test benches

bus couplers and other Devices.

2. If smoke is detected in test benches it will

generate alarm and turn it off.

Potrebbero piacerti anche

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Digital Thermometer Design With Orcad Simulation and Full Report With CalculationDocumento10 pagineDigital Thermometer Design With Orcad Simulation and Full Report With CalculationChabo D. WolfNessuna valutazione finora

- AREVA - Fault AnalysisDocumento106 pagineAREVA - Fault AnalysisAboMohamedBassam100% (1)

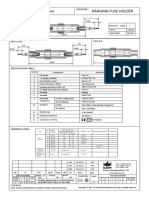

- Hanging fuse holder product detailsDocumento1 paginaHanging fuse holder product detailsbemlNessuna valutazione finora

- Basic Concept of Phasor - Lecture NotesDocumento8 pagineBasic Concept of Phasor - Lecture NotesEarl Patrick EugenioNessuna valutazione finora

- Section 21: Limit SwitchesDocumento40 pagineSection 21: Limit Switchesnew2trackNessuna valutazione finora

- Nuclear CondensedDocumento490 pagineNuclear CondensedJosé VellojínNessuna valutazione finora

- Wbut Measurement Question (EE402)Documento7 pagineWbut Measurement Question (EE402)Debdeep MukherjeeNessuna valutazione finora

- Institute of Aeronautical EngineeringDocumento4 pagineInstitute of Aeronautical EngineeringACE PROFILESNessuna valutazione finora

- Perancangan Dan Implementasi Sistem Monitoring Kecepatan Motor BLDC Hub Bergir Pada Sepeda ListrikDocumento8 paginePerancangan Dan Implementasi Sistem Monitoring Kecepatan Motor BLDC Hub Bergir Pada Sepeda ListrikAgung SlametNessuna valutazione finora

- Semiconductors Notes PDFDocumento20 pagineSemiconductors Notes PDFVishalNessuna valutazione finora

- 83 Revision Questions SolutionsDocumento5 pagine83 Revision Questions Solutionsmb1234Nessuna valutazione finora

- Technical Data: DescriptionDocumento4 pagineTechnical Data: DescriptionMiltongrimi GrimilNessuna valutazione finora

- Littelfuse Varistor LA Datasheet PDFDocumento13 pagineLittelfuse Varistor LA Datasheet PDFJohnny L. SimbulNessuna valutazione finora

- Standard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodDocumento7 pagineStandard Practice For Measuring Thickness by Manual Ultrasonic Pulse-Echo Contact MethodRenzo BellotaNessuna valutazione finora

- Recent Trend in Electrochemical Science and TechnologyDocumento316 pagineRecent Trend in Electrochemical Science and TechnologyCherry HamsteadNessuna valutazione finora

- Ba Msf220vu e PDFDocumento8 pagineBa Msf220vu e PDFSyariefNessuna valutazione finora

- XXGP65-16 18-TV VDocumento1 paginaXXGP65-16 18-TV VИмяNessuna valutazione finora

- Circuit Note: Fully Automatic High Performance Conductivity Measurement SystemDocumento10 pagineCircuit Note: Fully Automatic High Performance Conductivity Measurement SystemSupolNessuna valutazione finora

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocumento2 pagineData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNessuna valutazione finora

- IDL-800A Digital Lab SpecificationDocumento1 paginaIDL-800A Digital Lab SpecificationDr-Eng Imad ShaheenNessuna valutazione finora

- Sensors and Actuators SyllabusDocumento14 pagineSensors and Actuators SyllabusKeerthan R VarmaNessuna valutazione finora

- Rugged Multi-Axis Joystick Controls Heavy EquipmentDocumento11 pagineRugged Multi-Axis Joystick Controls Heavy Equipmentdjoko123Nessuna valutazione finora

- Moeller Sasy 60iDocumento50 pagineMoeller Sasy 60iOscar TorresNessuna valutazione finora

- R134a 12-24V DC 11-01 Cn46c702Documento24 pagineR134a 12-24V DC 11-01 Cn46c702latrancaNessuna valutazione finora

- Communication Engineering Asst. Prof. Dr. Ashwaq Q. Hameed Al Faisal UOT-Electrical Engineering Dept. Electronic Engineering BranchDocumento6 pagineCommunication Engineering Asst. Prof. Dr. Ashwaq Q. Hameed Al Faisal UOT-Electrical Engineering Dept. Electronic Engineering BranchAzza24 Azize24Nessuna valutazione finora

- Angle Controlled Current Regulated Rectifiers For AC/AC ConvertersDocumento7 pagineAngle Controlled Current Regulated Rectifiers For AC/AC ConvertersKanomba JavaNessuna valutazione finora

- Easy Ups 3s - E3sups15khDocumento3 pagineEasy Ups 3s - E3sups15khblackmamba etti jeanNessuna valutazione finora

- O & M Manual For The ATC-800, 3 Position Contactor Based Transfer SwitchDocumento44 pagineO & M Manual For The ATC-800, 3 Position Contactor Based Transfer SwitchmrtabiehjNessuna valutazione finora

- Renr7885renr7885 03 Sis CMCDocumento2 pagineRenr7885renr7885 03 Sis CMCsayeed younis sadaatNessuna valutazione finora