Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 1

Caricato da

Aiman Hazim0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

28 visualizzazioni4 paginen

Titolo originale

CHAPTER 1

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documenton

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

28 visualizzazioni4 pagineChapter 1

Caricato da

Aiman Hazimn

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

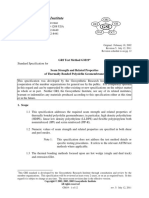

CHAPTER 1

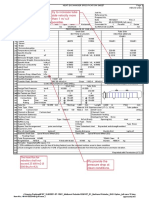

HEAT EXCHANGER (E-103)

PROCESS DETAIL

Water Th,out

T=

P= Stream INLET OUTLET

Stream No. 14 16

Temperature (°C) 63 65

Stream 14, Tc,in Stream 14, Tc,out

T= T= Pressure (bar) 1.2 2.3

P= P= Mass Flowrate (kg/hr) 11638.73 46714.04

Molar Flowrate (kmol/hr) 0.13226 1667.141

C2H4 0 24.648

Water H2 0 0

Th,in

T=

PE 0.13226 0

P= N2 0 1642.49

H2O 0 0

Phenol 0 0

Al(OH)3 0 0

Phosphate 0 0

C36H70O4Zn 0 0

SPECS

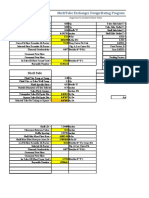

CHEMICAL DESIGN MECHANICAL DESIGN

General Parameter Value

Shell and Tube Heat Tube side Shell Side Unit

Type N/A

Exchanger

Design Pressure 2.2 2.2 Bar

Orientations of Tubes Horizontal N/A

Heat Load 1159.34 kW Design Temperature 110 140 °C

Heat Transfer Area 75.63 m2 Material of Construction Stainless Steel Stainless Steel N/A

Mean Temperature Corrosion Allowance 4 4 mm

61.57 °C

Difference Thickness 1.6 10.5 mm

True Mean

Welded Joint Efficiency 1.0 N/A

Temperature 51.1 °C

Difference

Type of Flange Bolted Flange – Welding Neck N/A

Overall Heat Transfer Head and Closure

316.27 W/m2.°C 1) Ellipsoidal Head

Coefficient 1) Type mm

2) 10.5

TUBE SIDE 2) Thickness

Inside Diameter, di 17.55 mm Insulation Type Mineral wool N/A

Outside Diameter, do 19.05 mm

Weight of Vessel 3957.4 N

Number of Tubes 345 N/A

Tube of Bundle Weight of Insulation 46.55 N

546 m

Diameter Weight of Tubes 85.81 N

Length of Tube 1.83 m Total Weights 4089.76 N

Number of Passes 2 N/A Vessel Support Type Saddle Support N/A

Heat Transfer

609.2 W/m2.°C Flange Type Bolted Flange Joint(Welding-Neck

Coefficient, hi N/A

Pressure Drop 0.435 kPa Flange)

Pattern Square pitch N/A Number of Baffles 8 N/A

SHELL SIDE

Shell Diameter, Ds 0.635 mm Flange Nom Pipe D b h D4 f Bolting No. d2 k d3

Baffle Spacing, Bs 0.190 mm

. Size o.d

Heat Transfer

Coefficient, hs

3958.08 W/m2.°C Shell 200 178. 320 20 44 258 3 M16 8 18 280 240

Pressure Drop 0.509 kPa 5

Tube 65 76.1 160 14 32 110 3 M12 4 14 130 100

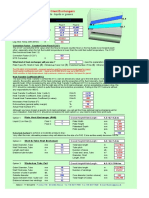

DESIGN DRAWING

Potrebbero piacerti anche

- Handbook of Heating, Ventilating and Air ConditioningDa EverandHandbook of Heating, Ventilating and Air ConditioningValutazione: 4 su 5 stelle4/5 (6)

- Module 1 & 2 (Tracking Radar) PDFDocumento52 pagineModule 1 & 2 (Tracking Radar) PDFDeeksha NaiduNessuna valutazione finora

- Bottom & Annular Plate Design: We Will Use Bottom Witout AnularDocumento25 pagineBottom & Annular Plate Design: We Will Use Bottom Witout AnularhgagNessuna valutazione finora

- Heat Exchanger Rating Calc SheetDocumento14 pagineHeat Exchanger Rating Calc SheetSatria 'igin' Girindra NugrahaNessuna valutazione finora

- Heat Exchanger Design and HT Coefficent Calculation From RC-6 BookDocumento20 pagineHeat Exchanger Design and HT Coefficent Calculation From RC-6 BookJag KhadseNessuna valutazione finora

- Helical Super Heater DesignDocumento13 pagineHelical Super Heater DesignG S DeshpandeNessuna valutazione finora

- Condenser DesignDocumento2 pagineCondenser DesignRahul ParmarNessuna valutazione finora

- PED (Design of Shell and Tube Heat Exchanger) 63Documento5 paginePED (Design of Shell and Tube Heat Exchanger) 63DineshNessuna valutazione finora

- Heat Exchanger RatingDocumento10 pagineHeat Exchanger RatingAnand BhiseNessuna valutazione finora

- PHE DesignDocumento53 paginePHE Designchgourishankar2000100% (1)

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21Documento4 pagineSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21SRINessuna valutazione finora

- Heat Exchanger Design for BreweryDocumento14 pagineHeat Exchanger Design for BreweryAnand BhiseNessuna valutazione finora

- Coil Sizing for Batch Cooling and HeatingDocumento8 pagineCoil Sizing for Batch Cooling and Heatingankur2061Nessuna valutazione finora

- Technological Institute of The PhilippinesDocumento25 pagineTechnological Institute of The PhilippinesJohn Leonard FazNessuna valutazione finora

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocumento8 pagineHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNessuna valutazione finora

- Jacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /HDocumento30 pagineJacketed Vessel Heat Transfer (Half Pipe Coil) : MM Inch MM RPM MM M /Hmanoj67% (3)

- Shell and Tube Heat Exchanger Design: Temperature of FluidsDocumento6 pagineShell and Tube Heat Exchanger Design: Temperature of FluidsRashmi PariharNessuna valutazione finora

- Condenser DesignDocumento2 pagineCondenser DesignrcalaforraNessuna valutazione finora

- Gas Chiller Datasheet PDFDocumento2 pagineGas Chiller Datasheet PDFidilfitriNessuna valutazione finora

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocumento37 pagineSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Gas-Gas Exchanger DatasheetDocumento3 pagineGas-Gas Exchanger DatasheetidilfitriNessuna valutazione finora

- Surface Condenser Thermal Analysis (100914)Documento11 pagineSurface Condenser Thermal Analysis (100914)amlanfacebookNessuna valutazione finora

- Shell&Tube TEMAsheet 1Documento1 paginaShell&Tube TEMAsheet 1Rikiya FebriyanNessuna valutazione finora

- Kathrein 80010761Documento2 pagineKathrein 80010761Sego Megono100% (1)

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDocumento4 pagineSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINessuna valutazione finora

- VG 320 Oil CoolerDocumento32 pagineVG 320 Oil CoolergsdaundhNessuna valutazione finora

- Fundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringDa EverandFundamentals of Fluidized-Bed Chemical Processes: Butterworths Monographs in Chemical EngineeringNessuna valutazione finora

- Half Pipe Coil AgitatedDocumento1 paginaHalf Pipe Coil AgitatedNITINNessuna valutazione finora

- 30 TR IG Tube PDFDocumento1 pagina30 TR IG Tube PDFshree awateNessuna valutazione finora

- Heat exchanger specification sheet vibration analysisDocumento3 pagineHeat exchanger specification sheet vibration analysisSRINessuna valutazione finora

- Heat Exchanger Specification Sheet SI UnitsDocumento1 paginaHeat Exchanger Specification Sheet SI UnitsdhaNessuna valutazione finora

- Hot Gas Recuperator Specification SheetDocumento1 paginaHot Gas Recuperator Specification Sheetmjaric81Nessuna valutazione finora

- Heat Exchanger Calculation Sheet - 1Documento10 pagineHeat Exchanger Calculation Sheet - 1Ritesh Dev MaityNessuna valutazione finora

- Heat Exchanger Plate TypeDocumento1 paginaHeat Exchanger Plate TypeDeepak jainNessuna valutazione finora

- Heat Exchanger SizingDocumento17 pagineHeat Exchanger SizingEbraham RammalNessuna valutazione finora

- Heat Exchanger DatasheetDocumento2 pagineHeat Exchanger DatasheetMohammad Mehdi JafariNessuna valutazione finora

- Gas Chiller DatasheetDocumento2 pagineGas Chiller DatasheetidilfitriNessuna valutazione finora

- Heat Exchanger Specification SheetDocumento4 pagineHeat Exchanger Specification SheetAnita PanthiNessuna valutazione finora

- Heat exchanger specification sheetDocumento2 pagineHeat exchanger specification sheetDycka Anugerah PuryantoroNessuna valutazione finora

- Ex Planlha Op2Documento5 pagineEx Planlha Op2adilsonrodriguesNessuna valutazione finora

- CHPT 5 ST Excel Heat Exch - Edit - 2Documento5 pagineCHPT 5 ST Excel Heat Exch - Edit - 2Claimir GuinzelliNessuna valutazione finora

- HE Rating Data Sheet v6Documento1 paginaHE Rating Data Sheet v6dhaNessuna valutazione finora

- Double - Pipe - Exchanger (Para o Lado Ar)Documento4 pagineDouble - Pipe - Exchanger (Para o Lado Ar)gabrieltravassosNessuna valutazione finora

- 600RT LMTD 2 T20Documento1 pagina600RT LMTD 2 T20syahmi yacobNessuna valutazione finora

- Heat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Documento2 pagineHeat Transfer in Pipe Flow - VDI Heat Atlas, 11. Edition 2013, G1Luis Fernando Castrillón MadrigalNessuna valutazione finora

- Heat Exchanger Specification SheetDocumento1 paginaHeat Exchanger Specification SheetRizal NajibNessuna valutazione finora

- General Lay-Out of AB&CO Heat ExchangersDocumento1 paginaGeneral Lay-Out of AB&CO Heat Exchangersfernando garza0% (1)

- PASES, AIRE 448308 LB - HR REVaa1.SEGDocumento1 paginaPASES, AIRE 448308 LB - HR REVaa1.SEGTIPAZONessuna valutazione finora

- CrudoDocumento2 pagineCrudoAndrés Felipe TáutivaNessuna valutazione finora

- HeaterSimulationResults 20112022 872204Documento17 pagineHeaterSimulationResults 20112022 872204Hamid MansouriNessuna valutazione finora

- Heat Exchanger RatingDocumento10 pagineHeat Exchanger RatinggabrieltravassosNessuna valutazione finora

- Heat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriDocumento1 paginaHeat Exchanger Specification Sheet Us Units: C:/Htri/Xchangersuite5/Samples/Xist - Shellsinseries - HtriNatarajan RavisankarNessuna valutazione finora

- 106-E-01 (Netralizing Unit) - TEMA SheeDocumento1 pagina106-E-01 (Netralizing Unit) - TEMA SheeMekar MeinaNessuna valutazione finora

- Juice Heater 1Documento1 paginaJuice Heater 1vijendrNessuna valutazione finora

- AQ10T-BFM, 363PL 2335kWDocumento2 pagineAQ10T-BFM, 363PL 2335kWLiviu ConstantinNessuna valutazione finora

- 1Documento1 pagina1kkkprotNessuna valutazione finora

- 7112.a Data SheetsDocumento7 pagine7112.a Data SheetsAlexis PradoNessuna valutazione finora

- New Heat Exchaner Design - 5mwDocumento20 pagineNew Heat Exchaner Design - 5mwDaniel Perez0% (1)

- Anexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPDocumento2 pagineAnexo 4 - Ficha Intercambiador de Calor de Placas 98.8 KW SWEPSicologo CimeNessuna valutazione finora

- WTS Sample PrintoutDocumento21 pagineWTS Sample Printoutsaka dewaNessuna valutazione finora

- Aspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMDocumento1 paginaAspen Exchanger Design and Rating Shell & Tube V10: File: B1 - 26.edr Printed: 7/1/2019 at 11:00:15 PMAlex AgualemaNessuna valutazione finora

- Output PDFDocumento1 paginaOutput PDFAlex AgualemaNessuna valutazione finora

- Simple and Inexpensive Microforge: by G. HilsonDocumento5 pagineSimple and Inexpensive Microforge: by G. Hilsonfoober123Nessuna valutazione finora

- Recursion: Fall 2002 CMSC 203 - Discrete Structures 1Documento18 pagineRecursion: Fall 2002 CMSC 203 - Discrete Structures 1Kris BraNessuna valutazione finora

- Rabin CryptosystemDocumento41 pagineRabin CryptosystemArkadev GhoshNessuna valutazione finora

- Mid Year Physics Exam Paper Sec 3 HaisingDocumento11 pagineMid Year Physics Exam Paper Sec 3 HaisingEmmanuel Elijah ErNessuna valutazione finora

- Eep-Commissioning of HV Panel Operational and Functional CheckupDocumento3 pagineEep-Commissioning of HV Panel Operational and Functional Checkupabdulyunus_amirNessuna valutazione finora

- Sterilizers of ParenteralsDocumento42 pagineSterilizers of ParenteralsHanuma KanthetiNessuna valutazione finora

- CHM 2045 Exam 2 Form Code ADocumento2 pagineCHM 2045 Exam 2 Form Code ABritanny NelsonNessuna valutazione finora

- Kids Book What So WhatDocumento3 pagineKids Book What So Whatapi-526691999Nessuna valutazione finora

- 1Documento10 pagine1Amit KumarNessuna valutazione finora

- Electrodo de Carbon PDFDocumento2 pagineElectrodo de Carbon PDFAlfredo FloresNessuna valutazione finora

- Thermoelectric Mini Fridge & WarmerDocumento37 pagineThermoelectric Mini Fridge & WarmerDinu RamanattukaraNessuna valutazione finora

- Geosynthetic Institute: GRI Test Method GM19Documento12 pagineGeosynthetic Institute: GRI Test Method GM19HeiderHuertaNessuna valutazione finora

- Physics Duty Chapter SevenDocumento23 paginePhysics Duty Chapter SevenScribdTranslationsNessuna valutazione finora

- 614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Documento12 pagine614460-Multi-Objective Material Selection For Wind Turbine Blade and Tower - Ashby's Approach - 10Erika Kawakami VasconcelosNessuna valutazione finora

- Coanda Effect Air-LiftDocumento19 pagineCoanda Effect Air-LiftJúlio Cesar RodriguesNessuna valutazione finora

- Emulsions, foams and gels: the science of colloidal dispersionsDocumento42 pagineEmulsions, foams and gels: the science of colloidal dispersionspalla gopalNessuna valutazione finora

- A Ghost in The MachineDocumento7 pagineA Ghost in The MachineSicklslicerNessuna valutazione finora

- Package Insert - PYROSPERSE™ Dispersing Agent (English) - Original - 27876Documento7 paginePackage Insert - PYROSPERSE™ Dispersing Agent (English) - Original - 27876Putri DozanNessuna valutazione finora

- Week 1 ScienceDocumento38 pagineWeek 1 ScienceEyphrille UmandapNessuna valutazione finora

- Arduino Modules L298N Dual H Bridge Motor ControllDocumento7 pagineArduino Modules L298N Dual H Bridge Motor ControllMarius DanilaNessuna valutazione finora

- Implementing A Virtual TrackballDocumento4 pagineImplementing A Virtual Trackballkinny1974Nessuna valutazione finora

- Year 10 Trigonometry 2Documento4 pagineYear 10 Trigonometry 2Jack LagerNessuna valutazione finora

- Getting Started With ANSYSDocumento19 pagineGetting Started With ANSYSThulasi RamNessuna valutazione finora

- Introduction to Soil Moduli & Stress-Strain BehaviorDocumento45 pagineIntroduction to Soil Moduli & Stress-Strain BehaviorYassin Abd El AalNessuna valutazione finora

- Online Courses From Top UniversitiesDocumento3 pagineOnline Courses From Top Universitiesephrem0% (2)

- Flywheels May SulatDocumento3 pagineFlywheels May SulatRonnieNessuna valutazione finora

- CH 6Documento21 pagineCH 6Narendran KumaravelNessuna valutazione finora

- CTV PRC001 E4 - 09012004 PDFDocumento24 pagineCTV PRC001 E4 - 09012004 PDFsuperpuma86Nessuna valutazione finora