Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Media For Industrial: Fermentation

Caricato da

ssfoodtech0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

301 visualizzazioni22 pagine1. Media formulations must provide nutrients like carbon, nitrogen, phosphorus, and sulfur to support microbial growth, as well as trace elements, vitamins, and buffers to control pH.

2. Traditionally, complex natural materials were used but they are unpredictable; defined media is preferred for consistency and product recovery.

3. Common carbon sources include carbohydrates like molasses, oils, and fats. Nitrogen sources can be inorganic salts or organic compounds like corn steep liquor. Minerals, chelators, growth factors, and buffers are also required components.

4. The choice and concentration of nutrients influences microbial growth and the yield of desired products.

Descrizione originale:

Various media formulations

Titolo originale

Fermentation Media

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento1. Media formulations must provide nutrients like carbon, nitrogen, phosphorus, and sulfur to support microbial growth, as well as trace elements, vitamins, and buffers to control pH.

2. Traditionally, complex natural materials were used but they are unpredictable; defined media is preferred for consistency and product recovery.

3. Common carbon sources include carbohydrates like molasses, oils, and fats. Nitrogen sources can be inorganic salts or organic compounds like corn steep liquor. Minerals, chelators, growth factors, and buffers are also required components.

4. The choice and concentration of nutrients influences microbial growth and the yield of desired products.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

301 visualizzazioni22 pagineMedia For Industrial: Fermentation

Caricato da

ssfoodtech1. Media formulations must provide nutrients like carbon, nitrogen, phosphorus, and sulfur to support microbial growth, as well as trace elements, vitamins, and buffers to control pH.

2. Traditionally, complex natural materials were used but they are unpredictable; defined media is preferred for consistency and product recovery.

3. Common carbon sources include carbohydrates like molasses, oils, and fats. Nitrogen sources can be inorganic salts or organic compounds like corn steep liquor. Minerals, chelators, growth factors, and buffers are also required components.

4. The choice and concentration of nutrients influences microbial growth and the yield of desired products.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 22

Media for Industrial

fermentation

Reference: Principles of Fermentation

Technology- Stanburry

On a large scale one must normally use sources of nutrients to create a

medium which will meet as many as possible of the following criteria:

Media Requirements and Media

formulations

• Large quantities of water is in need for

medium formulation.

• Media req. C, N, P & S.

• Minor req. as trace elements and vitamins

(biotin & riboflavin) may be in need.

• Media may include buffers or pH control (acid-

alkali additions).

• Antifoam agents, Inhibitors and Inducers may

be required.

• Historically – undefined complex natural materials used

– although they are cheaper but unpredictable

biomass/yield problems.

• Product recovery very difficult, residual components

my interfere with the recovery and contribute to the

BOD of the effluent.

• Although defined media is more expensive but it give

more predictable yield then undefined media.

• Control of pH and foam during growth in a fermenter

were indentified as two important parameters.

• Molasses would normally be used as the cheapest

carbohydrate to grow yeast biomass in a large scale

process. But this is not acceptable for Recombinant

protein production b/c of difficulties and cost for

purification.

Medium Formulation

• Medium formulation is an essential stage in the design

of successful laboratory experiments, pilot – scale

development and manufacturing process.

• The constituent of the medium must satisfy the

elemental requirements for cell biomass & metabolite

production and there must be an adequate supply of

energy for biosynthesis.

C + N+ O2 +other req ------- biomass + product + CO2 +

H2O + Heat

• Thus, to calculate the minimal quantities of nutrients

which will be needed to produce a specific amount of

biomass, it should calculate substrate concentration

necessary to produce required product yields.

• Coonye 1981 – some nutrient are frequently added in

substantial excess of that required eg P, K, some trace eg.

Zn, Cu. Conc of P is deliberately raised in many media to

increase the buffering capacity. It depend on the

medium design.

• Some microorganism can't synthesize specific nutrients

eg AA, vitamins or nucleotides. Once a specific growth

factor has been identified it can be incorporated into a

medium.

• C has a dual role in Biosynthesis & energy generation. C

requirement for biomass production under aerobic

condition may be estimated the cellular yield Y which is

defined as

• Quantity of cell dry matter produced/quantity of C

substrate utilized.

Energy Sources

• Energy comes either from oxidation of medium

components or from light.

• Most industrial microorganism are chemo-organotrophs,

therefore the commonest source of energy will be the

carbon (CHO), lipids & protein.

• Some micro-organisms can also use hydrocarbons or

methanol as carbon & energy sources.

Factor influencing the choice of carbon source:

Rate at which the C source is metabolized can often

influence the formation of biomass or production of

primary or secondary metabolites.

Fast growth due to high concentrations of rapidly

metabolized sugars is often associated with low

productivity of secondary metabolites.

• Main product of fermentation process depend on the choice

of C source.

• Eg. Ethanol, or SCP - 60-77% of the production cost depend

on cost of C source.

• it is the part of Company development program – to

determine the alternative C source to determine the yield.

• The purity of the C source may also affect the choice of

substance.

• The method of media preparation, particularly sterilization

may affect the suitability of CHO for individual fermentation

process.

• Its often best to sterilize sugar separately b/c they may react

with NH4 ions & AA to from black N containing compounds

which will inhibit the growth of many microorganism.

Carbohydrates

• Its common practice to use CHO in microbial

fermentation e.g starch from maiz grain

• It may also obtained from, others cereals, potatoes &

cassava.

• Hydrolyzed cassava starch is used as a major C source

for glutamic acid production.

• Sucrose is obtained from sugar cane & sugar beet. It is

commonly used in fermentation media in a very impure

form as beet or cane molasses which are the residues

left after crystallization of sugar soln in sugar refining.

• Molasses is used in the production of high volume/low

value products such as ethanol , SCP, organic and AA

and some microbial gums.

• Molasses or sucrose also may be used for

production of higher value/low bulk products

such as antibiotics, specially enzymes, vaccines &

fine chemicals.

• However, molasses based fermentation will often

need a more expensive & complicated extraction

/ purification procedure to remove impurities &

effluents which make the procedure costly.

• Corn steep liquor is a by product after starch

extraction from maize. Although primarily used as

a N source, it does contain lactic acid, small

amounts of reducing sugars & complex

polysaccharides.

Oils and Fats

• Oils were first used as carriers for antifoams in antibiotics

processes.

• Vegetables oils may also be used as C substrates, particularly for

their content of the fatty acid, oleic, linoleci and linolenic acid b/c

of cost are competitive with those of CHO.

• Bader 1984 – factors favouring the use of oils instead of CHO. A

typical oil contains approximately 2.4 times the energy of glucose

on a per weight basis.

• Oils also have a volume advantage as it would take 1.24 dm3 of soya

bean oil to add 10KCal energy to a fermenter whereas it would take

5dm3 of glucose or sucrose assuming that they are being added

50%w/w solutions.

• Oil also has antifoam properties

• Glycerol trioleat is known to be used in some fermentation

• Methly oleate used as the C substrate in cephalosporin production

Nitrogen sources:

• Most industrially used microorganism can utilize inorganic or

organic sources of nitrogen.

• Inorganic N may be supplied as NH3 gas, NH4 salts or nitrates.

NH3 has been used for pH control & as the major N source in a

defined medium for the commercial production of human

serum albumin by yeast.

• NH4 salts i.e (NH4)2SO4 will produce acid conditions & NH4NO3

normally cause an alkaline drift.

• When the NH4 ion has been exhausted, there is an alkaline

drift as the nitrate is used as n alternative N source.

• Organic N may be supplied as AA, protein or urea. Other

proteinaceous N compounds serving as sources of AA include

corn-steep liquor, soyas meal, peanut meal, cotton seed.

• In storage these products may be affected by moisture, temp,

& ageing.

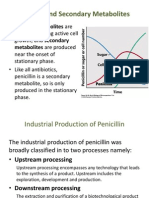

Factors influencing the choice of N source

• In Aspergilus nidulans NH3 also regulates the

production of alkaline & neutral proteases.

• In Antibiotic production by many microorganism

is influenced by the type and concentration of

the N in the culture medium.

• Antibiotic production only begins to increase in

the culture broth after most of the N consumed.

• Some complex N material cant be utilized by a

micro-organism & create problems in

downstream processing & effluent treatment.

This can be an important factor in the final choice

of substrate.

Minerals

• All micro-organism requires certain mineral elements for growth &

metabolism.

• In many media, Mg, P, K, S, Ca & Cl are essential components, Co,

Cu, Zn, Fe, Mn, Mb & Zn are also essential

• P is used as a Buffer to minimize pH changes when external pH is

not being used.

•in specific processes the conc of certain minerals may be very

critical.

•It also influence the production of bactricin, citric acid, ergot,

monomycin,novobiocin, oxytetracycline, polyene, ristomycin,

rifamycin, streptomycin, vacomycin & viomycin

Chelators

• Many media can’t be prepared or autoclaved

without the formation of a visible ppt of insoluble

metal PO4 .

• The problem of insoluble metal PO4 may be

eliminated by incorporating low conc of chelating

agents i.e EDTA, citric acid,polyphosphate etc

• These chelating agents form complexes with the

metal ions in a medium. The metal ions then my

be gradually utilized by the micro-organism.

• Chelating agent does not cause inhibition of

growth.

Growth Factors

• Vitamins, specific AA, fatty acids or sterols.

• Many of the natural C & N sources used in media

formulation contain all or some of the required

growth factors.

• If only one vitamins is required it may be move

economical to add a pure vitamin instead of large

bulk of cheaper multiple vitamins source. E.g Ca

pantothenate has been used in one medium

formulation for vinegar production. -

• In glutamic acid, limited conc of biotin must be

present in the medium, some requires thiamin.

Buffers

• The control of pH may be extremely important if

optimal productivity is to be achieved.

• Many media are buffered at about pH 7.0 by the

incorporation of CaCO3, if pH decreases the CO3 is

decomposed.

• PO4 which are the part of many media also play an

important role in buffering. High PO4 conc are critical in

the production of many secondary metabolites.

• C & N sources will also a basis for pH control as

buffering capacity can be provided by the protein,

peptides & AA such as in corn steep liquor.

• The pH may also be controlled externally by addition of

NH3 or NaOH & H2SO4.

The addition of precursors & metabolic regulators to media

• Some components of a fermentation medium help to

regulate the production of the product rather than support

the growth of the micro-organism. Such additive include,

precursors, inhibitors,

Precursors:

• Some chemicals when added to certain fermentation are

directly incorporated into the desired product.

• E.g Penicillin yields

• A range of diff side chain can be incorporated into the

penicillin moleucle, eg corn steep liquor increased the yield

of penicillin form 20 units to 100 units.

• Corn steep liquor contain phenylethlamine when

incorporated, it yield benzyl penicillin.

• Phenylacetic acid is widely used precursor in penicillin

production.

Inhibitors

• When certain inhibitors are added to

fermentations more of specific product may

be produced.

• Inhibitors have also been used to affect cell

wall structure and increase the permeability

for release of metabolites.

• The best example is the use of penicillin &

surfactants in glutamic acid production.

Inducers

• The majority of enzymes which are industrial interest

are inducible.

• Induced enzymes are synthesized only in response to

the presence in the environment of an inducer.

• Inducers are often substrate such as starch or dextrins

for amylase, maltose for pullulanase & pectin for

pectinase.

• Most inducers which are included in microbial enzyme

media are substrate or substrate analogues but

intermediates and products may sometime be used as

inducers.

• E.g maltodextrins will inudce amylase & fatty acids

induce lipase. (use depend upon the cost)

Fermentation Media

Thank you

Potrebbero piacerti anche

- Media For Industrial FermentationDocumento24 pagineMedia For Industrial Fermentationrawatpooran0560% (10)

- Module-9 (Theory) Media FormulationDocumento4 pagineModule-9 (Theory) Media FormulationriyaNessuna valutazione finora

- Industrial BiotechnologyDocumento57 pagineIndustrial BiotechnologyKavyaNessuna valutazione finora

- Chapter 5 Microbial BiotechnologyDocumento75 pagineChapter 5 Microbial BiotechnologymichaelNessuna valutazione finora

- Sterilization of Fermenter-1Documento11 pagineSterilization of Fermenter-1Shalini M100% (1)

- Lec 3.FERMENTATIONDocumento44 pagineLec 3.FERMENTATIONIsmaelovf100% (3)

- FermentationDocumento23 pagineFermentationr_bharathi100% (2)

- Vitamin B: Anushi Jain Roll No.: 08 Paper III MSC IiDocumento20 pagineVitamin B: Anushi Jain Roll No.: 08 Paper III MSC Iimy123Nessuna valutazione finora

- Air & Media SterilizationDocumento39 pagineAir & Media SterilizationEkon Ezung71% (7)

- Enzyme Inhibition in Drug Discovery and Development: The Good and the BadDa EverandEnzyme Inhibition in Drug Discovery and Development: The Good and the BadChuang LuNessuna valutazione finora

- Bioprocessing Technology for Production of Biopharmaceuticals and BioproductsDa EverandBioprocessing Technology for Production of Biopharmaceuticals and BioproductsClaire KomivesNessuna valutazione finora

- Fermentation TechnologyDocumento14 pagineFermentation TechnologyUmarNessuna valutazione finora

- BIOPOLDocumento4 pagineBIOPOLLewis TranNessuna valutazione finora

- Commercial Production of EnzymesDocumento4 pagineCommercial Production of EnzymesAli RazaNessuna valutazione finora

- Production of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia ColiDocumento5 pagineProduction of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia Coliapi-3743140Nessuna valutazione finora

- Bioprocess Engineering (BT 508) : Credits-4 Units - 6 Total Marks - 150Documento26 pagineBioprocess Engineering (BT 508) : Credits-4 Units - 6 Total Marks - 150Savita100% (1)

- Industrial MicrobiologyDocumento35 pagineIndustrial MicrobiologyNoor Ul Naeem100% (1)

- Ionic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesDa EverandIonic Liquids in Lipid Processing and Analysis: Opportunities and ChallengesXuebing XuNessuna valutazione finora

- Different Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitesDocumento11 pagineDifferent Types of Industrial Fermentors and Their Associated Operations For The Mass Production of MetabolitespavithraNessuna valutazione finora

- Basic Industrial BiotechnologyDocumento29 pagineBasic Industrial BiotechnologyBharathiNessuna valutazione finora

- Fermentation PDF NotesDocumento24 pagineFermentation PDF NotesJay-zee Shandu100% (5)

- Biopolymers: Sindhu Reka.R 14BBT047Documento14 pagineBiopolymers: Sindhu Reka.R 14BBT047aminsuhadiNessuna valutazione finora

- Strain ImprovementDocumento122 pagineStrain ImprovementRishanam RishanaNessuna valutazione finora

- Industrial Ptoduction of Vitamin b12Documento16 pagineIndustrial Ptoduction of Vitamin b12Sumit ChauhanNessuna valutazione finora

- Bioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyDocumento7 pagineBioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyMuhammad Fakhrizal Fahmi100% (1)

- Production of PenicillinDocumento16 pagineProduction of PenicillinMeenal KhannaNessuna valutazione finora

- Polymer Adhesives Note - DR Akinsiku PDFDocumento15 paginePolymer Adhesives Note - DR Akinsiku PDFGlory UsoroNessuna valutazione finora

- Food Biotechnology (ORGANIC ACIDS, ENZYMES, FOOD ADDITIVES)Documento61 pagineFood Biotechnology (ORGANIC ACIDS, ENZYMES, FOOD ADDITIVES)Dumisani Nguni100% (1)

- Enzyme Nomenclature 1978: This Edition Is a Revision of the Recommendations (1972) of the IUPAC–IUB Commission on Biochemical Nomenclature, and Has Been Approved for Publication by the Executive Committee of the International Union of BiochemistryDa EverandEnzyme Nomenclature 1978: This Edition Is a Revision of the Recommendations (1972) of the IUPAC–IUB Commission on Biochemical Nomenclature, and Has Been Approved for Publication by the Executive Committee of the International Union of BiochemistryValutazione: 4 su 5 stelle4/5 (3)

- Chapter 10 Biological Nitrogen FixationDocumento33 pagineChapter 10 Biological Nitrogen Fixationrajiv pathakNessuna valutazione finora

- Vaccines: Presented By: Arpita Batta EmailDocumento35 pagineVaccines: Presented By: Arpita Batta EmailarpitabattaNessuna valutazione finora

- Bacteriocin SlideDocumento8 pagineBacteriocin SlideGeorgette Ezechukwu0% (1)

- Week 1-Introduction of BioindustryDocumento31 pagineWeek 1-Introduction of BioindustryFery HaidirNessuna valutazione finora

- Introduction To Fermentation Technique & Fermenter: N.M AhmedDocumento20 pagineIntroduction To Fermentation Technique & Fermenter: N.M AhmedNaser_Ahmed11100% (1)

- Lecture 3Documento20 pagineLecture 3Biotechnology IIUM Kuantan100% (5)

- Direct Microbial Conversion of Biomass to Advanced BiofuelsDa EverandDirect Microbial Conversion of Biomass to Advanced BiofuelsMichael E HimmelNessuna valutazione finora

- Strain Improvement of Microorganisms PDFDocumento32 pagineStrain Improvement of Microorganisms PDFsatriomegaNessuna valutazione finora

- Biosynthesis of AntibioticsDa EverandBiosynthesis of AntibioticsJ SnellNessuna valutazione finora

- Fermentation Processes and Their Application PDFDocumento8 pagineFermentation Processes and Their Application PDFninasabelita100% (9)

- BF3000Documento6 pagineBF3000Jokanoe LertNessuna valutazione finora

- Production of Metabolites, Industrial Enzymes, AminoDocumento50 pagineProduction of Metabolites, Industrial Enzymes, AminoInuyashayahooNessuna valutazione finora

- Biotransformation 111201084539 Phpapp02Documento46 pagineBiotransformation 111201084539 Phpapp02thakur1989Nessuna valutazione finora

- Biomanufacturing History and PerspectiveDocumento12 pagineBiomanufacturing History and PerspectiveYedhaGuerrero100% (1)

- Membrane Research: Classic Origins and Current ConceptsDa EverandMembrane Research: Classic Origins and Current ConceptsA. L. Muggleton-HarrisNessuna valutazione finora

- Strain ImprovementDocumento15 pagineStrain ImprovementAlanChevalNessuna valutazione finora

- BLAST (Basic Local Alignment Search Tool)Documento23 pagineBLAST (Basic Local Alignment Search Tool)Polu Chattopadhyay100% (1)

- Biotechnology Lecture NoteDocumento121 pagineBiotechnology Lecture NoteSumit Swain100% (1)

- Chapter 5 Microbial BiotechnologyDocumento75 pagineChapter 5 Microbial BiotechnologyIna Ardan50% (2)

- Enzymes Ppt-NandanaDocumento26 pagineEnzymes Ppt-NandanaLingaraj Kumar100% (1)

- Enzymatic Starch HydrolysisDocumento107 pagineEnzymatic Starch HydrolysisManuel Rojas100% (1)

- Bubble Column Fermenter/BioreactorDocumento9 pagineBubble Column Fermenter/BioreactorLouellaNessuna valutazione finora

- Enzyme Chemistry of Phenolic Compounds: Proceedings of the Plant Phenolics Group Symposium, Liverpool, April 1962Da EverandEnzyme Chemistry of Phenolic Compounds: Proceedings of the Plant Phenolics Group Symposium, Liverpool, April 1962J. B. PridhamNessuna valutazione finora

- Upstream PenicillinDocumento6 pagineUpstream Penicillinzuzuzazazizi0% (1)

- Statistics for Food Scientists: Making Sense of the NumbersDa EverandStatistics for Food Scientists: Making Sense of the NumbersNessuna valutazione finora

- MBOE-201 07. Fermentation Economics PDFDocumento26 pagineMBOE-201 07. Fermentation Economics PDFPrithvi Shirahatti100% (1)

- Polymeric Supports for Enzyme Immobilization: Opportunities and ApplicationsDa EverandPolymeric Supports for Enzyme Immobilization: Opportunities and ApplicationsNessuna valutazione finora

- Biotechnology and Food Safety: Proceedings of the Second International SymposiumDa EverandBiotechnology and Food Safety: Proceedings of the Second International SymposiumDonald D. BillsValutazione: 5 su 5 stelle5/5 (1)

- Microbial Nutrition and GrowthDocumento30 pagineMicrobial Nutrition and GrowthOsaetin AnnNessuna valutazione finora

- Penicillin FermentationDocumento30 paginePenicillin FermentationUlfia Al RahmaNessuna valutazione finora

- Aerobic Growth of Heterotrophs in Rotating Disc Reactors & Fluidised Bed Biological ReactorsDocumento11 pagineAerobic Growth of Heterotrophs in Rotating Disc Reactors & Fluidised Bed Biological ReactorsssfoodtechNessuna valutazione finora

- Bioenergetics PDFDocumento4 pagineBioenergetics PDFssfoodtechNessuna valutazione finora

- Outline: Classification of Biochemical Operation Fundamentals of Biochemical OperationDocumento34 pagineOutline: Classification of Biochemical Operation Fundamentals of Biochemical OperationssfoodtechNessuna valutazione finora

- Mass Balance PDFDocumento8 pagineMass Balance PDFssfoodtechNessuna valutazione finora

- Aerobic Growth ModellingDocumento18 pagineAerobic Growth ModellingssfoodtechNessuna valutazione finora

- Pressure VesselDocumento51 paginePressure Vesselssfoodtech100% (1)

- Corrosion: Food Process Equipment Design Module-2Documento20 pagineCorrosion: Food Process Equipment Design Module-2ssfoodtechNessuna valutazione finora

- Energy End Thermo PDFDocumento31 pagineEnergy End Thermo PDFssfoodtechNessuna valutazione finora

- Plant Design & Layout - IntroductionDocumento44 paginePlant Design & Layout - Introductionssfoodtech100% (1)

- External Pressure in PVDocumento10 pagineExternal Pressure in PVssfoodtechNessuna valutazione finora

- Bioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesDocumento23 pagineBioreactor Engineering Module-1 Basic Design and Construction of A Fermentor and Its AncillariesssfoodtechNessuna valutazione finora

- Cashew Nut ProcessingDocumento19 pagineCashew Nut ProcessingssfoodtechNessuna valutazione finora

- Plant Design & Layout - IntroductionDocumento44 paginePlant Design & Layout - Introductionssfoodtech100% (1)

- Plant Location and TheoriesDocumento52 paginePlant Location and TheoriesssfoodtechNessuna valutazione finora

- Bioreactor Engineering: MODULE - 1-SterilisationDocumento24 pagineBioreactor Engineering: MODULE - 1-SterilisationssfoodtechNessuna valutazione finora

- Dairy Plant LayoutDocumento14 pagineDairy Plant Layoutssfoodtech100% (1)

- Measurement of Bioreactor K ADocumento18 pagineMeasurement of Bioreactor K AssfoodtechNessuna valutazione finora

- A Review - Self Nanoemulsifying Drug Delivery System (Snedds)Documento13 pagineA Review - Self Nanoemulsifying Drug Delivery System (Snedds)Lilia AndromedaNessuna valutazione finora

- INDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFDocumento9 pagineINDG254 CHEMICAL REACTION HAZARDS and The Risk of THERMAL Runaway PDFJayaprakasan Koyadan KorothNessuna valutazione finora

- Rilling OP Ata: IG Ccumulator NIT ATA Equired CcumulatorDocumento1 paginaRilling OP Ata: IG Ccumulator NIT ATA Equired CcumulatorKiryaki FrancisNessuna valutazione finora

- JIS G3452 - UpdatedDocumento7 pagineJIS G3452 - Updatedngocbinh8x100% (1)

- DOWSIL™ 982-H Curing Agent Black SDSDocumento21 pagineDOWSIL™ 982-H Curing Agent Black SDSAquatic studentNessuna valutazione finora

- Transport Phenomena Data Companio PDFDocumento160 pagineTransport Phenomena Data Companio PDFLavanya ChandrashekarNessuna valutazione finora

- Acceptance of Materials in Contact With Drinking Water: Belgian Federation For The Water SectorDocumento24 pagineAcceptance of Materials in Contact With Drinking Water: Belgian Federation For The Water SectorJagdish PatelNessuna valutazione finora

- Jotun Malathon TDSDocumento5 pagineJotun Malathon TDSBiju_PottayilNessuna valutazione finora

- Salient Features of UFFLDocumento92 pagineSalient Features of UFFLMd. Abu NayeemNessuna valutazione finora

- Deluge Valve - SD-DVA PDFDocumento15 pagineDeluge Valve - SD-DVA PDFboxyfunNessuna valutazione finora

- Candace MaharajDocumento11 pagineCandace MaharajCharlotte BNessuna valutazione finora

- BOMBA NEUMATICA ARGAL-ASTRA-EVO-DDE-Instruction-Manual-rev-11-2021Documento58 pagineBOMBA NEUMATICA ARGAL-ASTRA-EVO-DDE-Instruction-Manual-rev-11-2021Jose Luis Ari AchahuiNessuna valutazione finora

- VATER Elgate Fence & Gate Systems INFO List JULY19Documento6 pagineVATER Elgate Fence & Gate Systems INFO List JULY19GarryNessuna valutazione finora

- Preferred Features Advanced Technology Proven Design: Bulletin 4000Documento12 paginePreferred Features Advanced Technology Proven Design: Bulletin 4000saulomonNessuna valutazione finora

- H2 - Prelim 2009 Paper1Documento16 pagineH2 - Prelim 2009 Paper1Augustine NgNessuna valutazione finora

- ProjectDocumento18 pagineProjectRaja ShankarNessuna valutazione finora

- KEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.ADocumento6 pagineKEPCO's First 5000 MW of Flue Gas Desulfurization: Babcock & Wilcox Barberton, Ohio, U.S.AVishal RastogiNessuna valutazione finora

- Caterpillar 950F Maintenance Manual ExerptDocumento47 pagineCaterpillar 950F Maintenance Manual Exerpttransteven9394% (16)

- D 8088 - 16Documento6 pagineD 8088 - 16Nguyễn Như ThếNessuna valutazione finora

- Balancing Equations Using InspectionDocumento5 pagineBalancing Equations Using InspectionEugene MacapagalNessuna valutazione finora

- 20141008131049chapter 7cDocumento52 pagine20141008131049chapter 7cbatraz79Nessuna valutazione finora

- Trimdek Optima1Documento1 paginaTrimdek Optima1Malith MadushanNessuna valutazione finora

- VONTELL Project ReportDocumento20 pagineVONTELL Project ReportPankajNessuna valutazione finora

- HMF in HoneyDocumento5 pagineHMF in Honeybtl sylrNessuna valutazione finora

- Laporan Kunjungan Industri Bahasa InggrisDocumento14 pagineLaporan Kunjungan Industri Bahasa InggrisRaimu Oke67% (3)

- Sarnafil g476 PdsDocumento4 pagineSarnafil g476 PdsRialno TambunanNessuna valutazione finora

- XRF BR41146 Arl Optimx WDXRF SpectrometerDocumento8 pagineXRF BR41146 Arl Optimx WDXRF SpectrometerGilson JoseNessuna valutazione finora

- Metal PrimerDocumento1 paginaMetal PrimertUNNessuna valutazione finora

- Malleable Iron Pipe Fittings: Gourd BrandDocumento11 pagineMalleable Iron Pipe Fittings: Gourd BrandAamer Abdul MajeedNessuna valutazione finora

- Ceramic Dental Biomaterials and CAD/CAM Technology: State of The ArtDocumento10 pagineCeramic Dental Biomaterials and CAD/CAM Technology: State of The ArtMaria Fernanda Romero RinconNessuna valutazione finora