Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Making Confident Decisions

Caricato da

Sium Adnan Khan 15111530300 valutazioniIl 0% ha trovato utile questo documento (0 voti)

6 visualizzazioni37 pagineLecture 10

Titolo originale

Mgt460

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLecture 10

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

6 visualizzazioni37 pagineMaking Confident Decisions

Caricato da

Sium Adnan Khan 1511153030Lecture 10

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 37

Making Confident Decisions

Parameter Distributions from

Multiple Samples:

The Central Limit Theorem

Two important aspects are:

• Repetitions of the measurement event produce different

outcome results.

• This resulting measurement, or sampling distribution, is

normally distributed

• Statisticians call repeated measurements of a characteristic or

a process samples. So the variation that occurs in repeated

sampling events they call its sampling distribution.

Calculating Decision Risk

Confidence Intervals

• The key to objective decision-making lies in confidence intervals

• Use the central limit theorem to quantify how much confidence you

can place in any of your measurements or statistical conclusions

from samples

Confidence intervals for means

Making decisions with large samples

• Z is the sigma value corresponding to the desired level of confidence

you want to have.

• Anytime you calculate a confidence interval, you also have an

associated risk of being incorrect.

• This risk is simply the complement of the calculated confidence.

• The risk of incorrectly concluding that the population average is

within the calculated confidence interval when it really isn’t is called

alpha (α) risk.

Making decisions with small samples

• When the sample has anywhere from 2 to 30 data points, you have

to use a different factor in place of Z

• Statisticians call this new factor for small-sized samples t.

• t is more conservative because the smaller sample size lessens the

accuracy of the calculated value for the standard deviation

• Using t, the formula for the confidence interval around the true

population average becomes

• Where the value for t depends on desired level of confidence and

the number of data points in the sample.

Comparing averages

• Take samples from each of the different versions or conditions

you’re comparing.

• Calculate the appropriate confidence interval for each

different version or condition of the characteristic.

• Graphically or numerically determine whether the confidence

intervals of the different versions or conditions overlap at all.

Confidence intervals for standard

deviations

• To construct a confidence interval around your calculated

sample standard deviation, you have to use a new factor

invented by statisticians called Χ2 (CHI)

• The value of χ2 depends on how many data points are in the

sample, the more data points in the sample, the more

confident the estimate

• There are different values of χ2 for the lower and upper limits

of the confidence interval

• suppose your sample of five data points leads to a sample

standard deviation of 3.7. create a 95-percent confidence

interval for the population standard deviation

• Corresponding to a 95-percent confidence and n = 5. χ2 LOWER

= 11.365 and χ2 UPPER = 0.460.

• With 95- percent confidence, you know that the real

population standard deviation lies somewhere between 2.195

and 10.907.

Comparing Variances

Constructing a confidence interval around this ratio of variances

requires another statistical factor, F, whose value depends on three

things:

• The desired level of confidence,

• The number of data points in the numerator distribution (n1),

• The number of data points in the denominator distribution (n2)

• If the ratio confidence interval includes the value 1 within its

limits, the two populations have equal variability.

• If the confidence interval doesn’t contain the value of 1 within its

limits, the two populations have different amounts of variation.

• suppose you have a ten-point sample from population A, and its

variance=4 . Another population, called B, has a sample of five

points, and its variance=7.5 . Calculate the confidence interval the

variances.

• This confidence interval contains the value of 1 within its limits, so

all you can say with 95-percent confidence is that no evidence

indicates that the two populations have different variances.

Confidence intervals for

proportions

• To calculate the number of successes out of a certain number

of attempts like “four out of five dentists recommend

sugarless gum” this proportion can be written as

• Where y is the number of successes and n is the total number

of attempts or trials.

• Proportions can never be less than zero or greater than one

• Calculating a proportion creates yet another sampling distribution.

The resulting confidence interval around a calculated proportion is

• Example, if you wanted to be 90-percent sure of the calculated

proportion for the four out of five dentists, calculate the confidence

interval.

Difference of proportions

• you’re part of a company with two production lines. You suspect

that your Toledo (T) plant produces a higher proportion of good

items (yield) than your Buffalo (B) plant. You select samples of size

nT = nB = 300 from each plant and find that the number of good

items from the Toledo plant (yT) is 213, while the number from the

Buffalo plant (yB) is 189. That means that a 95-percent confidence

interval for the difference between the Toledo and the Buffalo

yields is

• equivalently, [0.004, 0.156]. Because this confidence interval

doesn’t include zero, you can conclude with 95-percent confidence

that the Toledo plant produces, on average, a higher proportion of

good items than the Buffalo plant.

DMAIC: Improving

and Controlling

Forecasting Future Performance

Improving and Controlling

• With the critical few factors known, now the

company is ready to embark a journey towards

improvements

• Now we need to quantify potential improvement

effects so that we can see how much in the output

we will get for any given adjustment to the critical

inputs.

• We also need to understand the relationships

between the input variables and the critical

outputs

• Knowing the outcome of a potential improvement

without spending the resources to test it out is the

essence of Six Sigma improvement power

Correlation

• Scatter plots are a great way to visually discover and explore

relationships between variables — both between Ys and Xs

and between Xs and Xs.

• The calculated correlation coefficient is always between –1

and 1

• The sign of r tells the direction of the relationship between

the variables.

• The absolute value of r tells how strong the relationship is

• Correlation tells only how linear the relationship between the

variables is.

• The scatter plot shows a negative relationship between the

curb weight of the vehicle and its fuel economy

• The relationship between the two variables is approximately

linear, meaning that its shape approximately follows a straight

line.

• The relationship between the variables is fairly strong

• Correlation basically just confirms the existence of a

linear relationship between two variables and quantifies

how linear that relationship is.

• Correlation doesn’t equal causation.

• The fact that two variables correlate doesn’t mean that

one causes the other.

Curve Fitting

Curve fitting, means determine the equation for

the curve that best fits the data

• It quantitatively shows what effect one variable has

on another, which variables are significant

influencers, and which ones are just in the noise

• Finally, it also shows how much of the system

behavior the equation does not explain.

• The goal of curve fitting is to develop an

approximate equation that describes the system’s or

process’s statistical behavior as much as possible.

• Regression is used to explain the statistical behavior

Simple linear regression

• In simple linear regression, assume that each observed

output point Yi can be described by a two-part equation:

• β0 + β1 X part of the equation for Y is just an equation for

straight line

• β0 by itself tells at what value the fitted line crosses the Y axis

• β1is the line’s slope

• The ε part is a normal, random distribution with a center value

equal to zero.

• Mathematically determine values for β0 and β1 so that the

resulting line fits the observed X – Y data as closely as possible

with the minimum amount of error

• Where xi and yi are the paired data points and and are the

calculated averages for all the X points and all the Y points,

respectively.

• For the example given before, β0=47.3 and β1=–0.00632. so

the line is ,

• Where represents the estimate or prediction for Y, not an

actual observed value for Y.

Point of Cautions

• Do not extend the predictions very far beyond

the range of the data in the study.

• The derived equation for the line is missing the ε

component.

• The line predicts only the expected average

performance.

• In reality, the actual performance level varies from

the predicted value

Discovering residuals and the

fitted model

• It is important to understand and quantify

the ε component of the regression

equation

• For each of the i data points in the study,

the error term ei can be calculated

• An error term ei shows how far off the

predictive equation line is from the

observed data.

• For example, referring to Table earlier in the lecture, the data

for the Toyota Camry shows that its curb weight is 3,140

pounds and its fuel economy is 29 mpg.

• Plugging an X value of 3,140 pounds into the derived

regression equation shows,

• The difference between the observed and the predicted fuel

economy is:

• These ei terms are called residuals or what’s left over after

using the predictive equation

• The beginning assumption of the predictive

linear equation is that it has a secondary ε part

that is a normal, random distribution with a

center value equal to zero.

• The most efficient way to check the predictive

linear equation’s validity is graphically reviewing

the residuals to make sure they’re behaving as

per the assumption

Create up to four different graphical checks of the

residuals

• A scatter plot of the residuals ei versus the predicted values

from the derived equation

• A scatter plot of the residuals ei versus the observed X data

• Additional scatter plots of the residuals ei versus any other X

variables that you didn’t include in your equation

• A run chart of the residuals ei versus the previous residuals

ei-1 if you collected your study data sequentially over time

In each of these graphical residual checks, find

• The variation has no obvious patterns and is truly random,

like a cloud of scattered dots.

• The residual variation is centered on the value of zero.

Examples of residual-checking plots for the earlier automobile

weight-fuel economy study are as follows:

• An added way to investigate how good the derived regression

model is involves looking at the variation of the output

variable Y.

• This assessment is based on a squared error basis.

• The total sum of the squared error (SSTO) in the output

variable Y

• Where Yi are the n observed output values.

• In a similar way, state the squared error from just the derived

regression equation (SSR) as

• where are Yi is the predicted estimates for the n data points.

• Finally, express the squared error from the remaining ε

variation (SSE) as

• Together, these three squared error terms can be related with

the simple sum

SSTO = SSR + SSE

You can do three important tests with these squared error terms:

• Calculate the coefficient of determination, R2, for your predictive

model.

• R2 tells you is how much of the total observed variation is

determined or explained by your linear model

• For a business setting, you want this number to be 80 percent or

higher.

• With a high R2 value, you can know that your predictions will be

close and not dominated by the unexplained variation.

• Ninety-four percent of the observed variation is explained by your

derived linear model.

• Quantify the unexplained ε variation in terms of its standard

deviation.

• The ε value is an inherent part of your predictive linear

equation, so you need a way to figure out how big its variation

is.

• This estimate comes in handy when you want to mimic what

may happen in reality.

• For the automobile curb weight versus fuel economy study,

you can estimate the standard deviation of the unexplained

variation as

• Perform an F test to quantify your confidence in the validity of

your regression model.

• statistically compare the variation explained by your

regression model to the unexplained variation.

• Another way to mathematically represent the variation in the

regression model is by an estimate of its variance

• Creating a ratio of this two is just like the confidence intervals

for comparing the size of two different distributions

• You can say with 95-percent or 99-percent confidence —

whichever level of confidence you select from the F table in

that your derived predictive model is, in fact, valid

• For the automobile curb weight versus fuel economy study, if

you want to be 99-percent confident with your n = 10 data

points, the F test of the variances becomes

• Because the calculated ratio value of 16.4 is greater than the

critical 99-percent F value of 11.3, you can conclude with 99-

percent confidence that your derived model is valid.

Multiple linear regression

• When you work to create an equation that includes

• more than one variable — such as Y = f(X1, X2, . . ., Xn) — you

use multiple linear regression.

• if you have a system where

• X1 and X2 both contribute to Y, the multiple linear regression

model becomes

Potrebbero piacerti anche

- Chapter 6Documento33 pagineChapter 6bashatigabuNessuna valutazione finora

- Simple Linear RegressionDocumento29 pagineSimple Linear RegressionshishirNessuna valutazione finora

- Linear RegressionDocumento23 pagineLinear RegressionRabiqa RaniNessuna valutazione finora

- Inferential StatisticsDocumento42 pagineInferential Statisticscw03309133Nessuna valutazione finora

- Chapter TwoDocumento41 pagineChapter Twokumlachew GebeyehuNessuna valutazione finora

- Linear RegressionDocumento25 pagineLinear RegressionAlinaNessuna valutazione finora

- BS ST MaterialDocumento109 pagineBS ST MaterialRohitNessuna valutazione finora

- 03 Statistics in Regrression AnalysisDocumento24 pagine03 Statistics in Regrression AnalysisXin NiNessuna valutazione finora

- Managerial Economics: Class: Mba 3.5 Semester V Instructor: Ms. Saira MajeedDocumento46 pagineManagerial Economics: Class: Mba 3.5 Semester V Instructor: Ms. Saira MajeedMuhammad Noman MehboobNessuna valutazione finora

- Module 4bootstrapping and Power AnalysisDocumento12 pagineModule 4bootstrapping and Power AnalysisDr. Pitchumani Angayarkanni, SRET, 16118Nessuna valutazione finora

- Chapter 3-Numerical MeasuresDocumento38 pagineChapter 3-Numerical MeasuresNadia TanzeemNessuna valutazione finora

- Factor AnalysisDocumento32 pagineFactor AnalysisSapan AnandNessuna valutazione finora

- Factor AnalysisDocumento32 pagineFactor AnalysisSapan AnandNessuna valutazione finora

- Presentation1 WEEK2 With AudioDocumento54 paginePresentation1 WEEK2 With AudioLaayba BasitNessuna valutazione finora

- Sampling DistDocumento40 pagineSampling DistSanket SharmaNessuna valutazione finora

- Simple Linear RegressionDocumento28 pagineSimple Linear Regressionlajwanti jethwaniNessuna valutazione finora

- Module 3 - Regression and Correlation AnalysisDocumento54 pagineModule 3 - Regression and Correlation AnalysisAirra Mhae IlaganNessuna valutazione finora

- Eco 5Documento30 pagineEco 5Nigussie BerhanuNessuna valutazione finora

- Factors Affecting Buying Pattern in Indian Television Industry and Competitor AnalysisDocumento26 pagineFactors Affecting Buying Pattern in Indian Television Industry and Competitor AnalysisSanchitJoshiNessuna valutazione finora

- Lecture 8-Association Between VariablesDocumento28 pagineLecture 8-Association Between VariablesLawrence MosizaNessuna valutazione finora

- Inferential StatisticsDocumento29 pagineInferential StatisticsLUMABAD CENYERNNessuna valutazione finora

- Budgeting Concepts and Forecoasting TechniquesDocumento26 pagineBudgeting Concepts and Forecoasting TechniquesajithsubramanianNessuna valutazione finora

- Budgeting Concepts and Forecasting TechniquesDocumento26 pagineBudgeting Concepts and Forecasting TechniquesajithsubramanianNessuna valutazione finora

- Unit 4 Factor, Discriminant, Conjoint, Innovation-DiffusionDocumento88 pagineUnit 4 Factor, Discriminant, Conjoint, Innovation-Diffusionkomalkataria2003Nessuna valutazione finora

- Budgetind Concepts and Forecoasting TechniquesDocumento26 pagineBudgetind Concepts and Forecoasting TechniquesajithsubramanianNessuna valutazione finora

- Week11-Lecture 11ML Algorithms Metrics - UpdatedDocumento29 pagineWeek11-Lecture 11ML Algorithms Metrics - UpdatedfgfdgfdgfdNessuna valutazione finora

- Correlation AnalysisDocumento17 pagineCorrelation AnalysisNabil MarufNessuna valutazione finora

- Hypothesis Testing: SEEQ2023 Basic EconometricDocumento23 pagineHypothesis Testing: SEEQ2023 Basic EconometricXin NiNessuna valutazione finora

- Logistic RegressionDocumento41 pagineLogistic RegressionSubodh KumarNessuna valutazione finora

- Research Methods Session 11 Data Preparation and Preliminary Data Analysis (Compatibility Mode)Documento9 pagineResearch Methods Session 11 Data Preparation and Preliminary Data Analysis (Compatibility Mode)Gopaul UshaNessuna valutazione finora

- 3 - Data Analysis - Tests of DifferencesDocumento50 pagine3 - Data Analysis - Tests of Differencesmnrk 1997Nessuna valutazione finora

- Simple Linear Regression With ExcelDocumento39 pagineSimple Linear Regression With ExcelAbimanyu ShenilNessuna valutazione finora

- A2 Physics Error Propagation 001Documento14 pagineA2 Physics Error Propagation 001fresh9129Nessuna valutazione finora

- Statistical Inference: EstimationDocumento24 pagineStatistical Inference: EstimationAdel KaadanNessuna valutazione finora

- Statistical InferenceDocumento33 pagineStatistical Inferencedeneke100% (1)

- Chapter 12Documento16 pagineChapter 12FatimaIjazNessuna valutazione finora

- Week 6 - Result and Analysis 2 (UP)Documento7 pagineWeek 6 - Result and Analysis 2 (UP)eddy siregarNessuna valutazione finora

- Regression IDocumento41 pagineRegression ISrijanNessuna valutazione finora

- Data Analysis Using Statsdirect A. Investigating ProbabilityDocumento8 pagineData Analysis Using Statsdirect A. Investigating Probabilityahmad_nazib_1Nessuna valutazione finora

- Regression PDFDocumento33 pagineRegression PDF波唐Nessuna valutazione finora

- Confidence LevelsDocumento8 pagineConfidence LevelsRutendo TarabukuNessuna valutazione finora

- Machine Learning and Linear RegressionDocumento55 pagineMachine Learning and Linear RegressionKapil Chandel100% (1)

- Audit SamplingDocumento18 pagineAudit SamplingAnonymous Ul3litqNessuna valutazione finora

- Univariate StatisticsDocumento54 pagineUnivariate Statisticsharsheen kaurNessuna valutazione finora

- 4 5 Chapter 4 ESTIMATION and 5 Hyp TestingDocumento180 pagine4 5 Chapter 4 ESTIMATION and 5 Hyp Testinghildamezmur9Nessuna valutazione finora

- Ch08 - Large-Sample EstimationDocumento28 pagineCh08 - Large-Sample EstimationislamNessuna valutazione finora

- Dr. Hussin Abdullah School of Economics, Finance and Banking, Uum CobDocumento12 pagineDr. Hussin Abdullah School of Economics, Finance and Banking, Uum Cobvivek1119Nessuna valutazione finora

- VIII - EstimationDocumento60 pagineVIII - EstimationBehar AbdurahemanNessuna valutazione finora

- CB3021 Week 11 SPSS ContinueDocumento73 pagineCB3021 Week 11 SPSS ContinueLam Lok YiNessuna valutazione finora

- Module-2 - Assessing Accuracy of ModelDocumento24 pagineModule-2 - Assessing Accuracy of ModelRoudra ChakrabortyNessuna valutazione finora

- SLRin RDocumento23 pagineSLRin RJyo BrahmaraNessuna valutazione finora

- Session 10 & 11 - EstimationDocumento31 pagineSession 10 & 11 - EstimationMona LisaNessuna valutazione finora

- Hypothesis TestingDocumento59 pagineHypothesis Testingshomitamaraewu0% (1)

- Interval EstimationDocumento30 pagineInterval Estimationsai revanthNessuna valutazione finora

- Session 7 Probability Distribution II - ContinuousDocumento30 pagineSession 7 Probability Distribution II - ContinuousSRV TECHSNessuna valutazione finora

- Statistical TermsDocumento25 pagineStatistical TermsNimra GhafoorNessuna valutazione finora

- Model ComparisonDocumento27 pagineModel ComparisonFerran RodríguezNessuna valutazione finora

- Econometrics Chap 3Documento19 pagineEconometrics Chap 3Jannatul FardusNessuna valutazione finora

- Session: 27: TopicDocumento62 pagineSession: 27: TopicMikias BekeleNessuna valutazione finora

- Gauging Gauges: Measurement System Analysis (Msa)Documento29 pagineGauging Gauges: Measurement System Analysis (Msa)Sium Adnan Khan 1511153030Nessuna valutazione finora

- MGT 460Documento18 pagineMGT 460Sium Adnan Khan 1511153030Nessuna valutazione finora

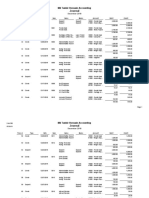

- General Ledger: MD Tanbir Hossain AccountingDocumento5 pagineGeneral Ledger: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Assessing Capability: Comparing The Voices of The Customer and The ProcessDocumento32 pagineAssessing Capability: Comparing The Voices of The Customer and The ProcessSium Adnan Khan 1511153030Nessuna valutazione finora

- DMAIC: Analyzing: Depicting and Analyzing Data Through Charts and GraphsDocumento27 pagineDMAIC: Analyzing: Depicting and Analyzing Data Through Charts and GraphsSium Adnan Khan 1511153030Nessuna valutazione finora

- Journal: MD Tanbir Hossain AccountingDocumento3 pagineJournal: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- General Ledger: MD Tanbir Hossain AccountingDocumento5 pagineGeneral Ledger: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Trial Balance: MD Tanbir Hossain AccountingDocumento1 paginaTrial Balance: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Balance Sheet: MD Tanbir Hossain AccountingDocumento1 paginaBalance Sheet: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Trial Balance: MD Tanbir Hossain AccountingDocumento1 paginaTrial Balance: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Journal: MD Tanbir Hossain AccountingDocumento3 pagineJournal: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Profit & Loss Detail: MD Tanbir Hossain AccountingDocumento2 pagineProfit & Loss Detail: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- General Journal Transaction: MD Tanbir Hossain AccountingDocumento1 paginaGeneral Journal Transaction: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Profit & Loss: MD Tanbir Hossain AccountingDocumento1 paginaProfit & Loss: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Stevenson Chapter 3 - ForecastingDocumento50 pagineStevenson Chapter 3 - ForecastingSium Adnan Khan 1511153030Nessuna valutazione finora

- Trial Balance: MD Tanbir Hossain AccountingDocumento1 paginaTrial Balance: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Balance Sheet: MD Tanbir Hossain AccountingDocumento1 paginaBalance Sheet: MD Tanbir Hossain AccountingSium Adnan Khan 1511153030Nessuna valutazione finora

- Ethical CaseDocumento15 pagineEthical CaseSium Adnan Khan 1511153030Nessuna valutazione finora

- Beximco 489Documento10 pagineBeximco 489Sium Adnan Khan 1511153030Nessuna valutazione finora

- PHI401.Final AssignmentDocumento7 paginePHI401.Final AssignmentSium Adnan Khan 1511153030Nessuna valutazione finora

- Stevenson Chapter 13 - Inventory ManagementDocumento53 pagineStevenson Chapter 13 - Inventory ManagementSium Adnan Khan 1511153030100% (1)

- MGT 460 CaseDocumento6 pagineMGT 460 CaseSium Adnan Khan 1511153030Nessuna valutazione finora

- Roma and The Question of Self-DeterminationDocumento30 pagineRoma and The Question of Self-DeterminationvictoriamssNessuna valutazione finora

- Backup Exec 2010, 2010 R2 and 2010 R3 Hardware Compatibility List (HCL)Documento248 pagineBackup Exec 2010, 2010 R2 and 2010 R3 Hardware Compatibility List (HCL)Brian SvendsenNessuna valutazione finora

- 40agilemethodsin40minutes 141020221938 Conversion Gate01 PDFDocumento104 pagine40agilemethodsin40minutes 141020221938 Conversion Gate01 PDFpjsystemNessuna valutazione finora

- Prizm Programming GuideDocumento168 paginePrizm Programming GuideBucur MateiNessuna valutazione finora

- Autoliv LeanDocumento50 pagineAutoliv LeanRajasekaran Murugan100% (1)

- Application Letter.Documento2 pagineApplication Letter.RinzuNessuna valutazione finora

- Assignment 1 PDFDocumento5 pagineAssignment 1 PDFAyesha WaheedNessuna valutazione finora

- Chapter One 1.1. Background of The Study: Iloilo City's Heritage Tourist Destinations Are Worth Keeping ForDocumento2 pagineChapter One 1.1. Background of The Study: Iloilo City's Heritage Tourist Destinations Are Worth Keeping ForCrisNessuna valutazione finora

- Note 5 - Acoustics Impedance TransmissionDocumento16 pagineNote 5 - Acoustics Impedance TransmissionABB TRX IJMNessuna valutazione finora

- Complexity TheoryDocumento91 pagineComplexity TheoryUdayakumar Krishnaswamy0% (1)

- CH 12Documento76 pagineCH 12Christian JeremiaNessuna valutazione finora

- Architectural Record KaustDocumento12 pagineArchitectural Record KaustMahmoued KhaliedNessuna valutazione finora

- Kriging InterpolationDocumento49 pagineKriging InterpolationJimmy MaharadjaNessuna valutazione finora

- Lec Verilog TrafficLight SynthesisDocumento32 pagineLec Verilog TrafficLight SynthesisKartikey ManchandaNessuna valutazione finora

- Fundamental of Bulk Solids Mixing and BlendingDocumento6 pagineFundamental of Bulk Solids Mixing and BlendingJessicalba Lou100% (1)

- STOCHASTIC FINITE ELEMENT METHOD: Response StatisticsDocumento2 pagineSTOCHASTIC FINITE ELEMENT METHOD: Response StatisticsRocky ABNessuna valutazione finora

- Collusion-Resistant Group Key Management Using Attribute-Based EncryptionDocumento15 pagineCollusion-Resistant Group Key Management Using Attribute-Based Encryptionsomebody314Nessuna valutazione finora

- Team Meeting - 6th MayDocumento11 pagineTeam Meeting - 6th MaySachin SharmaNessuna valutazione finora

- Asl Ga75 PDFDocumento76 pagineAsl Ga75 PDFMarco Soto100% (1)

- Atv DVWK A 281 e LibreDocumento25 pagineAtv DVWK A 281 e LibrerafapoNessuna valutazione finora

- Def ReadingDocumento1 paginaDef ReadingJembus WedutNessuna valutazione finora

- A1603 WTDocumento9 pagineA1603 WTnanichowsNessuna valutazione finora

- PSD - Trilok - Kalyan Medicals - June 29, 17 - Business Proposal Ver 1Documento7 paginePSD - Trilok - Kalyan Medicals - June 29, 17 - Business Proposal Ver 1papuNessuna valutazione finora

- Practice Types of SentenceDocumento6 paginePractice Types of SentenceTrần Hồ Quỳnh HươngNessuna valutazione finora

- Literary Research Essay: Conformity and RebellionDocumento2 pagineLiterary Research Essay: Conformity and Rebellioneliza025Nessuna valutazione finora

- Cesare Della RivieraDocumento3 pagineCesare Della RivieraCarlos Carlos AgueroNessuna valutazione finora

- Chapter 9 Decision Making Under UncertaintyDocumento15 pagineChapter 9 Decision Making Under UncertaintyjalilacastanoNessuna valutazione finora

- Netfinity Tape Solutions Sg245218Documento318 pagineNetfinity Tape Solutions Sg245218bupbechanhNessuna valutazione finora

- WHP English10 1ST QDocumento8 pagineWHP English10 1ST QXhiemay Datulayta CalaqueNessuna valutazione finora

- Using Keyframe SynfigDocumento1 paginaUsing Keyframe SynfigNdandungNessuna valutazione finora