Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Concept of Logistics

Caricato da

Soham100%(1)Il 100% ha trovato utile questo documento (1 voto)

46 visualizzazioni38 pagineLogistics involves managing the flow of goods and services from suppliers to customers. It includes transportation, inventory management, warehousing and integrating information across the supply chain. The goal is to meet customer needs by delivering the right products to the right place at the right time in a cost-effective manner. Effective logistics is important for supply chain management as it facilitates the movement of materials between organizations and adds value for customers.

Descrizione originale:

Supply Chain Management Module 1

Titolo originale

M-1

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoLogistics involves managing the flow of goods and services from suppliers to customers. It includes transportation, inventory management, warehousing and integrating information across the supply chain. The goal is to meet customer needs by delivering the right products to the right place at the right time in a cost-effective manner. Effective logistics is important for supply chain management as it facilitates the movement of materials between organizations and adds value for customers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

46 visualizzazioni38 pagineConcept of Logistics

Caricato da

SohamLogistics involves managing the flow of goods and services from suppliers to customers. It includes transportation, inventory management, warehousing and integrating information across the supply chain. The goal is to meet customer needs by delivering the right products to the right place at the right time in a cost-effective manner. Effective logistics is important for supply chain management as it facilitates the movement of materials between organizations and adds value for customers.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 38

Concept Of Logistics

• Logistics is all about providing the right

products/services at the right place and at the

right time.

• Logistics is concerned with getting products and

services where they are needed and when they

are desired.

• Logistics involves the integration of information,

transportation, inventory, warehousing, materials

handling and packaging.

Concept Of Logistics

• Logistical processes facilitates the flow of

materials from suppliers to the manufacturing

firms and the distribution of finished product

through marketing channels to the end

consumers.

• The complexity of logistics increases with the

number of industrial manufacturers, suppliers

and the channel intermediaries both in the

national scene as well as the global scenario.

Definitions of Logistics

• Logistics is defined as the process of

anticipating consumer needs and wants,

acquiring the capital, materials, people,

technologies and information necessary to

meet those needs and wants, optimizing

the goods or service ---- providing network

to customer requests and utilizing the

network to fulfill customer requests in a

timely manner.

Definitions of Logistics

• Logistics management is the process of

planning, implementing and controlling the

efficient, effective flow and storage of goods,

services and related information from point of

origin to point of consumption for the purpose of

conforming to customer requirements.

• Logistics management is also concerned with

the disposal and recycling / reuse of the

products.

• Logistics management adds value by creating

time utility and place utility.

Definitions of Logistics

• Logistics management is that part of

supply chain management that plans,

implements and controls the efficient and

effective forward and reverse flow and

storage of goods, services and related

information between the point of origin and

the point of consumption in order to meet

customer’s requirements (definition of

Council of Logistics Management).

Definitions of Logistics

• Logistics management activities include

inbound and outbound transportation

management, fleet management,

warehousing, materials handling , order

fulfillment, logistics network design,

inventory management, supply / demand

planning and management of third party

logistics service providers.

Scope and Importance of Logistics

• Logistics is not confined to manufacturing

operations alone. It is relevant to all types of

enterprises including government departments,

hospitals, universities, banks, financial service

institutions, wholesalers and retailers.

• Logistics includes cross functional co-ordination

activities. It co-ordinates the functions of

materials management, production planning and

control and physical distribution management

including finished goods inventory and selection

of transportation suppliers.

Scope and Importance of Logistics

• Logistics expenditure accounts to about 10% of the

GNP of the country.

• For individual firms, the expenditure may range from

5% to 35% of the sales depending on the type of

business, geographical area of operation and

weight/value ratio of products and materials.

• In manufacturing organizations, the activities such as

materials planning, purchasing, stores and inventory

control are centralized under materials management

and distribution of finished goods is done by

marketing department.

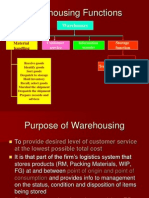

Components of Logistics

Management

Objectives of Logistics

Management

• Effectively and efficiently move the inventory in

the supply chain in order to extend the desired

level of customer service at the least possible

cost.

• Ensuring minimum or no damage to products

during transportation and storage.

• Ensuring quick response to customer

requirements.

• Achieve maximum economy in freight costs.

• Achieve consistent delivery performance.

• Building long term customer relationship.

Logistics Activities

1. Transportation – physical movement or

flow of goods through various modes.

2. Storage – proper storage and

preservation of goods.

3. Packaging – to protect the goods from

damage during transportation.

4. Materials handling – handling the

materials as it moves from storage to

packing and shipping areas.

Logistics Activities

5. Order fulfillment – reducing the delivery

lead time to the minimum and complete

the customer orders in time.

6. Inventory forecasting – accurate

forecasting of materials requirement.

7. Production planning – determining the

quantity to be produced to meet market

demand.

Logistics Activities

8. Purchasing – procurement of the

materials from the suppliers.

9. Customer service – decisions about

product availability and inventory lead

time are critical to customer service.

10. Site location – deciding the location of a

plant or a warehouse to minimize costs

of transportation.

Role of Logistics in Supply Chain

Management

• A supply chain refers to the way that materials

flow through different organizations, starting with

raw materials and ending with finished products

delivery to the ultimate consumer.

• Supply chain management can be viewed as a

pipeline or conduit for efficient and effective flow

of materials, services, information & money from

suppliers’ suppliers through the various

intermediate organizations to the customers’

customers.

Role of Logistics in Supply Chain

Management

• Supply chain management represents a logical

extension of the logistics concept and it is also

known as demand network management, value

chain management etc.

• The inbound and outbound logistics are primary

components of the value chain, that is

contributing value to the firm’s customers and

thereby making the firm financially viable.

• The inbound logistics involves transportation of

raw materials and components from suppliers to

the firm.

• The outbound logistics involves physical

distribution of finished goods.

Supply Chain & Value Chain

Logistics Costs

1. Cost of lost sales – the cost trade-off resulting

from varying levels of customer service is the

cost of lost sales.

2. Cost of customer service – expenses for

customer service support includes the costs of

order fulfillment, parts and service support and

costs of return goods handling.

3. Transportation costs – these vary with volume

of shipment, weight of shipment, distance

between point of origin and destination, mode

of transportation.

Logistics Costs

4. Warehousing costs – costs incurred for

storage activities.

5. Order processing costs – includes costs of

order transmission, order entry, order

processing etc.

6. Lot quantity costs – due to procurement /

production in lot quantities. These include (a)

setup costs (b) loss in capacity (c ) material

handling costs (d) price differentials (e) order

placement & follow up.

Logistics Costs

7. Inventory carrying costs – this is made up of

(a) capital costs or opportunity costs (b)

inventory service costs i.e. insurance and

taxes (c ) storage space costs (d) inventory

risk cost i.e. obsolescence, pilferage, damage

etc.

8. Total costs – effective logistics management

has the goal of reducing the total cost of

logistics rather than merely focusing on each

cost in isolation.

Integrated Logistics Management

• Involves managing the movement of raw

materials and components from sources of

supply to the manufacturing plant and the

movement of the finished goods from the

manufacturing plant to the warehouses or

to the retailers or to the final consumer.

• The network of relationships to be

managed by logistics can be explained

through a diagram.

Integrated Logistics Management

Systems Approach

• All functions or activities need to be understood

in terms of how they affect or are affected by

other elements or activities with which they

interact.

• Systems analysis views how specific functions

can be combined to create a whole that is

greater than the sum of the individual parts or

functions.

• Such a holistic approach stimulates a synergistic

relationship between the individual parts of a

system.

Systems Approach

• For e.g., even though it is desirable to

have high inventory levels to fulfill

customer orders, it also increases storage

costs as well as the risk of obsolescence.

Hence the necessity to trade-off the

unfavorable factors with the favorable

aspects before deciding the optimum

inventory levels.

Integrated Logistics

• The process of anticipating customer

needs and wants, acquiring the capital,

materials, people, technologies and

information necessary to meet those

needs, optimizing the goods or service i.e.

producing a network to fulfill customer

requests and utilizing the network to fulfill

customer requirements in a timely manner.

Integrated Logistics

• Integrated logistics is a service oriented

process. It supports marketing and

production. Even if the advertising

campaign and the salesforce are efficient,

marketing cannot fill customer orders

without integrated logistics. Even if the

products are produced in time, if they can

not be moved efficiently the purpose is not

met.

Integrated Logistics Information

Requirements

1. Inventory flow – information on the movement

of materials right from the initial shipment from

the supplier till the delivery of finished goods to

the customer.

2. Logistical operations – three areas

a. Physical distribution – linking manufacturers,

wholesalers & retailers to provide product

availability.

b. Manufacturing support – managing WIP, help

in formulation of MPS.

c. Procurement – co-ordination with suppliers.

Integrated Logistics Information

Requirements

3. Information flow – integrates the three

operating areas i.e. physical distribution,

manufacturing support and procurement.

Information facilitates co-ordination of

planning and control in day-to-day

operations. In the absence of

information, there will be wastage of

effort in the logistics system.

Integrated Logistics Information

System (ILIS)

• An ILIS can be defined as the involvement

of people, equipment and procedures

required to gather, sort, analyze, evaluate

and then distribute needed information to

the appropriate decision maker in a timely

and accurate manner so that they can

make quality logistics decisions.

Integrated Logistics Information

System (ILIS)

• ILIS is all about:

1. Getting the right information

2. Keeping the information accurate

3. Communicating the information effectively

• Components of ILIS:

1. Order processing system

2. Research and intelligence system

3. Decision support system

4. Reports and output system

Integrated Logistics Information

System (ILIS)

• Order processing system has direct impact on

the customer

• Research and intelligence systems scans and

monitors both the internal and external

environment. It covers (1) the integration of

logistics planning with overall corporate planning

(2) the management of interface with other

functions (3) strategic options for organization

and staffing (4) integration of information

technologies (5) make or buy decisions (6)

emphasis on productivity and quality

Integrated Logistics Information

System (ILIS)

• Decision support systems (DSS) – provide

solutions to complex logistics problems

making use of analytical modelling. It

consists of (1) basic file of internal &

external data (2) critical factor data file

which defines the scope of decision

making (3) policy and parameter data files

for each functional area (4) solution file of

past analysis results which are compared

against future analyses.

Integrated Logistics Information

System (ILIS)

• Reports and output system – planning outputs

include sales trends, economic forecasts and

other information pertaining to market place.

• Operating reports are useful for inventory

control, transportation scheduling and routing,

purchasing and production scheduling.

• Control reports are used to analyze expenses,

budgets & performance.

Integrated Logistics Information System (ILIS)

Integrated Logistics Information

System (ILIS)

• Electronic data interchange (EDI) – it is

the electronic transfer of standard

business documents between

organizations. EDI is used extensively in

ILIS to enhance the breadth, timeliness &

quality of data. EDI transmissions allow a

development to be directly processed and

acted upon by the organization which

receives the information.

Integrated Logistics Information

System (ILIS)

• Advantages of EDI:

1. Cost reduction

2. Increased productivity

3. Faster order cycle times

4. Better customer focus

5. Reduced clerical work

6. Reduced paper and postage

7. Better working relationships with partners

8. Means to achieve a competitive advantage

Integrated Logistics Information

System (ILIS)

• Artificial intelligence (AI) – it is concerned

with the concept and methods of inference

by a computer and the symbolic

representation of the knowledge used in

making inferences.

• AI includes a number of areas such as

computer aided instruction, voice

synthesis and recognition, robotics etc.

Integrated Logistics Information

System (ILIS)

• Artificial intelligence is used in logistics

management to:

1. Model response time requirements for

customer delivery

2. Model transportation cost and time for various

transportation modes and routings

3. Determine which warehouses should serve

which plants and which products

4. Model customer service response with various

levels of reliability

Integrated Logistics Information

System (ILIS)

• Expert systems (ES) – an expert system is a

computer program which uses knowledge and

reasoning techniques to solve problems

normally requiring the abilities of human experts.

• An expert system is an artificial intelligence

program which achieves competence in

performing specialized tasks by reasoning with

a body of knowledge about the task and the task

domain.

Potrebbero piacerti anche

- Logistics ManagementDocumento32 pagineLogistics ManagementPrashanthNessuna valutazione finora

- Logistics AnswersDocumento23 pagineLogistics AnswersSagar NankaniNessuna valutazione finora

- Logistics and Supply Chain Management: Dr. Abhijeet ChatterjeeDocumento50 pagineLogistics and Supply Chain Management: Dr. Abhijeet Chatterjeechaterji_aNessuna valutazione finora

- Logistics MGTDocumento28 pagineLogistics MGTJanmejai Bhargava100% (2)

- 305 OSCM - Logistics Management Unit-1Documento63 pagine305 OSCM - Logistics Management Unit-1Shil ShambharkarNessuna valutazione finora

- Logistics ManagementDocumento50 pagineLogistics ManagementOlawaleAbolarinNessuna valutazione finora

- Logistics Management-Unit2 CompleteDocumento93 pagineLogistics Management-Unit2 CompleteVasanthi Donthi100% (1)

- Unit 1logistics ManagementDocumento13 pagineUnit 1logistics ManagementSidhu boiiNessuna valutazione finora

- Chapter - 1 Introduction To Logistics ManagementDocumento38 pagineChapter - 1 Introduction To Logistics ManagementShruti100% (1)

- Logistics - Unit 1Documento34 pagineLogistics - Unit 1etiNessuna valutazione finora

- Logistics NotesDocumento18 pagineLogistics NotesRadha Raman SharmaNessuna valutazione finora

- Logistic Management: Unit 3Documento23 pagineLogistic Management: Unit 3Akhil CrastaNessuna valutazione finora

- Introduction To LogisticsDocumento38 pagineIntroduction To LogisticsVivekanand SinghNessuna valutazione finora

- 1.4 Different Types of Logistics ManagementDocumento21 pagine1.4 Different Types of Logistics ManagementLara Camille CelestialNessuna valutazione finora

- Inventory ManagementDocumento38 pagineInventory ManagementMckarey RobinsonNessuna valutazione finora

- Introduction To Logistics Management Module 5Documento33 pagineIntroduction To Logistics Management Module 5Kyle SikorskyNessuna valutazione finora

- Course PowerpointDocumento58 pagineCourse Powerpointmoges lakeNessuna valutazione finora

- SCM SummaryDocumento47 pagineSCM SummaryEmanuelle BakuluNessuna valutazione finora

- Intro of Supply Chain Management Lecture 1Documento20 pagineIntro of Supply Chain Management Lecture 1Syeda SidraNessuna valutazione finora

- Unit 1 - Introduction To Inventory ManagementDocumento17 pagineUnit 1 - Introduction To Inventory ManagementNguyễn Thành NamNessuna valutazione finora

- Components of Logistics Management: Supportive Component: ProcurementDocumento2 pagineComponents of Logistics Management: Supportive Component: ProcurementNaveen KaranNessuna valutazione finora

- Chapter 2 Role of Logistics in Supply Chains Learning ObjectivesDocumento13 pagineChapter 2 Role of Logistics in Supply Chains Learning ObjectivesAshik AlahiNessuna valutazione finora

- Basic of Logistics Management - 1553484948 PDFDocumento34 pagineBasic of Logistics Management - 1553484948 PDFManoj Kuchipudi100% (1)

- SCM ProcessesDocumento20 pagineSCM ProcessesVishnu Kumar S100% (1)

- Introduction To Supply Chain Management: Syed Tabish Hussain Iqra UniversityDocumento54 pagineIntroduction To Supply Chain Management: Syed Tabish Hussain Iqra UniversityfarahsayaniNessuna valutazione finora

- Operations and Warehouse ManagementDocumento3 pagineOperations and Warehouse ManagementJaiprakash RajpurohitNessuna valutazione finora

- Logistics ManagementDocumento3 pagineLogistics ManagementSUNIL DUTTNessuna valutazione finora

- Logistics ManagementDocumento16 pagineLogistics ManagementsmtbnmNessuna valutazione finora

- Logistical Interfaces With ProcurementDocumento7 pagineLogistical Interfaces With ProcurementJaymark CasingcaNessuna valutazione finora

- Warehouse FunctionsDocumento27 pagineWarehouse FunctionsSheila Ibay VillanuevaNessuna valutazione finora

- SCM - Chapter 01Documento68 pagineSCM - Chapter 01Talha6775Nessuna valutazione finora

- 3 - Supply Chain Integration CollaborationDocumento42 pagine3 - Supply Chain Integration CollaborationKumar Gaurab Jha0% (2)

- UNIT 1 LogisticsDocumento10 pagineUNIT 1 Logisticsanon_124527471Nessuna valutazione finora

- Defining Purchasing, Procurement, Supply Management, Materials Management & SCMDocumento34 pagineDefining Purchasing, Procurement, Supply Management, Materials Management & SCMaharish_iitkNessuna valutazione finora

- Logistics Supply Chain StrategyDocumento27 pagineLogistics Supply Chain StrategymuhibNessuna valutazione finora

- Material ManagementDocumento38 pagineMaterial ManagementanushavergheseNessuna valutazione finora

- ConclusionDocumento2 pagineConclusionMuthu Kumaran100% (1)

- Definition of LogisticsDocumento44 pagineDefinition of LogisticsPooja TripathiNessuna valutazione finora

- PDF Ba 5025 Logistics Management Notes - Compress PDFDocumento96 paginePDF Ba 5025 Logistics Management Notes - Compress PDFUdayanidhi RNessuna valutazione finora

- Assignment LogisticsDocumento9 pagineAssignment LogisticsArham Orb100% (1)

- Designing Distribution Network: in A Supply ChainDocumento55 pagineDesigning Distribution Network: in A Supply ChainShambhavi AryaNessuna valutazione finora

- Introduction To Logistics ManagementDocumento27 pagineIntroduction To Logistics ManagementFaisal Tanwar100% (1)

- Supply Chain Management - An Overview - RGDocumento71 pagineSupply Chain Management - An Overview - RGprakashinaibs100% (2)

- 1 - Business Functions, Processes and Data RequirementsDocumento64 pagine1 - Business Functions, Processes and Data Requirementsugurum668Nessuna valutazione finora

- Submitted To: Submitted byDocumento18 pagineSubmitted To: Submitted byRohit Patel100% (2)

- Inventory MGTDocumento35 pagineInventory MGTPankaj Agrawal100% (1)

- Inventory ManagementDocumento14 pagineInventory ManagementEoin Ornido100% (2)

- Module 1 Introduction To Logistics PDFDocumento49 pagineModule 1 Introduction To Logistics PDFChispa BoomNessuna valutazione finora

- L8 Logistics ManagementDocumento41 pagineL8 Logistics ManagementShahmien SevenNessuna valutazione finora

- Chapter 2 - Role of Logistics in Supply ChainsDocumento37 pagineChapter 2 - Role of Logistics in Supply ChainsArman100% (7)

- Elements of Logistics Management NotesDocumento59 pagineElements of Logistics Management Notesaksr27100% (5)

- Inventory ManagementDocumento7 pagineInventory ManagementSozo Net WorkNessuna valutazione finora

- Differences Between Logistics and Supply ChainDocumento3 pagineDifferences Between Logistics and Supply ChainNikhil BhaskarNessuna valutazione finora

- CH 01 Introduction To Supply Chain ManagementDocumento30 pagineCH 01 Introduction To Supply Chain Managementgadde bharatNessuna valutazione finora

- Logistics ManagementDocumento167 pagineLogistics Managementakaash023100% (1)

- Chapter 21Documento19 pagineChapter 21Fire BoltNessuna valutazione finora

- L3 Fundamentals of LogisticsDocumento40 pagineL3 Fundamentals of LogisticsDu Lich Vung TauNessuna valutazione finora

- Integrated LogisticsDocumento9 pagineIntegrated Logisticsyuktim100% (2)

- 2 Logistics in SCM 1Documento29 pagine2 Logistics in SCM 1Khai Wen OnexoxNessuna valutazione finora

- FintechDocumento2 pagineFintechSohamNessuna valutazione finora

- Zara: IT For Fast Fashion: Soham Dakhole ISM 24148Documento11 pagineZara: IT For Fast Fashion: Soham Dakhole ISM 24148SohamNessuna valutazione finora

- Automobile SectorDocumento2 pagineAutomobile SectorSohamNessuna valutazione finora

- Zara 24148 SohamDocumento11 pagineZara 24148 SohamSohamNessuna valutazione finora

- Inspiring Entrepreneur: Individual Assignment 1Documento2 pagineInspiring Entrepreneur: Individual Assignment 1SohamNessuna valutazione finora

- 3M Post It: Soham Dakhole 24148Documento2 pagine3M Post It: Soham Dakhole 24148SohamNessuna valutazione finora

- Alcon IncDocumento44 pagineAlcon IncDanilo Avalos100% (1)

- Business Intelligence BrochureDocumento12 pagineBusiness Intelligence BrochuregvozdokNessuna valutazione finora

- Foodworld NewDocumento4 pagineFoodworld NewS Vidya LakshmiNessuna valutazione finora

- Warehouse CV1Documento1 paginaWarehouse CV1Curtis KimberlyNessuna valutazione finora

- Supply Assignment 2Documento9 pagineSupply Assignment 2yasarinuNessuna valutazione finora

- CEBA-IARW Design Maintenance Modernization Guide - 2018 Update - FINALDocumento402 pagineCEBA-IARW Design Maintenance Modernization Guide - 2018 Update - FINALEduardo Depiné TarnowskiNessuna valutazione finora

- Stores ManagementDocumento43 pagineStores Managementatul_gaikwad_967% (3)

- Inventory Management-UssDocumento66 pagineInventory Management-UssShahid SyedNessuna valutazione finora

- Assignment 12 Case Study-Home Style CookiesDocumento3 pagineAssignment 12 Case Study-Home Style CookiesFish de Paie100% (2)

- Logistics Management, 3e Author: Vinod V. SopleDocumento15 pagineLogistics Management, 3e Author: Vinod V. Soplenithish patkarNessuna valutazione finora

- JLL Future of LogisticsDocumento8 pagineJLL Future of LogisticsAnirban DasguptaNessuna valutazione finora

- Port Pricing PDFDocumento86 paginePort Pricing PDFMw. MustolihNessuna valutazione finora

- Ome752 - SCM Unit IDocumento51 pagineOme752 - SCM Unit IlingeshNessuna valutazione finora

- Distribution Channel of LGDocumento3 pagineDistribution Channel of LGBadal BhattacharyaNessuna valutazione finora

- 3PL-Billing Functionality-Oracle WMS Cloud PDFDocumento16 pagine3PL-Billing Functionality-Oracle WMS Cloud PDFAnthonyStraussNessuna valutazione finora

- International Inventory Issues, Packaging Issues, Storage Issues & OthersDocumento5 pagineInternational Inventory Issues, Packaging Issues, Storage Issues & OthersAnuranjanSinha100% (4)

- Value Proposition - Marketing Assignment - Parimal Bobade-1Documento4 pagineValue Proposition - Marketing Assignment - Parimal Bobade-1Parimal bobadeNessuna valutazione finora

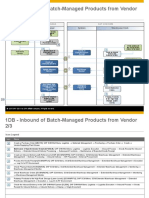

- 1DB - Inbound of Batch-Managed Products From Vendor 1/3: Vendor Purchaser System Warehouse ClerkDocumento3 pagine1DB - Inbound of Batch-Managed Products From Vendor 1/3: Vendor Purchaser System Warehouse ClerkminhasajayNessuna valutazione finora

- 3PLDocumento42 pagine3PLsanjeev kumar100% (1)

- NetworkDocumento16 pagineNetworkavnish kumarNessuna valutazione finora

- Sales Presentation On LG and SamsungDocumento30 pagineSales Presentation On LG and SamsungasifkingkhanNessuna valutazione finora

- Group12 Ho Thi Thu Hoa Cold Storage Warehouse A Case For Fruit ProductsDocumento71 pagineGroup12 Ho Thi Thu Hoa Cold Storage Warehouse A Case For Fruit ProductsKhánh AnNessuna valutazione finora

- Business Process Modeling: Using Ibm Websphere Business ModelerDocumento46 pagineBusiness Process Modeling: Using Ibm Websphere Business ModelerAlfonsoNessuna valutazione finora

- Warehouse Management System Literature ReviewDocumento7 pagineWarehouse Management System Literature Reviewzufehil0l0s2Nessuna valutazione finora

- case-study-Amazon.comDocumento8 paginecase-study-Amazon.comBaldeep Kaur100% (1)

- Lecture 7 - WAREHOUSING MANAGEMENTDocumento51 pagineLecture 7 - WAREHOUSING MANAGEMENTsamwel100% (1)

- Discussion QuestionsDocumento3 pagineDiscussion QuestionsGokul DasNessuna valutazione finora

- Research Compilation 2Documento105 pagineResearch Compilation 2angelicanulla423Nessuna valutazione finora

- Best Practice: Data Volume Management For RetailDocumento67 pagineBest Practice: Data Volume Management For Retaildri0510Nessuna valutazione finora

- Operations & Supply Chain Management (Unit 1)Documento43 pagineOperations & Supply Chain Management (Unit 1)Kiril IlievNessuna valutazione finora