Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

FEA Elements at OCU

Caricato da

Konderu AnilDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

FEA Elements at OCU

Caricato da

Konderu AnilCopyright:

Formati disponibili

MECH-4523/5523

Finite Element Analysis

Oklahoma Christian University

Element Types – Chapter 4, Sections 4.1-4.2

Fall 2016

Debra Whiteman Wood Department of Mechanical Engineering

Overview

• As can be seen by our

previous work, the

type of element

representation chosen

has a profound impact

on the overall answer

• In this chapter, we will

give a “brief” overview

and discussion of the

various types normally Our energy method depends on the “shape

found in FEA software. function”, which is a description of the

behavior of the element itself

Debra Whiteman Wood Department of Mechanical Engineering

Types of Elements

• Normally offered in FEA software

• Many variants of

these types exist!

Debra Whiteman Wood Department of Mechanical Engineering

Point (Mass) element

• Used to model a concentrated point mass

• Usually used in conjunction with spring elements

Debra Whiteman Wood Department of Mechanical Engineering

Line Elements

1-dimensional elements (we’ve already seen the

simplest type)

– Spar/Truss Elements

– Spring Elements

– Beam Elements

– Pipe Elements

– 2D Contact/Gap Elements

We will discuss some of these –

more detailed information is in the

text

Debra Whiteman Wood Department of Mechanical Engineering

Beam Elements In SolidWorks you will see this when you

select “Treat as Beam”

• Can handle bending plus axial

loading

• Requires cross-sectional

information

• Some even allow tapered

beams

Nodes can translate in two directions and

rotate in 1 direction

Debra Whiteman Wood Department of Mechanical Engineering

Pipe Elements

PIPE16 Element (ANSYS)

Essentially the same as beam elements, but internal and external pressure

are allowed.

Some variants even allow for buoyancy computations.

Debra Whiteman Wood Department of Mechanical Engineering

Area Elements

• 2 Dimensional with 2 fundamental shapes:

– Triangles (not typically used anymore)

– Rectangles

• Main Types:

– Plane Stress

– Plane Strain

– Axisymmetric

– Plate

• Do not allow for bending (3D deformation)

In SolidWorks you will see this when you

select “2D Simplification”

Debra Whiteman Wood Department of Mechanical Engineering

Plane Stress vs. Plane Strain

• Plane stress is a state Thin members!

What applications can you think of?

where there is negligible

stress in the z-direction

• Plane strain is a state

where this is negligible

strain in the z-direction

Thick members!

• The two don’t occur at the What applications can you think of?

same time due to the

Poisson effect, be careful

in your application of the

element types!

Debra Whiteman Wood Department of Mechanical Engineering

Axisymmetric Elements

• Discussed in previous lecture

• Simplification of a model by looking for geometrical

symmetry about an axis

Pressure vessels!

Deep Drawing and Metal Forming

Applications

Far more common than you think!

Can save A LOT of computation time

Debra Whiteman Wood Department of Mechanical Engineering

Simple Axisymmetric Case

Pipes, pressure vessels, cylindrical objects, etc.

Typically rather easy to apply.

Debra Whiteman Wood Department of Mechanical Engineering

Deep Drawing and Metal Forming

Debra Whiteman Wood Department of Mechanical Engineering

Deep Drawing and Metal Forming

Debra Whiteman Wood Department of Mechanical Engineering

An Advanced Axisymmetic Case

Note that this case also uses contact elements.

Due to the

nonlinear nature of

this type of

problem, the

computational cost

is high! As such, use

of a reduced mesh

(i.e. axisymmetric

elements) is very

warranted.

Debra Whiteman Wood Department of Mechanical Engineering

Curved Area Elements

• Curved plate elements that have both bending and axial

loading (membrane/stretching effects)

– Shell Elements

– 3D Contact elements

– 3D Surface Effect Elements

Applications? Numerous – any thin structure

sheet metal, thin-walled pressure vessels, ribbed supports, etc.

Debra Whiteman Wood Department of Mechanical Engineering

Shell Element Example

An extremely

common application

is that of the

reinforced shell. This

is very difficult to

model in FEA without

shell elements.

Debra Whiteman Wood Department of Mechanical Engineering

Summary and Conclusions

• In this section, we have overviewed

the most common types of elements

available for structural FE analysis

• Understanding the most appropriate

element for each situation is KEY to

responsible FEA. Using more

complicated elements than warranted

can actually REDUCE accuracy while Be certain to read the text.

greatly increasing the computational These slides are based on

cost of the analysis. the text, but do not address

everything included in the

readings.

Debra Whiteman Wood Department of Mechanical Engineering

SHAPE FUNCTIONS – CHAPTER 4,

SECTIONS 4.3 - 4.5

Debra Whiteman Wood Department of Mechanical Engineering

Overview

• Now that we have explored common element types and developed energy

methods that define our model, we will look at the shape functions that

define our element behavior.

• The concept of shape functions are critical for a mature understanding of

the FEA formulation process

Consider the following Rigid Wall

problem:

We break this beam into 3

Force

elements

Debra Whiteman Wood Department of Mechanical Engineering

1D Linear Shape Function

displacement

Rigid Wall

Blue = Actual

Force Red = Approximate

Our FEA software would

“approximate” this curve as a

series of 3 lines based on the Wall End

element formulation

Debra Whiteman Wood Department of Mechanical Engineering

1D Linear Shape Function

• Let’s look at our element with nodes i

and j, each having their own

displacement

• The shape function “S” describes the

way a node moves within the element

• For a line element such as this, the

displacement at any distance x can be

determined from:

u(X) = SiUi + SjUj

Debra Whiteman Wood Department of Mechanical Engineering

Coordinate Sets for 1D Truss Element

We need a global coordinate system, however:

– It is easier mathematically to NOT have everything in

terms of one giant coordinate system

– Integration is easier when we use local coordinates!

Each element has a local

coordinate system that is defined

from node I

The global distance X is simply:

𝑋 = 𝑋𝑖 + 𝑥

Debra Whiteman Wood Department of Mechanical Engineering

Local vs. Natural Coordinates

Each element also has a “natural”

coordinate system that is

essentially the local coordinates

in a dimensionless form

The natural coordinate system is

in the center of the element. The

distance from this coordinate is

designated as ξ (xi). It is defined 2𝑥

as -1 at node I and 1 at node j. 𝜉= −1

𝑙

This has advantages because we can integrate from -1 to 1 easily

Debra Whiteman Wood Department of Mechanical Engineering

Shape Function Properties

Shape functions have certain Si

properties that make life easier when

1

implementing the energy method

1. A shape function has a value of “1”

at its corresponding node and “0” at Xi Xj

the other adjacent node

2. The shape functions within an Sj

element all add up to unity 1

(𝑆𝑖 + 𝑆𝑗 = 1)

3. The sum of the derivatives of the

shape functions is zero Xi Xj

Debra Whiteman Wood Department of Mechanical Engineering

Increasing Accuracy

• Obviously, I can make my displacement

model more accurate by

increasing the number of Blue = Actual

elements Red = Approximate

• How else is this possible?

We can create an

interpolation formulation

and fit a quadratic function

rather than linear

Wall End

Debra Whiteman Wood Department of Mechanical Engineering

Quadratic Element Formulations

• In order to make a quadratic element, we need

additional nodes (3 to fit a quadratic curve)

Note that “k” is the middle node, this

is the standard formulation for a

quadratic element (not alphabetical)

Now my location at any value of x is:

u(X) = SiUi + SkUk +SjUj

Debra Whiteman Wood Department of Mechanical Engineering

Shape Functions

• For a 1D quadratic spar/truss element, the

approximations are given by LaGrange Shape

Functions

1 1

𝑆𝑖 = − 𝜉(1 − 𝜉) 𝑆𝑘 = (1 + 𝜉) (1 − 𝜉) 𝑆𝑗 = − 𝜉(1 − 𝜉)

2 2

Debra Whiteman Wood Department of Mechanical Engineering

Find Strain & Stress

• In natural coordinates the strain displacement matrix

for a 1D quadratic truss element is:

2 1 − 2𝜉 1 + 2𝜉

[𝐵]𝑚 = − −2𝜉

𝑙 2 2

• The strain is [B]{U}

• The stress is the elasticity matrix, [D], multiplied by

strain (for isotropic material, [D] is simply E)

𝜀 = 𝐵 {𝑈} 𝜎 = 𝐷 {𝜀}

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss [K]

• From Chap 3, we know that the stiffness matrix for

an element m is given by

1

𝐸𝐴𝑙

[𝐾]𝑚 = න 𝐵𝑇 𝐵 𝑑𝜉

2 −1

• Putting in our values for B given the shape functions,

we arrive at:

𝑖 𝑘 𝑗

𝐸 𝑖 𝐴𝑖 7 −8 1 𝑖

𝐾𝑖= −8 16 −8 𝑘

3𝑙𝑒

1 −8 7 𝑗

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss

• Note that this is NOT the same as the book. This is

the standard nomenclature and will lead to less

confusion.

𝑖 𝑘 𝑗 𝑖 𝑗 𝑘

𝐸 𝑖 𝐴𝑖 7 −8 1 𝑖 𝐸 𝑖 𝐴𝑖 7 1 −8 𝑖

𝑖 𝑖

𝐾 = −8 16 −8 𝑘 𝐾 = 1 7 −8 𝑗

3𝑙𝑒 3𝑙𝑒

1 −8 7 𝑗 −8 −8 16 − 8 𝑘

Debra Whiteman Wood Department of Mechanical Engineering

What About Forces?

• With the stiffness matrix, we can now solve for

displacements given what we know about the forces

- remember.. 𝑲 𝑼 = [𝑭]

• Lets define our force vector, now we have body

forces (weight) as well as point forces.

• The element body force vector, in terms of each

node i, k and j is given by 1/6 𝑖

𝑙 𝑏

𝑓𝐵 = 𝐴 𝑓 2/3 𝑘

2

1/6 𝑗

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (1/7)

The stepped solid shaft

supports its own weight PLUS

the 100 kN force at the free

100mm 𝜙=100mm

end

Determine the stress

distribution in the shaft using

100mm 𝜙=50mm 1D quadratic truss elements

The shaft is made from steel

with E=210GPa and 𝜌=7850

kg/𝑚3

𝐹=100 kN

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (2/7)

Using our previously derived

formula for the stiffness matrix

𝑖1

(Eq 4-46)

𝑖 𝑘 𝑗

𝐸 𝑖 𝐴𝑖 7 −8 1 𝑖 Element 1

𝑖 𝑘1

𝐾 = −8 16 −8 𝑘

3𝑙𝑒 𝑗

1 −8 7

𝑗1 , 𝑖2

7𝐴1 −8𝐴1 𝐴1 0 0

−8𝐴1 16𝐴1 −8𝐴1 0 0

𝐸 Element 2 𝑘2

𝐾= 𝐴1 −8𝐴1 7(𝐴1 + 𝐴2 ) −8𝐴2 𝐴2

3𝐿 16𝐴2 −8𝐴2

0 0 −8𝐴2

0 0 𝐴2 −8𝐴2 7𝐴2

𝑗2

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (3/7)

Body Forces (since we have weight) 𝐹𝑤𝑒 = 𝜌𝐴𝐿𝑔

Force = mass x acceleration

From Eq. 4-47, we have the body forces in terms of the shape functions:

1 1/6 𝑖

𝐴 𝑒 𝐿

{𝑓 𝐵 } 𝑒 = 𝑓𝑒𝑏 න 𝑆 𝑇 𝑑𝜉 = 𝐴𝑒 𝐿𝑓𝑒𝑏 2/3 𝑘

2 −1 1/6 𝑗

1/6 𝑖 1/6 𝑖

{𝑓 𝐵 } 1 = 𝜌𝐴12 𝐿2 𝑔 2/3 𝑘 {𝑓 𝐵 } 2 = 𝜌𝐴22 𝐿2 𝑔 2/3 𝑘

1/6 𝑗 1/6 𝑗

Element 1 Element 2

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (4/7)

1/6 𝑖 Assembling the entire body force vector yields:

{𝑓 𝐵 } 1 = 𝜌𝐴12 𝐿2 𝑔 2/3 𝑘 𝑓1𝐵 (𝑖)

1/6 𝑗 𝑓1𝐵 (𝑘)

𝑓𝐵 = 𝑓1𝐵 (𝑗) + 𝑓2𝐵 (𝑖)

1/6 𝑖

𝑓2𝐵 (𝑘)

{𝑓 𝐵 } 2 = 𝜌𝐴22 𝐿2 𝑔 2/3 𝑘

1/6 𝑗 𝑓2𝐵 (𝑗)

The global Force equation then becomes: The 𝑖 here designates the

“𝑖 𝑡ℎ ” term of the vector, in

1

𝑓1𝐵 (𝑖) this case 𝑓1𝐵 𝑖 = 6 𝜌𝐴12 𝐿2 𝑔

𝑓1𝐵 (𝑘)

𝐹 = 𝑓1𝐵 (𝑗) + 𝑓2𝐵 (𝑖)

𝑓2𝐵 (𝑘)

𝑓2𝐵 𝑗 + 𝐹

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (5/7)

Now we know that node 1 has zero

𝐾 𝑈 = {𝐹} displacement, or U1=0. This reduces our matrix

formulation to:

7𝐴1 −8𝐴1 𝐴1 0 0 0 𝑓1𝐵 (𝑖)

−8𝐴1 16𝐴1 −8𝐴1 0 0 𝑈2 𝑓1𝐵 (𝑘)

𝐸

𝐴1 −8𝐴1 7(𝐴1 + 𝐴2 ) −8𝐴2 𝐴2 𝑈3 = 𝑓1𝐵 (𝑗) + 𝑓2𝐵 (𝑖)

3𝐿 16𝐴2 −8𝐴2 𝑈4

0 0 −8𝐴2 𝑓2𝐵 (𝑘)

0 0 𝐴2 −8𝐴2 7𝐴2 𝑈5 𝑓2𝐵 𝑗 + 𝐹

System to Solve

Where:

1/6 𝑖 1/6 𝑖

𝐵

{𝑓 } 2 = 𝜌𝐴22 𝐿2 𝑔 2/3 𝑘 𝐵

{𝑓 } 1 = 𝜌𝐴12 𝐿2 𝑔 2/3 𝑘

1/6 𝑗 1/6 𝑗

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (6/7)

Solving for the displacement U, we get the following:

Now that we have displacements, we can move

forward to strain and stress

Debra Whiteman Wood Department of Mechanical Engineering

1D Quadratic Truss Example (7/7)

Using Equation 4-45

Define the Strain for each Element

0 U3

2 ( 1 2 ) 1 2 U 2 ( 1 2 ) 1 2

1( )

L

2 2 2( ) 2 4

U

2 2 L 2 2

U3 U5

8 8 8

1( 1) 6 10 1( 0) 6 10 1( 1) 6 10

7 7 7

2( 1) 2 10 2( 0) 2 10 2( 1) 2 10

Assemble the Strain Nodal Results

1( 1) 1( 0) 1( 1) 2( 1) 2( 0) 2( 1)

6.07 10

8 8

6.06 10

7

3.03 10 2.43 10

7

2.43 10

7

Determine the Stress Nodal Results

E ( 12739 12736 63664 50930 50930 ) Pa

Debra Whiteman Wood Department of Mechanical Engineering

Summary and Conclusions

In this presentation we have introduced the

concept of SHAPE FUNCTIONS. Shape

Functions are critical to a mature

understanding of the FEA formulation

process as they allow adaptation to

different element concepts.

We have also introduced the definition of

Global, Local, and Natural coordinates.

Natural coordinates (ranging between -1

and 1) are extremely advantageous when Be certain to read the text.

formulating the stiffness matrix as These slides are based on

integration over the domain of each the text, but do not address

element is required. everything included in the

readings.

Finally, we examined an example using an

1D quadratic truss element formulation.

Debra Whiteman Wood Department of Mechanical Engineering

BEAM ELEMENTS – SECTION 4.8

FALL 2016

Debra Whiteman Wood Department of Mechanical Engineering

Overview

• In your homework you were asked to perform an

analysis using 1D linear beam elements

• Tonight we will delve a bit deeper into beams and

the derivation of both 1D and 2D beams

• Why?

– Beams are an important element class, and will give an

idea of the complexity level involved in some of these

higher-order elements

Debra Whiteman Wood Department of Mechanical Engineering

Beam Element Properties and Value

Beam elements represent a 1D

structure that can move in 3D.

Beam elements differ from truss

or spar elements in that they

include:

• Bending

• Nodal Rotations

• Transverse Nodal DOF’s

• Potentially torsion

Beam elements are an important

part of FEA as they allow efficient

models to be made of slender,

flexible components.

Debra Whiteman Wood Department of Mechanical Engineering

1D Beam Element Formulation

(1/5)

We will begin with the fundamental equations from analytical beam theory.

We will limit our discussion to “linear” beam theory. Formulations do exist

for nonlinear beam elements (good research paper topic).

My d 2v M

2

I E dx EI

We now need to formulate the strain energy of a small differential length of

our beam element (length dx). The formula is the same form as introduced

earlier.

1 1 M2 1 M2

d dA dx 2 A y dA dx d 2 E I dx

2

2 A 2 EI

Debra Whiteman Wood Department of Mechanical Engineering

1D Beam Element Formulation

(2/5)

Now that we know the strain energy of a differential length of the beam, we

can integrate to determine the energy of the beam element.

2

L

1 d 2v

Total Strain Energy EI 2 dx

2 0 dx

Before we can proceed with Minimization of Total Potential Energy we need

to also account for the energy related with loading.

2

1

L

d 2v L

EI 2 dx f d v dx Fm vm M n n

2 0 dx 0 m n

Debra Whiteman Wood Department of Mechanical Engineering

1D Beam Element Formulation

(3/5)

Let’s start by focusing on a linear beam

element that only allows transverse

motion and rotation (no axial). The

shape functions for the element are

shown below (a bit more complicated to

derive, but essentially the same as

earlier).

1 1

Si 1 2 Si 1 1

2 2

4 4

1 1

S j 1 2 S j 1 1

2 2

4 4

Debra Whiteman Wood Department of Mechanical Engineering

1D Beam Element Formulation

(4/5)

The beam deflection is now given by …

dv dv

v( ) Si vi Si S j v j S j

d i d j

We will now clean the above expression

up a bit as follows …

le dv dv dx l dv

dx d

2 d dx d 2 dx

therefore …

le le

v( ) Si vi Si i S j v j S j j

2 2

Debra Whiteman Wood Department of Mechanical Engineering

1D Beam Element Formulation

(5/5)

Substituting the v() relationship into our

total potential energy formulations

allows one to reach the following:

12 6le 12 6le

6l 4l 2

6le 2le 2

1 E I

U K e U K e e 3 e e

T

e

2 le 12 6le 12 6le

e

6l 2le

2

6le 4le 2

U f

T

T f d le f d le 2 f d le f d le 2

f v dx f

d e

e

le

2 12 2 12

Debra Whiteman Wood Department of Mechanical Engineering

2D Beam Element Formulation

(1/4)

What if we want to extend our discussion

to more degrees of freedom. Consider

the case shown.

Each node now has three dof’s: two

translational and one rotation. This

configuration allows for axial strain. As

such our new stiffness matrix will

essentially be a proper assembly of the

[K] for the 1D beam element and the [K]

for the 1D truss or spar element.

U U i

T

Vi i U j V j j

A complicating factor, however, is that

the element geometry is 2D.

Debra Whiteman Wood Department of Mechanical Engineering

2D Beam Element Formulation

(2/4)

To avoid the complexity of working in 2D geometry, we will use a local

coordinate system that is oriented to align with the element.

U U i

T T

Vi i U j V j j U U 'i V 'i 'i U ' j V ' j ' j

'

0 0 0 0

This transformation 0 0 0 0

and

is accomplished 0 0 1 0 0 0 are

using a local-to-global L 0 0 0 0

direction

transformation cosines

matrix. 0 0 0 0

0 0 0 0 0 1

Debra Whiteman Wood Department of Mechanical Engineering

2D Beam Element Formulation

(3/4)

So, assembling our elemental stiffness matrix gives us the following results

for the 2D beam element …

EA EA

l 0 0 0 0

l

0 12 EI 6 EI

0

12 EI 6 EI

l3 l2 l3 l2

0 6 EI 4 EI 6 EI 2 EI

0 2

2

l 1

' e

K l l l

U Le T K 'e Le U

T

e

EA EA 2

0 0 0 0

l l

12 EI 6 EI 12 EI 6 EI

0 3 0 2

l l2 l3 l

6 EI 2 EI 6 EI 4 EI

0 0 2

l2 l l l

Debra Whiteman Wood Department of Mechanical Engineering

2D Beam Element Formulation

(4/4)

A similar operation can be performed for the distributed forcing …

T

d d 2 d

f le

d 2

f le f le f le

e

f' 0 0

2 12 2 12

Note that the distributed forcing does not have work (or energy) associated

with the local axial coordinate … Thus the zeros.

As you can see, implementation of a 2D beam element can be involved. 3D

elements are even more complicated as a far more complicated global-to-

local transformation matrix is required.

Debra Whiteman Wood Department of Mechanical Engineering

Summary / Conclusions

• In this presentation we have talked about

the basic derivation of a beam element.

The derivation is a bit more mathematically

complex than that of a truss element, but

essentially the same steps are involved.

• Understanding what goes into the

derivation of an FEA element formulation

is important. This understanding will help

you understand what can (and will) at

times go wrong within FEA.

• As you advance to more and more Be certain to read the text.

complicated modeling tasks, it will become These slides are based on

necessary for you to “dig into” the the text, but do not address

formulation theory of the code you are

using. Good quality FEA software provides everything included in the

considerable theory documentation to the readings.

end user. FEA is NOT a point-and-click

coding tool … it takes deep understanding

to use it wisely.

Debra Whiteman Wood Department of Mechanical Engineering

Potrebbero piacerti anche

- Ansys ManualDocumento124 pagineAnsys ManualUdamanNessuna valutazione finora

- FEM PresentationDocumento75 pagineFEM PresentationGooftilaaAniJiraachuunkooYesusiinNessuna valutazione finora

- Linear ProgrammingDocumento68 pagineLinear ProgrammingMy ANessuna valutazione finora

- Practical FEA GuideDocumento44 paginePractical FEA GuideLudovich MuyaNessuna valutazione finora

- Building Structural Systems Modeling GuideDocumento78 pagineBuilding Structural Systems Modeling GuidesmazNessuna valutazione finora

- Staad Length ParametersDocumento2 pagineStaad Length ParametersAkhil VNNessuna valutazione finora

- Asme SectionsDocumento56 pagineAsme SectionsalperbogaNessuna valutazione finora

- Asme SectionsDocumento56 pagineAsme SectionsalperbogaNessuna valutazione finora

- Midterm Exam - Attempt Review 1Documento15 pagineMidterm Exam - Attempt Review 1Erick GarciaNessuna valutazione finora

- G-8 3rd Summative TestDocumento2 pagineG-8 3rd Summative TestJulius Agacid BangeroNessuna valutazione finora

- Unit-IV Structural Analysis-II Part-A PDFDocumento22 pagineUnit-IV Structural Analysis-II Part-A PDFMK VNessuna valutazione finora

- Application of Finite Element Method in Structural DesignDocumento16 pagineApplication of Finite Element Method in Structural DesignAnil KadbhaneNessuna valutazione finora

- Finite Element Analysis PDFDocumento46 pagineFinite Element Analysis PDFrajani_bala15Nessuna valutazione finora

- Solidworks Simulation StandardDocumento110 pagineSolidworks Simulation Standardsherwin perezNessuna valutazione finora

- Prokon Brochure Structural Analysis 2017-08-29Documento8 pagineProkon Brochure Structural Analysis 2017-08-29SelvasathaNessuna valutazione finora

- Bentley Ram Concept GuideDocumento104 pagineBentley Ram Concept Guidechauhannisharg100% (1)

- CES 512: Finite Element Method Introduction, Theory, Applications & ImplementationDocumento32 pagineCES 512: Finite Element Method Introduction, Theory, Applications & Implementationshamsukarim2009Nessuna valutazione finora

- Finite Element Analysis Notes (Computer Aided Engineering)Documento48 pagineFinite Element Analysis Notes (Computer Aided Engineering)utub3abr0100% (5)

- MOM2E Chap2aDocumento16 pagineMOM2E Chap2apoom2007Nessuna valutazione finora

- Mathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersDa EverandMathematical Analysis of Quasi-Simultaneous Laser Welding on PolymersNessuna valutazione finora

- Introduction to Finite Element Analysis (FEADocumento50 pagineIntroduction to Finite Element Analysis (FEAPrakash KancharlaNessuna valutazione finora

- Theory of 2D MeshingDocumento26 pagineTheory of 2D MeshingManoj K VNessuna valutazione finora

- SimXpert R3.2 Modeling GuideDocumento202 pagineSimXpert R3.2 Modeling Guidepaulkastle100% (2)

- ANSYS FEA Software Pre-Processing, Processing & Post-ProcessingDocumento111 pagineANSYS FEA Software Pre-Processing, Processing & Post-ProcessingAjay ThomasNessuna valutazione finora

- Struct Element Types PDFDocumento5 pagineStruct Element Types PDFrockmanqhNessuna valutazione finora

- Struct - Element - Types - ANSYS (TIPOS DE ELEMENTOS E CARACTERÍSTICAS)Documento5 pagineStruct - Element - Types - ANSYS (TIPOS DE ELEMENTOS E CARACTERÍSTICAS)maiconNessuna valutazione finora

- Etabs L1Documento13 pagineEtabs L1Matt DesignNessuna valutazione finora

- NozzleproDocumento20 pagineNozzleprossmith2007Nessuna valutazione finora

- Introduction To Finite Element Methods: Dr. Kiran M. CDocumento47 pagineIntroduction To Finite Element Methods: Dr. Kiran M. CKiranNessuna valutazione finora

- Cad/Cam Lab: Venkitaraj K PDocumento60 pagineCad/Cam Lab: Venkitaraj K PJoe mNessuna valutazione finora

- AnsysDocumento14 pagineAnsysRavi NPDNessuna valutazione finora

- FEM - Sync Week 2Documento39 pagineFEM - Sync Week 2Wild BotNessuna valutazione finora

- FEM IntroductionDocumento29 pagineFEM IntroductionKrishna MurthyNessuna valutazione finora

- CH11 Finite Element Types 3D FEM 1Documento13 pagineCH11 Finite Element Types 3D FEM 1Ranjit Koshy AlexanderNessuna valutazione finora

- CVEN 345 - Lecture 1Documento2 pagineCVEN 345 - Lecture 1Moh SalNessuna valutazione finora

- MECH5605 - 2 - 4 - Direct Approach - 2D TrussDocumento18 pagineMECH5605 - 2 - 4 - Direct Approach - 2D TrussAkthamLoranseMansiNessuna valutazione finora

- Create FEA ModelDocumento13 pagineCreate FEA ModelAvinash ShindeNessuna valutazione finora

- Chapter 02 - Past Present FutureDocumento12 pagineChapter 02 - Past Present FuturedeepakNessuna valutazione finora

- Finite Element Method: A Brief History and Look at its Past, Present and FutureDocumento12 pagineFinite Element Method: A Brief History and Look at its Past, Present and FuturedeepakNessuna valutazione finora

- Tutorial 2Documento7 pagineTutorial 2MOMIN TOSHIN RAFIQ DILSHADNessuna valutazione finora

- Workshop Slides EVERFEDocumento52 pagineWorkshop Slides EVERFEtauquilNessuna valutazione finora

- General Procedure of FEA 7Documento30 pagineGeneral Procedure of FEA 7tauasi_1Nessuna valutazione finora

- Class Handout MFG500024 ClassHandout-MFG500024-Gillman-AU2021Documento19 pagineClass Handout MFG500024 ClassHandout-MFG500024-Gillman-AU2021Miguel FerreiraNessuna valutazione finora

- NAFEMS INDIA Workshop on Finite Element Methods and Practical Stress AnalysisDocumento38 pagineNAFEMS INDIA Workshop on Finite Element Methods and Practical Stress AnalysiskarthekeyanmenonNessuna valutazione finora

- ME411 FEM - L4 - Practical ConsiderationsDocumento64 pagineME411 FEM - L4 - Practical ConsiderationsZain Mustafa100% (1)

- Introduction To Ansys SoftwareDocumento49 pagineIntroduction To Ansys SoftwareAnonymous Clyy9NNessuna valutazione finora

- Finite Element Method PDFDocumento45 pagineFinite Element Method PDFGetachewNessuna valutazione finora

- Final Project Finite Element AnalysisDocumento41 pagineFinal Project Finite Element AnalysisAkhil KapoorNessuna valutazione finora

- Introduction to Finite Element Method (FEM) by Prof. G.Sreeram ReddyDocumento12 pagineIntroduction to Finite Element Method (FEM) by Prof. G.Sreeram ReddyManoj BallaNessuna valutazione finora

- Srm-Cad-Unit IvDocumento92 pagineSrm-Cad-Unit IvVikrant ThakurNessuna valutazione finora

- Last Time: - SubdivisionDocumento34 pagineLast Time: - Subdivisionieda1718Nessuna valutazione finora

- Aplicación de Elementos Finitos Con Ansys WorkbenchDocumento87 pagineAplicación de Elementos Finitos Con Ansys WorkbenchEdgarjavier Loor SolorzanoNessuna valutazione finora

- Fea ImpDocumento14 pagineFea ImpC61 Mahesh RathodNessuna valutazione finora

- FEM IntroductionDocumento29 pagineFEM IntroductionKrishna MurthyNessuna valutazione finora

- SME1308Documento224 pagineSME1308S.SIVAKUMARNessuna valutazione finora

- FEA Knowledge 1.4Documento20 pagineFEA Knowledge 1.4APURV THE Black Horse DRVNessuna valutazione finora

- CE571-DSM of FramesDocumento22 pagineCE571-DSM of FramesAhmed MaherNessuna valutazione finora

- Non-Linear Structural AnalysisDocumento12 pagineNon-Linear Structural AnalysisMohammed SallamNessuna valutazione finora

- Eurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringDocumento42 pagineEurocode 3: Department of Architecture & Civil Engineering Department of Architecture & Civil EngineeringNazihahNessuna valutazione finora

- What Is The Difference Between Linear and Nonlinear Analysis?Documento15 pagineWhat Is The Difference Between Linear and Nonlinear Analysis?JammiNessuna valutazione finora

- !!! - Проверка сетокDocumento19 pagine!!! - Проверка сетокMikeNessuna valutazione finora

- 7 - Modelling of StructuresDocumento45 pagine7 - Modelling of StructuresSepideh KhaleghiNessuna valutazione finora

- EEM Lecture 1 ElectromagneticsDocumento30 pagineEEM Lecture 1 ElectromagneticsJenifer PetrolaNessuna valutazione finora

- 10 Low and High Cycle FatigueDocumento14 pagine10 Low and High Cycle FatiguePRASAD326100% (1)

- Journal MaterialDocumento11 pagineJournal MaterialsitychanNessuna valutazione finora

- WB Connections DOC PDFDocumento15 pagineWB Connections DOC PDFKonderu AnilNessuna valutazione finora

- Fundamentals of GD&T - Alex KrulikowskiDocumento207 pagineFundamentals of GD&T - Alex Krulikowskidramilt92% (13)

- 2 D ElementsDocumento18 pagine2 D ElementsBennet KuriakoseNessuna valutazione finora

- GD & T Handout TTRC PDFDocumento34 pagineGD & T Handout TTRC PDFKonderu AnilNessuna valutazione finora

- Introduction WBDocumento21 pagineIntroduction WBBarathan RamachandranNessuna valutazione finora

- Ans FluDocumento232 pagineAns FluKonderu AnilNessuna valutazione finora

- GD & T Handout TTRC PDFDocumento34 pagineGD & T Handout TTRC PDFKonderu AnilNessuna valutazione finora

- Converge Nci ADocumento89 pagineConverge Nci ABebi VatanenNessuna valutazione finora

- Refernce 1 JournelDocumento10 pagineRefernce 1 JournelKonderu AnilNessuna valutazione finora

- Converge Nci ADocumento89 pagineConverge Nci ABebi VatanenNessuna valutazione finora

- Fluent Post Processing Lecture11-PostDocumento46 pagineFluent Post Processing Lecture11-PostLishan JayasooriyaNessuna valutazione finora

- Example 1: Milled Panel: Intention: Designing and Dimensioning in The SketcherDocumento4 pagineExample 1: Milled Panel: Intention: Designing and Dimensioning in The SketcherKonderu AnilNessuna valutazione finora

- Design and Calculation Ofsteam-Turbine D Isk W Heels: NtroductionDocumento16 pagineDesign and Calculation Ofsteam-Turbine D Isk W Heels: NtroductionKonderu AnilNessuna valutazione finora

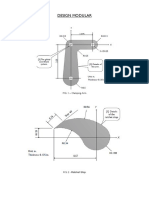

- Design Modular: FIG: 1 - Clamping ArmDocumento5 pagineDesign Modular: FIG: 1 - Clamping ArmKonderu AnilNessuna valutazione finora

- Converge Nci ADocumento89 pagineConverge Nci ABebi VatanenNessuna valutazione finora

- Fluent 13.0 Lecture10-TransientDocumento13 pagineFluent 13.0 Lecture10-Transientshraveen1991Nessuna valutazione finora

- Nonlinear Structural Materials Module Users Guide 12Documento78 pagineNonlinear Structural Materials Module Users Guide 12Konderu AnilNessuna valutazione finora

- STRUCTURAL - Chapter 6 - Spectrum Analysis (UP19980818)Documento31 pagineSTRUCTURAL - Chapter 6 - Spectrum Analysis (UP19980818)Konderu AnilNessuna valutazione finora

- Ansys CFX TutorialsDocumento788 pagineAnsys CFX TutorialsgarystevensozNessuna valutazione finora

- Fluent 13.0 Lecture10-TransientDocumento13 pagineFluent 13.0 Lecture10-Transientshraveen1991Nessuna valutazione finora

- Ansys CFX TutorialsDocumento788 pagineAnsys CFX TutorialsgarystevensozNessuna valutazione finora

- Nonlinear Structural Materials Module Users Guide 12Documento78 pagineNonlinear Structural Materials Module Users Guide 12Konderu AnilNessuna valutazione finora

- Nonlinear Structural Materials Module Users Guide 12Documento78 pagineNonlinear Structural Materials Module Users Guide 12Konderu AnilNessuna valutazione finora

- RD Sharma Class 11 Maths Chapter 2 RelationsDocumento18 pagineRD Sharma Class 11 Maths Chapter 2 RelationsShivam MutkuleNessuna valutazione finora

- Fallacy PDFDocumento5 pagineFallacy PDFMiliyon TilahunNessuna valutazione finora

- Scheme of ValuationDocumento20 pagineScheme of ValuationRaghu Nandan HukkardeNessuna valutazione finora

- 1st Periodical Exam - General MathematicsDocumento5 pagine1st Periodical Exam - General MathematicsLORENZO RAMIREZNessuna valutazione finora

- Graphs and Variations IDocumento34 pagineGraphs and Variations IA.BensonNessuna valutazione finora

- Table of Common Laplace TransformsDocumento2 pagineTable of Common Laplace TransformsJohn Carlo SacramentoNessuna valutazione finora

- V1498454791amathematics 9th Solution PDFDocumento108 pagineV1498454791amathematics 9th Solution PDFpriya11devNessuna valutazione finora

- Set TheoryDocumento20 pagineSet TheoryAbdulmejidAyalewNessuna valutazione finora

- Hartree-Fock For HeDocumento19 pagineHartree-Fock For HeAustin Yu LiuNessuna valutazione finora

- Optimum Structural Design Based On Isogeometric Analysis MethodDocumento5 pagineOptimum Structural Design Based On Isogeometric Analysis MethodficuniNessuna valutazione finora

- ElastisiteDocumento2 pagineElastisiteEray KoçNessuna valutazione finora

- Improved Decoding of Reed-Solomon and Algebraic-Geometry CodesDocumento11 pagineImproved Decoding of Reed-Solomon and Algebraic-Geometry CodesShanmuga SundaramNessuna valutazione finora

- Cardano's Method for Solving Cubic EquationsDocumento10 pagineCardano's Method for Solving Cubic EquationsAndrew ArahaNessuna valutazione finora

- FloresAlejandro Exercise1Documento10 pagineFloresAlejandro Exercise1kero92Nessuna valutazione finora

- 0.3 Functions and Graphs Contemporary Calculus 1Documento12 pagine0.3 Functions and Graphs Contemporary Calculus 1benalyn ignacioNessuna valutazione finora

- Linear Statistical Models Lecture NotesDocumento150 pagineLinear Statistical Models Lecture NotesFucKerWengieNessuna valutazione finora

- Mean Median ModeDocumento29 pagineMean Median ModeJc LanuzaNessuna valutazione finora

- CE2407B Lecture 3 PDFDocumento29 pagineCE2407B Lecture 3 PDFJeremus the MedicNessuna valutazione finora

- Spectra of Graph by HaemersDocumento229 pagineSpectra of Graph by HaemersbalamathsNessuna valutazione finora

- Module-3 PS: Algebraic Formulae and EquationsDocumento10 pagineModule-3 PS: Algebraic Formulae and Equationsvidishanialler100% (1)

- Module - 5.1Documento39 pagineModule - 5.1HarshitNessuna valutazione finora

- Purchase Chapter 8 Solutions Manual OnlineDocumento8 paginePurchase Chapter 8 Solutions Manual OnlinekirubelNessuna valutazione finora

- MLF Week6 Test Questions V3 SolutionDocumento7 pagineMLF Week6 Test Questions V3 SolutionMrityunjay Chakraborty100% (1)

- De Chapter 3Documento22 pagineDe Chapter 3hfzmusamaNessuna valutazione finora

- The quick approximation 99/70 for the square root of twoDocumento22 pagineThe quick approximation 99/70 for the square root of twoAlex LeeNessuna valutazione finora

- Chapter 7 Differential EquationsDocumento15 pagineChapter 7 Differential Equationssyamimi balkhisNessuna valutazione finora

- Numerical Methods in Civil Engg-Janusz ORKISZ PDFDocumento154 pagineNumerical Methods in Civil Engg-Janusz ORKISZ PDFRajesh CivilNessuna valutazione finora