Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

RC Detailing of Foundations

Caricato da

kishoreDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

RC Detailing of Foundations

Caricato da

kishoreCopyright:

Formati disponibili

Technical Training Program

foundations

GOD HATH DONE EVERYTHING BEAUTIFUL IN HIS TIME

Outline of Presentation

Types of footing

Following are the different types of footing used for

concrete structure

• Isolated footing

• Combined footings

• Strap footing

• Mat or raft foundation

• Pile foundation

RC Detailing Training Program 1

ISOLATED FOOTING

RC Detailing Training Program 2

Introduction

ISOLATED FOOTING

Isolated footings are provided under each column and may be

square, rectangular, or circular in plan. Footing may be flat or

tapered

RC Detailing Training Program 3

Detailing

Size of footing

Depth at footing

Depth of footing edge

Nominal and effective cover

Development length

Minimum and maximum steel

Spacing of bars and stirrups

RC Detailing Training Program 4

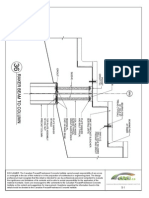

Detailing of Steel in Rectangular Footing as per IS : 456-2000

Reinforcement

Long and short direction

In short direction larger steel area is needed in the central portion and is given by

Ast ,centralband 2

Ast ,total, shortdirection ( L / B) 1

Reminder of the steel in end bands

f s .φ s

4τ

Development length= Ldt= = Ldt=

bd

RC Detailing Training Program 5

Detailing of Square footing

400

400

CROSS SECTION 4- #16

2700

3000 mm

GROUND LEVEL

4- #16

DEPTH OF

#6@220

FOUNDATION

#20@250 2700

≥ 500 mm

Ldt L dc

150 min.

75 300 min.

Ldt LEVELLING COURSE

75 PLAN

SECTIONAL ELEVATION

RC Detailing Training Program 6

Detailing of Rectangular footing

400

300

CROSS SECTION

GROUND LEVEL

DEPTH OF 6- #20

FOUNDATION #8@200

#16@200

≥ 500 mm

Ldt L dc

75

75 300 min.

Ldt LEVELLING COURSE PLAN

75

SECTIONAL ELEVATION

RC Detailing Training ProgramPLAN 7

Detailing of Rectangular footing

300

CROSS SECTION

3200

GROUND LEVEL

DEPTH OF 6- #20

FOUNDATION #8@200

≥ 500 mm #16@200

2200

Ldt L dc

75

75 300 min.

Ldt LEVELLING COURSE

75 EB CB= 2200 EB

SECTIONAL ELEVATION

PLAN

RC Detailing Training Program 8

Detailing with dowel bars

Dowel bars or

starter bars

(At least 0.5% of the cross section

area of the column or pedestal

with min 4 bars of 12mm dia.)

DEPTH OF

LAP

FOUNDATION

≥ 500 mm #16@200

Ldt L dc

75

75 300 min .

Ldt LEVELLING COURSE

75

SECTIONAL ELEVATION

RC Detailing Training Program 9

RC Detailing of Isolated footing

Reinforcement of the footing:

Minimum Reinforcement:

Minimum reinforcement and spacing shall be as per the requirements of solid slab.

0.15% - Fe 250

0.12% - Fe 415 & Fe 500

The spacing of the bars for main tensile reinforcement in solid slab shall be not more than thrice the

effective depth of slab or 450 mm, whichever is smaller.

The spacing of the distribution bars or the spacing of the bars provided against shrinkage and

temperature shall not be more than 5 times the effective depth of slab or 450 mm, whichever is

smaller.

RC Detailing Training Program 10

RC Detailing of Isolated footing

Minimum Diameter of bar:

The diameter of main reinforcing bar should not

less than 10mm.

Top Reinforcement: (Footing Subject to

Compression and Moment: Uplift)

Top reinforcement is provided when loss of

contact occurs .

Loss of contact will occur in case of structures

like conveyor, pipes, etc., where there is not much

dead load will act and the footing is allowed to

uplift.

RC Detailing Training Program 11

COMBINED FOOTING

RC Detailing Training Program 12

Fundamentals of RC Detailing of combined footing

What is combined footing?

Combined footings are provided to support two or more column loads

Necessity of combined footing:

when the isolated footings overlap.

when the exterior column is close to the property line with the result symmetrical isolated footing can not

be provided.

Types of Combined footings

Rectangular Combined Footing

Trapezoidal Combined Footing

Cantilever or Strap Combined Footing

Detailing

For combined footing, detailing of longitudinal and transverse bars is similar to that of beams.

RC Detailing Training Program 13

Types of combined footing

PROPERTY LINE

PROPERTY LINE

RECTANGULAR TRAPEZOIDAL

PROPERTY LINE

Strap Footing consists of an isolated footing of

two columns connected by a beam called strap

STRAP beam. The strap beam does not remain in

BEAM contact with the soil and thus does not transfer

any load to the soil.

STRAP

RC Detailing Training Program 14

RC Detailing of Rectangular combined footing

RC Detailing Training Program 15

RC Detailing of Trapezoidal Combined Footing

RC Detailing Training Program 16

RC Detailing of Strap footing

RC Detailing Training Program 17

RC Detailing of footing under Trench

Where ducts and trenches occur

in footing, special attention should

be given to detailing continuity of

top reinforcement. Specially

where moment transfer is

required

RC Detailing Training Program 18

Column on edges of footing

To prevent shear failure along the inclined

plane (corbel type of failure) in footing,

where a column is located on the edge, it

is advisable to provide horizontal U-type

bars around the vertical starter bars.

Column on edge of a footing.

RC Detailing Training Program 19

CONTINUOUS FOOTING UNDER WALLS

pockets may occur along the footing.

In continuous wall foundations, transverse

reinforcement should be provided when the projection

of the footing beyond the wall exceeds the thickness of

the footing.

It is also recommended that longitudinal

reinforcement be provided whenever an abrupt change

in the magnitude of the load or variation in ground

support or local loose pockets may occur along the

footing.

RC Detailing Training Program 20

PILE CAPS

RC Detailing Training Program 21

Introduction

Pile caps are thick slabs used to tie a group of piles together to support and transmit column loads to the

piles.

Design Aspects:

Two alternative theories Truss Theory and Beam Theory are used for Design of Pile caps.

When Shear span/depth ratio (av /d) < 0.6, Truss action.

When Shear span/depth ratio (av /d) > 2.0, Beam action.

In truss action Tensile force between pile head is taken by Load transfer in thick pile caps

reinforcement, so great care should be taken to tie the

end of reinforcement.

In beam action tensile reinforcement at the bottom act like the tension

reinforcement.

Truss action in pile caps

RC Detailing Training Program 22

Common Types of Pile caps

RC Detailing Training Program 23

Design Aspects

Single Pile

Due to Lateral Force, Moments develops.

Free head condition.

Two Pile

Fixed head condition.

Beam action.

Sufficient care should be taken to transfer bending in

the transverse direction.

SINGLE PILE

For Two Piles

RC Detailing Training Program 24

Detailing

Pile cap along with Column pedestal shall be

deep enough to allow for necessary anchorage

of column and pile reinforcement.

Side face reinforcement provided for bursting

tension around the pile cap = #12 @150

Clear overhang of the pile cap beyond

outermost pile=100-150mm

Clear cover shall not be less than 60mm

Reinforcement from the pile should be

properly tied to the pile cap.

Detailing as per Truss action

Anchoring the main steel at there ends

The ends of the steel given full anchorage by

providing full Ld.

RC Detailing Training Program 25

Arrangement of Reinforcement

1) Main bars placed at bottom in X-X direction

bent at ends to increase anchorage.

2) Main bars placed at bottom in Y-Y direction

bent at ends.

3) Two or three layers of 12mm dia. horizontal

ties as a secondary steel to resist bursting.

4) Column starter bars, which are L-shaped

≥ 300 mm

and turned back at the level of bottom

reinforcement.

5) Reinforcement from the pile extended into

the pile cap for its full Ld in compression.

6) Top steel provided as compression steel

(Required by calculation).

7) Link to the column bars.

8) Link to the pile reinforcement.

RC Detailing Training Program 26

Why top steel is required?

Tension in piles.

Due to water pressure.

To hold the stirrups.

Due to temperature and shrinkage.

Minimum reinforcement (Top and Bottom)

0.12% - Fe 415 & Fe 500.

RC Detailing Training Program 27

Potrebbero piacerti anche

- Introduction To AND: Reinforcement Detailing DrawingDocumento43 pagineIntroduction To AND: Reinforcement Detailing DrawingSandgrouse Raj100% (1)

- Rein F Detail Footing ColDocumento25 pagineRein F Detail Footing Colsom_bs79Nessuna valutazione finora

- Ejemplo Cercha PDFDocumento24 pagineEjemplo Cercha PDFWilliam CaballeroNessuna valutazione finora

- Lecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Documento35 pagineLecture 17 - Design of Reinforced Concrete Beams For Shear: November 1, 2001 CVEN 444Ram RamisettiNessuna valutazione finora

- 10 FT Restrained Wall Design of CMU Wall: See Analysis BelowDocumento1 pagina10 FT Restrained Wall Design of CMU Wall: See Analysis Belowmeetvinayak2007Nessuna valutazione finora

- 36 - Raker Beam To ColumnDocumento1 pagina36 - Raker Beam To ColumnSahand JeffNessuna valutazione finora

- W3 Deep FoundationDocumento42 pagineW3 Deep FoundationTeoh Zhi TongNessuna valutazione finora

- Guide To Evaluating Design Wind Loads To BS 6399-2 1997Documento52 pagineGuide To Evaluating Design Wind Loads To BS 6399-2 1997Esraa AhmadNessuna valutazione finora

- Slabs Beam DetailingDocumento40 pagineSlabs Beam DetailingAnik SenNessuna valutazione finora

- Multi-Storey Commercial Building DesignDocumento29 pagineMulti-Storey Commercial Building DesignkaushikrejaNessuna valutazione finora

- Technical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisDocumento6 pagineTechnical Report - STEEL - FRAMED BUILDING - Seismic - AnalysisAdnan NajemNessuna valutazione finora

- Example 1.5 - Quarter TurnDocumento8 pagineExample 1.5 - Quarter TurnHawaiiChongNessuna valutazione finora

- Column Pad DesignDocumento1 paginaColumn Pad DesignMunene NdumiaNessuna valutazione finora

- Ref Books ListDocumento2 pagineRef Books ListShubhankar KhareNessuna valutazione finora

- DBR Cvs AuditoriumDocumento9 pagineDBR Cvs AuditoriumJohn JacksonNessuna valutazione finora

- Static IndeterminacyDocumento16 pagineStatic Indeterminacyjeanniemanalo100% (3)

- Answer All QuestionsDocumento8 pagineAnswer All Questionsbrownpepper30100% (1)

- Beams With Variable DepthDocumento22 pagineBeams With Variable DepthNima Soufiani100% (1)

- Example 1.4 - Perpendicular To FlightDocumento14 pagineExample 1.4 - Perpendicular To FlightHawaiiChongNessuna valutazione finora

- Memorial Hall ReportDocumento19 pagineMemorial Hall ReportMike CarraggiNessuna valutazione finora

- Brick LintelsDocumento17 pagineBrick LintelsBharanidharan SelvanNessuna valutazione finora

- End Plates - Worked Examples With Partial Depth End Plate - Example 5Documento1 paginaEnd Plates - Worked Examples With Partial Depth End Plate - Example 5Kimutai Kirui AlphonceNessuna valutazione finora

- Deep FoundatioDocumento49 pagineDeep FoundatioSanthosh PurushothamanNessuna valutazione finora

- Retaining Wall Details Package 11.10Documento9 pagineRetaining Wall Details Package 11.10Mohammed AdelNessuna valutazione finora

- RC Design - ACIDocumento41 pagineRC Design - ACIAbebe WoldeNessuna valutazione finora

- Quick ReferenceDocumento32 pagineQuick ReferenceManoj RautNessuna valutazione finora

- Hinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Documento29 pagineHinusdtan College of Science & Technology: ECE-064 Earthquake Resistant Design UNIT-5Faraan KhanNessuna valutazione finora

- Pre Egineered Structural Steel Stadium Design BasisDocumento9 paginePre Egineered Structural Steel Stadium Design Basissahil bendreNessuna valutazione finora

- Eurocode - Load Combinations For Steel Structures - R1Documento26 pagineEurocode - Load Combinations For Steel Structures - R1anil97232Nessuna valutazione finora

- Slab-On-Grade Reinforcing DesignDocumento9 pagineSlab-On-Grade Reinforcing DesignAdam GreenlawNessuna valutazione finora

- Chapter 3 Stairs and StaircasesDocumento25 pagineChapter 3 Stairs and StaircasesRamiro TiconaNessuna valutazione finora

- Practical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppDocumento21 paginePractical Aspects On Detailing of RCC Members in Building Construction BY V.M.Rajan Ce/Civil/MtppAnonymous nwByj9L100% (1)

- Load Bearing StructureDocumento62 pagineLoad Bearing StructureRam Prasad AwasthiNessuna valutazione finora

- ETABS ColumndesignDocumento1 paginaETABS ColumndesignPujan NeupaneNessuna valutazione finora

- 7 Design ProceduresDocumento26 pagine7 Design ProcedureskavyadeepamNessuna valutazione finora

- Basement Wall DesignDocumento2 pagineBasement Wall DesignArindam RoyNessuna valutazione finora

- N1 Seismic JointsDocumento37 pagineN1 Seismic JointsmabuhamdNessuna valutazione finora

- Advantage SteelDocumento48 pagineAdvantage SteelCan AydoğmuşNessuna valutazione finora

- BUILDING MATERIAL (Types of Walls) and Swimming Pool DetailDocumento63 pagineBUILDING MATERIAL (Types of Walls) and Swimming Pool DetailTejas Joshi100% (1)

- HORDY Design Example ContinuedDocumento6 pagineHORDY Design Example Continuedabdul kareeNessuna valutazione finora

- (LECT-21,22) Prestressed Concrete SlabsDocumento22 pagine(LECT-21,22) Prestressed Concrete SlabsSushil MundelNessuna valutazione finora

- 2 Principles of Roof Truss DesignDocumento11 pagine2 Principles of Roof Truss DesignKapiya Dismas100% (1)

- British Problem 2 PDFDocumento7 pagineBritish Problem 2 PDFelixnzNessuna valutazione finora

- Analysis of Elevated Square Water Tank With Different Staging SystemDocumento4 pagineAnalysis of Elevated Square Water Tank With Different Staging SystemInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Conceptual Seismic DesignDocumento91 pagineConceptual Seismic Designshubham2395Nessuna valutazione finora

- Two Pile GroupDocumento12 pagineTwo Pile GroupJammy KingNessuna valutazione finora

- Gang-Nail Connectors - How They Work Gang-Nail Truss SystemDocumento5 pagineGang-Nail Connectors - How They Work Gang-Nail Truss SystemAnonymous acaD5VNessuna valutazione finora

- Product Data: Beam Lintels LengthsDocumento2 pagineProduct Data: Beam Lintels LengthsRakesh ParaliyaNessuna valutazione finora

- Cantilever SlabDocumento5 pagineCantilever SlabMd Humayun Kabir100% (1)

- Client:: Structural Analysis and Design Report StadiumDocumento39 pagineClient:: Structural Analysis and Design Report StadiumRoshan KejariwalNessuna valutazione finora

- 1673 Reinforcement Detailing in Concrete Structures A Structural MembersDocumento4 pagine1673 Reinforcement Detailing in Concrete Structures A Structural MembersTina SanNessuna valutazione finora

- Project Beam +columnDocumento107 pagineProject Beam +columnRajib Maharjan100% (1)

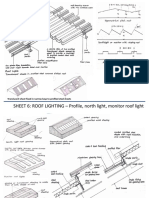

- SHEET 6: ROOF LIGHTING - Profile, North Light, Monitor Roof LightDocumento6 pagineSHEET 6: ROOF LIGHTING - Profile, North Light, Monitor Roof LightBharat GouripurNessuna valutazione finora

- RC Detailing of FoundationsDocumento28 pagineRC Detailing of FoundationskishoreNessuna valutazione finora

- Wilson Cables - FR.Documento12 pagineWilson Cables - FR.ថុន មករាNessuna valutazione finora

- Eterna CW: Kirloskar Brothers LimitedDocumento2 pagineEterna CW: Kirloskar Brothers Limitedudiptya_papai2007100% (1)

- XC10002X4R12U 11894 DatasheetDocumento2 pagineXC10002X4R12U 11894 DatasheetSteve SimpsonNessuna valutazione finora

- SpecificationDocumento6 pagineSpecificationMOHAMAD AMIR BIN HALIDNessuna valutazione finora

- Rebar Works: VCDLSJ2020Documento56 pagineRebar Works: VCDLSJ2020Abelost ZenithNessuna valutazione finora

- Stelmec VCBDocumento2 pagineStelmec VCBnithinmundackal3623Nessuna valutazione finora

- BuildingDocumento2 pagineBuildingkishoreNessuna valutazione finora

- Substation DesignDocumento1 paginaSubstation DesignkishoreNessuna valutazione finora

- BridgesDocumento1 paginaBridgeskishoreNessuna valutazione finora

- Box BridgesDocumento2 pagineBox BridgeskishoreNessuna valutazione finora

- Optimization in BreakerDocumento1 paginaOptimization in BreakerkishoreNessuna valutazione finora

- Architecturally Exposed Structural SteelDocumento16 pagineArchitecturally Exposed Structural SteelkishoreNessuna valutazione finora

- Grillage FoundationDocumento2 pagineGrillage FoundationkishoreNessuna valutazione finora

- PCC TowerDocumento1 paginaPCC TowerkishoreNessuna valutazione finora

- 1) Goods, 2) Service, 3) Goods & Service: Sensitivity: LNT Construction Internal UseDocumento11 pagine1) Goods, 2) Service, 3) Goods & Service: Sensitivity: LNT Construction Internal UsekishoreNessuna valutazione finora

- Personality DevelopmentDocumento17 paginePersonality DevelopmentkishoreNessuna valutazione finora

- RC Detailing of FoundationsDocumento28 pagineRC Detailing of FoundationskishoreNessuna valutazione finora

- Beam Reinforcement Detailing: God Hath Done Everything Beautiful in His TimeDocumento26 pagineBeam Reinforcement Detailing: God Hath Done Everything Beautiful in His TimekishoreNessuna valutazione finora

- Efeectiveness of Quality Management in Ti Ic: Sensitivity: LNT Construction Internal UseDocumento3 pagineEfeectiveness of Quality Management in Ti Ic: Sensitivity: LNT Construction Internal UsekishoreNessuna valutazione finora

- Digital Transformation: 13 September, 2019Documento59 pagineDigital Transformation: 13 September, 2019kishoreNessuna valutazione finora

- RC DetailingDocumento82 pagineRC DetailingkishoreNessuna valutazione finora

- A Classification of Structures and Mason PDFDocumento15 pagineA Classification of Structures and Mason PDFMassimo LatourNessuna valutazione finora

- PART 87 - 1 Flow Direction of Valve - Part 4 (Globe Valve)Documento7 paginePART 87 - 1 Flow Direction of Valve - Part 4 (Globe Valve)ravindra_jivaniNessuna valutazione finora

- Welding IntroductionDocumento23 pagineWelding IntroductionRaghu ChowdaryNessuna valutazione finora

- ADWEA - Vendor's ListDocumento312 pagineADWEA - Vendor's ListClark HonradoNessuna valutazione finora

- Koc-P-002 Part 1 Rev 3Documento29 pagineKoc-P-002 Part 1 Rev 3Hari KrishnanNessuna valutazione finora

- Draftsman Grade II Town Planning Surveyor GR IIDocumento13 pagineDraftsman Grade II Town Planning Surveyor GR IIBasil Baby-PisharathuNessuna valutazione finora

- Air Conditioner Control (Heating and Air Conditioning) - ALLDATA RepairDocumento2 pagineAir Conditioner Control (Heating and Air Conditioning) - ALLDATA Repairmemo velascoNessuna valutazione finora

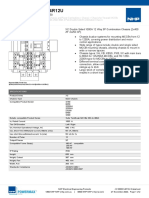

- Specification: Filter Regulator+LubricatorDocumento2 pagineSpecification: Filter Regulator+LubricatorLuiggi Javier Juliano BarraNessuna valutazione finora

- Countersunk Socket Head Screws MetricDocumento2 pagineCountersunk Socket Head Screws MetricSATHISHKUMAR MNessuna valutazione finora

- BOQ Ductile IronDocumento2 pagineBOQ Ductile IronAshraf SalehNessuna valutazione finora

- Dubai Municipality Exam - G+1Documento32 pagineDubai Municipality Exam - G+1rabia bano60% (5)

- Chiller Plant Calculation & Raw Data RequiredDocumento1 paginaChiller Plant Calculation & Raw Data RequiredBudi IswahyudiNessuna valutazione finora

- 30mX40m Plot BuildingDocumento6 pagine30mX40m Plot BuildingtahaelnourNessuna valutazione finora

- BucoDocumento3 pagineBucoYvala Zamora PercyNessuna valutazione finora

- Sika PDS - E - Sika Pocket Grout PDFDocumento2 pagineSika PDS - E - Sika Pocket Grout PDFlwin_oo2435Nessuna valutazione finora

- C20-C60 Valves DatasheetsDocumento10 pagineC20-C60 Valves DatasheetsFelipe LeiteNessuna valutazione finora

- Geap Technical Data SheetDocumento3 pagineGeap Technical Data SheetSahabNessuna valutazione finora

- What Is A Fatigue Test?: High Cycle Fatigue (HCF)Documento4 pagineWhat Is A Fatigue Test?: High Cycle Fatigue (HCF)Taif AlhashimNessuna valutazione finora

- Analysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEDocumento7 pagineAnalysis of Steam Turbine Blade Failure LOW PRESSURE TURBINEpoojaNessuna valutazione finora

- Regloplas 90smart en 1666951322Documento4 pagineRegloplas 90smart en 1666951322APOSENTO ALTO APOSENTO ALTONessuna valutazione finora

- SATIP-P-104-01 Rev 7 FinalDocumento4 pagineSATIP-P-104-01 Rev 7 FinalHatemS.MashaGbehNessuna valutazione finora

- PWD Schedule Rate AnalysisDocumento196 paginePWD Schedule Rate AnalysisSachin Chivate50% (2)

- Ductile Iron Culvert Pipe: Standard Specification ForDocumento5 pagineDuctile Iron Culvert Pipe: Standard Specification Forist93993Nessuna valutazione finora

- Green Pin Shackles - Certificates Overview and Specifications - 0Documento1 paginaGreen Pin Shackles - Certificates Overview and Specifications - 0Eduardo SolanoNessuna valutazione finora

- Chapter 3Documento22 pagineChapter 3JommarVocalTagalog100% (1)

- SABIC® LLDPE - 118NJA - Americas - Technical - Data - SheetDocumento2 pagineSABIC® LLDPE - 118NJA - Americas - Technical - Data - Sheetdiana sarmientoNessuna valutazione finora

- Installation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZDocumento52 pagineInstallation, Start-Up and Service Instructions: 50HJ006-014 Single-Package Rooftop Cooling Units 50 HZchaefaure4aNessuna valutazione finora

- Difference Between One Way Slab and Two Way Slab - CENA PDFDocumento5 pagineDifference Between One Way Slab and Two Way Slab - CENA PDFMary Scarlette CenaNessuna valutazione finora

- James Walker Oil and Gas GuideDocumento72 pagineJames Walker Oil and Gas GuidemcouchotNessuna valutazione finora

- Workshop Practice Lab Report PDFDocumento58 pagineWorkshop Practice Lab Report PDFAli ahmadNessuna valutazione finora