Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Disc Brake Diagnosis and Service: Automotive Technology, Fifth Edition

Caricato da

Лазар РадојичићTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Disc Brake Diagnosis and Service: Automotive Technology, Fifth Edition

Caricato da

Лазар РадојичићCopyright:

Formati disponibili

102

DISC BRAKE

DIAGNOSIS AND

SERVICE

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: Let the Owner

Drive When verifying the

customer complaint, ask the

owner or driver of the vehicle

to drive. Often, the problem is

best discovered if the vehicle is

being driven exactly the same

way as when the complaint

first occurred. For example,

the technician may brake

harder or softer than the driver

so the problem may not be

detected.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-1 Minimum thickness for various types of disc brake pads. Pad wear sensors often

make a “chirping” sound when the vehicle is moving if the pads are worn. Do not confuse that noise

for a defective wheel bearing or other fault.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-2 This cracked disc brake pad must be replaced even though it is thicker than the

minimum allowed by the vehicle manufacturer and the wear sensor was not close to the rotor.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-3 Be careful to observe the direction in which replacement linings are facing. Some

vehicle manufacturers offset the friction material on the steel backing to help prevent or minimize

tapered pad wear. Check service information for details as to which direction the pads should be

installed.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-4 Most disc brake calipers have a brake inspection opening. For a thorough

inspection, however, the caliper should be removed and the entire braking system thoroughly

inspected.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: The Bleed and

Squirt Test If you suspect a

brake is not being fully

released, simply loosen the

bleeder valve. If brake fluid

squirts out under pressure,

then the brake is being kept

applied. Look for a defective

flexible brake hose.

If the vehicle is off the ground,

the wheels should be able to

be rotated with the brakes off.

If a wheel is difficult or hard to

turn by hand and is easy to

turn after opening the bleeder

valve, then there is a brake

fluid restriction between the

master cylinder and the brake.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-5 (a) Both rear- and forward-mounted calipers have the bleeder valve at the top.

Some calipers will fit on the wrong side of the vehicle, yet not be able to be bled correctly because

the bleeder valve would point down, allowing trapped air to remain inside the caliper bore. If both

calipers are being removed at the same time, mark them “left” and “right.”

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-5 (b) Both rear- and forward-mounted calipers have the bleeder valve at the top.

Some calipers will fit on the wrong side of the vehicle, yet not be able to be bled correctly because

the bleeder valve would point down, allowing trapped air to remain inside the caliper bore. If both

calipers are being removed at the same time, mark them “left” and “right.”

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-6 Many manufacturers recommend removing one-half of the brake fluid from the

master cylinder before servicing disc brakes. Use a squeeze bulb and dispose of the used brake fluid

properly.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-7 Most manufacturers recommend that the bleeder valve be opened and the brake

fluid forced into a container rather than back into the master cylinder reservoir. This helps prevent

contaminated brake fluid from being forced into the master cylinder where the dirt and

contamination could cause problems.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-8 Many calipers use a hollow “banjo bolt” to retain the flexible brake line to the

caliper housing. The fitting is usually round like a banjo. The copper washers should always be

replaced and not reused.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-9 Caliper retaining bolts are often called guide pins. These guide pins are used to

retain the caliper to the steering knuckle. These pins also slide through metal bushings and rubber

O-rings.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-10 If the caliper is not being removed, it must be supported properly so that the

weight of the caliper is not pulling on the flexible rubber brake line. A suitable piece of wire, such as

a coat hanger, may be used.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-11 A wooden block or a folded shop cloth helps prevent damage when caliper pistons

are removed. Use extreme care when removing a caliper piston using compressed air. The pressure

applied can force the piston out of the caliper with tremendous force. Always follow service

information instructions.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-12 After the piston is removed from the caliper housing, the dust boot can often be

removed using a straightblade screwdriver.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-13 Phenolic (plastic) pistons should be carefully inspected.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

REAL WORLD FIX: Three Brake Jobs in

40,000 Miles A service technician was

asked to replace the front disc brake pads on a

Pontiac Grand Am because the sensors were

touching the rotors and making a squealing

sound. This was the third time that the front

brakes needed to be replaced. Previous brake

repairs had been limited to replacement of the

front disc brake pads only.

When the caliper was removed and the pads

inspected, it was discovered that a part of one

pad had broken and a piece of the lining was

missing. - SEE FIGURE 102–15.

Then the technician spotted something at the

rear of the vehicle that told the whole story—a

trailer hitch.

The owner confirmed that a heavy jet ski was

towed in hilly terrain. The technician

recommended overhauling the front disc brake

calipers to prevent the possibility of the front

pads dragging. The technician also

recommended an inspection of the rear

brakes. The rear brakes were glazed and out-

of-adjustment. The technician received

permission to replace the rear brakes,

overhaul both front calipers, and install quality

disc brake pads. When the customer returned,

the technician advised the customer to use the

transmission on long downhill roads to help

keep the brakes from overheating and failing

prematurely.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-14 If there are any surface flaws such as rust pits on the piston, it should be

replaced.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-15 These pads were found to be cracked and a section was missing from a part of

one pad.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-16 Removing the square-cut O-ring seal from the caliper bore. Use a wooden or

plastic tool to prevent damage to the seal groove.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-17 Some manufacturers recommend cleaning the inside of the caliper bore using a

honing tool as shown. Even though the caliper piston does not contact the inside of this bore,

removing any surface rust or corrosion is important to prevent future problems. If the honing

process cannot remove any pits or scored areas, the caliper should be replaced.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-18 Installing a new piston seal. Never reuse old rubber parts. A caliper overhaul kit

includes just two items: the square-cut piston seal O-ring and dust boot.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-19 Brake assembly fluid or clean brake fluid from a sealed container can be used to

lubricate the caliper seal and caliper pistons before assembly.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-20 Installing the caliper piston. Many calipers require that the dust boot be installed

in the groove of the piston and/or caliper before installing the piston.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: Using “Loaded

Calipers” Saves Time Many

technicians find that disassembly,

cleaning, and rebuilding calipers can

take a lot of time. Often the bleeder

valve breaks off or the caliper piston

is too corroded to reuse. This means

that the technician has to get a

replacement piston, caliper overhaul

kit (piston seal and boot), plus the

replacement friction pads and

hardware kit.

To save time (and sometimes

money), many technicians are simply

replacing the old used calipers with

“loaded calipers.” Loaded calipers are

remanufactured calipers that include

(come loaded with) the correct

replacement friction pads and all the

necessary hardware. - SEE FIGURE

102–26 .

Therefore, only one part number is

needed for each side of the vehicle

for a complete disc brake overhaul.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-21 Installing a piston into a caliper. Sometimes a C-clamp is needed to install the

piston. Both the piston and the piston seal should be coated in clean brake fluid before assembly.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-22 Seating the dust boot into the caliper housing using a special plastic seating tool.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-23 All rubber bushings should be lubricated with silicone brake grease for proper

operation.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-24 (a) Using a screwdriver to force the outboard pad into proper position before

bending the retaining tabs.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-24 (b) Use two hammers to bend the tab where it extends through the hole in the

caliper body.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-25 Often, a hammer is necessary to bend the retainer flange to make certain that

the pads fit tightly to the caliper. If the pads are loose, a “click” may be heard every time the brakes

are depressed. This click occurs when the pad(s) move and then hit the caliper or caliper mount. If

the pads are loose, a clicking noise may be heard while driving over rough road surfaces.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-26 A loaded caliper includes all hardware and shims with the correct pads all in one

convenient package, ready to install on the vehicle.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-27 Floating calipers must be able to slide during normal operation. Therefore, there

must be clearance between the caliper and the caliper mounting pads (abutments). Too little

clearance will prevent the caliper from sliding and too much clearance will cause the caliper to make

a clunking noise when the brakes are applied.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-28 Using an air-powered sanding disc to clean the caliper mount pads.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-29 Determine which face of the special tool best fits the holes or slots in the piston.

Sometimes needle-nose pliers can be used to rotate the piston back into the caliper bore.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-30 Note the twisted flexible brake line. This was caught by an automotive instructor

before the brake work on the vehicle was completed. The twisted brake line can cause brake hose

failure if not corrected.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: Always Double-

Check Your Work

Whenever reassembling

brakes, it is easy to twist the

flexible brake hose as shown in

- FIGURE 102–30 . To prevent

possible brake hose failure and

possibly an accident, always

double-check that the ribs on

the brake hose are straight.

The ribs allow the service

technician to easily spot if the

hose has been twisted.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: Increasing Pad Life Many

vehicles seem to wear out front disc brakes

more often than normal. Stop-and-go city-

type driving is often the cause. Driving style,

such as rapid stops, also causes a lot of wear

to occur.

The service technician can take some actions

to increase brake pad life that are easier than

having to cure the driver’s habits. These steps

include the following.

1. Make sure the rear brakes are properly

adjusted and working correctly. If the rear

brakes are not functioning, all of the braking is

accomplished by the front brakes alone.

NOTE: Remind the driver to apply the parking

brake regularly to help maintain proper rear

brake clearance on the rear brakes.

2. Use factory brake pads or premium brake

pads from a known manufacturer. Tests

performed by vehicle manufacturers show that

many aftermarket replacement brake pads fail

to deliver original equipment brake pad life.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-31 For best braking performance, purchase replacement disc brake pads that include

all clips and shims specified by the vehicle manufacturer. Some pads even come with a package of

the specified grease to use on the shims to reduce the possibility of brake noise.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

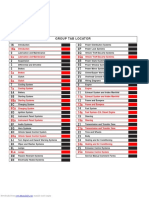

CHART 102–1 The causes of brake noise can have many reasons and corrections.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-32 Notice the beveled pads. The shape of the pad helps reduce brake noise.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: The Screwdriver Trick A low

brake pedal on GM vehicles equipped with rear

disc brakes is a common customer complaint.

Often the reason is a lack of self-adjustment

that should occur whenever the brake pedal

(or parking brake) is released. During brake

release, the pressure is removed from the

caliper piston and the spring inside the caliper

piston is free to adjust. Often this self-

adjustment does not occur and a low brake

pedal results.

A common trick that is used on the vehicle

assembly line is to use a screwdriver to hold

the piston against the rotor while an assistant

releases the brake pedal. - SEE FIGURE 102–

33 .

As the brake pedal is released, the adjusting

screw inside the caliper piston is free to move.

Sometimes, it may be necessary to tap on the

caliper itself with a dead-blow hammer to free

the adjusting screw. Repeat the process as

necessary until the proper brake pedal height

returns.

If this method does not work, replace the

caliper assembly.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: The Screwdriver

Trick (cont.) In summary,

recall these steps.

STEP 1 Have an assistant

depress the brake pedal.

STEP 2 Using a screwdriver

through the hole in the top of

the caliper, hold the piston

against the rotor. NOTE: Be

careful not to damage the dust

boot.

STEP 3 While still holding the

piston against the rotor, have

the assistant release the brake

pedal. The adjusting screw

adjusts when the brake pedal

is released and a slight

vibration or sound will be

noticed as the brake is

released. This vibration or

sound is created by the self-

adjusting mechanism inside

the caliper piston taking up the

excess clearance.

STEP 4 Repeat as necessary

until normal brake pedal height

is achieved.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-33 The screwdriver blade is used to keep the piston applied to allow self-adjustment

to occur when the brake pedal is released.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

TECH TIP: Pressure Testing

Can Help Find Problems A

stuck caliper or caliper slide is

often difficult to see or

diagnose as a problem because

the movement of the broken

pads is so little. Using a

pressure gauge between the

caliper piston and the rotor

(inboard) or between the rotor

and the caliper (outboard) can

tell the service technician if

there is a difference between

the left and the right side

brakes. - SEE FIGURE 102–34 .

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-34 (a) A brake pressure tester.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

Figure 102-34 (b) The small “pads” can be placed between the caliper piston and the rotor to

check for applied pressure and inserted between the caliper and the rotor on the outside of the rotor

to test the pressure—the pressure should be the same if the caliper is able to slide on its pins or

slides.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 1 After properly setting the hoist pads under the vehicle, raise the vehicle

to chest level and remove the lug nuts.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 2 Remove the wheel/tire assembly and place it where it will not get in the

way or be damaged.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 3 It is recommended that the entire brake assembly be washed using a

commercially available cleaner to avoid the possibility of allowing brake dust from becoming

airborne.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 4 If a commercial brake cleaning unit is not available, use brake cleaner

from an aerosol or pressurized container.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 5 To service the front disc brake pads on this vehicle, loosen the upper

caliper retainer bolt and remove the lower bolt.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 6 After the lower caliper bolt has been removed, the caliper assembly can

be lifted upward by pivoting on the upper retaining bolt.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 7 Use mechanic’s wire to hold the caliper in the raised position to allow

access to the disc brake pads.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 8 Notice that both the inboard and outboard pad remain attached to the

steering knuckle. The pads and shims can be lifted off.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 9 A C-clamp can be used to push the piston into the caliper, but be sure

to open the bleeder valve first.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 10 The bleeder valve should be opened to allow the old brake fluid to

flow out of the caliper and not be forced up into the ABS hydraulic unit or master cylinder.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 11 Often factory replacement disc brake pads include noise-dampening

shims, antirattle clips, and special “moly” disc brake grease that is to be used on the shims.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 12 All hardware, including this anchor shim, should be replaced.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 13 Install new shims after thoroughly cleaning the steering knuckle area

of any rust using a wire brush or other suitable tool.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 14 The replacement disc brake pads are installed next to the rotor and

held in place by the tension of the anchor shims.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 15 After double-checking that all shims, clips, and spacers are correctly

installed, lower the calipers and install this lower attaching bolt.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 16 Torque the retaining bolts to factory specifications. Repeat the process

on the other side and bleed the hydraulic system.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 17 Reinstall the wheel/tire assembly.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

102 DISC BRAKE DIAGNOSIS AND SERVICE

DISC BRAKE SERVICE 18 Torque the lug nuts to factory specifications or use a torque-limiting

adapter. Test drive the vehicle before returning it to the customer.

Automotive Technology, Fifth Edition © 2011 Pearson Education, Inc.

James Halderman All Rights Reserved

Potrebbero piacerti anche

- Ford Manual for Owners and Operators of Ford Cars and Trucks (1919)Da EverandFord Manual for Owners and Operators of Ford Cars and Trucks (1919)Nessuna valutazione finora

- 31-9244 Gdf510pxjxx Gdf520pxjxx Adt521pgjxx Gdt535pxjxx Gdt545pxjxx Gdf610pxjxx Gdf620hxjxx Gdt625pxjxx Gdt635hxjxxDocumento73 pagine31-9244 Gdf510pxjxx Gdf520pxjxx Adt521pgjxx Gdt535pxjxx Gdt545pxjxx Gdf610pxjxx Gdf620hxjxx Gdt625pxjxx Gdt635hxjxxAPmanualshop zNessuna valutazione finora

- SB 10072385 2280Documento312 pagineSB 10072385 2280David Solis0% (1)

- R35 Quick Start GuideDocumento12 pagineR35 Quick Start GuidemspetNessuna valutazione finora

- Malak Sher Khan Daily Vehicle Inspection (04-02-17)Documento1 paginaMalak Sher Khan Daily Vehicle Inspection (04-02-17)Afareen KhanNessuna valutazione finora

- Nissan Altima 2007-2012 Service Manual - Idle Air Volume Learning - Basic Inspection - Engine Control System QR25DE For CaliforniaDocumento5 pagineNissan Altima 2007-2012 Service Manual - Idle Air Volume Learning - Basic Inspection - Engine Control System QR25DE For CaliforniamojbarNessuna valutazione finora

- Ford CrownVic 1998 ManualDocumento160 pagineFord CrownVic 1998 ManualNasir AyubNessuna valutazione finora

- 200 CherokeeDocumento2.119 pagine200 CherokeeVinte RemodelarNessuna valutazione finora

- Dyno Test VariablesDocumento7 pagineDyno Test VariablesArto LehikoinenNessuna valutazione finora

- Rebuilding Nippon Denso Alternator 00-01 A - JeepForumDocumento14 pagineRebuilding Nippon Denso Alternator 00-01 A - JeepForumejen_glNessuna valutazione finora

- Volt Sandy BlogsDocumento9 pagineVolt Sandy BlogskrivasscribdNessuna valutazione finora

- John Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)Documento15 pagineJohn Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)zhuangfuqian31Nessuna valutazione finora

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Documento6 pagineIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064Nessuna valutazione finora

- Toro Super Recycler 3322-287Documento24 pagineToro Super Recycler 3322-287skustarzNessuna valutazione finora

- Chevrolet Avalanche ABSDocumento5 pagineChevrolet Avalanche ABSUlises AlfaroNessuna valutazione finora

- Acura RSX (02-06) Service Manual - Brakes OnlyDocumento27 pagineAcura RSX (02-06) Service Manual - Brakes OnlyWill Wolff-Myren67% (3)

- CoyoteDocumento2 pagineCoyoteFelipeOliveiraNessuna valutazione finora

- Acura TSX 2004 Manual and Power Steering, Steering Column, Gear and LinkageDocumento144 pagineAcura TSX 2004 Manual and Power Steering, Steering Column, Gear and Linkagejorge antonio guillenNessuna valutazione finora

- Document (4) HunterDocumento47 pagineDocument (4) HunterHector AraujoNessuna valutazione finora

- 2009 Mopar Perfomance PDFDocumento351 pagine2009 Mopar Perfomance PDFmacNessuna valutazione finora

- Xfer Case IdentificationDocumento9 pagineXfer Case IdentificationErickMaki0% (1)

- BMW 7 Series (G12) 2016+ Technical Doc - Owner's ManualDocumento314 pagineBMW 7 Series (G12) 2016+ Technical Doc - Owner's ManualPhan Văn100% (1)

- Kis Sportage 2006Documento30 pagineKis Sportage 2006Yessica Juarez GuerreroNessuna valutazione finora

- Jeep Renegade Quick Reference GuideDocumento161 pagineJeep Renegade Quick Reference GuideRafael Nakazato RecioNessuna valutazione finora

- 2011 Wheel Hub Assembly Catalog 022811Documento123 pagine2011 Wheel Hub Assembly Catalog 022811Tan JaiNessuna valutazione finora

- Golf TDi 2.0Documento162 pagineGolf TDi 2.0kilofome05Nessuna valutazione finora

- Stromberg Seriesaa ManualDocumento73 pagineStromberg Seriesaa ManualH K WNessuna valutazione finora

- CadillacDocumento42 pagineCadillacapi-384057547Nessuna valutazione finora

- 2001 OLDSMOBILE BRAVADA Service Repair Manual PDFDocumento37 pagine2001 OLDSMOBILE BRAVADA Service Repair Manual PDFjkfmmsmefNessuna valutazione finora

- Find Your Car's Date of Manufacture (VIN)Documento15 pagineFind Your Car's Date of Manufacture (VIN)Rohit SaxenaNessuna valutazione finora

- Pontiac CatalogDocumento141 paginePontiac Catalogtrolav8Nessuna valutazione finora

- Dodge CaliberDocumento332 pagineDodge Caliberapi-3731625Nessuna valutazione finora

- 2007 987 9 30 07 PCM2 NavigationDocumento7 pagine2007 987 9 30 07 PCM2 NavigationIonut DeaconescuNessuna valutazione finora

- 2010 Ginn Motor Company HHR Atlanta GADocumento8 pagine2010 Ginn Motor Company HHR Atlanta GAatlantachevroletNessuna valutazione finora

- 2017 JEP MPS Catalog FIN LR SPR PDFDocumento28 pagine2017 JEP MPS Catalog FIN LR SPR PDFEdwinNessuna valutazione finora

- Weedeater One Service ManualDocumento20 pagineWeedeater One Service ManualBrandon HarveyNessuna valutazione finora

- Indian, Victory TillbehörDocumento83 pagineIndian, Victory TillbehörNils AnderssonNessuna valutazione finora

- 60l Power StrokeDocumento106 pagine60l Power StrokethebigfishxNessuna valutazione finora

- 2020 Transit Order GuideDocumento43 pagine2020 Transit Order GuideAnonymous l4zDkQ4oiP100% (4)

- 2001 Ford Ranger Owners ManualDocumento272 pagine2001 Ford Ranger Owners ManualAaron Monk100% (1)

- IQ3 Haltech LD Manual v2 PDFDocumento92 pagineIQ3 Haltech LD Manual v2 PDFEdwinNessuna valutazione finora

- 1 5 0 0 / 2 5 0 0 / 3 5 0 0 2 0 1 6 Ram Truck: Owner'S ManualDocumento914 pagine1 5 0 0 / 2 5 0 0 / 3 5 0 0 2 0 1 6 Ram Truck: Owner'S ManualKorey BradleyNessuna valutazione finora

- All About AutosDocumento20 pagineAll About Autosriki187Nessuna valutazione finora

- Rearend Gear GuideDocumento18 pagineRearend Gear GuideJam BabNessuna valutazione finora

- Cylinder Head InstallDocumento2 pagineCylinder Head InstallMiguel Moreno FernándezNessuna valutazione finora

- CVT C Transmission TransaxleDocumento240 pagineCVT C Transmission TransaxleFX WamalaNessuna valutazione finora

- BRP Sea-Doo My20 RXT-X 300 UsDocumento2 pagineBRP Sea-Doo My20 RXT-X 300 UsDanung WicaksonoNessuna valutazione finora

- 14043.17D Passenger AWD PG R1.03 PDFDocumento79 pagine14043.17D Passenger AWD PG R1.03 PDFDavid LeeNessuna valutazione finora

- 24L FourDocumento28 pagine24L FourIqbal NugrohoNessuna valutazione finora

- 4HP24 PDFDocumento4 pagine4HP24 PDFAbbode HoraniNessuna valutazione finora

- Chevy Flow DataDocumento17 pagineChevy Flow Dataes_bsNessuna valutazione finora

- Motorcycle, Solo (Harley-Davidson Model WLA)Da EverandMotorcycle, Solo (Harley-Davidson Model WLA)Nessuna valutazione finora

- Quarter-Mile Mustangs: The History of Ford’s Pony Car at the Drag Strip 1964-1/2-1978Da EverandQuarter-Mile Mustangs: The History of Ford’s Pony Car at the Drag Strip 1964-1/2-1978Nessuna valutazione finora

- Hybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesDa EverandHybrid Electric & Alternative Automotive Propulsion: Low Carbon TechnologiesNessuna valutazione finora

- The Alfa Romeo Spider Owners Work Manual: 1962 - 1978Da EverandThe Alfa Romeo Spider Owners Work Manual: 1962 - 1978Nessuna valutazione finora

- Container Based Field HospitalDocumento2 pagineContainer Based Field HospitalЛазар РадојичићNessuna valutazione finora

- 03 Using The Creo Parametric InterfaceDocumento81 pagine03 Using The Creo Parametric InterfaceЛазар РадојичићNessuna valutazione finora

- 01 Introduction To The Creo Parametric Basic Modeling ProcessDocumento37 pagine01 Introduction To The Creo Parametric Basic Modeling ProcessЛазар РадојичићNessuna valutazione finora

- Fuel Injector FLow Bench PaperDocumento18 pagineFuel Injector FLow Bench PaperЛазар РадојичићNessuna valutazione finora

- Electric Aisle-Master Parts (06.2005)Documento120 pagineElectric Aisle-Master Parts (06.2005)Marc JoosenNessuna valutazione finora

- Purchase ListDocumento3 paginePurchase Listjunhui100% (1)

- Aklil Auto Level 4 Coc Online ExamDocumento7 pagineAklil Auto Level 4 Coc Online ExamTedo MekonnenNessuna valutazione finora

- Operation Manual of Overhead Crane EnglishDocumento21 pagineOperation Manual of Overhead Crane EnglishParthiban Karuna83% (6)

- Effect of Turbocharging On Exhaust Brake Performance in An AutomobileDocumento6 pagineEffect of Turbocharging On Exhaust Brake Performance in An Automobileabhisaxena93Nessuna valutazione finora

- MT 5020/6020 TRAINING: Brake SystemDocumento48 pagineMT 5020/6020 TRAINING: Brake SystemFrancisco RojasNessuna valutazione finora

- Hyster H10.00 DisplayDocumento22 pagineHyster H10.00 Displayvitor santosNessuna valutazione finora

- Complete PDFDocumento82 pagineComplete PDFleonardoNessuna valutazione finora

- Motor Grader: Dcec 112kW (150hp) at 2,200 RPM 3,660 MM 41 KM/H 70 KN 13,500 KGDocumento2 pagineMotor Grader: Dcec 112kW (150hp) at 2,200 RPM 3,660 MM 41 KM/H 70 KN 13,500 KGAkhmad SebehNessuna valutazione finora

- 440 Cable Pulling Capstan Winches, Cable FeedersDocumento21 pagine440 Cable Pulling Capstan Winches, Cable FeedersKlanac BrčkoNessuna valutazione finora

- Ez Pallet Lift Truck DJ PDFDocumento124 pagineEz Pallet Lift Truck DJ PDFDmitry100% (1)

- FANUC 30i-31i-32i MA Op - ManualDocumento174 pagineFANUC 30i-31i-32i MA Op - Manualpiersik100% (1)

- Conceptual Design of An Electric BikeDocumento22 pagineConceptual Design of An Electric BikemehmetNessuna valutazione finora

- VDA. Vehicle Specication. A 617116. D13ADocumento20 pagineVDA. Vehicle Specication. A 617116. D13ANestorNessuna valutazione finora

- Remote and Automatic ControlDocumento11 pagineRemote and Automatic ControldenramrNessuna valutazione finora

- Kinematics of Trauma PDFDocumento44 pagineKinematics of Trauma PDFJacob100% (1)

- Aehq6353-00 797FDocumento4 pagineAehq6353-00 797FEducacion Laboral AvanzadaNessuna valutazione finora

- 80ZV 80C4 5001 93309 00134 - UsaDocumento604 pagine80ZV 80C4 5001 93309 00134 - UsaДенис Сухарев100% (3)

- 09.2 Detailed Technical SpecificationsDocumento18 pagine09.2 Detailed Technical SpecificationsPreetiNessuna valutazione finora

- Group Presentation OutlineDocumento3 pagineGroup Presentation Outlineapi-515325048Nessuna valutazione finora

- Operator's Manual Electric EN 2010Documento67 pagineOperator's Manual Electric EN 2010Jose PereiraNessuna valutazione finora

- Technical Data - ADELCA 2020Documento1 paginaTechnical Data - ADELCA 2020Fernando PardoNessuna valutazione finora

- ABUS Electric Wire Rope CatalogueDocumento11 pagineABUS Electric Wire Rope CatalogueMahmoud AllamNessuna valutazione finora

- Machine Views: 966M and 972M Wheel Loader Hydraulic SystemDocumento2 pagineMachine Views: 966M and 972M Wheel Loader Hydraulic SystemLynda CarrollNessuna valutazione finora

- Parametros Montacargas ElectriocosDocumento47 pagineParametros Montacargas Electriocoshydromaq S.ANessuna valutazione finora

- Dokumen - Tips - Bomag bw177d 50 OperatorsmanualDocumento114 pagineDokumen - Tips - Bomag bw177d 50 OperatorsmanualKhairul Amri NasutionNessuna valutazione finora

- VW Scheduled MaintenanceDocumento8 pagineVW Scheduled MaintenancerobertoNessuna valutazione finora

- Hitachi HoistDocumento74 pagineHitachi HoistlifttecNessuna valutazione finora

- Research On Key Technology of Wire-Bending and Equipment DevelopmentDocumento7 pagineResearch On Key Technology of Wire-Bending and Equipment DevelopmentSamedNessuna valutazione finora

- List Part ALUN - For Sale - Okt 21Documento114 pagineList Part ALUN - For Sale - Okt 21Tonny RobertNessuna valutazione finora