Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 1 Introduction Farm Machinery

Caricato da

Siraj Busse0%(1)Il 0% ha trovato utile questo documento (1 voto)

508 visualizzazioni21 pagineDeals with performance of farm mchinery

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoDeals with performance of farm mchinery

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0%(1)Il 0% ha trovato utile questo documento (1 voto)

508 visualizzazioni21 pagineChapter 1 Introduction Farm Machinery

Caricato da

Siraj BusseDeals with performance of farm mchinery

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 21

ADAMA SCIENCE AND TECHNOLOGY UNIVESRITY

SCHOOL OF MECHANICAL, CHEMICAL AND MATERIAL ENGINEERING

DEPARTMENT OF VEHICLE AND MECHANICAL SYSTEM

FARM MACHINERY AND IMPLEMENTS

YEAR: 4TH

ACADEMIC YEAR 2018/2019

BY SIRAJ K.

CHAPTER 1: INTRODUCTION TO FARM MACHINERY

1. Farm Mechanization

Mechanization of agriculture was an important factor in

reducing labor demands for farming and making it

available to develop other industries.

Mechanized agriculture is, however, energy and capital

intensive.

Energy costs and the availability of capital to buy

machines determine the level of mechanization in a

society.

Thus, production agriculture is facing many challenges.

Farm mechanization is an important element of

modernization of agriculture.

Farm Productivity is positively correlated with

the availability of farm power coupled with

efficient farm implements and their judicious

utilization.

Agricultural mechanization not only enables

efficient utilization of various inputs such as

seeds, fertilizers, plant protection chemicals

and water for irrigation but also it helps in

poverty alleviation by making farming an

attractive enterprise.

There is no doubt that agricultural mechanization

for the multitude of smallholder farmers in sub-

Saharan Africa (SSA) has been a neglected issue for

too long.

The application of farm power to appropriate tools,

implements and machines – “farm mechanization” –

is an essential agricultural input with the potential

to transform rural families’ livelihoods by facilitating

increased output of higher value products while

eliminating the drudgery associated with human

muscle-powered agricultural production.

Such an improved situation for smallholder

farmers can enable access to input supply chains

and integration in modern food systems and thus

provide for more income, renewed business

opportunities and further value addition.

Moreover agricultural mechanization in its

broadest sense can contribute significantly to the

development of food systems, as it has the

potential to render post-harvest, processing and

marketing activities and functions more efficient,

effective and environmentally friendly.

FAO (2014b) summarizes the main

reasons for changing the power source

for crop production from muscles (human

or animal) to tractors:

i. Potential to expand the area under cultivation.

ii. Ability to perform operations at the right time

to maximize production potential.

iii. Multi-functionality – tractors can be used, not

only for crop production,

iv. Compensation for seasonal labour shortages

v. Reduction of the drudgery associated with the

use of human muscle power for tasks,

Farm Power is an essential input in agriculture

for timely field operations for increasing

production and productivity of land.

Farm power is used for operating different types

of machinery like tillage, planting, plant

protection, harvesting and threshing machinery

and other stationary jobs like operating

irrigation equipment, threshers/ shellers /

cleaners/ graders, etc.

2. Sources of Farm Power

A. Mobile Power

1. Human (men, women, children), 2. Draught animals

(bullocks, buffaloes, camels, horses and ponies, mules and

donkeys), 3. Tractors, 4. Power tillers, 5. Self propelled

machines (combines, dozers, reapers, sprayers etc.)

B. Stationary Power

1. Diesel/oil engines (for pump sets, threshers, sprayers

and other stationary operations)

2. Electric motors (for pump sets, threshers, sprayers and

other stationary operations)

Sources of farm power

There are different sources of farm power

available which are classified as

(i) Human power

(ii) Animal power

(iii) Mechanical power (Tractors + Power tillers +

Oil engines)

(iv) Electrical power

(v) Renewable energy (Biogas + Solar energy +

Wind energy)

HUMAN POWER

Human power is the main source for

operating small implements and tools at

the farm.

Stationary work like chaff cutting, lifting,

water, threshing, winnowing etc. are also

done by manual labour.

An average man can develop maximum

power of about 0.1 hp for doing farm

ANIMAL POWER

The most important source of power on the

farm all over the world is animal.

Power developed by an average pair of bullocks

about 1 hp for usual farm work.

Bullocks are employed for all types farm work

in all seasons.

Besides bullocks, other animals like camels,

buffaloes, horses, donkeys, mules and

elephants are also used at some places.

ANIMAL POWER

The average force a draft animal can exert is

nearly one-tenth of its body weight

It is estimated that nearly 80 per cent of the

total draft power used in agriculture throughout

the world is still provided by animals, although

the number of agricultural tractors has become

double after every ten years since 1930.

The thermal efficiency of diesel engine varies

from 32 to 38 per cent whereas that of petrol

engine varies from 25 to 32 per cent.

In modern days, almost all the tractors and

power tillers are operated by diesel engines.

Diesel engines are used for operating irrigation

pumps, flour mills, oil ghanis, cotton gins, chaff

cutter, sugarcane crusher, threshers,

winnowers etc

MECHANICAL POWER

Broadly speaking, mechanical power includes

stationary oil engines, tractors , power tillers

and self propelled combines.

Internal combustion engine is a good device for

converting liquid fuel into useful

work(mechanical work).

These engines are two types

(1) Spark ignition engines (Petrol or Kerosene

engine)

(2) Compression ignition engines (Diesel engines)

ELECTRICAL POWER

Electrical power is used mostly in the form of

electrical motors on the farms.

Motor is a very useful machine for farmers.

It is clean, quest and smooth running.

Its maintenance and operation needs less attention

and care.

The operating cost remains almost constant

throughout its life.

Electrical power is used for water pumping, diary

industry, cold storage, farm product processing, fruit

industry and many similar things

RENEWABLE ENERGY

It is the energy mainly obtained from renewable

sources of energy like sun, wind, biomass etc.

Biogas energy, wind energy and solar energy are

used in agriculture and domestic purposes with

suitable devices.

Renewable energy can be used for lighting,

cooking, water heating, space heating, water

distillation, food processing, water pumping, and

electric generation.

This type of energy is inexhaustible in nature.

WIND POWER

The availability of wind power for farm work is

quite limited.

Where the wind velocity is more than 32 km/hr,

wind mills can be used for lifting water.

Even today the wind power has not been fully

harnessed.

3. Mechanical Power Transmission Devices

1 V-BELT DRIVES

V-belts are employed extensively in agricultural

machinery applications in which it is not necessary to

maintain exact speed ratios.

V-belts tend to cushion shock loads, do not require

lubrication, and are less likely to become misaligned

than are other types of drives.

They can be operated at speeds as high as 33 m/s,

although speeds in agricultural machinery applications

seldom exceed 15 m/s. V-belts are not suitable for high

torque at low speeds.

2. CHAIN DRIVES

Perhaps the first use of a chain drive was made in a

reaper by Cyrus McCormick in 1837.

Today chain drives play an important part in many

agricultural machines such as hay balers, corn pickers,

combines, cotton pickers, and beet harvesters.

As opposed to V-belt drives, chain drives are used

where it is important to maintain an exact speed ratio.

Another benefit is that chain drives are capable of

transmitting a large amount of power at slower speeds.

However, chain drives require better shaft alignment

and more maintenance than V-belt drives.

3.POWER-TAKE-OFF DRIVES

A power-take-off (PTO) drive provides a means for

transmitting rotary power to machines that are coupled

to a tractor.

The most common location for the PTO shaft is at the

rear of the tractor, but some tractors have auxiliary

PTO shafts at other locations.

The direction of rotation, rotational speed, approximate

location, and exact dimensions of the PTO shaft were

standardized by the ASAE in 1926 so that equipment of

different manufacturers could be interchanged.

With growth in tractorsize, it became necessary to

develop faster and larger PTO shafts to transmit

the increased available power.

They are the 35 mm (diameter) shafts with

standard rotation speeds of 540 rev/min and 1000

rev/min.

The shaft with a standard speed of 540 rev/min is

used on tractors with up to 65 kW PTO power.

The 35 mm shaft with a standard speed of 1000

rev/min is used on tractors with 45 to 120 kW of

PTO power.

Potrebbero piacerti anche

- Organic Production of Coffee, Okra, Tomato, Mango and BananaDa EverandOrganic Production of Coffee, Okra, Tomato, Mango and BananaNessuna valutazione finora

- Agri CH 1Documento50 pagineAgri CH 1wardi tube100% (1)

- Sources of Farm PowerDocumento22 pagineSources of Farm PowerAmrish raj100% (4)

- Introduction To Agricultural MechanizationDocumento30 pagineIntroduction To Agricultural MechanizationdegagaNessuna valutazione finora

- Agri Mech ModuleDocumento65 pagineAgri Mech ModuleDiana Grace DomingoNessuna valutazione finora

- Farm Machinery IDocumento6 pagineFarm Machinery IAnthony ContrerasNessuna valutazione finora

- I-1e FarmMech 1-19Documento20 pagineI-1e FarmMech 1-19Hanz Learny LalisanNessuna valutazione finora

- ARS Syllabus Farm MachineryDocumento2 pagineARS Syllabus Farm MachineryVijay ChavanNessuna valutazione finora

- Module 1 Agricultural Mechanics and MechanizationDocumento16 pagineModule 1 Agricultural Mechanics and MechanizationDavie Martinez100% (2)

- II-6 Agronomy 1-23Documento24 pagineII-6 Agronomy 1-23SannyBombeoJomocNessuna valutazione finora

- Law. QuestionDocumento3 pagineLaw. QuestionGener Habala NavarroNessuna valutazione finora

- Corn Roadmap 2011-2017Documento32 pagineCorn Roadmap 2011-2017philmaize100% (5)

- Farm Machinery SelectionDocumento8 pagineFarm Machinery Selectionsunilbhol0% (1)

- Practical Manual ON: Agronomy of Major Cereal and Pulses AGRO-5217Documento26 paginePractical Manual ON: Agronomy of Major Cereal and Pulses AGRO-5217Tejindarjit Kaur Gill Bahga100% (2)

- Recalled Question CapSU Pont Final 1 1Documento27 pagineRecalled Question CapSU Pont Final 1 1Ailene del RosarioNessuna valutazione finora

- Part 1 Mock Questions-YeahDocumento4 paginePart 1 Mock Questions-YeahMisheru Misaki AyuzawaNessuna valutazione finora

- 1 AE 44 Syllabus 2019Documento12 pagine1 AE 44 Syllabus 2019stephene larim100% (1)

- Psychrometry: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerDocumento15 paginePsychrometry: 2022 Agricultural and Biosystems Engineering Board Exam ReviewerBilly AgustinNessuna valutazione finora

- 5-6. General Management Practices and Animal Health Program - PDFDocumento61 pagine5-6. General Management Practices and Animal Health Program - PDFRoxan Mae AmplayoNessuna valutazione finora

- Farm Power and Machinery ManagementDocumento124 pagineFarm Power and Machinery ManagementBirjesh YaduvanshiNessuna valutazione finora

- AMTEC Presentation July 2019-PSABE ReviewDocumento99 pagineAMTEC Presentation July 2019-PSABE ReviewRachele Janice Capuchino Ramirez100% (1)

- Lecture Notes of AAG 222 IV SEMDocumento66 pagineLecture Notes of AAG 222 IV SEMSachin KumarNessuna valutazione finora

- Agricultural Engineering AGDocumento3 pagineAgricultural Engineering AGAyush ChopraNessuna valutazione finora

- CLSU ABE Review 2022 APE Chap 02 Human PowerDocumento23 pagineCLSU ABE Review 2022 APE Chap 02 Human PowerBilly AgustinNessuna valutazione finora

- Human and Draft Animal PowerDocumento26 pagineHuman and Draft Animal PowerROLDAN QUITOS100% (1)

- Rheological Properties of Food and Agricultural ProductsDocumento7 pagineRheological Properties of Food and Agricultural ProductsRizki AhmadNessuna valutazione finora

- AME-Chap17-Economic Analysis of Agricultural MachinesDocumento5 pagineAME-Chap17-Economic Analysis of Agricultural MachinesJordan YapNessuna valutazione finora

- Lab 7 Sprinkler EkitDocumento17 pagineLab 7 Sprinkler EkitRuby Ekit100% (1)

- Terminologies in Agricultural Machinery and EquipmentDocumento5 pagineTerminologies in Agricultural Machinery and EquipmentJillNessuna valutazione finora

- Crop Identification and NamesDocumento4 pagineCrop Identification and NamesehsanranaNessuna valutazione finora

- Board Exam Questions 2016Documento6 pagineBoard Exam Questions 2016JC Yabis100% (1)

- 2.5 Familiarization With Power Transmission System ClutchDocumento10 pagine2.5 Familiarization With Power Transmission System ClutchAravind RajNessuna valutazione finora

- CLSU ABE Review 2022 APE Chap 03 Draft Animal PowerDocumento29 pagineCLSU ABE Review 2022 APE Chap 03 Draft Animal PowerBilly AgustinNessuna valutazione finora

- III 5 CropProcessing 1 8Documento8 pagineIII 5 CropProcessing 1 8SannyBombeoJomocNessuna valutazione finora

- Calculating Farm Machinery Field CapacitiesDocumento6 pagineCalculating Farm Machinery Field CapacitiesJireh Loquinario100% (1)

- Farm Power and Machinery: Northern Iloilo Polytechnic State College Barotac Viejo CampusDocumento9 pagineFarm Power and Machinery: Northern Iloilo Polytechnic State College Barotac Viejo CampusNylanor Mae Dalisay Oallac100% (1)

- Fundamentals of Agricultural Engineering - 1Documento8 pagineFundamentals of Agricultural Engineering - 1sheil.cogay100% (1)

- III 6 RicePostProd 1 8Documento9 pagineIII 6 RicePostProd 1 8SannyBombeoJomocNessuna valutazione finora

- Assignment 205 - Precision FarmingDocumento12 pagineAssignment 205 - Precision Farmingrituag_bitmesra3888100% (2)

- Farm Building and StructureDocumento15 pagineFarm Building and StructureOlabanjo Shefiu OlamijiNessuna valutazione finora

- Establishment of OrchardDocumento15 pagineEstablishment of OrchardGanpat Lal SharmaNessuna valutazione finora

- III 7 CornPostPro 1 4Documento4 pagineIII 7 CornPostPro 1 4SannyBombeoJomocNessuna valutazione finora

- Ch.3 AgronomyDocumento9 pagineCh.3 AgronomyVijayakumar MannepalliNessuna valutazione finora

- Development of Agricultural Engineering in The Philippines: Arnold R. ElepañoDocumento37 pagineDevelopment of Agricultural Engineering in The Philippines: Arnold R. ElepañoAlfredo CondeNessuna valutazione finora

- 2017 PDFDocumento28 pagine2017 PDFKeith Elysah Monoy EspinaNessuna valutazione finora

- Registered Professional Agricultural Engineer (RPAE) - Every Person Admitted To The PracticeDocumento3 pagineRegistered Professional Agricultural Engineer (RPAE) - Every Person Admitted To The PracticeFrances PasanaNessuna valutazione finora

- Circuitous PatternDocumento3 pagineCircuitous Patternditz_n90805Nessuna valutazione finora

- Lecture 12 Secondary Tillage PDFDocumento7 pagineLecture 12 Secondary Tillage PDFsujan paudelNessuna valutazione finora

- Biological Control To Maintain Natural Densities of Insects and Mites by Field Releases of Lady Beetles (Coleoptera - Coccinellidae)Documento7 pagineBiological Control To Maintain Natural Densities of Insects and Mites by Field Releases of Lady Beetles (Coleoptera - Coccinellidae)Juan Vera SanchezNessuna valutazione finora

- Introduction To Agriculture: Definition, History, Conventional FarmingDocumento8 pagineIntroduction To Agriculture: Definition, History, Conventional FarmingALISON ALI100% (1)

- Area 1Documento7 pagineArea 1Krisher DhayNessuna valutazione finora

- Citrus CommercializationDocumento23 pagineCitrus Commercializationannacarmelaaa100% (1)

- Agronomy at A GlanceDocumento42 pagineAgronomy at A Glanceshree.agr413850% (2)

- Crop ScienceDocumento17 pagineCrop ScienceMary Andrea Sumalde DioNessuna valutazione finora

- TILLAGE SlideDocumento18 pagineTILLAGE SlideArnab PaulNessuna valutazione finora

- Ag. Power, Machinery, and Allied Subject - Part 4Documento100 pagineAg. Power, Machinery, and Allied Subject - Part 4Vonne Bryan IhalasNessuna valutazione finora

- History of Irrigation of The PhilippinesDocumento4 pagineHistory of Irrigation of The PhilippinesCristine CabuteNessuna valutazione finora

- Methods: Threshing and Shelling EquipmentDocumento8 pagineMethods: Threshing and Shelling EquipmentJordan YapNessuna valutazione finora

- Donkor - Questionnaire On Post Harvest Losses of Hot PepperDocumento5 pagineDonkor - Questionnaire On Post Harvest Losses of Hot PepperGeorge Aryeetey80% (5)

- Wa0000.Documento83 pagineWa0000.Rushikesh WankhedeNessuna valutazione finora

- Part II Furrow Opener Depth Control Components PDFDocumento3 paginePart II Furrow Opener Depth Control Components PDFSiraj Busse100% (1)

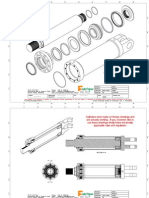

- Hydraulic Cylinder by Syed Jaffer PDFDocumento39 pagineHydraulic Cylinder by Syed Jaffer PDFSiraj Busse100% (7)

- Chapter One Agricultural TractorDocumento67 pagineChapter One Agricultural TractorSiraj Busse100% (1)

- Sas/Or 14.3 User's Guide: The Nonlinear Programming SolverDocumento63 pagineSas/Or 14.3 User's Guide: The Nonlinear Programming SolverSiraj BusseNessuna valutazione finora

- Chapter 2 Tillage ImplementsDocumento35 pagineChapter 2 Tillage ImplementsSiraj Busse100% (1)

- Part I Soil Engaging Components PDFDocumento7 paginePart I Soil Engaging Components PDFSiraj BusseNessuna valutazione finora

- Chapter 2 Physical Properties of Hydraulic FluidDocumento26 pagineChapter 2 Physical Properties of Hydraulic FluidSiraj BusseNessuna valutazione finora

- Chapter 1 Introduction To Fluid PowerDocumento33 pagineChapter 1 Introduction To Fluid PowerSiraj Busse100% (4)

- Chapter 8: Fluid Basic Electrical and Logic Control SystemDocumento34 pagineChapter 8: Fluid Basic Electrical and Logic Control SystemSiraj BusseNessuna valutazione finora

- Chapter 5.design of Sowing and Planting MachineDocumento5 pagineChapter 5.design of Sowing and Planting MachineSiraj Busse100% (2)

- Chapter 3: Engine and Vehicle Testing: BAE 517 - Lecture 3Documento24 pagineChapter 3: Engine and Vehicle Testing: BAE 517 - Lecture 3Siraj BusseNessuna valutazione finora

- 6.1. Pack Animals: Chapter 6: Equipment For TransportDocumento16 pagine6.1. Pack Animals: Chapter 6: Equipment For TransportSiraj BusseNessuna valutazione finora

- Chapter 1Documento32 pagineChapter 1Siraj BusseNessuna valutazione finora

- Chapter 2: Engine Performance Measures: BAE 517 - Lecture 2Documento40 pagineChapter 2: Engine Performance Measures: BAE 517 - Lecture 2Siraj BusseNessuna valutazione finora

- Chapter 1: Development of Off-Road Vehicles: BAE 517 - Lecture 1Documento29 pagineChapter 1: Development of Off-Road Vehicles: BAE 517 - Lecture 1Siraj BusseNessuna valutazione finora

- Chapter 1Documento32 pagineChapter 1Siraj BusseNessuna valutazione finora

- Chapter One: Introduction To Draught Technology: Draught Animal Technology Lecture Notes By: Siraj KedirDocumento27 pagineChapter One: Introduction To Draught Technology: Draught Animal Technology Lecture Notes By: Siraj KedirSiraj BusseNessuna valutazione finora

- 3.2 Hydraulic CylinderDocumento27 pagine3.2 Hydraulic CylinderSiraj Busse100% (1)

- 5.1. Air Preparation: Chapter 5: Pneumatic SystemsDocumento36 pagine5.1. Air Preparation: Chapter 5: Pneumatic SystemsSiraj BusseNessuna valutazione finora

- Chapter FourDocumento27 pagineChapter FourSiraj BusseNessuna valutazione finora

- 3.1 Hydraulic PumpDocumento22 pagine3.1 Hydraulic PumpSiraj BusseNessuna valutazione finora

- Topic: Chapter One: Introduction To Draught Animal TechnologyDocumento44 pagineTopic: Chapter One: Introduction To Draught Animal TechnologySiraj BusseNessuna valutazione finora

- Chapter 1Documento43 pagineChapter 1Siraj BusseNessuna valutazione finora

- Work Boats Waflaf 2346 - 7760Documento8 pagineWork Boats Waflaf 2346 - 7760Adhietama SumarsonoNessuna valutazione finora

- TM - 9 2350 292 20 2Documento20 pagineTM - 9 2350 292 20 2ahmed.mohamed365.amNessuna valutazione finora

- HMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationDocumento44 pagineHMF/A/V/R-02. Hydraulic Motors For Closed and Open Loop OperationhoiNessuna valutazione finora

- ZF Ecosplit 1341 758 101 Operating Instructions PDFDocumento27 pagineZF Ecosplit 1341 758 101 Operating Instructions PDFnamduong368100% (2)

- Allison Fire Pump Mode Io4096enDocumento2 pagineAllison Fire Pump Mode Io4096enfernandoNessuna valutazione finora

- Mahindra Tractor 4540 4550 4wd Operator ManualDocumento23 pagineMahindra Tractor 4540 4550 4wd Operator Manualvictoriareid020896fcb99% (124)

- Operating Manual: Gear PumpDocumento31 pagineOperating Manual: Gear PumpЖеня СтецьNessuna valutazione finora

- As 1121.3-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - Main PTO DiDocumento8 pagineAs 1121.3-2007 Agricultural Tractor Power Take-Offs Rear-Mounted Power Take-Off Types 1 2 and 3 - Main PTO DiSAI Global - APACNessuna valutazione finora

- MJP Designers Guide Nov11Documento15 pagineMJP Designers Guide Nov11Thiha BoBoNessuna valutazione finora

- Volvo VN / VHD / Vah: Driver's HandbookDocumento28 pagineVolvo VN / VHD / Vah: Driver's HandbookRegistr RegistrNessuna valutazione finora

- FT NEW PRICE LIST 4.10.2021-Converted-UnlockedDocumento693 pagineFT NEW PRICE LIST 4.10.2021-Converted-UnlockedAmit Chopra AmitNessuna valutazione finora

- Muncie - Understanding Truck Mounted Hydraulic SystemsDocumento40 pagineMuncie - Understanding Truck Mounted Hydraulic SystemsStarchyLittleOleMe100% (2)

- PTO-HT16,+PTO-HT20 Eng 01 310017016Documento1 paginaPTO-HT16,+PTO-HT20 Eng 01 310017016jamesNessuna valutazione finora

- Parts Manual Yanmar VIO82Documento187 pagineParts Manual Yanmar VIO82Stephen Rivett100% (1)

- Parts Catalog UR V 290 SeriesDocumento386 pagineParts Catalog UR V 290 Seriesrossonero_pirlo21100% (1)

- Tractor Safety Book Module 4Documento78 pagineTractor Safety Book Module 4Prisaca RădășeniNessuna valutazione finora

- Terex Tr40 Off Highway Truck Parts BookDocumento20 pagineTerex Tr40 Off Highway Truck Parts Bookjames100% (28)

- JD 5045 D 4WD (ICT) BudniDocumento10 pagineJD 5045 D 4WD (ICT) BudniShyam Katare100% (1)

- Tractor: Workshop ManualDocumento696 pagineTractor: Workshop ManualJuan CarlosNessuna valutazione finora

- Fuso Canter 6 0t SegmenDocumento146 pagineFuso Canter 6 0t SegmenKasidin100% (2)

- Manual Operare Valtra T180-t190 PDFDocumento230 pagineManual Operare Valtra T180-t190 PDFramiro0001Nessuna valutazione finora

- Case MX285Documento4 pagineCase MX285cozmin05ebvNessuna valutazione finora

- CT660 Technical SpecificationsDocumento5 pagineCT660 Technical SpecificationsFabrizio Jesus Morales SalirrosasNessuna valutazione finora

- Masson Guide 2010Documento26 pagineMasson Guide 2010EserNessuna valutazione finora

- Inst Manual Engine General 47706356Documento164 pagineInst Manual Engine General 47706356giri_placid100% (1)

- Kubota MU 4501 Tractor - T-1034-1559-2016 PDFDocumento13 pagineKubota MU 4501 Tractor - T-1034-1559-2016 PDFSathish EnjapellyNessuna valutazione finora

- John Deere 120-332 Attachment & Tractor Interchangeability (Dated Feb04)Documento11 pagineJohn Deere 120-332 Attachment & Tractor Interchangeability (Dated Feb04)Shane Clarke100% (1)

- Muncie TG Series PTO Service Parts ManualDocumento24 pagineMuncie TG Series PTO Service Parts ManualPdroGsus Abregú TerronesNessuna valutazione finora

- Allison HD4060 Service Manual PDFDocumento83 pagineAllison HD4060 Service Manual PDFKyle Crandall100% (2)

- Muncie Power Product BrochureDocumento12 pagineMuncie Power Product Brochurewrath_of_marsNessuna valutazione finora