Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Arch 64

Caricato da

Kookie BTS0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

103 visualizzazioni24 pagine1) Concrete slabs are commonly used as floors and ceilings in buildings and come in various forms like flat slabs, ribbed slabs, and waffle slabs.

2) Flat slabs have capitals or drop panels at column tops for support and are uniform in thickness. Ribbed slabs have voids to reduce weight while increasing strength. Waffle slabs have interior voids to reduce compression stresses around supports.

3) Alternative construction methods for slabs include pre-cast slabs used in high-rises, lift slabs which are cast and then lifted into place, and slip forms where reinforced walls are continuously poured and supported.

Descrizione originale:

Cast in place and pre- cast Concrete (Building technology)

Titolo originale

ARCH 64

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento1) Concrete slabs are commonly used as floors and ceilings in buildings and come in various forms like flat slabs, ribbed slabs, and waffle slabs.

2) Flat slabs have capitals or drop panels at column tops for support and are uniform in thickness. Ribbed slabs have voids to reduce weight while increasing strength. Waffle slabs have interior voids to reduce compression stresses around supports.

3) Alternative construction methods for slabs include pre-cast slabs used in high-rises, lift slabs which are cast and then lifted into place, and slip forms where reinforced walls are continuously poured and supported.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

103 visualizzazioni24 pagineArch 64

Caricato da

Kookie BTS1) Concrete slabs are commonly used as floors and ceilings in buildings and come in various forms like flat slabs, ribbed slabs, and waffle slabs.

2) Flat slabs have capitals or drop panels at column tops for support and are uniform in thickness. Ribbed slabs have voids to reduce weight while increasing strength. Waffle slabs have interior voids to reduce compression stresses around supports.

3) Alternative construction methods for slabs include pre-cast slabs used in high-rises, lift slabs which are cast and then lifted into place, and slip forms where reinforced walls are continuously poured and supported.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 24

ARCH 64/Building Tech 5

Alternative Bldg Construction

Chapter 1:

CAST IN PLACE &

PRE-CAST

ARCHT. MARCELINO E. DUMPA,ASST. PROF

Introduction

• In many domestic and industrial buildings a

thick concrete slab, supported on foundations or

directly on the subsoil, is used to construct the

ground floor of a building. These can either be

"ground-bearing" or "suspended" slabs.

• In high rise buildings and skyscrapers,

thinner, pre-cast concrete slabs are slung

between the steel frames to form the floors and

ceilings on each level.

Concrete Slab

• A concrete slab is a common structural element

of modern buildings. Horizontal slabs of

steel reinforced concrete, typically between 4 and

20 inches (100 and 500 millimeters) thick, are

most often used to construct floors and ceilings,

while thinner slabs are also used for exterior

paving.

• Sometimes these thinner slabs, ranging from 2

inches (51 mm) to 6 inches (150 mm) thick, are

called mud slabs, particularly when used under

the main floor slabs or in crawl spaces.

A. FLOOR SLAB SYSTEM

• Slabs and columns are constructed without

beams. Primarily designed to resist gravity

loads, these systems possess very limited

ability to resist earthquake forces.

7 Types of Slabs:

1. Flat 5. Lift

2. Flat Plate 6. Span Stress

3. Ribbed 7. Slip Form Method

4. Waffle

Flat Slab

Have capitals and/or drop panels at the

tops of columns.

A capital is the upper portion of the

column, which is usually of conical shape

and larger in cross-section than the

remaining portion of the column; a drop

panel is a thickened portion of the slab in

the area adjacent to a column.

Flat plates

A one- or two-way system usually

supported directly on columns or load

bearing walls.

It is one of the most common forms of

construction of floors in buildings.

The principal feature of the flat plate floor

is a uniform or near-uniform thickness

with a flat soffit which requires only

simple formwork and is easy to construct.

DIAGRAM

Flat Plate Slab

Flat Slab with Capital

Ribbed Floor Slab

• Introducing voids to the soffit of a slab reduces

dead weight and increases the efficiency of the

concrete section.

• A slightly deeper section is required but these

stiffer floors facilitate longer spans and provision

of holes. Economic in the range 8 to 12 m.

• The advent of expanded polystyrene moulds has

made the choice of trough profile infinite and

largely superseded the use of standard T moulds.

• Ribs should be at least 125 mm wide to suit

reinforcement detailing.

DIAGRAM

ADVANTAGES

• Medium to long spans

• Lightweight

• Holes in topping easily accommodated

• Large holes can be accommodated

• Profile may be expressed architecturally, or

used for heat transfer in passive cooling

Waffle Slab

• Waffles are generally limited to the interior of a slab,

leaving one or two of the forms out to create a solid fill

around the supports.

• The solid fills provide the strength required for shear

transfer to the supports. The fills also reduce the

compression stresses at the soffit of the floor around

the supports, thus avoiding the necessity of bottom

reinforcement in this region.

• Typical waffle constructions using unbonded tendons.

A light top mesh over the waffles is generally the only

top reinforcement at the interior of the floor panels.

ADVANTAGES

• The principal advantage of a waffle slab or

joist constriction is the composite interaction

of the stem and the topping slab.

• The relative position of one with respect to

the other provides the stiffness characteristic

of a ribbed slab.

Lift Slab

• Lift slab construction is a method of

constructing concrete buildings by casting the

floor or roof slab on top of the previous slab

and then raising (jacking) the slab up

with hydraulic jacks, so being cheaper and

faster as not requiring boxing and supports for

casting in situ.

Lift Slab Construction

ADVANTAGES

• Eliminates the need for redundant formwork as

only shuttering required on the edges, therefore

casting concrete slabs is the simplest stage in

whole constriction process of lift-slab method.

• Reduced handling and hoisting of materials and

supplies that can simply be placed on top of the

slabs and lifted with them.

• Only use for 15- 16 storey building. No large span

slab are constructed in this type of construction.

Slip Form System

• Method of vertically extruding a reinforced concrete section and is

suitable for construction of core walls in high-rise structures – lift

shafts, stair shafts, towers.

• The formwork rises continuously, at a rate of about 300 mm per

hour, supporting itself on the core and not relying on support or

access from other parts of the building or permanent works.

• Allows for the continuous pouring of concrete into walls of a

structure and only stops when the full required height of the

structure has been reached.

• The height of the formwork is designed in such a way that while the

top of the formwork is being filled by concrete the lowest layer of

concrete poured earlier has already gained an initial set. When the

formwork is moved upwards the concrete that is then exposed

remains firm.

B. WALL PANEL SYSTEM

4 TYPES OF WALL PANEL SYSTEM

1. Flat Type

2. Ribbed Type

3. Window and Wall Type

4. Tilt Up Wall System

THE END

Potrebbero piacerti anche

- Building Technology 05Documento75 pagineBuilding Technology 05Bryan TuddaoNessuna valutazione finora

- Building Tech. 5Documento26 pagineBuilding Tech. 5Bryan PongaoNessuna valutazione finora

- Group 1 Report Cast in Place and Precast Slab TypesDocumento55 pagineGroup 1 Report Cast in Place and Precast Slab TypesAlwyn RamosNessuna valutazione finora

- Building TechnologyDocumento9 pagineBuilding TechnologyLeila Ysabel FranciscoNessuna valutazione finora

- BT5Documento17 pagineBT5Katkat MarasiganNessuna valutazione finora

- Floor System and Roof Slab System: (Cast-In-Place and Pre-Cast)Documento81 pagineFloor System and Roof Slab System: (Cast-In-Place and Pre-Cast)Alwyn RamosNessuna valutazione finora

- Concrete Floor SystemsDocumento40 pagineConcrete Floor SystemsDinuNessuna valutazione finora

- 01-1 Spanstress Floor SystemDocumento14 pagine01-1 Spanstress Floor SystemJohn GaringNessuna valutazione finora

- 01 Cast in Place and Pre-CastDocumento17 pagine01 Cast in Place and Pre-CastPatrisha UretaNessuna valutazione finora

- Building Technology 5: Alternative Building Construction SystemsDocumento67 pagineBuilding Technology 5: Alternative Building Construction Systemsdaisy samonte0% (1)

- What Is Wall Panel System Report Power PointDocumento37 pagineWhat Is Wall Panel System Report Power PointAlwyn RamosNessuna valutazione finora

- The PPT!Documento13 pagineThe PPT!Meghna MasurekarNessuna valutazione finora

- BMC - Building ComponentsDocumento3 pagineBMC - Building Componentsসন্দীপ চন্দ্রNessuna valutazione finora

- Wall Panel Systems: Building Technology 5Documento25 pagineWall Panel Systems: Building Technology 5Dash AssxEzioNessuna valutazione finora

- Building-Technology-Notes WOOD TO CEMENTDocumento12 pagineBuilding-Technology-Notes WOOD TO CEMENTJohn Milan Octeza100% (1)

- Division 9 - Materials and Finishes: Page 1 of 8Documento8 pagineDivision 9 - Materials and Finishes: Page 1 of 8UmarNessuna valutazione finora

- Group III High Rise StructuresDocumento23 pagineGroup III High Rise StructuresJitendra FarkadeNessuna valutazione finora

- Movement SystemDocumento71 pagineMovement SystemSophia Manila Silla100% (4)

- Membrane Structure: Building TechnologyDocumento10 pagineMembrane Structure: Building Technologybernard louie abanillaNessuna valutazione finora

- Wall Panel SystemDocumento6 pagineWall Panel SystemDaryl AguilarNessuna valutazione finora

- 08 - Lecture 08 - Building Materials and Construction IIDocumento30 pagine08 - Lecture 08 - Building Materials and Construction IIYohans EjiguNessuna valutazione finora

- Floor SystemsDocumento3 pagineFloor SystemsNicole Blanco50% (2)

- Building Technology Materials PDFDocumento10 pagineBuilding Technology Materials PDFnyahahaNessuna valutazione finora

- Housing-Lecture 4 - 1605592046 PDFDocumento23 pagineHousing-Lecture 4 - 1605592046 PDFZilan DilshadNessuna valutazione finora

- 5 Lift Slab MethodDocumento11 pagine5 Lift Slab MethodKartik100% (1)

- Liftformslabconstruction 160907075019 PDFDocumento12 pagineLiftformslabconstruction 160907075019 PDFishikaNessuna valutazione finora

- Mod 1 Precast and Cast in PlaceDocumento28 pagineMod 1 Precast and Cast in PlaceNiel SalgadoNessuna valutazione finora

- Advantages of Using The Following Floor and Roof Slab SystemDocumento1 paginaAdvantages of Using The Following Floor and Roof Slab SystemMarlo LucesNessuna valutazione finora

- Building SuperstructuresDocumento37 pagineBuilding Superstructuresaudilicious0% (3)

- Structural System in High Rise BuildingDocumento7 pagineStructural System in High Rise BuildingjenitaNessuna valutazione finora

- Alternative Construction Solution and DocumentationDocumento27 pagineAlternative Construction Solution and DocumentationJean KianNessuna valutazione finora

- Shell StructuresDocumento34 pagineShell StructuresHOONG123Nessuna valutazione finora

- Membrane StructuresDocumento7 pagineMembrane StructuresHyacynth Pedrosa MenesesNessuna valutazione finora

- TOA 1 (Intro To Theory)Documento43 pagineTOA 1 (Intro To Theory)Josh HabanNessuna valutazione finora

- Building Tech 5Documento33 pagineBuilding Tech 5Lawrence Martinez100% (1)

- Introduction To Alternative Building Construction SystemDocumento52 pagineIntroduction To Alternative Building Construction SystemNicole FrancisNessuna valutazione finora

- LECT 7 CirculationDocumento72 pagineLECT 7 CirculationRojayne100% (1)

- New Developments in Lift Slab Construction - tcm45-343687Documento3 pagineNew Developments in Lift Slab Construction - tcm45-343687Tomasz WiatrNessuna valutazione finora

- Composite ConstructionDocumento26 pagineComposite ConstructionPatrick MalelangNessuna valutazione finora

- How To Use Rule 7 & 8 - by Ar. LeeDocumento9 pagineHow To Use Rule 7 & 8 - by Ar. LeeQuinn HarloweNessuna valutazione finora

- Parts of The BuildingDocumento16 pagineParts of The BuildingAkshaya Dheer MadugulaNessuna valutazione finora

- Community ArchitectureDocumento5 pagineCommunity ArchitecturejodieNessuna valutazione finora

- E DesignDocumento88 pagineE DesignChristmark ZuñigaNessuna valutazione finora

- Tropical Design - HandoutDocumento21 pagineTropical Design - HandoutpatNessuna valutazione finora

- Difference Between One Way Slab and Two Way SlabDocumento2 pagineDifference Between One Way Slab and Two Way SlabTr SunielNessuna valutazione finora

- Registration As An Apec ArchitectDocumento6 pagineRegistration As An Apec ArchitectTonyDingleNessuna valutazione finora

- Floor System and Roof Slab SystemDocumento10 pagineFloor System and Roof Slab SystemKristine NatividadNessuna valutazione finora

- Building Technology 05 (Cast-In Place & Pre-Cast, Floor System & Roof Slab System, Prestressed Concrete)Documento47 pagineBuilding Technology 05 (Cast-In Place & Pre-Cast, Floor System & Roof Slab System, Prestressed Concrete)Editha BaniquedNessuna valutazione finora

- Building Technology 4 Part 10Documento2 pagineBuilding Technology 4 Part 10Jade BarbosaNessuna valutazione finora

- Building Tech 5Documento2 pagineBuilding Tech 5Ren MariNessuna valutazione finora

- Alternative Building Construction Systems Research WorkDocumento15 pagineAlternative Building Construction Systems Research WorkPurchia Pague100% (1)

- Ribbed Type Wall Panel SystemDocumento9 pagineRibbed Type Wall Panel Systemerick100% (1)

- Types of Wall PanelingDocumento7 pagineTypes of Wall Panelingsm_jdsNessuna valutazione finora

- Shell StructuresDocumento57 pagineShell StructuresSayed Jalilullah Ahmadi0% (1)

- HOA 1 Lecture Module 2Documento30 pagineHOA 1 Lecture Module 2David OrtegaNessuna valutazione finora

- Terms Used in RoofDocumento2 pagineTerms Used in Roofrahul_5587_265238786Nessuna valutazione finora

- Building Utilities Module 2 Lesson 1Documento9 pagineBuilding Utilities Module 2 Lesson 1Bryan ManlapigNessuna valutazione finora

- 01 Alternative Methods of Structural ConstructionDocumento30 pagine01 Alternative Methods of Structural ConstructionJohn GaringNessuna valutazione finora

- RESEARCHno 1 BT5Documento8 pagineRESEARCHno 1 BT5Mj Cassandra Yumul SamiaNessuna valutazione finora

- HUSANA, Thessaly Aubrey S. - BT115Research1Documento27 pagineHUSANA, Thessaly Aubrey S. - BT115Research1Thessaly HusanaNessuna valutazione finora

- History of ArchitectureDocumento13 pagineHistory of ArchitectureKookie BTSNessuna valutazione finora

- Road Interchange Student ResearchDocumento12 pagineRoad Interchange Student ResearchKookie BTS100% (1)

- Building LawsDocumento85 pagineBuilding LawsKookie BTSNessuna valutazione finora

- Fits and Misfits of Housing by John F. TurnerDocumento8 pagineFits and Misfits of Housing by John F. TurnerKookie BTSNessuna valutazione finora

- MDG and SDGDocumento3 pagineMDG and SDGKookie BTS100% (1)

- Final Report SOLID WASTEDocumento35 pagineFinal Report SOLID WASTEKookie BTSNessuna valutazione finora

- Housing Options: Session 3Documento53 pagineHousing Options: Session 3Kookie BTSNessuna valutazione finora

- Pre Design ServicesDocumento27 paginePre Design ServicesKookie BTSNessuna valutazione finora

- 3.0 The Ecosystems: Science, Environment and SocietyDocumento39 pagine3.0 The Ecosystems: Science, Environment and SocietyKookie BTS100% (1)

- Chap 2 Prestressed ConcreteDocumento20 pagineChap 2 Prestressed ConcreteKookie BTSNessuna valutazione finora

- Current State, Challenges, and Issues: Introduction To Urban and Regional PlanningDocumento11 pagineCurrent State, Challenges, and Issues: Introduction To Urban and Regional PlanningKookie BTSNessuna valutazione finora

- RisersDocumento3 pagineRisersSubsea_Team100% (1)

- Case Study 1 - Waterstop-RXDocumento2 pagineCase Study 1 - Waterstop-RXCarlos VasquezNessuna valutazione finora

- Competitive Bidding ProceedureDocumento84 pagineCompetitive Bidding ProceedureAndrew ArahaNessuna valutazione finora

- ABR PresentaitionDocumento13 pagineABR PresentaitionJony IslamNessuna valutazione finora

- Regulation: Main ValveDocumento1 paginaRegulation: Main Valvebilal almelegyNessuna valutazione finora

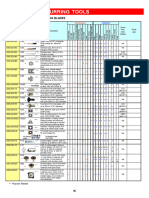

- "Shaviv" Deburring ToolsDocumento1 pagina"Shaviv" Deburring ToolsRino SutrisnoNessuna valutazione finora

- 19AIC Almeida and BalanonDocumento9 pagine19AIC Almeida and BalanonEmil ParangueNessuna valutazione finora

- 38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsDocumento7 pagine38 - Liquid Metal Assisted Cracking of Galvanized Structural Steel SectionsMarjan SubanNessuna valutazione finora

- Chapter 1B: Shell Structure: Lecture Notes of Building Construction IV Shells &domesDocumento23 pagineChapter 1B: Shell Structure: Lecture Notes of Building Construction IV Shells &domesRitika100% (1)

- FE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas EngineeringDocumento2 pagineFE-Analysis of An Integrated Plate Connection Between Jacket Structure and Skirt-Pile Sleeve - (2) - MMC Oil & Gas EngineeringherisiswantogoNessuna valutazione finora

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Documento9 pagineInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Denys Zhukov100% (1)

- Section 14665 - Gantry Cranes City of San Diego, CWP Guidelines Part 1 - GeneralDocumento2 pagineSection 14665 - Gantry Cranes City of San Diego, CWP Guidelines Part 1 - GeneralUmmi Ummi UmmiNessuna valutazione finora

- Thermal Loads Criticality: Aersys Knowledge UnitDocumento4 pagineThermal Loads Criticality: Aersys Knowledge UnitSimon DelmasNessuna valutazione finora

- Morth Market Rate PDFDocumento2 pagineMorth Market Rate PDFAnonymous 9oapvTdNdNessuna valutazione finora

- MB Brochure EN 2020Documento20 pagineMB Brochure EN 2020Yaman mNessuna valutazione finora

- Noiseless Concrete PavementsDocumento8 pagineNoiseless Concrete PavementsachsahNessuna valutazione finora

- CSSBI Tablas de Carga Perfiles PDFDocumento60 pagineCSSBI Tablas de Carga Perfiles PDFRamón RocaNessuna valutazione finora

- NSV Anti-Vibration MountsDocumento31 pagineNSV Anti-Vibration MountskirmaniNessuna valutazione finora

- ABS Submersible Mixer RW 200, 50HzDocumento2 pagineABS Submersible Mixer RW 200, 50Hzalisya.blwsNessuna valutazione finora

- Hazard and Risk - Western Basin Dredging and Disposal ProjectDocumento20 pagineHazard and Risk - Western Basin Dredging and Disposal ProjectRonnie oliveiraNessuna valutazione finora

- Aesthetic Theory of Structural Function in Architectural FormDocumento11 pagineAesthetic Theory of Structural Function in Architectural FormSyed Ahmed KabeerNessuna valutazione finora

- Suspension DiagramsDocumento35 pagineSuspension Diagramsakti gonzo100% (1)

- Kalpataru - Residency - Tower A Plan BookletDocumento7 pagineKalpataru - Residency - Tower A Plan BookletAditi VishwakarmaNessuna valutazione finora

- Shotcreting Method Statement - RMZ The VaultDocumento3 pagineShotcreting Method Statement - RMZ The VaultRakesh ReddyNessuna valutazione finora

- KKB Project ListDocumento18 pagineKKB Project ListLarry Tan100% (1)

- Shurjoint Installation Handbook-2009 - 1Documento131 pagineShurjoint Installation Handbook-2009 - 1DANE80Nessuna valutazione finora

- Ensuring Efficient Reliability For Marine Thermal Systems: Industry OverviewDocumento24 pagineEnsuring Efficient Reliability For Marine Thermal Systems: Industry Overviewpetar petar100% (1)

- Piles CPWD Specs2009Documento31 paginePiles CPWD Specs2009nipunNessuna valutazione finora

- LSD 17 002408 PR06 Gas enDocumento17 pagineLSD 17 002408 PR06 Gas enFrank DetailerNessuna valutazione finora

- Residential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1Documento4 pagineResidential Driveways Encroachmentsencroachment S: Regulations For Driveway and Encroachment Control 8-1luke elbertNessuna valutazione finora