Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pharmaceutical Development

Caricato da

mekaielTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pharmaceutical Development

Caricato da

mekaielCopyright:

Formati disponibili

2-3.

Pharmaceutical Development

Satish Mallya

Quality Workshop, Copenhagen May 18-21, 2014

1| Satish Mallya January

May20-22, 2010

18-21,2014

Outline

Focus on immediate release solid dosage forms

Guidance

Elements

Case Studies

2| Satish Mallya January

May20-22, 2010

18-21,2014

TRS970 Annex 4

Overarching Principles:

– The Pharmaceutical development section should contain information on the

development studies conducted to establish that the dosage form, the

formulation, manufacturing process, container-closure system,

microbiological attributes and usage instructions are appropriate for the

purpose specified in the product dossier.

– Additionally, this section should identify and describe the formulation and

process attributes (critical parameters) that can influence batch

reproducibility, product performance and FPP quality.

3| Satish Mallya January

May20-22, 2010

18-21,2014

TRS970 Annex 4/ICH Q8

Define Quality Target Product Profile (QTPP) as it relates to quality, safety and

efficacy considering, for example, the route of administration, dosage form,

bioavailability, strength and stability;

Identify Critical Quality Attributes (CQA) of the FPP so as to adequately

control the product characteristics that could have an impact on quality;

Discuss CQAs of the API(s), excipients and container-closure system(s)

including the selection of the type, grade and amount to deliver drug product of

the desired quality;

Discuss the selection criteria for the manufacturing process and the

control strategy required to manufacture commercial lots meeting the QTPP in

a consistent manner.

4| Satish Mallya January

May20-22, 2010

18-21,2014

QTTP & CQA

Define Quality Target Product Profile (QTPP) as it relates to quality, safety and

efficacy considering, for example, the route of administration, dosage form,

bioavailability, strength and stability;

Identify Critical Quality Attributes (CQA) of the FPP so as to adequately

control the product characteristics that could have an impact on quality;

Discuss CQAs of the API(s), excipients and container-closure system(s)

including the selection of the type, grade and amount to deliver drug product of

the desired quality;

Discuss the selection criteria for the manufacturing process and the

control strategy required to manufacture commercial lots meeting the QTPP in

a consistent manner

5| Satish Mallya January

May20-22, 2010

18-21,2014

QTPP & CQA

QTPP: A prospective summary of the quality characteristics of a drug product

that ideally will be achieved to ensure the desired quality, taking into account

safety and efficacy of the drug product.

CQA: A physical, chemical, biological or microbiological property or characteristic

that should be within an appropriate limit, range, or distribution to ensure the

desired product quality.

6| Satish Mallya January

May20-22, 2010

18-21,2014

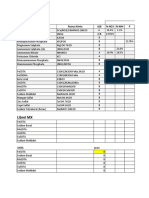

Case Study #1

Identify the QTPPs and CQAs in the following table (product: 100mg IR tablets)

Element/Attribute Target QTPP CQA Element/Attribute Target QTPP CQA

Identification positive √ Stability 24 M at RT

Dosage form Tablet Dissolution NLT75%/30min

Container/closure Blisters Pharmacokinetics Bioequivalent

to RP

Assay 100% LC Water content NMT 4.0%

Content uniformity USP<905 Route of administration Oral √

>

Strength 100 mg Related substances Ind -NMT0.2%

Total:- NMT

1.5%

Microbial limits Ph.Eur

7| Satish Mallya January

May20-22, 2010

18-21,2014

TRS970 Annex 4/ICH Q8

Define Quality Target Product Profile (QTPP) as it relates to quality, safety and

efficacy considering, for example, the route of administration, dosage form,

bioavailability, strength and stability;

Identify Critical Quality Attributes (CQA) of the FPP so as to adequately

control the product characteristics that could have an impact on quality;

Discuss CQAs of the API(s), excipients and container-closure system(s)

including the selection of the type, grade and amount to deliver drug product of

the desired quality;

Discuss the selection criteria for the manufacturing process and the

control strategy required to manufacture commercial lots meeting the QTPP in

a consistent manner

8| Satish Mallya January

May20-22, 2010

18-21,2014

CQAs of the API & Excipients

Key physicochemical characteristics of the API that can influence the

performance of the FPP:

– Physical properties: particle size distribution, bulk and tap densities,

crystalline form, hygroscopicity,

solubility ;

– Chemical properties: stability under temperature, humidity, oxidative,

photolytic conditions

– Biological properties: permeability, partition coefficient, BCS

The compatibility of the API(s) with each other (FDCs) and with excipients;

The choice of excipients, their concentration and their characteristics that can

influence the FPP performance.

9| Satish Mallya January

May20-22, 2010

18-21,2014

Processes

Wet granulation Dry Granulation Direct Compression

Milling Milling Milling

What happens to the API

Pre-blending Pre-blending Blending/lubrication

Addition of binder Slugging/Roller Compaction

Screening wet massDry screening

Drying

Screening of granules

Blending of lubricant Blending of lubricant

Tablet compression Tablet Compression Tablet Compression

10 | Satish Mallya January

May20-22, 2010

18-21,2014

CQA of the C/C System

Rationale for selection of the container closure system

Suitability of the container closure system for storage and

transportation, including the storage and shipping container for bulk

PP

Safety of packaging materials

Protection from moisture and light

Compatibility of the FPP with packaging materials

11 | Satish Mallya January

May20-22, 2010

18-21,2014

TRS970 Annex 4/ICH Q8

Define Quality Target Product Profile (QTPP) as it relates to quality, safety and

efficacy considering, for example, the route of administration, dosage form,

bioavailability, strength and stability;

Identify Critical Quality Attributes (CQA) of the FPP so as to adequately

control the product characteristics that could have an impact on quality;

Discuss CQAs of the API(s), excipients and container-closure system(s)

including the selection of the type, grade and amount to deliver drug product of

the desired quality;

Discuss the selection criteria for the manufacturing process and the

control strategy required to manufacture commercial lots meeting the QTPP in

a consistent manner.

12 | Satish Mallya January

May20-22, 2010

18-21,2014

Manufacturing Process Development

Justification for the selection of the manufacturing

process and in-process controls;

– Appropriateness of the equipment used;

– Identification of critical process parameters (CPP)

Justification for differences between the manufacturing

processes used to produce batches for bioequivalence

studies or primary stability studies and the commercial

process.

13 | Satish Mallya January

May20-22, 2010

18-21,2014

Critical Process Parameter (CPP)

A process parameter whose variability has an impact on a

critical quality attribute (CQA) and therefore should be

monitored or controlled to ensure the process produces

the desired quality

– Blending

– Granulation

– Drying (LOD)

– Compression

– Coating

14 | Satish Mallya January

May20-22, 2010

18-21,2014

Other Considerations

Justification for overages

Issues surrounding score line - uniformity testing (i.e. Content uniformity for split

portions containing less than 5 mg or less than 5% of the weight of the dosage

unit portion, or mass uniformity for other situations) should be performed on each

split portion from a minimum of 10 randomly selected whole tablets.

In-vitro dissolution

– Development of discriminatory method

– Generation of dissolution profiles

Optimization and Scale-up

15 | Satish Mallya January

May20-22, 2010

18-21,2014

Optimization Studies

Studies are undertaken to optimize:

– quantity of binder

– quantity of disintegrant

– LOD

Different trial batches having varying amounts of disintegrant and binder are

used;

Results of granule flowability, tablet characteristics and comparative dissolution

profiles are compared;

Granules with different LOD levels are compressed and results with respect to

flowability and tablet characteristics are used to finalize formulation;

The formulation so developed is considered to be optimized when there are no

problems (e.g. capping) and the dissolution profile matches the innovator product

16 | Satish Mallya January

May20-22, 2010

18-21,2014

Case Study #2

Applicant has developed an IR tablet product containing light and moisture

sensitive API. The API belongs to BCS class 2 and exists in 2 polymorphic forms.

The API constitutes 4% of the formulation. The SmPC reports that the tablets are

uncoated and scored bisected

API/Excipient Manufacturing CPP Others

Process

TOC Wet Granulation Blending (BU) Divisibility: Weight

Variation/Content

Uniformity

XRD Dry Granulation Granulation F2 calculations

PSD Direct Compression Drying (LOD) Geometric dilution

Compatibility Compression

Coating (spray rate)

17 | Satish Mallya January

May20-22, 2010

18-21,2014

Thanks

?Questions

18 | Satish Mallya January

May20-22, 2010

18-21,2014

Potrebbero piacerti anche

- Cocaine Microwave DryingDocumento7 pagineCocaine Microwave Dryingzomar21Nessuna valutazione finora

- Folk MedicineDocumento84 pagineFolk MedicinemekaielNessuna valutazione finora

- Practical Lab ManualDocumento15 paginePractical Lab ManualMahesh Chougule100% (1)

- Acute Subacute ChronicDocumento59 pagineAcute Subacute Chronicaziskf100% (1)

- AntibioticsDocumento39 pagineAntibioticsmekaiel100% (2)

- USP 1086 Impurities in Drug Substances and Drug ProductsDocumento3 pagineUSP 1086 Impurities in Drug Substances and Drug ProductsMuhammad JamilNessuna valutazione finora

- Oral Solutions, Suspensions and Mixtures: Page 1 of 4Documento4 pagineOral Solutions, Suspensions and Mixtures: Page 1 of 4Suganda LeksshmyNessuna valutazione finora

- ICH Quality Guidelines: An Implementation GuideDa EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleNessuna valutazione finora

- 2010 - Recent Advances of Capillary Electrophoresis in Pharmaceutical AnalysisDocumento24 pagine2010 - Recent Advances of Capillary Electrophoresis in Pharmaceutical AnalysisStefana SzántóNessuna valutazione finora

- Biogenics & BiosimilarsDocumento239 pagineBiogenics & BiosimilarsSooraj Rajasekharan Kartha100% (1)

- Tarnish & CorrosionDocumento48 pagineTarnish & CorrosionmujtabaNessuna valutazione finora

- Determination of Vitamin b6 by Means of DifferentialDocumento7 pagineDetermination of Vitamin b6 by Means of DifferentialthuNessuna valutazione finora

- Pressure Drop Compressible FlowDocumento14 paginePressure Drop Compressible Flowdilip matalNessuna valutazione finora

- A To Z of Enzyme TechnologyDocumento303 pagineA To Z of Enzyme TechnologyJake PoppeNessuna valutazione finora

- 1088 in Vitro & in Vivo Evaluation of Dosage Forms - USP 36 PDFDocumento10 pagine1088 in Vitro & in Vivo Evaluation of Dosage Forms - USP 36 PDFKarlaBadongNessuna valutazione finora

- Preview Book Introduction HPLCDocumento29 paginePreview Book Introduction HPLCarun231187Nessuna valutazione finora

- Controlled Drug Delivery Fundamentals and Applications, Second Edition by Joseph Robinson, Vincent H. L. LeeDocumento730 pagineControlled Drug Delivery Fundamentals and Applications, Second Edition by Joseph Robinson, Vincent H. L. Leeuday saini100% (1)

- Quality Assurance in PharmacyDocumento43 pagineQuality Assurance in Pharmacymekaiel100% (1)

- 12-Theory and Practice of Contemporary Pharmaceutics-CRC Press (2004)Documento579 pagine12-Theory and Practice of Contemporary Pharmaceutics-CRC Press (2004)zlib8880Nessuna valutazione finora

- Vitamin B6Documento13 pagineVitamin B6anggi yulianNessuna valutazione finora

- Biochemical Oxygen Demand (Bod) PDFDocumento12 pagineBiochemical Oxygen Demand (Bod) PDFGilberto ContrerasNessuna valutazione finora

- Chemical Analysis of Foods - HENRY EDWARD COXDocumento348 pagineChemical Analysis of Foods - HENRY EDWARD COXpradhan poovaiah100% (1)

- GC-MS-MS Analysis of Pesticide Residues in Green Tea Extracted by QuEChERSDocumento1 paginaGC-MS-MS Analysis of Pesticide Residues in Green Tea Extracted by QuEChERSAmerican Lab100% (1)

- Excel Meracik Nutrisi Bandung 11 Feb 2018Documento30 pagineExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuNessuna valutazione finora

- Biogas Production SystemsDocumento22 pagineBiogas Production SystemsEmiliano Rodriguez TellezNessuna valutazione finora

- IB Cabotegravir v10Documento285 pagineIB Cabotegravir v10Luana MarinsNessuna valutazione finora

- Preformulation enDocumento20 paginePreformulation enaroravikas100% (1)

- Curcumin From Turemeric 2Documento4 pagineCurcumin From Turemeric 2Raj Nemala Raj NemalaNessuna valutazione finora

- Technique Used For Study of Bio Synthetic PathwayDocumento9 pagineTechnique Used For Study of Bio Synthetic Pathwayshankul kumar95% (19)

- Aspirin SynthesisDocumento48 pagineAspirin SynthesisPaolo PepsNessuna valutazione finora

- GlycosidesDocumento18 pagineGlycosidesAnonymous TCbZigVqNessuna valutazione finora

- 1 ThesisDocumento236 pagine1 ThesisLong ManNessuna valutazione finora

- Screening of Antidiabetic Drugs: Presented ByDocumento35 pagineScreening of Antidiabetic Drugs: Presented BysharonNessuna valutazione finora

- Lecture5 Pharmaceutics (Buffer Partition)Documento6 pagineLecture5 Pharmaceutics (Buffer Partition)haroon41Nessuna valutazione finora

- Granules SBDocumento43 pagineGranules SBMirza Salman BaigNessuna valutazione finora

- Notes Dosage Form DesignDocumento9 pagineNotes Dosage Form DesignDee PañaresNessuna valutazione finora

- Experiment No. 3: Preparation of SoapDocumento16 pagineExperiment No. 3: Preparation of SoapTrisha TadiosaNessuna valutazione finora

- Screening Methods in Pharmacology. Volume II (1971) - Robert A. Turner and Peter HebbornDocumento291 pagineScreening Methods in Pharmacology. Volume II (1971) - Robert A. Turner and Peter HebbornSiddharth AhujaNessuna valutazione finora

- Semester 3 Syllabus B PharmaDocumento18 pagineSemester 3 Syllabus B Pharmaabhishek sharmaNessuna valutazione finora

- Role of Additives in Formulation Development & ProcessingDocumento38 pagineRole of Additives in Formulation Development & ProcessingAjay Kumar0% (1)

- BP 181212054815Documento74 pagineBP 181212054815Ahmad AinurofiqNessuna valutazione finora

- Handbook 6th Sem PharmacyDocumento35 pagineHandbook 6th Sem PharmacyJai MinhasNessuna valutazione finora

- GRDDSDocumento31 pagineGRDDSMuhammad Azam TahirNessuna valutazione finora

- Phycocyanin Extraction Study Sarada Et Al 1999Documento7 paginePhycocyanin Extraction Study Sarada Et Al 1999PatzkornBoonNessuna valutazione finora

- Advanced Pharmaceutical AnalysisDocumento4 pagineAdvanced Pharmaceutical AnalysisRezaul RazibNessuna valutazione finora

- Enteric Coated Aspirin Tablets FinalDocumento72 pagineEnteric Coated Aspirin Tablets Finalronak_panchal_21Nessuna valutazione finora

- Thesis FinalDocumento102 pagineThesis FinalMittul ThekdiNessuna valutazione finora

- Factors Affecting Stability of Formulations: Dr. Satish A. Patel M. Pharm, Ph. DDocumento38 pagineFactors Affecting Stability of Formulations: Dr. Satish A. Patel M. Pharm, Ph. DMr. HIMANSHU PALIWALNessuna valutazione finora

- Sigma Aldrich Grading ChartDocumento2 pagineSigma Aldrich Grading Chartjm06100% (1)

- Ftir and Gc-Fid CharacterizationDocumento8 pagineFtir and Gc-Fid CharacterizationIpeghan Otaraku100% (1)

- Bioavailability Study of MetforminDocumento53 pagineBioavailability Study of MetforminKadhar Kaliloor Rahman100% (1)

- AbsorptionDocumento84 pagineAbsorptionDr. Bharat JainNessuna valutazione finora

- Pre FormulationDocumento55 paginePre FormulationEduardo Santos AlquimistaNessuna valutazione finora

- Drug Excipoent InteractionDocumento23 pagineDrug Excipoent InteractionDeepti GuptaNessuna valutazione finora

- Antithyroid Drugs by Sejal Khuman Advanced phARMACOLGY 2Documento29 pagineAntithyroid Drugs by Sejal Khuman Advanced phARMACOLGY 2Sejal khumanNessuna valutazione finora

- PPTDocumento28 paginePPTRaj KumarNessuna valutazione finora

- Physicochemical Factors Under Preformulation Study: Contents:-I. Physical Characteristics A. Bulk CharacteristicDocumento18 paginePhysicochemical Factors Under Preformulation Study: Contents:-I. Physical Characteristics A. Bulk CharacteristicFIRDA TRYANANessuna valutazione finora

- Applications of Solid-Phase Microextraction in Food AnalysisDocumento28 pagineApplications of Solid-Phase Microextraction in Food AnalysisAnonymous xGc8MRRysNessuna valutazione finora

- BPHM 806 LabDocumento23 pagineBPHM 806 LabRajwinder Onkar SinghNessuna valutazione finora

- Ex 6 - TLCDocumento9 pagineEx 6 - TLCMonica Hitomi MekaruNessuna valutazione finora

- Scale Up and Postapproval Changes (Supac) Guidance For Industry: A Regulatory NoteDocumento9 pagineScale Up and Postapproval Changes (Supac) Guidance For Industry: A Regulatory NoteAKKAD PHARMANessuna valutazione finora

- A Review of On Preformulation Studies of DrugsDocumento11 pagineA Review of On Preformulation Studies of DrugsPanji Wirawan0% (1)

- Bcs Classification of DrugsDocumento12 pagineBcs Classification of Drugsjigarpatel5Nessuna valutazione finora

- DPCODocumento30 pagineDPCOArya SreedharanNessuna valutazione finora

- Preformulation Testing of Solid Dosage FormsDocumento100 paginePreformulation Testing of Solid Dosage FormsprinceamitNessuna valutazione finora

- Pharmaceuticalpreformulation PDFDocumento332 paginePharmaceuticalpreformulation PDFKrishna ReddyNessuna valutazione finora

- Pharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesDocumento7 paginePharmaceutics-Chapter-2-Packaging-Materialsxgchbu Gyvy-NotesBEST OF BESTNessuna valutazione finora

- Hospital-Pharmacy Management System: A UAE Case Study: A. Khelifi, D. Ahmed, R. Salem, N. AliDocumento10 pagineHospital-Pharmacy Management System: A UAE Case Study: A. Khelifi, D. Ahmed, R. Salem, N. AlimekaielNessuna valutazione finora

- Drugs Acting On CNS: Prof. A O Elkhawad Umst Khartoum, SudanDocumento80 pagineDrugs Acting On CNS: Prof. A O Elkhawad Umst Khartoum, SudanmekaielNessuna valutazione finora

- Medical Representative Basic TipsDocumento8 pagineMedical Representative Basic TipsmekaielNessuna valutazione finora

- Service Manual: First Edition Second Printing Part No. 52709Documento440 pagineService Manual: First Edition Second Printing Part No. 52709Jhon Hever Benitez100% (1)

- Coordination CompoundDocumento76 pagineCoordination Compoundashok pradhanNessuna valutazione finora

- Table 1A List of Material Specifications (Cont'd) : (C) A Manufacturer May Supplement These MandatoryDocumento1 paginaTable 1A List of Material Specifications (Cont'd) : (C) A Manufacturer May Supplement These MandatoryPanchal ShaileshNessuna valutazione finora

- Hdpe SK 6100Documento1 paginaHdpe SK 6100Le Minh TuanNessuna valutazione finora

- Ster RadDocumento4 pagineSter RadKlos BettoNessuna valutazione finora

- NCERT Exemplar Problems For Solid State Class XIIDocumento16 pagineNCERT Exemplar Problems For Solid State Class XIISuparnaNessuna valutazione finora

- SDS - Nasiol PerShoes v1.0Documento10 pagineSDS - Nasiol PerShoes v1.0Ezgi ArslanNessuna valutazione finora

- SPT2021 Butadiene AAMDocumento29 pagineSPT2021 Butadiene AAMTasneem MNessuna valutazione finora

- Catalogo Alu MarketDocumento40 pagineCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- IncroquatBehenylTMS 50DataSheetDocumento7 pagineIncroquatBehenylTMS 50DataSheetKirk BorromeoNessuna valutazione finora

- Measurements of Surface TensionDocumento11 pagineMeasurements of Surface TensionHema ParasuramanNessuna valutazione finora

- Philippine Mineral DepositsDocumento9 paginePhilippine Mineral DepositsLara CharisseNessuna valutazione finora

- Hardness Temperature in MetalsDocumento6 pagineHardness Temperature in MetalsStevenJacomeNessuna valutazione finora

- Kelebihan Kekurangan Kromatografi KolomDocumento8 pagineKelebihan Kekurangan Kromatografi KolomFendy FendyNessuna valutazione finora

- Class 12 Important QuestionsDocumento4 pagineClass 12 Important Questionsmisraadyasha6Nessuna valutazione finora

- Worksheet - Experiment 9 MilkDocumento2 pagineWorksheet - Experiment 9 MilkYuraNessuna valutazione finora

- Grundfosliterature-836 - (PG 10,24-25)Documento226 pagineGrundfosliterature-836 - (PG 10,24-25)anggun100% (1)

- 2 Manuale D Uso GB 03 12 CE C-0104Documento33 pagine2 Manuale D Uso GB 03 12 CE C-0104vtechelectricNessuna valutazione finora

- Philippines FreshwaterDocumento11 paginePhilippines FreshwaterBJ Allon Mallari100% (1)

- Rectifier Design For Fuel Ethanol PlantsDocumento7 pagineRectifier Design For Fuel Ethanol PlantsenjoygurujiNessuna valutazione finora

- (Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersDocumento13 pagine(Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersHafez HawasNessuna valutazione finora

- Imidazoline-Théorie Ferm1954Documento21 pagineImidazoline-Théorie Ferm1954Belkhadem FatimaNessuna valutazione finora

- Separating The Components of PanacetinDocumento3 pagineSeparating The Components of PanacetinElvis J TaverasNessuna valutazione finora

- Adrif Vision List New 11.02.2021Documento2 pagineAdrif Vision List New 11.02.2021rahsreeNessuna valutazione finora