Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Presentation 1

Caricato da

g1260338Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Presentation 1

Caricato da

g1260338Copyright:

Formati disponibili

Format.

no: TPM/KPI/05

TPM MACHINE PERFORMANCE MEASUREMENT FOR ASSEMBLY LINE Rerv.no:

Rerv.Date:

0

18.06.2015

KEY PERFORMANCE INDICATOR KEY ACTIVITY INDICATORs circle

SL.NO ASSEMBLY

Objectives Benchmark Target Activity Target Responsibility Status

Eliminating Tool & Casual labour searching time. July'2015 circle leader

open

Reducing clamping & De clamping time in setting July'2015 circle leader

open

Reducing Transportation time from Tool rack to machine. August'15 circle leader,tool room

open

Eliminating supporting tools searching time . July'2015 circle leader,tool room

open

Providing standard blocks instead of setting pieces. June'2015 circle leader,tool room

closed

Providing operator movement around the machine by creating spacious atmosphere. August'15 circle leader

open

circle leader,

37.5

1 PRODUCTIVITY 30 pieces/hour Implementing conveyors instead of standard pallets to keep the sub assemblies. August'15 maintanence team

pieces/hour

member open

Reducing stacking time of springs ,Hub.sideplates and washers on work table. July'2015 circle leader

open

circle leader,quality

Reducing no of washers by introducing standard washers. August'15

incharge open

Reducing movement time time from spring Assembly table to stop pin Rivetting table. August'15 circle leader

open

Reducingoperator fatigue by reducing sub assembly table ht. June'2015 circle leader

closed

August'15 circle leader

Reducing Anvil change over time open

June'2015 circle leader,tool room

Providing standard bunk closed

Reducing setup approval time. July'2015 circle leader ,quality

open

2 Reducing inspection time by introducing attribute Gauges. July'2015 circle leader ,quality

open

QUALITY 481 0 Ensuring availability of same Grade springs. July'2015 circle leader ,quality

open

Eliminating stop pin twist July'2015 circle leader ,quality

open

Ensuring defect free Raw materials from supplier end. July'2015 circle leader ,quality

open

3 Reducing alignment time b/w punch and Anvil. August'15 circle leader,tool room

open

Increase the Rivet storage capacity in Rivet pocket. July'2015 circle leader

open

3' hrs 0'

MACHINE circle leader,

BREAKDOWN BREAKDOWN Proper maintenance in the machine parts like Rivet path to avoid problems like Rivet

July'2015 maintanence team

Tilting & Double Riveting.

member open

circle leader,

By doing regular JH avoid forced deterioration of m/c parts and maintaining m/c child

June'2015 maintanence team

parts history card to change over the parts during natural deterioration.

member closed

4 KAIZEN 0/MONTH 2/MONTH Increase the number of kaizens by operator training July'2015 circle leader

on process

5 5S SCORE 80% 90% By doing regular JH June'2015 zone leader

closed

6 OEE 65% 95% Improving OEE by doing kaizens, and reducing non-value added activities July'2015 zone leader

open

TPM KOBETSU KAIZEN AMREP

Format.no: TPM/KPI/01

TPM MACHINE PERFORMANCE MEASUREMENT FOR PRESS SHOP Rerv.no: 0

18.06.2015

Rerv.Date:

KEY PERFORMANCE KEY ACTIVITY INDICATORs circle

SL.NO INDICATOR P1

Objectives Benchmark Target Activity Target Responsibility Status

Reducing the clamping & declamping time in setting. July'2015 Circle leader open

Reducing searching time for tool trolly and casual labour. July'2015 Circle leader open

Reducing searching time of Bolts, Nuts & setting blocks. june'2015 Circle leader closed

Reducing movement time of operator from m/c to do sub activities July'2015 Circle leader open

Reducing setup approval time. July'2015 Circle leader, quality open

Reducing the trolly movement. August'2015 Circle leader open

Reducing the unloading & loading time of component. june'2015 Circle leader open

1 PRODUCTIVITY 550 pieces/hour 600 pieces/hour

Eliminating waiting time for component movement. July'2015 Circle leader open

Reducing coil loading & unloading time. July'2015 Circle leader open

Reducing time of movement of tool from tool rack. July'2015 Circle leader open

Increasing the tool life by changing material of punch and die. june'2015 Circle leader,tool room closed

Reducing time for searching tool. june'2015 Circle leader,tool room closed

Eliminating knockout problem. July'2015 Circle leader,tool room open

Reducing JH cleaning time. July'2015 circle leader, facilitator open

Eliminating endcut . July'2015 Circle leader, quality open

2 August'2015 Circle leader, quality

Reducing inspection time . open

Eliminating wrong location . July'2015 Circle leader, quality open

Eliminating offset. July'2015 Circle leader, quality open

QUALITY 523 0

July'2015 Circle leader, quality

Eliminating flatness issue and forming variation. open

Eliminating damage in all operations. July'2015 Circle leader, quality

open

July'2015 Circle leader, quality

Eliminating heavy burr. open

3 Eliminating SOC August'2015 Circle team open

August'2015 Circle team

Increase the frequency of initial cleaning. open

3' hrs

MACHINE 0' BREAKDOWN By doing regular JH avoid forced deteroiation of m/c parts and

BREAKDOWN

maintaining m/c childparts history card to change over the parts during june'2015 Circle team

natural deteroiation.

on process

4 KAIZEN 0/MONTH 2/MONTH Increase the number of kaizens by operator training june'2015 circle team on process

5 5S SCORE 80% 90% By doing regular JH june'2015 circle team closed

6 OEE 45% 75% Improving OEE by doing kaizens, and reducing non-value added activites june'2015 circle team

on process

TPM KOBETSU KAIZEN AMREP

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Refrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBDocumento18 pagineRefrigerator: Owner S Instructions SR-17NFB SR-19NFB SR-22NFBjchunga_lauNessuna valutazione finora

- Technical Submittal For Precast Concrete Low ResDocumento119 pagineTechnical Submittal For Precast Concrete Low ReshmoncktonNessuna valutazione finora

- Procedure of Testing Steering Gears On ShipDocumento1 paginaProcedure of Testing Steering Gears On Shipmavericksailor50% (2)

- Material Master - HAWA MaterialDocumento6 pagineMaterial Master - HAWA MaterialmeddebyounesNessuna valutazione finora

- RC Pier DelbennaDocumento25 pagineRC Pier DelbennaEngineeri TadiyosNessuna valutazione finora

- Vessel Requirement DetailsDocumento11 pagineVessel Requirement DetailsFxgNessuna valutazione finora

- Ssp278 - The Audi A4 CabrioletDocumento64 pagineSsp278 - The Audi A4 CabrioletOblioCarliontatulOblio100% (1)

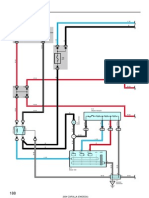

- 2004 Corolla Air Conditioning Wiring DiagramDocumento4 pagine2004 Corolla Air Conditioning Wiring Diagramjldamasceno100% (2)

- Scramjet EngineDocumento23 pagineScramjet EngineamitNessuna valutazione finora

- Comparative Analysis of Transportation NDocumento12 pagineComparative Analysis of Transportation NdooeelhNessuna valutazione finora

- Mazda 3 BrochureDocumento16 pagineMazda 3 BrochurebacooNessuna valutazione finora

- Sea Ports - Exports & Imports by INDIRA SARKARDocumento3 pagineSea Ports - Exports & Imports by INDIRA SARKARShambhavi RaiNessuna valutazione finora

- Hobart - Air Warfare DestroyerDocumento13 pagineHobart - Air Warfare DestroyerhindujudaicNessuna valutazione finora

- Chapter 7 Vehicle Routing and SchedulingDocumento31 pagineChapter 7 Vehicle Routing and Schedulingchangyq71% (7)

- Chapter 4 - Supply Chain ManagementDocumento30 pagineChapter 4 - Supply Chain ManagementAinatul Alia AlliasNessuna valutazione finora

- Tendernotice 1Documento7 pagineTendernotice 1RR PatelNessuna valutazione finora

- WHAT IS HYDROGRAPHY - NOAA Hydro Training 2009Documento32 pagineWHAT IS HYDROGRAPHY - NOAA Hydro Training 2009Tony ThomasNessuna valutazione finora

- Pantaloon ReportDocumento16 paginePantaloon ReportHimanshu Rastogi100% (1)

- Crane Design and CalculationDocumento28 pagineCrane Design and Calculationodim7370% (23)

- Flyover RFPDocumento51 pagineFlyover RFPPavement VasupradaNessuna valutazione finora

- Nilam Bekti Sumardhani-BTH-NKRHCD-BTJ-FLIGHT - ORIGINATINGDocumento4 pagineNilam Bekti Sumardhani-BTH-NKRHCD-BTJ-FLIGHT - ORIGINATINGahlan zulfakhriNessuna valutazione finora

- Mode Choice Modelling For Work Trips in Calicut City: Tushara T, Rajalakshmi P, Bino I KoshyDocumento8 pagineMode Choice Modelling For Work Trips in Calicut City: Tushara T, Rajalakshmi P, Bino I KoshyjoemarNessuna valutazione finora

- Santiago CalatravaDocumento12 pagineSantiago Calatravadplpthk1502Nessuna valutazione finora

- Essay ViolenceDocumento3 pagineEssay Violencefz6z1n2p100% (2)

- Case Study: Helge Ingstad - Sola TSDocumento19 pagineCase Study: Helge Ingstad - Sola TSakshayvNessuna valutazione finora

- The Impact of Supply Chain CostDocumento18 pagineThe Impact of Supply Chain CostGab ColobongNessuna valutazione finora

- Open Letter To Hon. Narendra Modi, Prime Minister of India Regarding Dubious Quality of Road Paving BitumenDocumento5 pagineOpen Letter To Hon. Narendra Modi, Prime Minister of India Regarding Dubious Quality of Road Paving BitumenProf. Prithvi Singh Kandhal100% (1)

- Bulk Carrier Condition Survey ReportDocumento33 pagineBulk Carrier Condition Survey Reportalxgam100% (1)

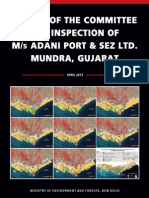

- Report of The Committee For Inspection of M/s Adani Port & SEZ Ltd. Mundra, GujaratDocumento96 pagineReport of The Committee For Inspection of M/s Adani Port & SEZ Ltd. Mundra, GujaratLalit MauryaNessuna valutazione finora

- Road ScholarDocumento2 pagineRoad Scholar:)Nessuna valutazione finora