Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Development of Novel Self-Healing Polymer Composites For Use in Wind Turbine Blades

Caricato da

Tayyab Ahsan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni31 paginerm

Titolo originale

rm

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentorm

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

25 visualizzazioni31 pagineDevelopment of Novel Self-Healing Polymer Composites For Use in Wind Turbine Blades

Caricato da

Tayyab Ahsanrm

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 31

Development of Novel Self-Healing

Polymer Composites for Use in Wind

Turbine Blades

ABDUL SAMI JAVED

MSE-12

REGISTRATION ID-

206776

Outline

Self-Healing Processes

Classification

Scope

Experimentation

Results and Discussions

Conclusion

References

Inspiration

This approach is inspired from nature where the wounds in mammals are healed by bleeding of

vascular network underneath the skin

History of Self Healing Polymers

The first ever designed self-healing polymer was

called ‘Terminator’

This polymer is made of permanently cross linked

poly(urea-urethane) elastomeric network that

mends itself.

Classification of Self Healing Polymers

Microencapsulation Healing System

Microvascular Healing System

Intrinsic Healing Systems

Autonomic healing

Microencapsulation Healing System

Monomer is encapsulated and embedded within the thermosetting polymer.

When the crack reaches the microcapsule, the capsule breaks and the monomer bleeds into the

crack, where it can polymerize and mend the crack

Mechanism

Ring Opening Metathesis Polymerization (ROMP)

Dicyclopentadiene (DCPD) is stored in liquid form in the microcapsule

Grubb’s Catalyst polymerizes DCPD to poly DCPD which initiates the process of self-healing.

Microencapsulation Healing Mechanism

Listing of capsule-based self-healing

systems

Microvascular Healing Systems

Contains the healing agent in a network in the

form of capillaries or hollow channels, which

may be interconnected until damage triggers

self-healing.

Fabrication difficult

Vascular networks can be 1

dimensional, 2 dimensional or 3

dimensional.

The healing and hardening agents are

present in different capillaries that

react when the tubes break.

Scope

Wind power generation is expanding as a high potential renewable resource, there is huge

technological progress in terms of design and manufacturing of the wind turbines, with shapes

of turbines being regularly updated world over

The wings of wind turbines are made up of fibre-reinforced epoxy.

The wings get damaged due to alternating load caused by variations in the wind

Their lifetime can be extended using self healing materials

Experimentation

PMC were made using Volan finish glass fiber material

The molding procedure employed was vacuum assisted resin transfer molding(VARTM)

Six layers of glass fiber provided the required thickness for testing

VARTM

Six layers of glass fibers over wax coated die/base plate

Over these, a layer of peel ply and breather material was laid and they were then covered and

sealed by a vacuum bag which has provisions for resin-hardener mixture inlet and outlet

The setup was checked for vacuum leakages and the gaps were sealed.

VARTM

Parameters

Materials Commercial grade marine epoxy resin

Medium cure hardener

Mixing ratio 3:1 by volume

Suction pressure 551.58 kPa

Curing Temperature Room temperature

Curing time 24 hrs

VARTM

The samples containing microtubes involved an

additional step of accurate placement of the

microtubes between the glass fiber layers prior

to the molding process

The tubes were made of commercially available

Borosilicate glass capillary tubing.

Sample With-tubes/without- Use of catalyst and Uniqueness in

number tubes healing agent composition

composite of sample

1 Without-tubes No Control sample

2 With tubes No Tubes as a central

layer

3 With tubes Yes Tubes as a central

layer

4 With tubes Yes Tubes as the

penultimate

layer

5 With tubes Yes Tubes as the last layer

List of samples with their uniqueness

VARTM

Results & Discussions

SEM image of the glass fibers reinforcing the composite

SEM of sample prepared by VARTM

SEM image of the fractured mold sample that was subjected

to destructive tensile testing

SEM of sample prepared by Handlayup

SEM image of the fractured mold sample that was subjected

to destructive tensile testing

Tensile Strength Comparison

Flexural Strength comparison

Flexural Strength comparison

Flexural Strength comparison

Healing Efficiency Comparison

Wind Tunnel testing of self-healing blade

The scaled down wind turbine was for more

than 3 hours, out of which it was run about

2 hours at its maximum wind speed of

16.5m/s through its test section.

Extra weights were added to create

imbalance and stress the self-healing

specimen to impart cracks

Wind Tunnel testing of self-healing blade

Before wind tunnel test After wind tunnel test

Conclusion

Average recovery of flexural strength of 92.12% using the tubes as the central layer, 87.11%

using tubes as the penultimate layer, and 84.52% using tubes as the last layer

A 25% decrease in average tensile strength and 9% decrease in average flexural strength

References

[1] Dan Utech, "The Promise of Wind Energy," The White House Blog, 12 March 2015.[Online]. Available:

https://www.whitehouse.gov/blog/2015/03/12/promise-wind-energy.

[2] U. S. Department of Energy, "Wind Vision," American Wind Energy Association, 2015.[Online].

Available:http://www.awea.org/content.aspx?ItemNumber=7300&RDtoken=61421&userID=&navItemNumber=7077.

[3] S. Campbell, "Annual blade failures estimated at around 3,800," WindPower Monthly, 14 May 2015. [Online].

Available:

http://www.windpowermonthly.com/article/1347145/annual-blade-failures-estimatedaround- 3800. [Accessed 2016].

[4] B. S. Nivedh, "Major Failures in the Wind Trubine Components and the Importance of Periodic Inspections,"

www.windinsider.com, November 2014. [Online]. Available:

http://www.dewi.de/dewi_res/fileadmin/pdf/papers/WindInsider_November_2014.pdf.

[5] C. Smith, "Fires are major cause of wind farm failure, according to new research," Imperial college London, 17 July

2014. [Online]. Available:

http://www3.imperial.ac.uk/newsandeventspggrp/imperialcollege/newssummary/new

s_17-7-2014-8-56-10.

Potrebbero piacerti anche

- Rizal and The Theory of NationalismDocumento37 pagineRizal and The Theory of NationalismLiza Betua Sotelo78% (58)

- ASTM - D3574-17 - EspumasDocumento30 pagineASTM - D3574-17 - Espumasclaudio5475100% (3)

- ASTM C 1185 Cement SheetDocumento9 pagineASTM C 1185 Cement SheetReshan VidurangaNessuna valutazione finora

- CH09 EOC QuestionsDocumento22 pagineCH09 EOC QuestionsSuresh ShahNessuna valutazione finora

- ASTM D2842 06 Water Absorption Test MethodDocumento10 pagineASTM D2842 06 Water Absorption Test MethodAnonymous BXmahb50% (1)

- ASTM D3574 11 - Standard Test Methods For Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamsDocumento29 pagineASTM D3574 11 - Standard Test Methods For Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamsAndre Spirim100% (1)

- Excel Tips Tricks e-BookV1.1 PDFDocumento20 pagineExcel Tips Tricks e-BookV1.1 PDFSulabhNessuna valutazione finora

- Features and ApplicationsDocumento36 pagineFeatures and ApplicationsFWEFWEFWNessuna valutazione finora

- Development of Novel Self-Healing Polymer Composites For UseDocumento34 pagineDevelopment of Novel Self-Healing Polymer Composites For UseTayyab AhsanNessuna valutazione finora

- ASTMMXDTest UFE1343Documento9 pagineASTMMXDTest UFE1343sahar vahdatifarNessuna valutazione finora

- Hydrostatic Pressure Resistance of Waterproofing Membranes: Standard Test Method ForDocumento3 pagineHydrostatic Pressure Resistance of Waterproofing Membranes: Standard Test Method ForSiddesh VinchurkarNessuna valutazione finora

- Mi 2008 1 en TT 1Documento3 pagineMi 2008 1 en TT 1john BustosNessuna valutazione finora

- Full Membrane SeparationDocumento11 pagineFull Membrane SeparationohdausNessuna valutazione finora

- Astm E595.2025241-1Documento9 pagineAstm E595.2025241-1jun floresNessuna valutazione finora

- C1560-Accelerated AgeingDocumento2 pagineC1560-Accelerated AgeingBrinder DhanoaNessuna valutazione finora

- Specific Gravity of Pigments: Standard Test Methods ForDocumento5 pagineSpecific Gravity of Pigments: Standard Test Methods ForFernando Berrospi GarayNessuna valutazione finora

- Nafion/PTFE Composite Membranes For Fuel Cell ApplicationsDocumento11 pagineNafion/PTFE Composite Membranes For Fuel Cell ApplicationsauliaNessuna valutazione finora

- Flexural Strength of Heat Polymerized PoDocumento4 pagineFlexural Strength of Heat Polymerized PoMorteza AtaeiNessuna valutazione finora

- Membrane Test UnitDocumento14 pagineMembrane Test UnitAzzian AriffinNessuna valutazione finora

- Ben Ameur 2014Documento11 pagineBen Ameur 2014ricardo.abejonNessuna valutazione finora

- Environmental Stress Crack Resistance of PEDocumento6 pagineEnvironmental Stress Crack Resistance of PEMohsin ShahNessuna valutazione finora

- E300 PDFDocumento24 pagineE300 PDFjfhl_12Nessuna valutazione finora

- Astn D 3681 - 01 PDFDocumento8 pagineAstn D 3681 - 01 PDFrajesh makwanaNessuna valutazione finora

- Astm D153Documento5 pagineAstm D153EngrWasiAhmadNessuna valutazione finora

- Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesDocumento4 pagineCompressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer ConcretesJesús Luis Arce GuillermoNessuna valutazione finora

- ASTM C-1306 - Standard Method For Hydrostatic Pressure Resistance of A Liquid-Applied Waterproofing Membrane PDFDocumento3 pagineASTM C-1306 - Standard Method For Hydrostatic Pressure Resistance of A Liquid-Applied Waterproofing Membrane PDFLeonardo Otto CoutinhoNessuna valutazione finora

- Abstract - The Membrane Separation TechniqueDocumento6 pagineAbstract - The Membrane Separation TechniqueROSMAZLYANA AZIA ROSLINessuna valutazione finora

- Cross Flow Filtration HandbookDocumento21 pagineCross Flow Filtration Handbooksahar vahdatifarNessuna valutazione finora

- D 3863 - 87 (2011)Documento3 pagineD 3863 - 87 (2011)mkaseem74Nessuna valutazione finora

- D 5117 - 96 - RduxmtctotyDocumento3 pagineD 5117 - 96 - RduxmtctotysusanaNessuna valutazione finora

- Selection of Healing Agents For A Vascular Self-Healing ApplicationDocumento9 pagineSelection of Healing Agents For A Vascular Self-Healing ApplicationviniciushsrNessuna valutazione finora

- Dresiani MaretiDocumento9 pagineDresiani MaretiSurya WijayaNessuna valutazione finora

- DialysisDocumento27 pagineDialysisalen19819072Nessuna valutazione finora

- Bucky PaperDocumento22 pagineBucky PaperShreyashkumar ZingadeNessuna valutazione finora

- Ineos Environmental Stress Crack Resistance of PeDocumento4 pagineIneos Environmental Stress Crack Resistance of PeDayanand SharmaNessuna valutazione finora

- Astm F3299.23586Documento4 pagineAstm F3299.23586Zohreh MosaferiNessuna valutazione finora

- Evaluating Hygrothermal Corrosion Resistance of Permanent Magnet AlloysDocumento5 pagineEvaluating Hygrothermal Corrosion Resistance of Permanent Magnet AlloysDanZel DanNessuna valutazione finora

- Astm d3574 17 EspumasDocumento30 pagineAstm d3574 17 EspumasJuan ManuelNessuna valutazione finora

- A Novel Use For Capillary Channel Fibers: Enhanced Engineered Tissue SystemsDocumento4 pagineA Novel Use For Capillary Channel Fibers: Enhanced Engineered Tissue Systemsdilan bro SLNessuna valutazione finora

- Spiral Flow of Low-Pressure Thermosetting Molding Compounds: Standard Test Method ForDocumento3 pagineSpiral Flow of Low-Pressure Thermosetting Molding Compounds: Standard Test Method ForHİLMİKISANessuna valutazione finora

- ASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamDocumento29 pagineASTM-3574-11 Flexible Cellular Materials-Slab, Bonded, and Molded Urethane FoamheobukonNessuna valutazione finora

- C 461 - 81 R03 QZQ2MQDocumento3 pagineC 461 - 81 R03 QZQ2MQM RNessuna valutazione finora

- D 5117 Â " 03 RDUXMTC - PDFDocumento3 pagineD 5117 Â " 03 RDUXMTC - PDFRCA_CONSULTORESNessuna valutazione finora

- Water Resistance: Rain TestDocumento2 pagineWater Resistance: Rain TestJackie Li100% (1)

- AbstractDocumento4 pagineAbstractRadhi AbdullahNessuna valutazione finora

- Condition Assessment Study On Stator Bars, After 40 Years of OperationDocumento4 pagineCondition Assessment Study On Stator Bars, After 40 Years of Operationnir205Nessuna valutazione finora

- Flextreme 20200710Documento13 pagineFlextreme 20200710suadNessuna valutazione finora

- AbstractDocumento15 pagineAbstractRadhi AbdullahNessuna valutazione finora

- Sampling and Testing Non-Asbestos Fiber-Cement Flat Sheet, Roofing and Siding Shingles, and ClapboardsDocumento9 pagineSampling and Testing Non-Asbestos Fiber-Cement Flat Sheet, Roofing and Siding Shingles, and Clapboardsnatoymahal188Nessuna valutazione finora

- C 302 - 95 - Qzmwmi05nqDocumento3 pagineC 302 - 95 - Qzmwmi05nqElvis Lionel FLORES ROCANessuna valutazione finora

- D 5641.-11 Prueba de Camara VacioDocumento4 pagineD 5641.-11 Prueba de Camara VacioSantiago GonzálezNessuna valutazione finora

- Contamination Outgassing Characteristics of Spacecraft MaterialsDocumento16 pagineContamination Outgassing Characteristics of Spacecraft Materialsjun floresNessuna valutazione finora

- D 2143 - 94 - RdixndmtotqDocumento3 pagineD 2143 - 94 - Rdixndmtotqjohn tanNessuna valutazione finora

- C 1819 - 15 PDFDocumento17 pagineC 1819 - 15 PDFConnieNessuna valutazione finora

- C1258 PDFDocumento2 pagineC1258 PDFsenthilNessuna valutazione finora

- Astm C1306Documento3 pagineAstm C1306fahadNessuna valutazione finora

- Crossflow Filtration: HandbookDocumento20 pagineCrossflow Filtration: HandbookAlgirdas BaranauskasNessuna valutazione finora

- D 2143 - 00 - Rdixndm - PDFDocumento3 pagineD 2143 - 00 - Rdixndm - PDFAndre CasteloNessuna valutazione finora

- F 148 - 95 - Rje0oc05nqDocumento2 pagineF 148 - 95 - Rje0oc05nqjamaljamal20Nessuna valutazione finora

- Final Tesile Testing ReportDocumento12 pagineFinal Tesile Testing Reportismael hashiNessuna valutazione finora

- F1216 PDFDocumento7 pagineF1216 PDFFengki AdaroNessuna valutazione finora

- Phys, Chem Tests For ITNs, Hole Enlargement ResistanceDocumento15 paginePhys, Chem Tests For ITNs, Hole Enlargement Resistancehoa nguyenNessuna valutazione finora

- Channels, Carriers, and Pumps: An Introduction to Membrane TransportDa EverandChannels, Carriers, and Pumps: An Introduction to Membrane TransportNessuna valutazione finora

- Modified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975Da EverandModified Polymers, Their Preparation and Properties: Main Lectures Presented at the Fourth Bratislava Conference on Polymers, Bratislava, Czechoslovakia, 1-4 July 1975A. RomanovValutazione: 5 su 5 stelle5/5 (1)

- EM Operationsmgt HR 13Documento20 pagineEM Operationsmgt HR 13Tayyab AhsanNessuna valutazione finora

- Fantastic Report On Document1: X'Pert Highscore Report PanalyticalDocumento7 pagineFantastic Report On Document1: X'Pert Highscore Report PanalyticalTayyab AhsanNessuna valutazione finora

- ADocumento69 pagineASilviaNessuna valutazione finora

- Surface Engineering & Characterization: Dr. Ahmed Umar Munawar Office 321 Ahmed - Munawar@scme - Nust.edu - PKDocumento19 pagineSurface Engineering & Characterization: Dr. Ahmed Umar Munawar Office 321 Ahmed - Munawar@scme - Nust.edu - PKTayyab AhsanNessuna valutazione finora

- Course: Materials Thermodynamics (MSE-811) Assignment: 01 Submitted By: M. Tayyab Ahsan Reg: 00000203393 Submitted To: DateDocumento1 paginaCourse: Materials Thermodynamics (MSE-811) Assignment: 01 Submitted By: M. Tayyab Ahsan Reg: 00000203393 Submitted To: DateTayyab AhsanNessuna valutazione finora

- Surface Engineering & Characterization: Dr. Ahmed Umar MunawarDocumento22 pagineSurface Engineering & Characterization: Dr. Ahmed Umar MunawarTayyab AhsanNessuna valutazione finora

- Course: Materials Thermodynamics (MSE-811) Assignment: 01 Submitted By: M. Tayyab Ahsan Reg: 00000203393 Submitted To: DateDocumento1 paginaCourse: Materials Thermodynamics (MSE-811) Assignment: 01 Submitted By: M. Tayyab Ahsan Reg: 00000203393 Submitted To: DateTayyab AhsanNessuna valutazione finora

- Probability and Stochastic Processes Quiz Solution ManualDocumento83 pagineProbability and Stochastic Processes Quiz Solution Manualsugianto_thoengNessuna valutazione finora

- Crevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedDocumento19 pagineCrevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedTayyab AhsanNessuna valutazione finora

- Ayesha Malik Nouman ZubairDocumento32 pagineAyesha Malik Nouman ZubairTayyab AhsanNessuna valutazione finora

- Crevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedDocumento19 pagineCrevice Corrosion: Present By: Mohsin Muhyuddin Haroon RasheedTayyab AhsanNessuna valutazione finora

- Steps in Mineral Processing: Lec 3, September 26, 2014Documento12 pagineSteps in Mineral Processing: Lec 3, September 26, 2014Tayyab AhsanNessuna valutazione finora

- 10-Lec Nov. 8, 2014 EMDocumento15 pagine10-Lec Nov. 8, 2014 EMTayyab AhsanNessuna valutazione finora

- Lecture 8 Testing of BiomaterialsDocumento23 pagineLecture 8 Testing of BiomaterialsTayyab AhsanNessuna valutazione finora

- Final Project InstructionsDocumento2 pagineFinal Project InstructionsTayyab AhsanNessuna valutazione finora

- KMDocumento4 pagineKMTayyab AhsanNessuna valutazione finora

- New Text DocumentDocumento1 paginaNew Text DocumentTayyab AhsanNessuna valutazione finora

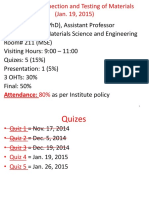

- Lec 1 W 15Documento14 pagineLec 1 W 15Tayyab AhsanNessuna valutazione finora

- Surfaces: - Mechanical ConceptDocumento8 pagineSurfaces: - Mechanical ConceptTayyab AhsanNessuna valutazione finora

- Intergranular Corrosion 05Documento32 pagineIntergranular Corrosion 05Tayyab Ahsan100% (1)

- MSE 332 Lec 1Documento30 pagineMSE 332 Lec 1Tayyab AhsanNessuna valutazione finora

- Lec. 3 3 March 2014 SEDocumento6 pagineLec. 3 3 March 2014 SETayyab AhsanNessuna valutazione finora

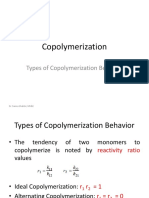

- Ionic Polymerization: Dr. Saima Shabbir, MS&EDocumento19 pagineIonic Polymerization: Dr. Saima Shabbir, MS&ETayyab AhsanNessuna valutazione finora

- Functionality Principle: Dr. Saima Shabbir, MS&EDocumento15 pagineFunctionality Principle: Dr. Saima Shabbir, MS&ETayyab AhsanNessuna valutazione finora

- Statistical Theory: Molecular Mass Distributions Step Growth PolymerizationDocumento21 pagineStatistical Theory: Molecular Mass Distributions Step Growth PolymerizationTayyab AhsanNessuna valutazione finora

- Polymers Lecture 24Documento16 paginePolymers Lecture 24Tayyab AhsanNessuna valutazione finora

- Polymers Lecture 9Documento18 paginePolymers Lecture 9Tayyab AhsanNessuna valutazione finora

- AVT 2217 Module 5 Aiport Lighting SystemDocumento15 pagineAVT 2217 Module 5 Aiport Lighting SystemJane PazNessuna valutazione finora

- VRV Heat Recovery REYQ-XDocumento20 pagineVRV Heat Recovery REYQ-XFrancisco LinaresNessuna valutazione finora

- Matrix Analysis of Networks: J. R. LucasDocumento63 pagineMatrix Analysis of Networks: J. R. LucasNethmini SamarawickramaNessuna valutazione finora

- BD Bactec Mgit 960 Mycobacteria Culture SystemDocumento6 pagineBD Bactec Mgit 960 Mycobacteria Culture SystemHuguens DesrosiersNessuna valutazione finora

- Welding SymbolDocumento8 pagineWelding SymbolMuhammad Cahya Adi PNessuna valutazione finora

- Accenture United Nations Global Compact IndexDocumento4 pagineAccenture United Nations Global Compact IndexBlasNessuna valutazione finora

- High Low MethodDocumento4 pagineHigh Low MethodSamreen LodhiNessuna valutazione finora

- Problem Set 1Documento2 pagineProblem Set 1Lovedeep SinghNessuna valutazione finora

- Technical Seminar Report CV94Documento62 pagineTechnical Seminar Report CV941MS19CV053 KARTHIK B SNessuna valutazione finora

- Simulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationDocumento5 pagineSimulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationMohd NafishNessuna valutazione finora

- Vichinsky Et Al.2019Documento11 pagineVichinsky Et Al.2019Kuliah Semester 4Nessuna valutazione finora

- Socio Economic Conditions of Migrant LabourDocumento7 pagineSocio Economic Conditions of Migrant LabourDR SEKHARNessuna valutazione finora

- Risk Management Q1Documento8 pagineRisk Management Q1Parth MuniNessuna valutazione finora

- Artikel Jurnal Siti Tsuwaibatul ADocumento11 pagineArtikel Jurnal Siti Tsuwaibatul Aaslamiyah1024Nessuna valutazione finora

- Skinner Reinforcement TodayDocumento6 pagineSkinner Reinforcement TodayEnrique Hernández RosasNessuna valutazione finora

- A4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Documento25 pagineA4v56hw1 0r0xxo1o-S R909410979 233 19 04 03Alonso TabordaNessuna valutazione finora

- Criteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysDocumento5 pagineCriteria For Use in Evaluation of Testing Laboratories and Organizations For Examination and Inspection of Steel, Stainless Steel, and Related AlloysProduction DepartmentNessuna valutazione finora

- V Packing SealDocumento10 pagineV Packing SealBobby ArbianugrohoNessuna valutazione finora

- X20PS9600-en V1.20Documento10 pagineX20PS9600-en V1.20PREVENCIONISTA HUAQUIANNessuna valutazione finora

- 82 - Engineering Mechanics Refresher SetDocumento6 pagine82 - Engineering Mechanics Refresher Setdevilene nayazakoNessuna valutazione finora

- Banksy Responses Done With A Partner 655512Documento122 pagineBanksy Responses Done With A Partner 655512api-569248887Nessuna valutazione finora

- Very High Frequency Omni-Directional Range: Alejandro Patt CarrionDocumento21 pagineVery High Frequency Omni-Directional Range: Alejandro Patt CarrionAlejandro PattNessuna valutazione finora

- 2020-21 Series Test 1 QPDocumento1 pagina2020-21 Series Test 1 QPred18ggmuNessuna valutazione finora

- Real-World Data Is Dirty: Data Cleansing and The Merge/Purge ProblemDocumento29 pagineReal-World Data Is Dirty: Data Cleansing and The Merge/Purge Problemapi-19731161Nessuna valutazione finora

- Psyc 1100 Research ExperimentDocumento10 paginePsyc 1100 Research Experimentapi-242343747Nessuna valutazione finora

- One Page Mistake ProofingDocumento1 paginaOne Page Mistake Proofingtuan mai vanNessuna valutazione finora

- Air Washer Test RigDocumento5 pagineAir Washer Test RigJagdish Singh MehtaNessuna valutazione finora