Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Key Performance Indicators

Caricato da

Fran JimenezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Key Performance Indicators

Caricato da

Fran JimenezCopyright:

Formati disponibili

ABB Basic Quality Tools Series

Key Performance Indicators

Identifying and using key metrics for performance

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 1

KPI - Content

What is it for?

Understand how KPIs are deployed as relevant local goals

Used to identify, measure and monitor the performance of key elements of the

process

KPIs are part of policy deployment

Where could I use it?

At the local level to monitor process outputs and performance against scorecard

As part of listening to the Voice of the Customer

To monitor shared goals and objectives

Alignment to the business objectives links to the Voice of the Business

How do I use it?

Questions to ask when choosing a KPI

Evaluating metrics

KPIs for a service process

CTQ tolerance limits

Process metric worksheet

Risks and how to avoid them

Use of existing data which may not be relevant

Cheating

Costs versus benefits of collecting data for the metrics

Examples

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 2

KPI - What is it for?

Uses of this tool:

KPIs are used to measure and monitor our performance against the characteristics which we

determine are critical for us to deliver our business plan

Used at different levels from long term objectives, through shared goals and down to local level

At local level we will often use the Voice of the Customer (VOC) to help identify our process metrics

Expected Benefits:

Gives alignment across the organisation when used in

conjunction with a longer term business plan

Provides clear focus for the policy deployment of this plan

Helps identify where there are shared goals and objectives

across all functions

More specifically, at a local level it is an essential tool in

monitoring and controlling our processes, and driving

improvement in the areas which will increase the satisfaction of

our customers

Clear and well defined KPIs will give us sound baselines from

which to continue to improve our performance

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 3

KPI- Where could I use it?

Background: Uses:

Key Performance Indicators (KPIs) are the Often used at a high level to identify the key

means by which we measure and monitor measures for the business to work on to achieve

our performance. longer term objectives VOB

A good KPI must reflect a characteristic Translates into shared goals and objectives

which is key to delivering success, and possibly at department or functional level

which will drive our behaviours and actions

to do so. Typically used at local level to assess our delivery

performance against the CTQ requirements by

KPIs are used at several levels in an using a Key Performance Indicator (KPI) a

organisation, from quantifying the vision process metric which is:

and long term plan, through the policy

deployment process which translates these Defined through the eyes of the customer

into relevant measures and targets at local How they would measure what good looks like

level against their needs

A fixed target with tolerance zones

The basis to assess process capability and to

implement process control

A process metric can describe performance at a

point in time; over a period of time; at a point in the

process; overall for a set of process steps

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 4

KPI - How do I use it?

Some questions to ask when selecting a KPI

Do we have existing measures in use within our business or process that can be

used?

If NO, then develop a measure and ask:

Does the measure match how the customer defines the process quality?

If performance changed, as reflected through the measure, would the customer

feel the impact?

Does the measure define success and failure?

Will it provide an insight into defect rates?

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 5

KPI - How do I use it?

Evaluating metrics

Criteria for evaluation of process metrics:

Importance: Are you measuring the things that really matter?

Ease: Does the measurement flow from the activity being monitored?

Actionable: Can the metric initiate appropriate actions?

Examples:

Effectiveness Efficiency

A measure of how well the

A measure of resource

process step meets or exceeds

utilisation in the process step

customer requirements

Defects Cost per transaction

Complaints Time per process step

Billing accuracy No. of staff per process step

One touch transactions Bill of materials per process step

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 6

KPI - How do I use it?

For a service process

KPIs are Based on Speed and Accuracy

SPEED ACCURACY

Decision / action cycle time Correctness and clarity

Response time Completeness and closure

Recovery time Fairness and consistency

Timelines met Knowledge of the service agent

No dead time Empathy of the service agent

Sustaining a balance of

Not necessarily delivered as fast as

thoroughness, efficiency and

possible but rather delivered

positive experience across all

consistently against expectations

encounters with the customer

held by or set for the customer.

On Time On Quality

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 7

KPI - How do I use it?

CTQ Tolerance Limits

Perceived Customer

Customer Requirement

Lower

In manufacturing, customer tolerance limits Value

USL

come from technical specifications

For services, tolerances are based on data

regarding customer needs and frustration levels LSL

as discovered through the Voice of the Customer Upper

-4 +1

Set limits at the point where customer

satisfaction begins to noticeably fall off Requirement

Delivery to Schedule (days)

This is driven by what the customer feels is

acceptable, not by what you think is

Delivery from 4

economically feasible

days early to 1 day

The limits around the CTQ become your late is OK for me.

target zone for consistent process

performance

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 8

KPI - Local Process Metric Worksheet

Metric Name Description How Measured Target & Limits

Safety

Quality

On Time

Delivery

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 9

KPIs - Risks and how to avoid them

Risks : Steps to avoid them :

Existing measures are used because they are available or This can result in the metrics being virtually useless

they will do. we have to measure what is relevant to the key

characteristic. Understanding the Voice of the Customer

and converting this to the CTQ are essential tasks.

Cheating. When a local metric can be made better at the

Have a balancing metric for the same process that will

expense of another metric, either locally or at the process

expose cheating on the primary metric. For example, if

customer

OTD is a primary metric, finished goods inventory is the

balancing metric.

Metrics are selected which may be perfect for the Take time to consider whether the metric really is

customer but which are difficult or expensive to collect important, easy to collect and actionable get the

and monitor balance right between the time and cost of collecting the

data against the benefit of the metric itself

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 10

Example: Local Process Measures

LV Motors Vsters Sweden

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 11

Example: Local KPIs used in a Kaizen

Reduce cost of material staging

Target of this Kaizen in a

receiving department was to

KPIs improve OTD and Efficiency.

Focus here is on Efficiency.

Notice the target: Reduce cost to

$34 (current costs are not stable:

$33 to $42 during last 6 months)

Notice the analysis of cost

breakdown.

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 12

KPI - Example: Objectives Link to Measures

ABB Drives New Berlin Wisconsin USA

Revenue

Orders

EBIT Safety

OCF Quality

Warranty

RM Inventory

Global FG Inventory

Efficiency

Objectives OTD

(Board of Directors Growth

EC - Division) People

Safety

Quality

LV Drive Efficiency

OTD

Objectives

(BU)

Shared

Goals & Measures

(LBU Operations)

Focused Factory

Goals & Measures

(Workstation Team)

ABB Group July 27, 2010 | Slide #

15 July 2010, Slide 13

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Fast Guide To Oee PDFDocumento27 pagineFast Guide To Oee PDFAtakan TunaliNessuna valutazione finora

- The Complete Guide to Simple OEE MeasurementDocumento26 pagineThe Complete Guide to Simple OEE MeasurementWan Sek Choon100% (2)

- Lubrication PDFDocumento123 pagineLubrication PDFFran JimenezNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Operational Excellence InsightsDocumento45 pagineOperational Excellence InsightsFran JimenezNessuna valutazione finora

- 8th Maintenance Forum Presentation FinalDocumento31 pagine8th Maintenance Forum Presentation FinalFran JimenezNessuna valutazione finora

- Introduction to TPM - Total Productive MaintenanceDocumento31 pagineIntroduction to TPM - Total Productive MaintenanceFran JimenezNessuna valutazione finora

- Customer Experience Journey MapDocumento1 paginaCustomer Experience Journey MapdiazortegaNessuna valutazione finora

- Ball Mill OptimizationDocumento7 pagineBall Mill OptimizationWael Fanous100% (1)

- El Rol Del Planeador de MantenimientoDocumento2 pagineEl Rol Del Planeador de MantenimientoFran JimenezNessuna valutazione finora

- (Materials Management - Logistics Series 12) John W. Toomey (Auth.) - Inventory Management - Principles, Concepts and Techniques-Springer US (2000)Documento226 pagine(Materials Management - Logistics Series 12) John W. Toomey (Auth.) - Inventory Management - Principles, Concepts and Techniques-Springer US (2000)Mehdi Poornikoo100% (1)

- ABB Reliability FingerprintDocumento17 pagineABB Reliability FingerprintFran JimenezNessuna valutazione finora

- OEMS OverviewDocumento20 pagineOEMS OverviewEn NdyNessuna valutazione finora

- Jidoka ToyotaDocumento20 pagineJidoka Toyotajesham124100% (1)

- Aligning HR & Business StrategyDocumento25 pagineAligning HR & Business StrategyAnwar RabiaNessuna valutazione finora

- Cement Grinding OptimizationDocumento9 pagineCement Grinding OptimizationFran JimenezNessuna valutazione finora

- Strategic Sourcing Process Rev3 SharedDocumento6 pagineStrategic Sourcing Process Rev3 Sharedloulou23Nessuna valutazione finora

- Cement Grinding OPtimizationDocumento13 pagineCement Grinding OPtimizationTgemunuNessuna valutazione finora

- Reliability and Maintenance (RAM) : The Path To World-Class PerformanceDocumento27 pagineReliability and Maintenance (RAM) : The Path To World-Class PerformanceFran JimenezNessuna valutazione finora

- Agile Requirements Management and Regulatory Compliance A Practical Live ApproachDocumento16 pagineAgile Requirements Management and Regulatory Compliance A Practical Live ApproachrajeevhrNessuna valutazione finora

- 7 How To Write A Report and Presentation v3Documento7 pagine7 How To Write A Report and Presentation v3Jeremiah HiiNessuna valutazione finora

- Maintenance Approaches For Different Production MethodsDocumento14 pagineMaintenance Approaches For Different Production MethodsGerardo MartinNessuna valutazione finora

- TPM ConceptDocumento18 pagineTPM ConceptFran JimenezNessuna valutazione finora

- The Next Generation of Internal Auditors The Fight For TalentDocumento38 pagineThe Next Generation of Internal Auditors The Fight For TalentFran JimenezNessuna valutazione finora

- Barriers in TPM Implementation in Industries PDFDocumento6 pagineBarriers in TPM Implementation in Industries PDFFran JimenezNessuna valutazione finora

- Learning by DoingDocumento39 pagineLearning by DoingFran JimenezNessuna valutazione finora

- Barriers in TPM Implementation in Industries PDFDocumento6 pagineBarriers in TPM Implementation in Industries PDFFran JimenezNessuna valutazione finora

- FMC Screw ConveyorsDocumento101 pagineFMC Screw ConveyorsOscar Alvitez DominguezNessuna valutazione finora

- CoalDocumento24 pagineCoalFran JimenezNessuna valutazione finora

- Troubleshooting Screw ConveyorDocumento5 pagineTroubleshooting Screw ConveyorFran JimenezNessuna valutazione finora

- 4 Phases of Reliability Centered LubricationDocumento4 pagine4 Phases of Reliability Centered LubricationFran JimenezNessuna valutazione finora

- Goodman Screw Conveyor PDFDocumento9 pagineGoodman Screw Conveyor PDFFran JimenezNessuna valutazione finora

- Article Cement Plant Modernization GCM 12-2016 2Documento4 pagineArticle Cement Plant Modernization GCM 12-2016 2Muhammad RomzuddinNessuna valutazione finora

- Texto MineriaDocumento6 pagineTexto MineriaNoir LagNessuna valutazione finora

- Cement Grinding Process SimulationDocumento13 pagineCement Grinding Process SimulationKalindaMadusankaDasanayakaNessuna valutazione finora

- CementDocumento4 pagineCementFran JimenezNessuna valutazione finora

- Process Groups: PMP® Process Chart Based On PMBOK® 6th EditionDocumento1 paginaProcess Groups: PMP® Process Chart Based On PMBOK® 6th EditionAbhishek PNessuna valutazione finora

- 3529205Documento4 pagine3529205HarishNessuna valutazione finora

- Polling MemoDocumento1 paginaPolling MemoJon RalstonNessuna valutazione finora

- Communication Audit Proposal - L BrandsDocumento8 pagineCommunication Audit Proposal - L Brandsapi-295563108100% (1)

- SCM and TQMDocumento15 pagineSCM and TQMDev BhargavaNessuna valutazione finora

- Learning To Evolve A Review of Contemporary Lean - Hines Holweg RichDocumento52 pagineLearning To Evolve A Review of Contemporary Lean - Hines Holweg Richalbchile100% (1)

- Mind Tree Future OutlookDocumento3 pagineMind Tree Future OutlookNilotpal MahantyNessuna valutazione finora

- ISO 9001 - 2008 RequirementDocumento9 pagineISO 9001 - 2008 RequirementNavnath TamhaneNessuna valutazione finora

- Chapter 1 Testbank Topic Grid: Garrison/Noreen/Brewer, Managerial Accounting, Twelfth Edition 1-1Documento2 pagineChapter 1 Testbank Topic Grid: Garrison/Noreen/Brewer, Managerial Accounting, Twelfth Edition 1-1Jane Michelle EmanNessuna valutazione finora

- PRESENTATION ON: - Supply Chain MangementDocumento16 paginePRESENTATION ON: - Supply Chain MangementSabah MemonNessuna valutazione finora

- Xynexis-Company ProfileDocumento20 pagineXynexis-Company ProfileAlexander AryaNessuna valutazione finora

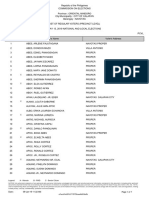

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsDocumento2 pagineCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsNessuna valutazione finora

- PLM SyllabusDocumento1 paginaPLM SyllabusGnaneswaran NarayananNessuna valutazione finora

- LG Electronics transforms global procurementDocumento4 pagineLG Electronics transforms global procurementPatricia DasecoNessuna valutazione finora

- BSBFIM501 Manage Budgets and Financial Plans: Learner GuideDocumento71 pagineBSBFIM501 Manage Budgets and Financial Plans: Learner GuideAshWin ShresthaNessuna valutazione finora

- Microsoft Operations Framework (v4.0) Foundation Workshop (3days)Documento2 pagineMicrosoft Operations Framework (v4.0) Foundation Workshop (3days)Prasetyo BawonoNessuna valutazione finora

- Competency Mapping - A Strategic Approach in Talent ManagementDocumento20 pagineCompetency Mapping - A Strategic Approach in Talent ManagementAnonymous 0zM5ZzZXCNessuna valutazione finora

- Navotas DecDocumento23 pagineNavotas DecAngelika CalingasanNessuna valutazione finora

- 10 Rockefeller Habits - BriefDocumento4 pagine10 Rockefeller Habits - BriefMeetu SharmaNessuna valutazione finora

- Ch06 The Production ProcessDocumento75 pagineCh06 The Production ProcessTommyutomowijaya0% (1)

- MACRON EXPRESS SERVICES PVT.LTD. Salary SlipsDocumento15 pagineMACRON EXPRESS SERVICES PVT.LTD. Salary SlipsDS Ghatkopar EastNessuna valutazione finora

- ObservationDocumento7 pagineObservationJaymark BombitaNessuna valutazione finora

- AcknowledgementDocumento14 pagineAcknowledgementaishwariyaraviNessuna valutazione finora

- Organizational Structure IB EgyptDocumento6 pagineOrganizational Structure IB EgyptyaduthattilNessuna valutazione finora