Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Reaction Separation System

Caricato da

ack0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginarEACTION SEPERATION SYSTEM

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentorEACTION SEPERATION SYSTEM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

9 visualizzazioni1 paginaReaction Separation System

Caricato da

ackrEACTION SEPERATION SYSTEM

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

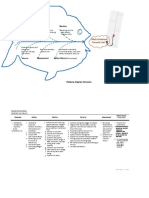

Reaction Separation System

FBMR is an alternative to the current steam reforming

technologies .

Porous Stainless steel Current technologies faces a number of constraints the

Palladium Membrane

main being the requirement of high exit temperatures

Catalyst Bed due to the Thermodynamics.

The system is constructed using two concentric tubes

where the external layer is made of stainless steel while

the inner layer is made up of Palladium based

Fig 1: Cross Sectional Area of the

membrane.

membrane reactor

Palladium membrane was selected because hydrogen gas

can permeate it.

The catalyst is placed in the annular space between the

tubes.

Steam, Methane gas and N2 is added to the area where

the catalyst is placed which is the annular space between

the two tubes.

Effects of Pressure on the performance of the membrane Its job is to combine chemical reaction and hydrogen

Pressure generally increases the conversion and rate of reaction separation in only one system reducing capital costs.

A range of optimum pressure have to be used to avoid the rupturing of the

membrane

A study have shown after other variables have been fixed and pressure is

varied from between 2 bar to 10 bar ,as the operating pressure or the pressure

of the feed was increased, the H2 mole fraction in the retentate decreases

implying H2 removal (Rui Ma et al. , 2016)

Potrebbero piacerti anche

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionDa EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNessuna valutazione finora

- BK g4 Gas Meter ManualDocumento2 pagineBK g4 Gas Meter ManualSaulat LoneNessuna valutazione finora

- Overlay Reduce Tube Erosion & Corr BTA-BR-0001Documento4 pagineOverlay Reduce Tube Erosion & Corr BTA-BR-0001Anonymous nw5AXJqjdNessuna valutazione finora

- 6-H2-AMP Workshop-PSUDocumento25 pagine6-H2-AMP Workshop-PSUAlaa FaidNessuna valutazione finora

- SSW - April 2020 - Lowres Pages 42 45 PDFDocumento4 pagineSSW - April 2020 - Lowres Pages 42 45 PDFBaher ElsheikhNessuna valutazione finora

- Introduction To Thin Film TechnologyDocumento43 pagineIntroduction To Thin Film TechnologyZiad Mohmed Fawzy100% (1)

- PDF Ca Repromat e 7 2012.en.40Documento4 paginePDF Ca Repromat e 7 2012.en.40Henry SunarkoNessuna valutazione finora

- Class 6 - 19th AugustDocumento50 pagineClass 6 - 19th AugustAADESH GUPTANessuna valutazione finora

- Rocket PropulsionDocumento7 pagineRocket PropulsionHARSHEEN KOURNessuna valutazione finora

- Kourosh KhosravianiDocumento1 paginaKourosh KhosravianiAng LiNessuna valutazione finora

- Paolo Martini: Antofagasta, Chile 6 Oct. 2009Documento29 paginePaolo Martini: Antofagasta, Chile 6 Oct. 2009Muhammad SaadullahNessuna valutazione finora

- Module 4 (Design of Separation Columns)Documento25 pagineModule 4 (Design of Separation Columns)esiri aluyaNessuna valutazione finora

- Flixborough Disaster Material Presentation EditDocumento12 pagineFlixborough Disaster Material Presentation EditmiexaraNessuna valutazione finora

- Autochem2920 Brochure 2017 - 2Documento5 pagineAutochem2920 Brochure 2017 - 2bau.bau.bau.bauuNessuna valutazione finora

- Hydro Tal CitesDocumento1 paginaHydro Tal CitesMohamed EL AmineNessuna valutazione finora

- Autochem 2950 HP - BrochureDocumento8 pagineAutochem 2950 HP - Brochurerestor3dNessuna valutazione finora

- Case Study - Candu - EN - WebDocumento3 pagineCase Study - Candu - EN - WebedavidNessuna valutazione finora

- UPS12-280MRX: Valve Regulated Lead Acid BatteryDocumento2 pagineUPS12-280MRX: Valve Regulated Lead Acid BatteryCristopher JayloNessuna valutazione finora

- "Refractory - Is It Working For You?": Cliff KnightDocumento1 pagina"Refractory - Is It Working For You?": Cliff KnightzalzizaNessuna valutazione finora

- WESP - Wet Electrostatic Precipitator®: Engineered To Protect Our EnvironmentDocumento3 pagineWESP - Wet Electrostatic Precipitator®: Engineered To Protect Our Environmentnurul ismiNessuna valutazione finora

- CERAPEM MembranesDocumento27 pagineCERAPEM MembranesshadyghanemNessuna valutazione finora

- UPS12-280R MRX: Valve Regulated Lead Acid BatteryDocumento2 pagineUPS12-280R MRX: Valve Regulated Lead Acid BatteryMuneer AhamedNessuna valutazione finora

- 4 - Ore Reduction Technology Madelein Todd PDFDocumento17 pagine4 - Ore Reduction Technology Madelein Todd PDFThe GantengNessuna valutazione finora

- Article CoolingIndia May 2012Documento5 pagineArticle CoolingIndia May 2012Ganesh PMNessuna valutazione finora

- Engine Emissions: MTCS5012, Advanced Vehicle and Engine Management System Week 12Documento21 pagineEngine Emissions: MTCS5012, Advanced Vehicle and Engine Management System Week 12Fateh SyedNessuna valutazione finora

- Emitterline Lime en LeachingDocumento2 pagineEmitterline Lime en LeachingvictorNessuna valutazione finora

- Proteção CatódicaDocumento5 pagineProteção CatódicaCarlos SandinoNessuna valutazione finora

- ML ACR Class 1 Pressure BoundaryDocumento24 pagineML ACR Class 1 Pressure BoundarySiddhartha GaubaNessuna valutazione finora

- Selected Design and Development of Vacuum ChamberDocumento3 pagineSelected Design and Development of Vacuum Chamberpatel_saunak7470Nessuna valutazione finora

- GinoEse PDFDocumento98 pagineGinoEse PDFAnonymous Jcr1ES8QYuNessuna valutazione finora

- Bateria UPSs PLP Catalog 0520Documento8 pagineBateria UPSs PLP Catalog 0520Rubenik Lima de SouzaNessuna valutazione finora

- SBS Performance SpecificationsDocumento6 pagineSBS Performance SpecificationsAhmed ZeharaNessuna valutazione finora

- Fyp 1Documento26 pagineFyp 1Taha RahatNessuna valutazione finora

- Flame HardeningDocumento2 pagineFlame Hardenings_manikandanNessuna valutazione finora

- Battery Performance Specifications: Telecommunications Nebs CompliantDocumento6 pagineBattery Performance Specifications: Telecommunications Nebs Compliantlucien altidorNessuna valutazione finora

- Petrolume® Series: Hazardous LocationsDocumento4 paginePetrolume® Series: Hazardous LocationsAnonymous v4akjrQxKNessuna valutazione finora

- Membrane Reactor by Shivani MunishwarDocumento32 pagineMembrane Reactor by Shivani MunishwarShivani MunishwarNessuna valutazione finora

- UPS12-600MRX: Valve Regulated Lead Acid BatteryDocumento2 pagineUPS12-600MRX: Valve Regulated Lead Acid BatteryAbdulrahim khanNessuna valutazione finora

- Plasma Arc Machining - Lect 2Documento17 paginePlasma Arc Machining - Lect 2sachhpNessuna valutazione finora

- Catlog Joints Up To 1 KV XLPEDocumento4 pagineCatlog Joints Up To 1 KV XLPEbalraz_cudNessuna valutazione finora

- Outline: Optimum Spray Cooling in Continuous Slab Casting Process Under Productivity ImprovementDocumento5 pagineOutline: Optimum Spray Cooling in Continuous Slab Casting Process Under Productivity ImprovementKiatkajohn WorapradyaNessuna valutazione finora

- Spontaneous and Stimulated EmissionsDocumento17 pagineSpontaneous and Stimulated EmissionsDeepak KumarNessuna valutazione finora

- Cleaning Heater Convection Tubes PDFDocumento5 pagineCleaning Heater Convection Tubes PDFbakhtiari_afNessuna valutazione finora

- Insulation Systems For Refrigerant Piping: Insulation Properties at Below-Ambient TemperaturesDocumento11 pagineInsulation Systems For Refrigerant Piping: Insulation Properties at Below-Ambient TemperaturesFlorin OnucNessuna valutazione finora

- 2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICDocumento35 pagine2013 Serrafero Saipem Asian NandS OmegaBond Tubing Technology at GPICHummel Johnson0% (1)

- EagleBurgmann - E07111 - E1 - Mechanical Seal H75VN in Cumene Pump Station - 11.10Documento1 paginaEagleBurgmann - E07111 - E1 - Mechanical Seal H75VN in Cumene Pump Station - 11.10lendiaNessuna valutazione finora

- Circuit Breaker-2Documento37 pagineCircuit Breaker-2Ankan Roy AnkanNessuna valutazione finora

- pd022 Rawls 2015 oDocumento19 paginepd022 Rawls 2015 oJoão CarlosNessuna valutazione finora

- In Focus Pipe Wraps BelzonaDocumento4 pagineIn Focus Pipe Wraps BelzonaAhmed ELmlahyNessuna valutazione finora

- Group Project-BDocumento1 paginaGroup Project-BthibebongtranNessuna valutazione finora

- 6M - RCA Cond Vac DerationDocumento2 pagine6M - RCA Cond Vac DerationInja Victoria ManawataoNessuna valutazione finora

- Biomass Gas I Fiers by IISCDocumento6 pagineBiomass Gas I Fiers by IISCHimanshu1712Nessuna valutazione finora

- Oil Leakage From BushingDocumento1 paginaOil Leakage From BushingAshish BiswasNessuna valutazione finora

- Air-Core Neutral Grounding ReactorsDocumento2 pagineAir-Core Neutral Grounding ReactorsharpreetNessuna valutazione finora

- Morgan Carbon Bearings: Application DataDocumento10 pagineMorgan Carbon Bearings: Application Datamado reouNessuna valutazione finora

- Teknologi Film Tipis: MikroelektronikaDocumento31 pagineTeknologi Film Tipis: Mikroelektronika21Rivaldus LonggesNessuna valutazione finora

- Aluminium Transformer Vs Copper Transformer:: A Technical and Economic ComparisonDocumento4 pagineAluminium Transformer Vs Copper Transformer:: A Technical and Economic ComparisonAyoub CherkaouiNessuna valutazione finora

- Nuclear Fissionfusion 12Documento1 paginaNuclear Fissionfusion 12kurac123Nessuna valutazione finora

- Stealth Coating For AerospaceDocumento25 pagineStealth Coating For Aerospacerohankumar.6143Nessuna valutazione finora

- Semantan FMDocumento8 pagineSemantan FMackNessuna valutazione finora

- TOC Vs UV-VisDocumento10 pagineTOC Vs UV-VisackNessuna valutazione finora

- Black Shales PDFDocumento9 pagineBlack Shales PDFackNessuna valutazione finora

- 01 Full ChaptDocumento56 pagine01 Full ChaptLewis PattenNessuna valutazione finora

- Black Shales PDFDocumento9 pagineBlack Shales PDFackNessuna valutazione finora

- The 10 Deep Learning Methods AI Practitioners Need To ApplyDocumento19 pagineThe 10 Deep Learning Methods AI Practitioners Need To ApplyackNessuna valutazione finora

- Biot Theory (Almost) For Dummies-Patzek - Oral PDFDocumento32 pagineBiot Theory (Almost) For Dummies-Patzek - Oral PDFNima DaneshNessuna valutazione finora

- Bjorum - New Coring TechnhnologyDocumento20 pagineBjorum - New Coring TechnhnologyackNessuna valutazione finora

- Chapter 03 W5 L1 Discrete Prob Dist - Bin and Poisson 2015 UTP C2Documento13 pagineChapter 03 W5 L1 Discrete Prob Dist - Bin and Poisson 2015 UTP C2ackNessuna valutazione finora

- Chapter 04 W6 L1 Cont Prob Dist - Exp and STD Normal 2015 UTP C3 PDFDocumento14 pagineChapter 04 W6 L1 Cont Prob Dist - Exp and STD Normal 2015 UTP C3 PDFEvan ChinNessuna valutazione finora

- Workplace SafetyDocumento1 paginaWorkplace SafetyackNessuna valutazione finora

- Chapter 05 W7 L2 L3 Statistical Process Control 2015 UTP C5Documento17 pagineChapter 05 W7 L2 L3 Statistical Process Control 2015 UTP C5ackNessuna valutazione finora

- Chapter 04 W6 L2 Cont Prob Dist - Non STD Normal and Others 2015Documento12 pagineChapter 04 W6 L2 Cont Prob Dist - Non STD Normal and Others 2015ackNessuna valutazione finora

- Chapter 03 W4 L2 Continuos Random Variable 2015 UTP C3Documento8 pagineChapter 03 W4 L2 Continuos Random Variable 2015 UTP C3ackNessuna valutazione finora

- USGS Wentworth Grain Size ChartDocumento1 paginaUSGS Wentworth Grain Size Chartetchplain100% (1)

- Chapter 04 W6 L1 Cont Prob Dist - Exp and STD Normal 2015 UTP C3 PDFDocumento14 pagineChapter 04 W6 L1 Cont Prob Dist - Exp and STD Normal 2015 UTP C3 PDFEvan ChinNessuna valutazione finora

- Chapter 10 w13 w14 l1 l2 Doe and Anova 2015 c10Documento22 pagineChapter 10 w13 w14 l1 l2 Doe and Anova 2015 c10ackNessuna valutazione finora

- Chapter 01 Probability L1 2015Documento10 pagineChapter 01 Probability L1 2015Hairi YusriNessuna valutazione finora

- Lab 1pH DeterminationDocumento2 pagineLab 1pH DeterminationackNessuna valutazione finora

- Chapter 06 W9 L6 L7 Hypoyhesis Testing C6Documento17 pagineChapter 06 W9 L6 L7 Hypoyhesis Testing C6ackNessuna valutazione finora

- Formula CardDocumento8 pagineFormula Carddoodoo999Nessuna valutazione finora

- Clastic Sedimentology Aeolian Depositional Environment May 2016 1Documento38 pagineClastic Sedimentology Aeolian Depositional Environment May 2016 1ack100% (1)

- Bulk ModulusDocumento4 pagineBulk ModulusBruna MacedoNessuna valutazione finora

- Basics of Geothermal Energy Production and UseDocumento55 pagineBasics of Geothermal Energy Production and UseBruno Andrade Freitas FalcãoNessuna valutazione finora

- Boiler DraughtDocumento4 pagineBoiler Draughtshivrant shivrant0% (1)

- Antiprex® CEN Chelating AgentDocumento1 paginaAntiprex® CEN Chelating AgentxerxeshakaNessuna valutazione finora

- Pranav 1Documento14 paginePranav 1DesignNessuna valutazione finora

- List of Approved OLR Antimicrobials For PoultryDocumento33 pagineList of Approved OLR Antimicrobials For PoultryVo Long ThuanNessuna valutazione finora

- N 15862Documento12 pagineN 15862Saleem BaigNessuna valutazione finora

- Tutorial Chapter 02 - AnswerDocumento8 pagineTutorial Chapter 02 - AnswerFateh Hakeem100% (4)

- E FT 6Documento1 paginaE FT 6Phil YianNessuna valutazione finora

- Yarde Metals Shapes CatalogDocumento493 pagineYarde Metals Shapes Catalogdncz69Nessuna valutazione finora

- 01 Samss 048 PDFDocumento21 pagine01 Samss 048 PDFMohamed SolimanNessuna valutazione finora

- 500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGDocumento7 pagine500kW BG Specs - Patruus IL6 TWIN PACK Biogas - 2 X 250 BGbinstartedNessuna valutazione finora

- BITZER Output Data: Created On: 16/05/2017 16:44:22Documento5 pagineBITZER Output Data: Created On: 16/05/2017 16:44:22Hasan Syaiful INessuna valutazione finora

- Manufacturing Process of Carbon BlackDocumento2 pagineManufacturing Process of Carbon Blackreska100% (1)

- Hook Pallet Capacity CalculationDocumento2 pagineHook Pallet Capacity CalculationrustamriyadiNessuna valutazione finora

- Paschen's LawDocumento6 paginePaschen's LawKhan YousafzaiNessuna valutazione finora

- Hall Sensors Selection GuideDocumento2 pagineHall Sensors Selection GuideMiltongrimi GrimilNessuna valutazione finora

- KTC-KTCG Series ManualDocumento20 pagineKTC-KTCG Series ManualWheat State welding LLC Jeremy100% (1)

- EZ Clean 1500Documento4 pagineEZ Clean 1500sebasalinashjNessuna valutazione finora

- Extra High Voltage XLPE Cables: LntrodllctiollDocumento3 pagineExtra High Voltage XLPE Cables: LntrodllctiollNika ThaiNessuna valutazione finora

- Rheovis As 1920Documento2 pagineRheovis As 1920Victor LopezNessuna valutazione finora

- An Introduction To Centrifugal PumpsDocumento3 pagineAn Introduction To Centrifugal PumpsCaiyun LimNessuna valutazione finora

- Envicool Cabinet Air Conditioner Service ManualDocumento22 pagineEnvicool Cabinet Air Conditioner Service ManualCONSORCIO TECA 2019100% (2)

- Marine BoilerDocumento30 pagineMarine BoilerCarloNessuna valutazione finora

- Chapter 2 IntroductionDocumento7 pagineChapter 2 IntroductionJoseph Allan100% (1)

- Sample Problem #1Documento7 pagineSample Problem #1DozdiNessuna valutazione finora

- Supra 644, 744, 844 Beginning With Serial# Hfy90593608 - Sunbelt ...Documento68 pagineSupra 644, 744, 844 Beginning With Serial# Hfy90593608 - Sunbelt ...Glacial100% (1)

- Documents - MX - Fisher Desuperheaters Bulletin April 2008 PDFDocumento12 pagineDocuments - MX - Fisher Desuperheaters Bulletin April 2008 PDFsaji_t1984Nessuna valutazione finora

- Chapter 1 Technology and DevelopmentDocumento46 pagineChapter 1 Technology and DevelopmentKeep ThrowNessuna valutazione finora

- Changshu Walsin Specialty Steel Co., LTD: Company ProfileDocumento1 paginaChangshu Walsin Specialty Steel Co., LTD: Company ProfileHarish KrishnamoorthyNessuna valutazione finora

- Sample Leak Testing Report For Ast TankDocumento1 paginaSample Leak Testing Report For Ast TankArimoro Cyril Obuse43% (7)

- 3 Types of Traffic Count: 3.1 Manual CountsDocumento3 pagine3 Types of Traffic Count: 3.1 Manual CountsRichard BryanNessuna valutazione finora