Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heat Pump (Utility)

Caricato da

Bilal ZafarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heat Pump (Utility)

Caricato da

Bilal ZafarCopyright:

Formati disponibili

HEAT PUMP(UTILITY)

SENSITIVITY ANALYSIS

Pressure drop vs Tube internal diameter

350

300 301 293

Pressure drop (kpa)

250

200

179

150 151

126

100

50

0

12 12.5 13 13.5 14 14.5 15

Tube Internal diameter (10^3m)

Pressure drop vs Flow rate

500

472

450

Pressure drop(kpa)

400

350

316

300

250

200

179

150

100 96

50

27

0

0 5 10 15 20 25 30

Flow rate (^3/)

MATERIAL & ENERGY BALANCE

Crude glycerol

Helium Flow-rate Energy used in Energy used in Heat

Production Supplied in Energy used in Energy used in

in Heat Pump evaporator Exchanger (kj/hr)

Rate Feed Stream Compressor (kJ/hr) Expander (kJ/hr)

(kg/hr) (kj/hr)

(kg/hr)

High Production 2030244 32349913

20100 10000 44514368 14223770

(100% )

Mean

1624195 25879930

Production 16080 8000 35611494 11379016

(80%)

Low Production 1218146 19409948

12060 6000 26708621 8534262

(60%)

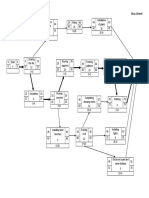

Equipment Control Selection

Auxiliary Equipment

Thermocouple

Transmitter

Valves

Piping

Primary parameters that are Piping sizes

considered before making a choice

of piping size and material to be Identity of the Thickness of the

used: pipe pipe (inch)

Design pressure 0-5 0.0235

Diameter of the pipe

1 0.0177

Mechanical corrosion

Allowable stress 2 0.154

3 0.103

Feed 0.0015

Output 0.0178

Construction material for the major

parts of heat exchanger

Tube: Stainless steel (304)

Shell: Stainless steel (304)

Baffles: Stainless steel (304)

Rear header: Stainless steel (304)

Heat exchanger design

Dimensions

Parameters Size Unit

Heat Transfer Area 108 2

Cross sectional Area of the 0.293 2

tube

Outer diameter of shell 0.960 m

Length of the head 20.7 m

Nozzle internal diameter 0.947 m

Height of the baffle 0.0757 m

Total no of tubes required for 369

heat

Cross sectional 3D drawing

Engineering Drawing

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- HU - Century Station - PAL517PDocumento232 pagineHU - Century Station - PAL517PTony Monaghan100% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Industrial Machine and ControlsDocumento31 pagineIndustrial Machine and ControlsCarol Soi100% (4)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- MV Lec PDFDocumento102 pagineMV Lec PDFJonas Datu100% (1)

- Swot AnalysisDocumento6 pagineSwot AnalysisBilal Zafar100% (1)

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaDocumento8 pagineUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaNessuna valutazione finora

- Ch06 Allocating Resources To The ProjectDocumento55 pagineCh06 Allocating Resources To The ProjectJosh ChamaNessuna valutazione finora

- Tetra IntroductionDocumento65 pagineTetra Introductionuniversidaddistrital100% (2)

- Process Strategy: Powerpoint Slides by Jeff HeylDocumento13 pagineProcess Strategy: Powerpoint Slides by Jeff HeylMuizzNessuna valutazione finora

- Assignment 1 Group 12Documento59 pagineAssignment 1 Group 12Bilal ZafarNessuna valutazione finora

- SampleDocumento9 pagineSampleBilal ZafarNessuna valutazione finora

- Finding The Volume For These StructuresDocumento2 pagineFinding The Volume For These StructuresBilal ZafarNessuna valutazione finora

- Acetone Parameters Drum 1: Xy DiagramDocumento6 pagineAcetone Parameters Drum 1: Xy DiagramBilal ZafarNessuna valutazione finora

- Txy Diagram For Mixture of D and E: Total Pressure (MM HG) : Antoine Coefficients For Acetone (D)Documento12 pagineTxy Diagram For Mixture of D and E: Total Pressure (MM HG) : Antoine Coefficients For Acetone (D)Bilal ZafarNessuna valutazione finora

- Muhmmad Bilal ZafarDocumento2 pagineMuhmmad Bilal ZafarBilal ZafarNessuna valutazione finora

- Ps7 SolutionsdvdDocumento14 paginePs7 SolutionsdvdBilal ZafarNessuna valutazione finora

- Lab Rules and RegulatigyiiygonsDocumento6 pagineLab Rules and RegulatigyiiygonsBilal ZafarNessuna valutazione finora

- Fmicb 10 02876Documento11 pagineFmicb 10 02876Angeles SuarezNessuna valutazione finora

- Lesson Plan SustainabilityDocumento5 pagineLesson Plan Sustainabilityapi-501066857Nessuna valutazione finora

- Schneider Contactors DatasheetDocumento130 pagineSchneider Contactors DatasheetVishal JainNessuna valutazione finora

- Formal Letter LPDocumento2 pagineFormal Letter LPLow Eng Han100% (1)

- Dissertation 7 HeraldDocumento3 pagineDissertation 7 HeraldNaison Shingirai PfavayiNessuna valutazione finora

- Part Time Civil SyllabusDocumento67 paginePart Time Civil SyllabusEr Govind Singh ChauhanNessuna valutazione finora

- Rubric For Aet570 BenchmarkDocumento4 pagineRubric For Aet570 Benchmarkapi-255765082Nessuna valutazione finora

- BS en Iso 06509-1995 (2000)Documento10 pagineBS en Iso 06509-1995 (2000)vewigop197Nessuna valutazione finora

- HemoptysisDocumento30 pagineHemoptysisMarshall ThompsonNessuna valutazione finora

- Buildingawinningsalesforce WP DdiDocumento14 pagineBuildingawinningsalesforce WP DdiMawaheb ContractingNessuna valutazione finora

- Audi R8 Advert Analysis by Masum Ahmed 10PDocumento2 pagineAudi R8 Advert Analysis by Masum Ahmed 10PMasum95Nessuna valutazione finora

- Paramount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceDocumento1 paginaParamount Healthcare Management Private Limited: First Reminder Letter Without PrejudiceSwapnil TiwariNessuna valutazione finora

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Documento3 pagineTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngNessuna valutazione finora

- Specialty Coffee Association of Indonesia Cupping Form (ARABICA)Documento1 paginaSpecialty Coffee Association of Indonesia Cupping Form (ARABICA)Saiffullah RaisNessuna valutazione finora

- Meniere's Disease - Retinal Detatchment - GlaucomaDocumento3 pagineMeniere's Disease - Retinal Detatchment - Glaucomaybet03Nessuna valutazione finora

- Baxter - Heraeus Megafuge 1,2 - User ManualDocumento13 pagineBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliNessuna valutazione finora

- Hetal Patel: Team Leader - SalesDocumento2 pagineHetal Patel: Team Leader - SalesPrashant kumarNessuna valutazione finora

- AcousticsDocumento122 pagineAcousticsEclipse YuNessuna valutazione finora

- P. E. and Health ReportDocumento20 pagineP. E. and Health ReportLESSLY ABRENCILLONessuna valutazione finora

- NGCP EstimatesDocumento19 pagineNGCP EstimatesAggasid ArnelNessuna valutazione finora

- Specification Sheet: Case I Case Ii Operating ConditionsDocumento1 paginaSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarNessuna valutazione finora

- Manual: Functional SafetyDocumento24 pagineManual: Functional SafetymhaioocNessuna valutazione finora