Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2a62001d-b2fe-406f-bc4c-597c53a23a00

Caricato da

Jhonny TorralbaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2a62001d-b2fe-406f-bc4c-597c53a23a00

Caricato da

Jhonny TorralbaCopyright:

Formati disponibili

An Introduction to Vehicle

Networks, Scan Tools, and

Multiplexing

Presented by: Paul

Baltusis

Powertrain Control System

Engineering

Diagnostic Systems

Department

OBD-II Technical

Specialist

September 28, 2002 Revised: September 28,

Page 1

2002

In-Vehicle Networks

In-vehicle networking, also known as

multiplexing, is a method for

transferring data between electronic

modules via a serial data bus.

September 28, 2002 Page 2

Benefits of Networking

Eliminates redundant sensors and dedicated

wires for each function (lower cost, lower

weight, better reliability)

Reduces number of wires and connectors

(lower cost, lower weight, better reliability,

easier-to-package wiring harness)

Allows more features and more flexibility

(modules share data, more flexible design

and vehicle option content)

Allows adding features via software

upgrades

September 28, 2002 Page 3

Benefits of Networking

September 28, 2002 Page 4

Networking Methods

Class A Generic UART (Universal

Asynchronous Receiver/Transmitter) or

other custom low speed device < 10

Kbps.

Class B Medium speed, for example

J1850, between 10 Kbps and 125 Kbps

(Ford DCL and SCP, GM Class 2)

Class C High Speed, for example CAN

2.0, between 125 Kbps and 1,000 Kbps

(Controller Area Network)

September 28, 2002 Page 5

OBD Communication Protocols

OBD-II and EOBD regulations define the

communication protocols that can be

used for diagnostics.

The intent was to reduce the

proliferation of manufacturer-specific

protocols used for diagnostics.

This would lead to more generic, less

expensive scan tools.

September 28, 2002 Page 6

OBD Communication Protocols

ISO 9141-2 (K-Line)

ISO 14230-4 (Keyword Protocol 2000)

J1850 41.6 Kbps Pulse Width Modulated

J1850 10.4 Kbps Variable Pulse Width

J2284/ISO 15765-4 (CAN)

September 28, 2002 Page 7

OBD Communication Protocols

Only one OBD-compliant link may be

brought out to the J1962 Data Link

Connector

OBD-II allows only 500 kbps CAN, EOBD

allows 250 and 500 kbps.

CARB will force all manufacturers to use

CAN for the 2008 MY

J2534 (pass through reprogramming)

must use a generic OBD link.

September 28, 2002 Page 8

Controller Area Network

CAN is a network protocol used to

interconnect a network of electronic

control modules or nodes.

Typically, a two wire, twisted pair cable

is used.

CAN has a stringent set of rules,

implemented in the CAN chip, that

supports the serial transfer of

information between two or more nodes.

September 28, 2002 Page 9

CAN Network

Where does CAN fit in the range of

networks?

Networks are usually based on size:

WAN Wide Area Network (Internet)

LAN Local Area Network (Ethernet)

SAN Small Area Network (CAN)

September 28, 2002 Page 10

CAN

CARB allows the use of CAN for 2003 MY

and beyond vehicles.

EOBD allows the use of CAN for 2001 CY

and beyond vehicles.

Some US manufacturers are planning to

start using CAN starting on some

vehicles in the 2003 MY.

CARB requires the use of CAN on all

vehicles for the 2008 MY and beyond.

September 28, 2002 Page 11

CAN

CAN messages have a specified structure

that is specified in CAN standards.

CAN networks have rules (bitwise

arbitration) for dealing with colliding

messages when two modules start

transmitting messages at the same time.

There are two formats for addressing

11 bit and 29 bit identifiers. 11-bit has a

2032 message limit, 29-bit allows for

millions of distinct messages.

September 28, 2002 Page 12

CAN Basic Message Structure

September 28, 2002 Page 13

CAN Message Arbitration

September 28, 2002 Page 14

J1850 41.6 PWM

J1850 41.6 PWM is used by Ford. Ford

internally calls this protocol Standard

Corporate Protocol (SCP)

SCP is a true network protocol that

incorporates bus arbitration.

SCP is used for both vehicle network

communication and diagnostic

communication.

September 28, 2002 Page 15

J1850 10.4 VPW

J1850 10.4 VPW is used by General

Motors. GM internally calls this protocol

Class 2.

Class 2 is a true network protocol that

incorporates bus arbitration.

Class 2 is used for both vehicle network

communication and diagnostic

communication.

September 28, 2002 Page 16

ISO 9141

ISO 9141 is used by many Japanese

manufacturers.

ISO 9141 is not a network protocol, it

can only be used for diagnostics.

There is no bus arbitration. It can be

used to connect one diagnostic tool to a

vehicle control module.

ISO 9141 is relatively slow 10.4 Kbps

September 28, 2002 Page 17

KWP 2000

KWP is used by many European

manufacturers. It uses an enhanced set

of diagnostic messages but retains the

ISO 9141 physical layer.

KWP is not a network protocol, it can

only be used for diagnostics.

There is no bus arbitration. It can be

used to connect one diagnostic tool to

one or more vehicle control modules.

KWP is relatively slow 10.4 Kbps

September 28, 2002 Page 18

Types of Network Messages

There are two types of network messages

Diagnostic messages

Normal Mode messages

Normal Mode messages are used to share

information between modules on the

network during normal vehicle operation,

e.g. instrument cluster sends fuel level info

(percent fill) to PCM.

Normal mode messages always use

physical addressing.

September 28, 2002 Page 19

Types of Network Messages

Diagnostic Mode messages are used to

communicate between a test tool and a

module on the network.

Diagnostic messages can use either

physical addressing or functional

addressing.

Manufacturer-specific tools normally use

physical addressing

Generic OBD tools use functional

addressing because the configuration of the

network and network addresses do not

have to be known for every specific vehicle

September 28, 2002 Page 20

SAE/ISO Diagnostic Specifications

Vehicle diagnostic communication

specifications have been written by the

Society of Automotive Engineers (SAE)

and by various International Standards

Organization (ISO) workgroups.

These standards are referenced by the

California, Federal and European OBD

regulations.

US regulations reference SAE standards,

European regulations reference

equivalent ISO standards.

September 28, 2002 Page 21

SAE/ISO Diagnostic Specifications

Legislated diagnostics

SAE J1930/ISO 15031-2 Electrical/Electronic Systems

Diagnostic Terms, Definitions, Abbreviations and Acronyms

SAE J1962/ISO 15031-3 Diagnostic Connector

SAE J1978/ISO 15031-4 OBD-II Scan Tool

SAE J1979/ISO 15031-5 E/E Diagnostic Test

Modes

SAE J2012/ISO 15031-6 Diagnostic Trouble Codes

SAE J2186/ISO 15031-7 E/E Data Link Security

Non legislated diagnostics

SAE J2190/ISO 14229 Enhanced E/E Diagnostic

Test Modes

September 28, 2002 Page 22

SAE/ISO Multiplex Specifications

Legislated multiplex standards

SAE J1850 (Class B Data Comm.

Network Interface)

ISO 9141-2 (K-Line)

ISO 14230-4 (Keyword Protocol 2000)

SAE J2284/ISO 15765-4 (CAN)

J2534 Recommended Practice for Pass-

Thru Vehicle Programming

September 28, 2002 Page 23

SAE J1930 Terms and Acronyms

J1930 attempts to limit the proliferation

of terms, abbreviations and acronyms

used in motor vehicle service literature.

Examples

Ford uses ECT (engine coolant temp sensor),

GM uses CTS (coolant temp sensor), J1930

uses ECT

Ford uses ISC (idle speed control), J1930 uses

IAC (idle air control)

Ford uses EEC-V, J1930 uses PCM (powertrain

control module)

September 28, 2002 Page 24

SAE J1930 Terms and Acronyms

J1930 describes a consistent methodology

for naming components and systems.

MODIFIERS BASE WORD

What is Where Which What does What

Purpose? Is it? Temp? it sense?Is it?

Sensor (most generic)

Temperature Sensor

Coolant Temperature Sensor

Engine Coolant Temperature Sensor

Instrumentation Engine Coolant Temperature Sensor (most specific)

Least <<<<<< SIGNIFICANCE >>>>>> Most

September 28, 2002 Page 25

SAE J1962 Data Link Connector

J1962 describes the functional

requirements for the vehicle and test

tool data link connector (DLC):

In-vehicle location/access

Connector design

Terminal assignments

Electrical interface requirements

September 28, 2002 Page 26

SAE J1962 Data Link Connector

The 16-pin DLC assignments are

specified in SAE J1962/ISO 15031-3

Pin 1 - Discretionary Pin 9 Discretionary

Pin 2 Bus + J1850 Pin 10 Bus J1850

Pin 3 Discretionary Pin 11 Discretionary

Pin 4 Chassis Ground Pin 12 Discretionary

Pin 5 Signal Ground Pin 13 - Discretionary

Pin 6 CAN High Pin 14 CAN Low

Pin 7 K-Line ISO9141/KWP Pin 15 L-Line ISO9141/KWP

Pin 8 Discretionary Pin 16 Unswitched Battery +

September 28, 2002 Page 27

SAE J1962 Data Link Connector

The general location of the DLC is specified

in J1962, however, CARB and EPA

regulations are more restrictive.

CARB specifies that DLC must be on drivers

side of vehicle centerline, not on center

console, or behind storage accessories.

A covered DLC must have label (e.g. OBD)

approved by CARB.

Pin 16 must have < 20 Volts (not 24 or 42

V)

September 28, 2002 Page 28

SAE J1978 Generic Scan Tool

J1978 defines the minimum functionality

required by an OBD-II Scan Tool

Automatic hands-off determination of the

communication interface

Displays status and results of on-board

diagnostic evaluations

Displays pending and confirmed DTCs

Displays current data, freeze frame data,

and vehicle information

Clears DTCs, test results and freeze frame

Provides a user manual/help facility

September 28, 2002 Page 29

SAE J2012 Diagnostic Trouble

Codes

J2012 defines a set of diagnostic trouble

codes (DTCs) where industry uniformity

has been achieved.

DTCs consist of an alpha character

followed by four characters

Pxxxx is reserved for powertrain DTCs

Bxxxx is reserved for body DTCs

Cxxxx is reserved for chassis DTCs

Uxxxx is reserved for network DTCs

September 28, 2002 Page 30

SAE J2012 Diagnostic Trouble

Codes

The second character designates whether

the DTCs and a generic SAE DTC or a

manufacturer-specific DTC.

P0xxx, P2xxx, P3400, and U0xxx are

generic DTCs

P1xxx, P30xx, P3100, P32xx and P33xx are

manufacturer-specific DTCs

The remaining characters designate the

system associated with the fault. The

characters are hex and can range from 0 F.

September 28, 2002 Page 31

SAE J2012 Diagnostic Trouble

Codes

The J2012 committee defines new DTCs

on a quarterly basis, based on

manufacturer requests.

The J2012 committee assigns DTCs in a

uniform manner using J1930

terminology.

Sample output:

P2632 Fuel Pump B Control Circuit / Open

P2633 Fuel Pump B Control Circuit Low

P2634 Fuel Pump B Control Circuit High

P2636 Fuel Pump B Low Flow/Performance

September 28, 2002 Page 32

SAE J2012 Diagnostic Trouble

Codes

Sample input:

P0A00 Motor Electronics Coolant Temp Sensor Circuit

P0A01 Motor Electr. Coolant Temp Sensor Circuit

Range / Performance

P0A02 Motor Electr. Coolant Temp Sensor Circuit Low

P0A03 Motor Electr. Coolant Temp Sensor Circuit High

P0A04 Motor Electr. Coolant Temp Sensor Circuit

Intermittent / Erratic

Sample network DTCs:

U0001 High Speed CAN Communication Bus

U0101 Lost Communication with TCM

U0302 Software Incompatibility with TCM

U0402 Invalid Data Received From TCM

September 28, 2002 Page 33

SAE J2186 Data Link Security

J2186 defines a method to access

secured vehicle controller functions.

Three parameters control security

access

the seed (sent by controller) and key

(sent by external device)

the delay time (minimum delay time

between attempts)

the number of false access attempts

September 28, 2002 Page 34

SAE J1979 Diagnostic Test Modes

SAE J1979/ISO 15031-5 defines standard

diagnostic test modes.

Diagnostic/emission critical control

modules must implement these

diagnostic test modes. They must be on

the OBD data link or must use another

module as a gateway.

CARB defines engine and transmission

control modules as emission-critical.

September 28, 2002 Page 35

SAE J1979 Diagnostic Test Modes

Any other control module that performs

a major OBD-II monitor or performs CCM

monitoring for more than two

components is considered to be

diagnostic critical.

If a diagnostic/emission critical control

module is reprogrammable, it must

respond with Mode $09 CALID and CVN.

It must be able to be reprogrammed

using a SAE J2534 interface.

September 28, 2002 Page 36

SAE J1979 Diagnostic Test Modes

J1979 specifies a set of standard messages

that can be used by scan tool to obtain

OBD-II data from a vehicle. (Modes $01 to

$09)

Functional addressing is used instead of

physical addressing for all messages

because the test tool does not know which

systems on the vehicle have the OBD

information that is requested.

Response times to messages are specified.

Message lengths are specified.

September 28, 2002 Page 37

SAE J1979 Diagnostic Test Modes

Messages must utilize a standard set of

header bytes specified for each

communication protocol.

The remainder of the message (the data

bytes) specify the type of message (test

mode) and specific data that is being

requested.

Header byte definitions are specified on

the next two slides.

September 28, 2002 Page 38

SAE J1979 Header Bytes

Header bytes (Hex) Data bytes

Priority/Type Target address (hex) Source address (hex) #1 #2 #3 #4 #5 #6 #7 ERR RESP

Diagnostic request at 10.4 kbit/s: SAE J1850 and ISO 9141-2

68 6A F1 Maximum 7 data bytes Yes No

Diagnostic response at 10.4 kbit/s: SAE J1850 and ISO 9141-2

48 6B ECU addr Maximum 7 data bytes Yes No

Diagnostic request at 10.4 kbit/s (ISO 14230-4)

11LL LLLLb 33 F1 Maximum 7 data bytes Yes No

Diagnostic response at 10.4 kbit/s (ISO14230-4)

10LL LLLLb F1 addr Maximum 7 data bytes Yes No

Diagnostic request at 41.6 kbit/s (SAE J1850)

61 6A F1 Maximum 7 data bytes Yes Yes

Diagnostic response at 41.6 kbit/s (SAE J1850)

41 6B addr Maximum 7 data bytes Yes Yes

Header bytes CAN frame data field

CAN Identifier (11 or 29 bit) #1 #2 #3 #4 #5 #6 #7 #8

PCI

Byte

September 28, 2002 Page 39

SAE J1979 CAN Header Bytes

CAN Id bit position: 28 24 23 16 15 8 7 0

functional CAN Id 18 hex DB hex Target Address (33) Source Address (F1)

physical CAN Id 18 hex DA hex Target Address (xx) Source Address (FI)

CAN identifier Description (11-bit addressing)

(hex)

7DF CAN identifier for functionally addressed request messages sent by the external test equipment.

7E0 Physical request CAN identifier from the external test equipment to ECU #1

7E8 Physical response CAN identifier from ECU #1 to the external test equipment

7E1 Physical request CAN identifier from the external test equipment to ECU #2

7E9 Physical response CAN identifier from ECU #2 to the external test equipment

7E2 Physical request CAN identifier from the external test equipment to ECU #3

7EA Physical response CAN identifier from ECU #3 to the external test equipment

7E3 Physical request CAN identifier from the external test equipment to ECU #4

7EB Physical response CAN identifier from ECU #4 to the external test equipment

7E4 Physical request CAN identifier from the external test equipment to ECU #5

7EC Physical response CAN identifier from ECU #5 to the external test equipment

7E5 Physical request CAN identifier from the external test equipment to ECU #6

7ED Physical response CAN identifier from ECU #6 to the external test equipment

7E6 Physical request CAN identifier from the external test equipment to ECU #7

7EE Physical response CAN identifier from ECU #7 to the external test equipment

7E7 Physical request CAN identifier from the external test equipment to ECU #8

7EF Physical response CAN identifier from ECU #8 to the external test equipment

September 28, 2002 Page 40

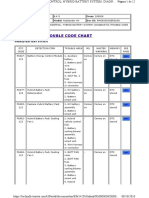

Ford Module Addresses

Module Phys Adr Func Adr Rec Adr Xmit Adr Func Rec Adr Func Xmit

Adr

(J1850) (J1850) (CAN) (CAN) (CAN) (CAN)

PCM $10 $6A $7E0 $7E8 $7DF $7E8

(Powertrain Control Module)

TCM $18 $6A $7E1 $7E9 $7DF $7E9

(Transmission Control Module)

ABS $28 $6A $7E2 $7EA $7DF non-OBD

(Anti-lock Brake System)

AHCM $0F $6A $7E3 $7EB $7DF non-OBD

(Auxiliary Heater Control Module)

TCCM $18 $6A $7E4 $7EC $7DF non-OBD

(Transfer Case Control Module)

AFCM $16 $6A $7E5 $7ED $7DF $7ED

(Alternative Fuel Control Module)

SPCM $11 $6A $7E6 $7EE $7DF $7EE

(Secondary PCM)

September 28, 2002 Page 41

Mode $01 Retrieve Diagnostic Data

Mode $01 provides diagnostic data,

commonly called PIDs (Parameter ID)

Service technicians can use the data to

troubleshoot sensors, check OBD monitor

completion, MIL status, etc.

Test tool specifies the requested data by

PID number ($00 through $FF)

PIDs are defined in J1979 (number, units,

conversion/scaling factor, acronym)

PIDs must show raw values not

substituted values if a sensor fails

September 28, 2002 Page 42

Mode $01 Retrieve Diagnostic Data

The message format used to make a PID

request is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request Current Powertrain Diagnostic Data

Request Powertrain 01 PID

Diagnostic Data

Report Current Powertrain Diagnostic Data

Report Powertrain 41 PID data data data data

Diagnostic Data A B C D

(opt) (opt) (opt)

September 28, 2002 Page 43

PID $01 I/M Readiness

PID Description Data Scaling/bit External test equipment

(hex) byte SI (Metric) / English display

01 Monitor status since DTCs cleared A

(bit)

# of DTCs stored in this ECU 0-6 Hexadecimal DTC_CNT: xxxx

Malfunction Indicator Lamp (MIL) 7 0 = MIL OFF; 1 = MIL ON MIL: OFF or ON

Status

Supported tests which are continuous B byte 2 of 4 (Low Nibble) Support status of continuous monitors:

(bit)

Misfire monitoring 0 0 = monitor not MIS_SUP: NO or YES

supported (NO)

Fuel system monitoring 1 0 = monitor not FUEL_SUP: NO or YES

supported (NO)

Comprehensive component 2 0 = monitor not CCM_SUP: NO or YES

monitoring supported (NO)

reserved (bit shall be reported as 0) 3 ---

Misfire monitoring 4 0 = monitor complete, or MIS_RDY: YES or NO

not applicable (YES)

Fuel system monitoring 5 0 = monitor complete, or FUEL_RDY: YES or NO

not applicable (YES)

Comprehensive component 6 0 = monitor complete, or CCM_RDY: YES or NO

monitoring not applicable (YES)

reserved (bit shall be reported as 0) 7 ---

Supported tests run at least once per C byte 3 of 4 Support status of non-continuous monitors:

trip (bit)

Catalyst monitoring 0 CAT_SUP: NO or YES

Heated catalyst monitoring 1 HCAT_SUP: NO or YES

Evaporative system monitoring 2 0 = monitor not EVAP_SUP: NO or YES

supported (NO)

Secondary air system monitoring 3 1 = monitor supported AIR_SUP: NO or YES

A/C system refrigerant monitoring 4 (YES) ACRF_SUP: NO or YES

Oxygen sensor monitoring 5 O2S_SUP: NO or YES

Oxygen sensor heater monitoring 6 HTR_SUP: NO or YES

EGR system monitoring 7 EGR_SUP: NO or YES

Status of tests run at least once per D byte 4 of 4 Completion status of non-continuous

trip (bit) monitors since DTCs cleared:

Catalyst monitoring 0 CAT_RDY: YES or NO

Heated catalyst monitoring 1 HCAT_RDY: YES or NO

Evaporative system monitoring 2 0 = monitor complete, or EVAP_RDY: YES or NO

not applicable (YES)

Secondary air system monitoring 3 1 = monitor not complete AIR_RDY: YES or NO

A/C system refrigerant monitoring 4 (NO) ACRF_RDY: YES or NO

Oxygen sensor monitoring 5 O2S_RDY: YES or NO

Oxygen sensor heater monitoring 6 HTR_RDY: YES or NO

EGR system monitoring 7 EGR_RDY: YES or NO

September 28, 2002 Page 44

PID $02 and $03

PID Description Data Scaling/bit External test equipment

(hex) byte SI (Metric) / English display

01 Monitor status since DTCs cleared A

(bit)

# of DTCs stored in this ECU 0-6 Hexadecimal DTC_CNT: xxxx

Malfunction Indicator Lamp (MIL) 7 0 = MIL OFF; 1 = MIL ON MIL: OFF or ON

Status

Supported tests which are continuous B byte 2 of 4 (Low Nibble) Support status of continuous monitors:

(bit)

Misfire monitoring 0 0 = monitor not MIS_SUP: NO or YES

supported (NO)

Fuel system monitoring 1 0 = monitor not FUEL_SUP: NO or YES

supported (NO)

Comprehensive component 2 0 = monitor not CCM_SUP: NO or YES

monitoring supported (NO)

reserved (bit shall be reported as 0) 3 ---

Misfire monitoring 4 0 = monitor complete, or MIS_RDY: YES or NO

not applicable (YES)

Fuel system monitoring 5 0 = monitor complete, or FUEL_RDY: YES or NO

not applicable (YES)

Comprehensive component 6 0 = monitor complete, or CCM_RDY: YES or NO

monitoring not applicable (YES)

reserved (bit shall be reported as 0) 7 ---

Supported tests run at least once per C byte 3 of 4 Support status of non-continuous monitors:

trip (bit)

Catalyst monitoring 0 CAT_SUP: NO or YES

Heated catalyst monitoring 1 HCAT_SUP: NO or YES

Evaporative system monitoring 2 0 = monitor not EVAP_SUP: NO or YES

supported (NO)

Secondary air system monitoring 3 1 = monitor supported AIR_SUP: NO or YES

A/C system refrigerant monitoring 4 (YES) ACRF_SUP: NO or YES

Oxygen sensor monitoring 5 O2S_SUP: NO or YES

Oxygen sensor heater monitoring 6 HTR_SUP: NO or YES

EGR system monitoring 7 EGR_SUP: NO or YES

Status of tests run at least once per D byte 4 of 4 Completion status of non-continuous

trip (bit) monitors since DTCs cleared:

Catalyst monitoring 0 CAT_RDY: YES or NO

Heated catalyst monitoring 1 HCAT_RDY: YES or NO

Evaporative system monitoring 2 0 = monitor complete, or EVAP_RDY: YES or NO

not applicable (YES)

Secondary air system monitoring 3 1 = monitor not complete AIR_RDY: YES or NO

A/C system refrigerant monitoring 4 (NO) ACRF_RDY: YES or NO

Oxygen sensor monitoring 5 O2S_RDY: YES or NO

Oxygen sensor heater monitoring 6 HTR_RDY: YES or NO

EGR system monitoring 7 EGR_RDY: YES or NO

September 28, 2002 Page 45

PIDs $04 - $11

04 Calculated LOAD Value! A 0% 100 % 100/255 % LOAD_PCT: xxx.x %

LOAD_PCT = [current airflow] / [(peak airflow at WOT@STP as a function of rpm) * (BARO/29.92) *

SQRT(298/(AAT+273))]

Characteristics of LOAD_PCT are:

Reaches 1.0 at WOT at any altitude, temperature or rpm for both naturally aspirated and boosted engines.

Indicates percent of peak available torque.

Linearly correlated with engine vacuum

Often used to schedule power enrichment.

Compression ignition engines (diesels) shall support this PID using fuel flow in place of airflow for the

above calculations.

05 Engine Coolant Temperature A -40 C +215 C 1 C with ECT: xxx C (xxx F)

-40 C offset

06 Short Term Fuel Trim - Bank 1 A -100 % +99.22 % 100/128 % SHRTFT1: xxx.x %

(lean) (rich) (0 % at 128) SHRTFT3: xxx.x %

07 Long Term Fuel Trim - Bank 1 A -100 % +99.22 % 100/128 % LONGFT1: xxx.x %

(lean) (rich) (0 % at 128) LONGFT3: xxx.x %

08 Short Term Fuel Trim - Bank 2 A -100 % +99.22 % 100/128 % SHRTFT2: xxx.x %

(lean) (rich) (0 % at 128) SHRTFT4: xxx.x %

09 Long Term Fuel Trim Bank 2 A -100 % +99.22 % 100/128 % LONGFT2: xxx.x %

(lean) (rich) (0 % at 128) LONGFT4: xxx.x %

0A Fuel Rail Pressure (gauge) A 0 kPa 765 kPa 3 kPa per bit FRP: xxx kPa (xx.x psi)

(gauge) (gauge) (gauge)

0B Intake Manifold Absolute A 0 kPa 255 kPa 1 kPa per bit MAP: xxx kPa (xx.x inHg)

Pressure (absolute) (absolute)

-1 -1

0C Engine RPM A, 0 min 16383.75 rpm per bit RPM: xxxxx min

-1

B min

0D Vehicle Speed Sensor A 0 km/h 255 km/h 1 km/h per bit VSS: xxx km/h (xxx mph)

0E Ignition Timing Advance for #1 A -64 63.5 with SPARKADV: xx

Cylinder 0 at 128

0F Intake Air Temperature A -40 C +215 C 1 C with IAT: xxx C (xxx F)

-40 C offset

10 Air Flow Rate from Mass Air A, 0 g/s 655.35 0.01 g/s MAF: xxx.xx g/s (xxxx.x lb/min)

Flow Sensor B g/s

11 Absolute Throttle Position A 0% 100 % 100/255 % TP: xxx.x %

September 28, 2002 Page 46

PIDs $12 - $1B

12 Commanded Secondary Air A byte 1 of 1 AIR_STAT:

Status (bit)

(if supported, one, and only 0 1 = upstream of first catalytic converter AIR_STAT: UPS

one bit at a time can be set 1 1 = downstream of first catalytic converter inlet AIR_STAT: DNS

to a 1) 2 1 = atmosphere / off AIR_STAT: OFF

3-7 reserved (bits shall be reported as 0) ---

13 Location of Oxygen Sensors A byte 1 of 4 O2SLOC:

(bit)

(where sensor 1 is closest 0 1 = Bank 1 - Sensor 1 present at that location O2S11

to the engine. Each bit 1 1 = Bank 1 - Sensor 2 present at that location O2S12

indicates the presence or 2 1 = Bank 1 - Sensor 3 present at that location O2S13

absence of an oxygen 3 1 = Bank 1 - Sensor 4 present at that location O2S14

sensor at the following 4 1 = Bank 2 - Sensor 1 present at that location O2S21

location) 5 1 = Bank 2 - Sensor 2 present at that location O2S22

6 1 = Bank 2 - Sensor 3 present at that location O2S23

7 1 = Bank 2 - Sensor 4 present at that location O2S24

14 Bank 1 Sensor 1 These PIDs shall be used for a

15 Bank 1 Sensor 2 conventional, 0 to 1 Volt oxygen

16 Bank 1 Sensor 3 sensor. Any sensor with a different full

17 Bank 1 Sensor 4 scale value shall be normalized to

18 Bank 2 Sensor 1 provide nominal full scale at $C8 (200

19 Bank 2 Sensor 2 decimal). Wide-range/linear oxygen

1A Bank 2 Sensor 3 sensors shall use PIDs $24 to $2B or

1B Bank 2 Sensor 4 PIDs $34 to $3B.

Oxygen Sensor Output Voltage A 0V 1.275 V 0.005 V O2Sxy: x.xxx V

(Bx-Sy)

Short Term Fuel Trim (Bx-Sy) B -100.00 % 99.22 % 100/128 % SHRTFTxy: xxx.x %

(lean) (rich) (0 % at 128)

September 28, 2002 Page 47

PIDs $1C - $1E

1C OBD requirements to which A byte 1 of 1 OBDSUP:

vehicle is designed (hex) (State Encoded Variable)

01 OBD II (California ARB) OBD II

02 OBD (Federal EPA) OBD

03 OBD and OBD II OBD and OBD II

04 OBD I OBD I

05 Not OBD compliant NO OBD

06 EOBD EOBD

07 EOBD and OBD II EOBD and OBD II

08 EOBD and OBD EOBD and OBD

09 EOBD, OBD and OBD II EOBD, OBD and OBD II

0A JOBD JOBD

0B JOBD and OBD II JOBD and OBD II

0C JOBD and EOBD JOBD and EOBD

0D JOBD, EOBD, and OBD II JOBD, EOBD, and OBD II

0E - FF reserved by document ---

1D Location of oxygen sensors A byte 1 of 1 O2SLOC:

(bit)

(where sensor 1 is closest to 0 1 = Bank 1 - Sensor 1 present at that location O2S11

the engine. Each bit 1 1 = Bank 1 - Sensor 2 present at that location O2S12

indicates the presence or 2 1 = Bank 2 - Sensor 1 present at that location O2S21

absence of an oxygen sensor 3 1 = Bank 2 - Sensor 2 present at that location O2S22

at the following location) 4 1 = Bank 3 - Sensor 1 present at that location O2S31

5 1 = Bank 3 - Sensor 2 present at that location O2S32

6 1 = Bank 4 - Sensor 1 present at that location O2S41

7 1 = Bank 4 - Sensor 2 present at that location O2S42

1E Auxiliary Input Status A byte 1 of 1 Auxiliary Input Status

(bit)

Power Take Off (PTO) Status 0 0 = PTO not active (OFF); PTO_STAT: OFF or ON

1 = PTO active (ON)

1-7 reserved (bits shall be reported as 0) ---

September 28, 2002 Page 48

PIDs $1F - $2B

1F Time Since Engine Start A, B 0 sec. 65,535 1 second per RUNTM: xxxxx sec.

sec. count

21 Distance Traveled While MIL is A, B 0 km 65535 km 1 km per MIL_DIST: xxxxx km (xxxxx

Activated count miles)

22 Fuel Rail Pressure relative to manifold A, B 0 kPa 5177.27 0.079 kPa per FRP: xxxx.xxx kPa (xxx.x PSI)

vacuum kPa bit unsigned

23 Fuel Rail Pressure A, B 0 kPa 655350 10 kPa per bit FRP: xxxxxx kPa (xxxxx.x PSI)

kPa unsigned

24 Bank 1 Sensor 1 (wide range O2S) PIDs $24 to $2B shall be

25 Bank 1 Sensor 2 (wide range O2S) used for linear or wide-ratio

26 Bank 1 Sensor 3 (wide range O2S) Oxygen Sensors when

27 Bank 1 Sensor 4 (wide range O2S) equivalence ratio and voltage

28 Bank 2 Sensor 1 (wide range O2S) are displayed

29 Bank 2 Sensor 2 (wide range O2S)

2A Bank 2 Sensor 3 (wide range O2S)

2B Bank 2 Sensor 4 (wide range O2S)

Equivalence Ratio (lambda) (Bx-Sy) A, B 0 1.999 0.0000305 EQ_RATxy: x.xxx

Oxygen Sensor Voltage (Bx-Sy) C, D 0V 7.999 V 0.000122 V O2Sxy: x.xxx V

September 28, 2002 Page 49

PIDs $2C - $33

2C Commanded EGR A 0% 100% 100/255 % EGR_PCT: xxx.x%

(no flow) (max. flow)

2D EGR Error = (EGR actual EGR A -100 % +99.22 % 100/128 % EGR_ERR: xxx.x%

commanded) / EGR (less than (more than (0 % at 128)

commanded * 100% commanded) commanded)

2E Commanded Evaporative Purge A 0% 100% 100/255 % EVAP_PCT: xxx.x %

no flow max. flow

2F Fuel Level Input A 0% 100% 100/255 % FLI: xxx.x %

no fuel max. fuel

capacity

30 Number of warm-ups since A 0 255 1 warm-up WARM_UPS: xxx

diagnostic trouble codes cleared per count

31 Distance since diagnostic A, B 0 km 65,535 km 1 km per CLR_DIST: xxxxx km (xxxxx

trouble codes cleared count miles)

32 Evap System Vapor Pressure A, B ($8000) ($7FFF) 0.25 Pa per EVAP_VP: xxxx.xx Pa (xx.xxx

-8192 Pa 8191 Pa bit signed in H2O)

(-32.8878 (32.8838

inH2O) inH2O)

33 Barometric Pressure A 0 kPa 255 kPa 1 kPa per bit BARO: xxx kPa (xx.x inHg)

(absolute) (absolute) (absolute)

September 28, 2002 Page 50

PIDs $34 - $3F

34 Bank 1 - Sensor 1 (wide range O2S) PIDs $34 to $3B shall be

35 Bank 1 - Sensor 2 (wide range O2S) used for linear or wide-ratio

36 Bank 1 - Sensor 3 (wide range O2S) Oxygen Sensors when

37 Bank 1 - Sensor 4 (wide range O2S) equivalence ratio and current

38 Bank 2 - Sensor 1 (wide range O2S) are displayed

39 Bank 2 - Sensor 2 (wide range O2S)

3A Bank 2 - Sensor 3 (wide range O2S)

3B Bank 2 - Sensor 4 (wide range O2S)

Equivalence Ratio (lambda) (Bx-Sy) A, B 0 1.999 0.0000305 EQ_RATxy: x.xxx

Oxygen Sensor Current (Bx-Sy) C, D -128 127.996 0.00390625 mA O2Sxy: x.xxx mA

mA mA ($8000 = 0 mA)

3C Catalyst Temperature Bank 1, A, B -40 C +6513.5 C 0.1 C / bit with CATEMP11: xxxx.x C (xxxx.x

Sensor 1 -40 C offset F)

3D Catalyst Temperature Bank 2, A, B -40 C +6513.5 C 0.1 C / bit with - CATEMP21: xxxx.x C (xxxx.x

Sensor 1 40 C offset F)

3E Catalyst Temperature Bank 1, A, B -40 C +6513.5 C 0.1 C / bit with - CATEMP12: xxxx.x C (xxxx.x

Sensor 2 40 C offset F)

3F Catalyst Temperature Bank 2, A, B -40 C +6513.5 C 0.1 C / bit with - CATEMP22: xxxx.x C (xxxx.x

Sensor 2 40 C offset F)

September 28, 2002 Page 51

PID $41

41 Monitor status this driving cycle A

Reserved - shall be reported as $00 0-7 ---

Enable status of continuous monitors B byte 2 of 4 (Low Nibble) Enable status of continuous monitors this

this monitoring cycle: (bit) monitoring cycle: NO means disabled for

rest of this monitoring cycle or not supported

Misfire monitoring 0 0 = monitor disabled for MIS_ENA: NO or YES

Fuel system monitoring 1 rest of this monitoring FUEL_ENA: NO or YES

Comprehensive component 2 cycle or not CCM_ENA: YES

monitoring supported (NO)

reserved (bit shall be reported as 0) 3

Completion status of continuous B byte 2 of 4 (High Nibble) Completion status of continuous monitors

monitors this monitoring cycle: (bit) this monitoring cycle:

Misfire monitoring 4 See PID $01 to determine MIS_CMPL: YES or NO

Fuel system monitoring 5 which monitors are FUELCMPL: YES or NO

supported CCM_CMPL: YES or NO

Comprehensive component 6

0 = monitor complete this

monitoring monitoring cycle, or

reserved (bit shall be reported as 0) 7 not supported (YES)

41 Monitor status this driving cycle

Enable status of non-continuous C byte 3 of 4 Enable status of non-continuous monitors

monitors this monitoring cycle: (bit) this monitoring cycle:

Catalyst monitoring 0 CAT_ENA: YES or NO

Heated catalyst monitoring 1 0 = monitor disabled for HCAT_ENA: YES or NO

Evaporative system monitoring 2 rest of this monitoring EVAP_ENA: YES or NO

cycle (NO) AIR_ENA: YES or NO

Secondary air system monitoring 3

1 = monitor enabled for ACRF_ENA: YES or NO

A/C system refrigerant monitoring 4 this monitoring cycle O2S_ENA: YES or NO

Oxygen sensor monitoring 5 (YES) HTR_ENA: YES or NO

Oxygen sensor heater monitoring 6 EGR_ENA: YES or NO

EGR system monitoring 7

Completion status of non-continuous D byte 4 of 4 Completion status of non-continuous

monitors this monitoring cycle: (bit) monitors this monitoring cycle:

Catalyst monitoring 0 See PID $01 to determine CAT_CMPL: YES or NO

Heated catalyst monitoring 1 which monitors are HCATCMPL: YES or NO

Evaporative system monitoring 2 supported. EVAPCMPL: YES or NO

0 = monitor complete this AIR_CMPL: YES or NO

Secondary air system monitoring 3

monitoring cycle, or ACRFCMPL: YES or NO

A/C system refrigerant monitoring 4 not supported (YES) O2S_CMPL: YES or NO

Oxygen sensor monitoring 5 1 = monitor not complete HTR_CMPL: YES or NO

Oxygen sensor heater monitoring 6 this monitoring cycle EGR_CMPL: YES or NO

EGR system monitoring 7 (NO)

September 28, 2002 Page 52

PIDs $42 - $4E

42 Control module voltage A, B 0V 65.535 V 0.001 V per bit VPWR: xx.xxx V

43 Absolute Load Value A, B 0% 25700 % 100/255 % LOAD_ABS: xxx.x%

LOAD_ABS = [air mass (g / intake stroke)] / [1.184 (g / intake stroke) * cylinder displacement in litres]

Characteristics of LOAD_ABS are:

Ranges from 0 to approximately 0.95 for naturally aspirated engines, 0 4 for boosted engines,

Linearly correlated with engine indicated and brake torque, Often used to schedule spark and EGR rates,

Peak value of LOAD_ABS correlates with volumetric efficiency at WOT.,

Indicates the pumping efficiency of the engine for diagnostic purposes.

44 Commanded Equivalence Ratio A, B 0 1.999 0.0000305 EQ_RAT: x.xxx

Fuel systems that utilize conventional oxygen sensor shall display the commanded open loop equivalence ratio while

the fuel control system is in open loop. EQ_RAT shall indicate 1.0 while in closed loop fuel.

Fuel systems that utilize wide-range/linear oxygen sensors shall display the commanded equivalence ratio in both open

loop and closed loop operation.

To obtain the actual A/F ratio being commanded, multiply the stoichiometric A/F ratio by the equivalence ratio. For

example, for gasoline, stoichiometric is 14.64:1 ratio. If the fuel control system was commanding an 0.95 EQ_RAT, the

commanded A/F ratio to the engine would be 14.64 * 0.95 = 13.9 A/F

45 Relative Throttle Position A 0% 100 % 100/255 % TP_R: xxx.x %

46 Ambient air temperature A -40 C +215 C 1 C with AAT: xxx C / xxx F

(same scaling as IAT - $0F) -40 C offset

47 Absolute Throttle Position B A 0% 100 % 100/255 % TP_B: xxx.x %

48 Absolute Throttle Position C A 0% 100 % 100/255 % TP_C: xxx.x %

49 Accelerator Pedal Position D A 0% 100 % 100/255 % APP_D: xxx.x %

4A Accelerator Pedal Position E A 0% 100 % 100/255 % APP_E: xxx.x %

4B Accelerator Pedal Position F A 0% 100 % 100/255 % APP_F: xxx.x %

4C Commanded Throttle Actuator A 0% 100% 100/255 % TAC_PCT: xxx.x%

Control (closed (wide open

throttle) throttle)

4D Minutes run by the engine while A, B 0 min 65535 min 1 min per MIL_TIME: xxxx hrs, xx min

MIL activated count

4E Time since diagnostic trouble A, B 0 min 65535 min 1 min per CLR_TIME: xxxx hrs, xx min

codes cleared count

September 28, 2002 Page 53

Mode $02 Freeze Frame

Mode $02 stores Mode $01 PID data at the

time a pending or confirmed DTC is stored.

Fuel system and misfire DTCs have a

higher priority and overwrite any existing

data.

Service technicians can use the data to

understand the conditions at the time the

malfunction occurred.

Only one frame ($00) is required to be

stored.

September 28, 2002 Page 54

Mode $02 Freeze Frame

Freeze frame can be useful, however,

there are some caveats.

Freeze frame is stored when the DTC is

stored, not when the problem began.

For circuit faults, it usually takes 5

seconds to store a DTC.

Misfire is evaluated every 1,000 revs. A

misfire DTC may be stored 60-90

seconds after the misfire initially

occurred, at substantially different rpm

and load conditions.

September 28, 2002 Page 55

Mode $02 Freeze Frame

The message format used to retrieve freeze

frame is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request Powertrain Freeze Frame Data

Request Powertrain 02 PID frame

Freeze Frame Data no.

Report Powertrain Freeze Frame Data

(only valid if Mode $02 PID $02 DTC is not $00 00)

Report Powertrain 42 PID frame data data data data

Freeze Frame Data no. A B C D

(opt) (opt) (opt)

September 28, 2002 Page 56

Mode $03 Retrieve emission-related

DTCs

Mode $03 reports confirmed, emission-

related DTCs.

Service technicians and I/M test stations

use this mode to determine what

malfunction turned on the MIL.

Mode $03 reports history codes for 40

warm-ups after the MIL is extinguished.

September 28, 2002 Page 57

Mode $03 Retrieve emission-related

DTCs

The message format used to retrieve

emission-related DTCs is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request number of codes from all modules

Request number of 01 01

Powertrain DTC

Report number of codes (each module)

Report number of stored 41 01 # DTC Eval. Eval. Eval.

powertrain DTC & Supp. Supp. Status

MIL #1 #2

Request codes from all modules

Request Powertrain DTC 03

Report codes (each module)

Report Powertrain DTC 43 Code #1 Code #2 Code #3

or 00 00 or 00 00 or 00 00

September 28, 2002 Page 58

Mode $04 Clear DTCs and Diagnostic

Information

Mode $04 clears/erases DTCs and resets

diagnostic data at the time a pending or

confirmed DTC was stored. Diagnostic

data includes freeze frame, I/M

readiness, monitor status, PIDs for

MIL_DIST, WARM_UPS, CLR_DIST, Mode

$06 data.

Service technicians can use this mode

to turn off the MIL after a repair and to

validate a repair.

September 28, 2002 Page 59

Mode $04 Clear DTCs and Diagnostic

Information

The message format used to clear DTCs is as

follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request to Clear/Reset Emission-Related Diagnostic Information

Clear Powertrain DTC 04

Report when Emission-Related Diagnostic Information is Reset

Powertrain DTC cleared 44

September 28, 2002 Page 60

Mode $05 Retrieve Oxygen Sensor Data

Mode $05 provides test results for

oxygen sensors.

This mode is no longer used for CAN

applications. All data is still available

using Mode $06.

September 28, 2002 Page 61

Mode $05 Retrieve Oxygen Sensor Data

The message format used to retrieve oxygen

sensor data is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request Oxygen Sensor Test Results

Request Oxygen Sensor 05 Test ID 02S #

Test Results

Report Oxygen Sensor Test ID Support - Optional

(Test IDs $00, $20, $40, $60, $80, $A0, $C0, $E0)

Report Oxygen Sensor 45 Test 02S # Support for the next 32 test IDs

Test ID Support ID following the requested ID is

indicated in data bytes #4 through #7

Report Oxygen Sensor Test Results

(All Test IDs That Dont Indicate Test ID Support

Data is only valid if Mode $01 PID $01 indicates Oxygen sensor

monitoring is supported and the test is complete)

Report Oxygen Sensor 45 Test 02S # test value min max

Test Results ID limit limit

(opt)* (opt)*

September 28, 2002 Page 62

Mode $05 Retrieve Oxygen Sensor Data

Data Description

Byte

2 Which Test ID:

$00 - Test IDs supported - optional ($01 to $20)

$01 - Rich to lean sensor threshold voltage (constant)

$02 - Lean to rich sensor threshold voltage (constant)

$03 - Low sensor voltage for switch time calculation (constant)

$04 - High sensor voltage for switch time calculation (constant)

$05 - Rich to lean sensor switch time (calculated)

$06 - Lean to rich sensor switch time (calculated)

$07 - Minimum sensor voltage for test cycle (calculated)

$08 - Maximum sensor voltage for test cycle (calculated)

$09 - Time between sensor transitions (calculated)

$0A - $1F - reserved

$20 - Test IDs supported - optional ($21 to $40)

September 28, 2002 Page 63

Mode $06 Retrieve OBD test results and

malfunction limits

Mode $06 provides monitoring test

values and malfunction limits for

various OBD monitors.

Service technicians can use the data to

see which monitors failed and by how

much, or to validate repairs.

Parts manufacturers can use this data to

ensure replacement part compatibility.

September 28, 2002 Page 64

Mode $06 Retrieve OBD test results and

malfunction limits

Mode $06 test values and limits are un-

scaled, decimal numbers in J1850, ISO

9141-2 and ISO 1423-4. Manufacturers

need to provide conversion factors for

technicians to utilize this data.

ISO 15765-4 messages provide units and

scaling as part of the message. Generic

scan tools will be able to convert these to

engineering units

September 28, 2002 Page 65

Mode $06 Retrieve OBD test results and

malfunction limits

The message format used to retrieve OBD test results is as

follows: Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request Test Results

Request Test Results 06 Test

ID

Report Test ID Support

(Test IDs $00, $20, $40, $60, $80, $A0, $C0, $E0)

Report Test ID Support 46 Test FF Support for the next 32 test

ID IDs following the requested

ID for any component is

indicated in data bytes #4

through #7

Report Test Results - Multiple Responses may be Transmitted

(Test IDs other than $00, $20, $40, $60, $80, $A0, $C0, $E0

Data is only valid if Mode $01 PID $01 indicates

the monitoring test is supported and the test is complete)

Report Test Results 46 Test Test Limit

ID Type & test value test limit

Component

ID

MSB LSB MSB LSB

September 28, 2002 Page 66

Mode $06 Retrieve OBD test results and limits

J1979 CATALYST MONITOR MODE $06 DATA

Test ID Comp ID Description for J1850 Units

$10 $11 Bank 1 switch-ratio and max. limit unitless

$10 $21 Bank 2 switch-ratio and max. limit unitless

$10 $10 Bank 1 index-ratio and max. limit unitless

$10 $20 Bank 2 index-ratio and max. limit unitless

Monitor ID Test ID Description for CAN

$21 $80 Bank 1 index-ratio and max. limit unitless

$22 $80 Bank 2 index-ratio and max. limit unitless

Conversion for J1850 Test ID $10: multiply by 0.0156 to get a value from 0 to 1.0

J1979 Secondary Air Mode $06 Data

Test ID Comp ID Description for J1850 Units

$30 $11 HO2S11 voltage for upstream flow test and rich limit volts

$30 $21 HO2S21 voltage for upstream flow test and rich limit volts

$31 $00 HO2S lean time for upstream flow test and time limit seconds

Monitor ID Test ID Description for CAN Units

$71 $80 HO2S11 voltage for upstream flow test and rich limit volts

$71 $81 HO2S21 voltage for upstream flow test and rich limit volts

$71 $82 HO2S lean time for upstream flow test and time limit seconds

Conversion for Test ID $30: multiply by 0.00098 to get volts

Conversion for Test ID $31: multiply by 0.125 to get seconds

September 28, 2002 Page 67

Mode $06 Retrieve OBD test results limits

J1979 Misfire Mode $06 Data

Test ID Comp ID Description for J1850 Units

$50 $00 Total engine misfire and emission threshold misfire rate (updated percent

every 1,000 revolutions)

$53 $00 - $0A Cylinder-specific misfire and catalyst damage threshold misfire rate percent

(either cat damage or emission threshold) (updated when DTC set or

clears)

$54 $00 Highest catalyst-damage misfire and catalyst damage threshold misfire percent

rate (updated when DTC set or clears)

$55 $00 Highest emission-threshold misfire and emission threshold misfire rate percent

(updated when DTC set or clears)

$56 $00 Cylinder events tested and number of events required for a 1000 rev events

test

Monitor ID Test ID Description for CAN

A1 $80 Total engine misfire and catalyst damage misfire rate (updated every percent

200 revolutions)

A1 $81 Total engine misfire and emission threshold misfire rate (updated percent

every 1,000 revolutions)

A1 $82 Highest catalyst-damage misfire and catalyst damage threshold misfire percent

rate (updated when DTC set or clears)

A1 $83 Highest emission-threshold misfire and emission threshold misfire rate percent

(updated when DTC set or clears)

o

A1 $84 Inferred catalyst mid-bed temperature C

A2 AD $0B EWMA misfire counts for last 10 driving cycles events

A2 AD $0C Misfire counts for last/current driving cycle events

A2 AD $80 Cylinder X misfire rate and catalyst damage misfire rate (updated percent

every 200 revolutions)

A2 AD $81 Cylinder X misfire rate and emission threshold misfire rate (updated percent

every 1,000 revolutions)

Conversion for Test IDs $50 through $55: multiply by 0.000015 to get percent

Conversion for Test ID $56: multiply by 1 to get ignition events

September 28, 2002 Page 68

Mode $06 Retrieve OBD test results limits

J1979 Evaporative System Mode $06 Data

Test ID Comp ID Description for J1850 Units

$26 $00 Phase 0 Initial tank vacuum and minimum limit in H20

$26 $00 Phase 0 Initial tank vacuum and maximum limit in H20

$27 $00 Phase 2 0.040 cruise leak check vacuum bleed-up and in H20

maximum 0.040 leak threshold

$28 $00 Phase 2 0.020 cruise leak check vacuum bleed-up and max in H20

leak threshold

$2A $00 Phase 4 Vapor generation maximum change in pressure and in H20

max threshold

$2B $00 Phase 4 Vapor generation maximum absolute pressure rise and in H20

max threshold

$2C $00 Phase 2 0.020 idle leak check vacuum bleed-up and maximum in H20

leak threshold

$2D $00 Phase 2 0.020 idle leak check vacuum bleed-up and max no- in H20

leak threshold

Conversion for Test IDs $26 through $2D: Take value, subtract 32,768, and then multiply result by 0.00195 to

get inches of H20. The result can be positive or negative.

Note: Default values (-64 in H20) will be display for all the above TIDs if the evap monitor has never

completed. If all or some phases of the monitor have completed on the current or last driving cycle, default

values will be displayed for any phases that had not completed.

September 28, 2002 Page 69

Mode $06 Retrieve OBD test results limits

Test ID Comp ID Description for J1850 (new 2003 MY strategies) Units

$61 $00 Phase 0 Initial tank vacuum and minimum vacuum limit (data for in H20

P1450 excessive vacuum)

$62 $00 Phase 4 Vapor generation minimum change in pressure and in H20

minimum vacuum limit (data for P1450, VMV stuck open)

$63 $00 Phase 0 Initial tank vacuum and gross leak maximum vacuum in H20

limit (data for P0455/P0457 gross leak/cap off)

$64 $00 Phase 2 0.040 cruise leak check vacuum bleed-up and in H20

maximum vacuum limit (data for P0442 0.040" leak)

$65 $00 Phase 2 0.020 idle leak check vacuum bleed-up and maximum in H20

vacuum limit (data for P0456 0.020" leak)

Conversion for Test IDs $61 through $65: Take value, subtract 32,768, and then multiply result by 0.00195 to

get inches of H20. The result can be positive or negative.

Note: Default values (0.0 in H20) will be displayed for all the above TIDs if the evap monitor has never

completed. Each TID is associated with a particular DTC. The TID for the appropriate DTC will be updated

based on the current or last driving cycle, default values will be displayed for any phases that have not

completed.

Monitor ID Test ID Description for CAN (new 2003 MY strategies) Units

$3A $80 Phase 0 Initial tank vacuum and minimum vacuum limit (data for Pascals

P1450 excessive vacuum)

$3A $81 Phase 4 Vapor generation minimum change in pressure and Pascals

minimum vacuum limit (data for P1450, VMV stuck open)

$3A $82 Phase 0 Initial tank vacuum and gross leak maximum vacuum Pascals

limit (data for P0455/P0457 gross leak/cap off)

$3B $80 Phase 2 0.040 cruise leak check vacuum bleed-up and Pascals

maximum vacuum limit (data for P0442 0.040" leak)

$3C $80 Phase 2 0.020 idle leak check vacuum bleed-up and maximum Pascals

vacuum limit (data for P0456 0.020" leak)

Note: Default values (0.0 in H20) will be displayed for all the above TIDs if the evap monitor has never

completed. Each TID is associated with a particular DTC. The TID for the appropriate DTC will be updated

based on the current or last driving cycle, default values will be displayed for any phases that have not

completed.

September 28, 2002 Page 70

Mode $06 Retrieve OBD test results limits

J1979 Front HO2S Mode $06 Data

Test ID Comp ID Description for J1850 Units

$01 $11 HO2S11 voltage amplitude and voltage threshold Volts

$01 $21 HO2S21 voltage amplitude and voltage threshold Volts

$03 $01 Upstream O2 sensor switch-point voltage Volts

Monitor ID Test ID Description for CAN

$01 $80 HO2S11 voltage amplitude and voltage threshold Volts

$01 $01 H02S11 sensor switch-point voltage Volts

$05 $80 HO2S21 voltage amplitude and voltage threshold Volts

$05 $01 H02S21 sensor switch-point voltage Volts

Conversion for Test IDs $01 through $03: multiply by 0.00098 to get volts

September 28, 2002 Page 71

Mode $06 Retrieve OBD test results limits

J1979 Rear HO2S Mode $06 Data

Test ID Comp ID Description for J1850 Units

$03 $02 Downstream O2 sensor switch-point voltage volts

Conversion for Test ID $03: multiply by 0.00098 to get volts

Monitor ID Test ID Description for CAN

$02 $01 HO2S12 sensor switch-point voltage volts

$06 $01 HO2S22 sensor switch-point voltage volts

$03 $01 HO2S13 sensor switch-point voltage volts

$07 $01 HO2S23 sensor switch-point voltage volts

September 28, 2002 Page 72

Mode $06 Retrieve OBD test results limits

J1979 HO2S Heater Mode $06 Data

Test ID Comp ID Description for J1850 Units

$04 $11 Maximum HO2S11 Heater Current Amps

$04 $11 Minimum HO2S11 Heater Current Amps

$04 $21 Maximum HO2S21 Heater Current Amps

$04 $21 Minimum HO2S21 Heater Current Amps

$04 $12 Maximum HO2S12 Heater Current Amps

$04 $12 Minimum HO2S12 Heater Current Amps

$04 $22 Maximum HO2S22 Heater Current Amps

$04 $22 Minimum HO2S22 Heater Current Amps

Conversion for Test IDs $04: multiply by 0.003906 to get amps

Monitor ID Test ID Description for CAN Units

$01 $81 HO2S11 Heater Current Amps

$05 $81 HO2S21 Heater Current Amps

$02 $81 HO2S12 Heater Current Amps

$06 $81 HO2S22 Heater Current Amps

$03 $81 HO2S13 Heater Current Amps

$07 $81 HO2S23 Heater Current Amps

September 28, 2002 Page 73

Mode $06 Retrieve OBD test results limits

J1979 DPFE EGR Stuck Open Mode $06 Data

Test ID Comp ID Description for J1850 Units

$45 $20 Delta pressure for stuck open test and threshold volts

Conversion for Test ID $45: Multiply by 0.0156 to get A/D counts (0-1024) or 0.0000763 to get voltage

Monitor ID Test ID Description for CAN Conventional DPFE Units

$31 $84 Delta pressure for stuck open test and threshold kPa

J1979 DPFE EGR Hose Check Mode $06 Data

Test ID Comp ID Description for J1850 Units

$42 $11 Delta pressure for upstream hose test and threshold in. H20

$42 $12 Delta pressure for downstream hose test and threshold in. H20

Conversion for Test ID $42: Take value, subtract 32,768, and then multiply result by 0.0078 to get inches of

H20. The result can be positive or negative.

Monitor ID Test ID Description for CAN Conventional DPFE

$31 $80 Delta pressure for upstream hose test and threshold kPa

$31 $81 Delta pressure for downstream hose test and threshold kPa

J1979 EGR Flow Check Mode $06 Data

Test ID Comp ID Description for J1850 Units

$49 $30 Delta pressure for flow test and threshold in. H20

$4B $30 EVR dutycycle for flow test and threshold percent

Conversion for Test ID $4B: multiply by 0.0000305 to get percent dutycycle.

Conversion for Test ID $49: Take value, subtract 32,768, then multiply result by 0.0078 to get inches of H20.

The result can be positive or negative.

Monitor ID Test ID Description for CAN Conventional DPFE Units

$31 $85 Delta pressure for flow test and threshold kPa

September 28, 2002 Page 74

Mode $06 Retrieve OBD test results and

malfunction limits

Example of Mode $06:

TestID CompIDTest Value Min Max

$10 $11 Cat monitor switch ratio 45 0 48

Bank 1

$10 $21 Cat monitor Switch ratio 42 0 48

Bank 2

Conversion: multiply by 0.0156 to get a value from 0 to 1.0

Bank 1 = 45 * 0.0156 = 0.702

Bank 2 = 42 * 0.0156 = 0.655

Threshold = 48 * 0.0156 = 0.749

This catalyst is about to fail. A normal 100K catalyst should have a

0 to 0.1 switch ratio!

September 28, 2002 Page 75

Mode $07 Retrieve pending DTCs

Mode $07 reports pending, emission-

related DTCs.

Starting in the 2005 MY, all pending

DTCs must be reported, not just

continuous pending DTCs.

Staring in the 2005 MY, a pending DTC

must be reported if the last monitoring

cycle had a malfunction.

Service technicians can use pending

codes for faster validation or a repair.

September 28, 2002 Page 76

Mode $07 Retrieve pending DTCs

The message format used to retrieve

pending, emission-related DTCs is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request test results for continuously monitored systems

Request test results 07

Report test results for continuously monitored systems

Report test results 47 Code #1 Code #2 Code #3

or 00 00 or 00 00 or 00 00

September 28, 2002 Page 77

Mode $08 Request on-board device

control

Mode $08 allows a service technician to

invoke an on-board test mode.

Only one test mode (Test ID $01) is

currently defined. It allows a service or

an I/M technician to seal the

evaporative system for a pressure test.

On Ford systems, this closes the

canister vent solenoid for a 10 minute

time duration.

September 28, 2002 Page 78

Mode $08 Request on-board device

control

The message format used to request on-

board device control is as follows:

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request control of on-board device

Request control of 08 Test ID Data A Data B Data C Data D Data E

on-board device or or or or or

$00 $00 $00 $00 $00

Report control of on-board device

Report control of on- 48 Test ID Data A Data B Data C Data D Data E

board device or or or or or

$00 $00 $00 $00 $00

September 28, 2002 Page 79

Mode $09 Retrieve vehicle information

Mode $09 allows a service tech or I/M

test technician to obtain vehicle VIN,

module calibration number (CALID),

Calibration Verification Number (CVN).

VIN is required for 2005 MY, the vehicle

can only report one VIN.

CALID is required for 2005 MY.

A unique CALID is required for each

emission-related calibration on the

vehicle. A unique CALID is required even

if only a bit if data changes.

September 28, 2002 Page 80

Mode $09 Retrieve vehicle information

(continued)

A CVN must be supplied for each CALID

In 2005 MY, CVN must be calculated

every driving cycle and stored in Keep

Alive Memory so that it can be retrieved

with the engine off or engine running.

CVN must not be erased by Mode $04.

CARB must approve CVN algorithm.

Manufacturers must provide CALID and

CVN information to facilitate I/M testing.

September 28, 2002 Page 81

Mode $09 Retrieve vehicle information

(continued)

Starting in the 2005 MY, CARB will

require industry-standard counters that

display how often OBD monitors run

during real-world driving conditions as

compared to a CARB-specified driving

cycle.

In-use performance counters will be

required for catalyst, O2 sensor, EGR,

secondary air, and evaporative system

monitors.

September 28, 2002 Page 82

Mode $09 Retrieve vehicle information

The message format used to retrieve vehicle

information is as follows:

Info Type $02 is VIN, $04 is CALID(s), $06 is

CVN(s), $08 is in-use performance counters

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request Vehicle Information

Request Vehicle 09 Info.

Information Type

Report Vehicle Information

Report Vehicle 49 Info. message data data data data

Information Type count A B C D

September 28, 2002 Page 83

Inspection/Maintenance Readiness

Many I/M test facilities will soon (Jan

1, 2002) be using OBD-II diagnostic

information in place of tailpipe

emissions tests.

They will check MIL lamp, MIL status

bit (PID 01, Data A, bit 7) and OBD

monitor readiness (PID 01).

For 2005 MY, they may check VIN,

CALIDs and CVNs

September 28, 2002 Page 84

Inspection/Maintenance Readiness

(continued)

CALIDs ensure that the correct (not

recalled) software is on the vehicle.

CVNs ensure that the module software

was not tampered with.

MIL status must not indicate MIL on

during bulb prove out unless the MIL is

being commanded on by a confirmed

DTC.

Monitor readiness bits must be in Keep

Alive Memory

September 28, 2002 Page 85

Inspection/Maintenance Readiness

(continued)

I/M readiness status may be displayed

to the customer using the MIL.

After 15-20 seconds of MIL prove out,

the MIL can blink for 5-10 seconds if the

vehicle is not ready for I/M testing.

For the 2005 MY, CARB will require a

scan tool communication validation of

every production calibration using a

J1699-3 tool.

September 28, 2002 Page 86

SAE/ISO Diagnostic Specifications

Non-legislated diagnostic messages are

defined by SAE J2190 and ISO 14229

These are commonly referred to

manufacturer-specific test modes.

Manufacturers can use these messages

to perform manufacturer-specific tests

and obtain manufacturer-specific data

from any control module.

Almost all manufacturers provide this

info to the Equipment and Tool Institute

(ETI), the consortium of scan tool

manufacturers.

September 28, 2002 Page 87

SAE/ISO Diagnostic Specifications

Common uses for these messages are:

Obtain manufacturer-specific PIDs

Initiate on-board self-test

Obtain packets of PID data (rapid data)

Control module outputs

Reprogram flash memory

Configure modules

The J2190 messages are very similar to the

J1979 messages in structure and content.

Only physical addresses are used,

responses are required.

September 28, 2002 Page 88

J2190 Mode $13

Mode $13 reports all DTCs (emission

and non-emission, confirmed and

pending.)

Very similar Data

toBytes

Mode(Hex) $03

#1 #2 #3 #4 #5 #6 #7

Request all codes

Request all powertrain 13

DTCs (MIL, non-MIL,

pending)

Report all codes

Report all powertrain DTCs 53 Code #1 Code #2 Code #3

(MIL, non-MIL, pending) or 00 00 or 00 00 or 00 00

No codes to report, exit normally without results

General Response 7F 13 00 00 00 62

September 28, 2002 Page 89

J2190 Mode $14

Mode $14 clears all DTCs.

Very similar to Mode $04

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request clear codes

Request clear all codes, 14

(MIL, non-MIL, pending)

Confirm codes clear

Confirm all codes were 54

cleared (individual clearing

of codes not supported)

No codes to report, exit normally without results

General Response 7F 14 data data 00 12

byte #2 byte #3

September 28, 2002 Page 90

J2190 Mode $22

Mode $22 is used to get PIDs. PID numbers,

scaling and units are defined by manufacturer

and are specific to their individual systems.

Very similar to Mode $01

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request data by PID

Request PID Access 22 PID PID

(high (low

byte) byte)

Report data by PID

Report PID Data 62 PID PID data 1 data 2 data 3 data 4

(high (low (opt) (opt) (opt) (opt)

byte) byte)

Invalid PID requested, request not supported

General Response 7F 22 data data 00 12

byte #2 byte #3

September 28, 2002 Page 91

J2190 Mode $23

Mode $23 is used to download data by direct

memory address.

Test tool gets raw data.

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request data by DMR

Request DMR Access 23 address address address

EEC-V (high (mid (low

byte) byte) byte)

Report data by DMR

Report DMR Data 63 address address data 1 data 2 data 3 data 4

EEC-V (high (low (opt) (opt) (opt) (opt)

byte) byte)

Invalid DMR requested, request not supported

General Response 7F 23 address address 00 12

(high (mid

byte or byte or

high high

word word

MSB) LSB)

September 28, 2002 Page 92

J2190 Mode $2A

Mode $2A is used to get a string of PIDs in one

message; a rapid packet.

Used with Mode $2C to define rapid packet.

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request diagnostic data by packets

Request Rapid Packet 2A Data DPID DPID DPID DPID DPID

rate #1 #2 #3 #4 #5

(opt) (opt) (opt) (opt)

Data rate value: 00 - stop sending packet

04 - repeat at fast rate, type A

Report diagnostic data by packets

Report Rapid Packet 6A DPID data 1 data 2 data 3 data 4 data 5

#1 (opt) (opt) (opt) (opt)

Report diagnostic data by packet number n

Report Rapid Packet 6A DPID data 1 data 2 data 3 data 4 data 5

#n (opt) (opt) (opt) (opt)

Invalid DPID or invalid data rate requested

General Response 7F 2A data DPID DPID 12

rate #1 #2 or

00

September 28, 2002 Page 93

J2190 Mode $30

Mode $30 is used to directly control module

outputs like shift solenoids, IAC, AIR pump,

EGR, etc. (requires Mode $27 security access)

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Perform parameter substitution

Parameter Substitution 30 Chann. Subst. Subst.

ID Value Value

high low

byte byte

Confirm diagnostic routine entered

General Response 7F 30 Chann. Subst. Subst. 00

ID Value Value

high low

byte byte

Invalid conditions, test running, or test not supported

General Response 7F 31 Test # 00 00 31, 22,

33, or

12

September 28, 2002 Page 94

J2190 Mode $31

Mode $31 is used to request an on-board test,

based on test number.

Test Number On-demand Self Test Mode

$81 Key On Engine Off (gas and diesel)

$82 Key on Engine Running (gas and diesel)

$84 Output Test Mode (gas and diesel)

$88 Key On Engine Running Glow Plug Test (diesel)

$91 Key On Engine Off Injector Buzz Test (diesel)

$92 Key On Engine Running Cylinder Contribution Test

(diesel)

$95 Key OnBytes

Data Engine

(Hex) Running Switch Test (diesel)

#1 #2 #3 #4 #5 #6 #7

Perform diagnostic routine by test number

Diagnostic Routine Entry 31 Test #

Confirm diagnostic routine entered

General Response 7F 31 Test # 00 00 00

Invalid conditions, test running, or test not supported

General Response 7F 31 Test # 00 00 22, or

12

September 28, 2002 Page 95

J2190 Mode $36

Mode $36 is used for reprogramming.

(requires Mode $27 security access and

Mode $34 Download Entry request)

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Request to enter download mode

Download Block Data 36 data 1 data 2 data 3 data 4 data 5 data 6

or 00 or 00 or 00 or 00 or 00

Not in download mode

General Response 7F 36 data 1 data 2 data 3 22

September 28, 2002 Page 96

J2190 Mode $3F

Mode $3F is used to indicate that the

test tool is still online and prevent a

diagnostic session time-out.

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

Tester Present

Tester Present 3F

Acknowledge tester

General Response 7F 3F 00 00 00 00

September 28, 2002 Page 97

J2190 Mode $7F

Mode $7F is used by the control module to

respond to a test tool request.

Data Bytes (Hex)

#1 #2 #3 #4 #5 #6 #7

General acknowledge

General Response 7F Data Data Data Data Ackn

byte #1 byte #2 byte #3 byte #4 or

of of of of Reject

request request request request code

Acknowledge or Reject Code:

$00 - General affirmative

$10 - General reject

$11 - Mode not supported

$12 - Invalid format, sub-function not supported

$21 - Busy, repeat request

$22 - Condition not correct, sequence error

$23 - Routine not complete

$31 - Request out of range

$33 - Access denied, device secured

$34 - Access granted

$50 - Upload not accepted

$61 - Normal exit with results

$62 - Normal exit without results

$63 - Abnormal exit with results

$64 - Abnormal exit without results

September 28, 2002 Page 98

J1979 Message Traffic Example

Clear DTCs (Mode 04)

TX MSG: J1850PWM 61 6A F1 04

RX MSG: J1850PWM 01 6B 10 44

Request PIDs (Mode 01) [PID $00 defines which PIDs are

supported ]

TX MSG: J1850PWM 61 6A F1 01 00

RX MSG: J1850PWM 01 6B 10 41 00 BF 9F B9 10

Request PID 04 (LOAD_PCT)

TX MSG: J1850PWM 61 6A F1 01 04

RX MSG: J1850PWM 01 6B 10 41 04 00 [LOAD_PCT = 0%]

Request PID 05 (ECT)

TX MSG: J1850PWM 61 6A F1 01 05

RX MSG: J1850[PWM 01 6B 10 41 05 4A [ECT = 74 deg F]

Request PID 11 (TP)

TX MSG: J1850PWM 61 6A F1 01 11

RX MSG: J1850PWM 01 6B 10 41 11 32 [TP = 19%]

Request PID 1C (OBD Type)

TX MSG: J1850PWM 61 6A F1 01 1C

RX MSG: J1850PWM 01 6B 10 41 1C 01 [OBD_TYPE = 1 = OBD-II]

September 28, 2002 Page 99

J1979 Message Traffic Example

Request Mode 09 info

TX MSG: J1850PWM 61 6A F1 09 00 [request Mode 09 items

supported]

RX MSG: J1850PWM 01 6B 10 49 00 01 FC 00 00 00

TX MSG: J1850PWM 61 6A F1 09 01

RX MSG: J1850PWM 01 6B 10 49 01 05 [number of VIN messages = 5]

TX MSG: J1850PWM 61 6A F1 09 02 [item 02 = VIN]

RX MSG: J1850PWM 01 6B 10 49 02 01 00 00 00 31

RX MSG: J1850PWM 01 6B 10 49 02 02 46 54 59 52

RX MSG: J1850PWM 01 6B 10 49 02 03 34 34 45 37

RX MSG: J1850PWM 01 6B 10 49 02 04 32 54 41 33

RX MSG: J1850PWM 01 6B 10 49 02 05 31 39 37 38 [VIN = 1FTYR44E72TA31978]

Request Pending DTCs (Mode 07)

TX MSG: J1850PWM 61 6A F1 07

RX MSG: J1850PWM 01 6B 10 47 01 13 01 02 00 00 [Pending DTC P0113, P0102

detected]

September 28, 2002 Page 100

J1979 Message Traffic Example

Request Freeze Frame Support (Mode 02) [PID $00 defines which PIDs are

supported ]

TX MSG: J1850PWM 61 6A F1 02 00 00

RX MSG: J1850PWM 01 6B 10 42 00 00 7F 98 00 00

Request Freeze Frame PID 02

TX MSG: J1850PWM 61 6A F1 02 02 00

RX MSG: J1850PWM 01 6B 10 42 02 00 01 13 [DTC that stored frame =

P0113]

Request DTCs (mode 03)

TX MSG: J1850PWM 61 6A F1 03 [No response to OBD request, no

DTCs]

Request DTCs (Mode 03)

TX MSG: J1850PWM 61 6A F1 03

RX MSG: J1850PWM 01 6B 10 43 01 13 00 00 00 00 [Stored DTC P0113

detected]

September 28, 2002 Page 101

The End

I hope this presentation took some

of the mystery out of diagnostic

scan tool communication.

Thank you for your interest and

attention!

September 28, 2002 Page 102

Potrebbero piacerti anche

- CMXC007 Upgrade Kit ManualDocumento97 pagineCMXC007 Upgrade Kit ManualJESUSCALVILLONessuna valutazione finora

- Skoda Kodiaq Electrical System EngDocumento210 pagineSkoda Kodiaq Electrical System EngСергей ДаниловNessuna valutazione finora

- J1939 Line in Modbus Master Modbus Slave MTU Slave NMEA Listener NMEA Talker OPC Client Simulation System IO Tank Calculation Tcp/Ip TTPDocumento125 pagineJ1939 Line in Modbus Master Modbus Slave MTU Slave NMEA Listener NMEA Talker OPC Client Simulation System IO Tank Calculation Tcp/Ip TTPBruno SilvaNessuna valutazione finora

- 1994 850 Wiring DiagramDocumento178 pagine1994 850 Wiring DiagramrlgglobalNessuna valutazione finora

- Iso 11898 3 2006 en PDFDocumento11 pagineIso 11898 3 2006 en PDFSebastian Linares RugelesNessuna valutazione finora

- Chrysler - CCD (Chrysler Collision Detection) Data Bus - Carprog - 博客园Documento21 pagineChrysler - CCD (Chrysler Collision Detection) Data Bus - Carprog - 博客园Francisco López RosasNessuna valutazione finora

- SM 11Documento128 pagineSM 11jaciel leonNessuna valutazione finora

- Grand CherokeeDocumento15 pagineGrand Cherokee陳潤生Nessuna valutazione finora

- Electrical SystemDocumento446 pagineElectrical SystemChamp PowerNessuna valutazione finora

- DAF XF CF Euro 4, 5 Electrical Wiring DiagramsDocumento199 pagineDAF XF CF Euro 4, 5 Electrical Wiring DiagramsgsmhelpeveshamNessuna valutazione finora

- Protocol Automotive IndustryDocumento17 pagineProtocol Automotive IndustryUtpal100% (8)

- 2009-08-29 161926 Honda Accord V6 P0401Documento11 pagine2009-08-29 161926 Honda Accord V6 P0401Quoc Huynh100% (1)

- VW Caddy 2016+ - 4-Cylinder Injection Engine (1.6l Engine, 4 Valves, MPI) (CWVA) - Get FreeDocumento244 pagineVW Caddy 2016+ - 4-Cylinder Injection Engine (1.6l Engine, 4 Valves, MPI) (CWVA) - Get FreeJuvencio CastroNessuna valutazione finora

- Freelander 1 MY01 - Land Rover Academy Training WorkbookDocumento246 pagineFreelander 1 MY01 - Land Rover Academy Training WorkbookWan SaulNessuna valutazione finora

- RS-485 Communications ProtocolDocumento20 pagineRS-485 Communications ProtocolManish Vohra100% (2)

- Ford Mondeo Manual enDocumento306 pagineFord Mondeo Manual enDaniel SmithNessuna valutazione finora

- Last Modified: Jan 31, 2023Documento165 pagineLast Modified: Jan 31, 2023profesorjuniperusNessuna valutazione finora

- 9 Swift Vol2 BodyDocumento196 pagine9 Swift Vol2 BodyGerardo Diaz100% (1)

- 2016 Transit Connect RedDocumento24 pagine2016 Transit Connect RedMacklin Aleman100% (1)

- New-Generation VQ Engine Briefing: Yo Usuba Senior Vice PresidentDocumento50 pagineNew-Generation VQ Engine Briefing: Yo Usuba Senior Vice PresidentPaul Rodriguez100% (1)

- PG Murano 2006Documento72 paginePG Murano 2006Alexander GutierrezNessuna valutazione finora

- FCA Engine Mangement Operation and DiagDocumento272 pagineFCA Engine Mangement Operation and DiagCristobal MedinaNessuna valutazione finora

- Berger Lahr Servodrives WPM311Documento100 pagineBerger Lahr Servodrives WPM311Luis Fernando SabogalNessuna valutazione finora

- Ec 2007 SedanDocumento547 pagineEc 2007 SedanJeanJonesNessuna valutazione finora

- K-Suite 2.35 - Alientech News & BlogDocumento20 pagineK-Suite 2.35 - Alientech News & BlogBrahim SalahNessuna valutazione finora

- Lin ProtocolDocumento40 pagineLin Protocolabdou ht100% (1)

- FastIron 07400 ConfigGuideDocumento2.128 pagineFastIron 07400 ConfigGuidedmadhavarajNessuna valutazione finora

- 2007 Nissan Armada 44Documento78 pagine2007 Nissan Armada 44Sameh ElmahdyNessuna valutazione finora

- Ch6 COMMUNICATION PROTOCOLS PDFDocumento52 pagineCh6 COMMUNICATION PROTOCOLS PDFalejandro sanchezNessuna valutazione finora

- N13 Manual PDFDocumento238 pagineN13 Manual PDFignitionyemiNessuna valutazione finora

- Can FordDocumento3 pagineCan Fordrodrigo michelNessuna valutazione finora

- MyCANIC User ManualDocumento19 pagineMyCANIC User ManualSaddam Basim100% (2)

- fmp1648 PDFDocumento2 paginefmp1648 PDFM Safi Arshad AliNessuna valutazione finora

- Ethernet: Introduction To NetworksDocumento62 pagineEthernet: Introduction To NetworksAdie Madi AsmadiNessuna valutazione finora

- Automotive ISO 9141 Serial Link Driver: Technical DataDocumento18 pagineAutomotive ISO 9141 Serial Link Driver: Technical DataP GlNessuna valutazione finora

- 2011 Ford Transit Connect ElectricDocumento1 pagina2011 Ford Transit Connect ElectricFord Motor CompanyNessuna valutazione finora

- OMVL Tuning Instructions 081210Documento2 pagineOMVL Tuning Instructions 081210leeroy381100% (2)

- SprinterDocumento292 pagineSprinterHector HectorNessuna valutazione finora

- Nippon PDFDocumento96 pagineNippon PDFEugen BratuNessuna valutazione finora

- VCDS Coding For Footwell LightsDocumento1 paginaVCDS Coding For Footwell LightsValentin EneNessuna valutazione finora

- AN930A - J1939 C Library For CAN-Enabled PICmicro PDFDocumento28 pagineAN930A - J1939 C Library For CAN-Enabled PICmicro PDFCarlos Eduardo Caparroz DuarteNessuna valutazione finora

- Ford TrasnDocumento65 pagineFord TrasngeorgedenielNessuna valutazione finora

- Curso Scaner NextechDocumento56 pagineCurso Scaner NextechJuan Manuel VasquezNessuna valutazione finora

- CAN HandoutDocumento16 pagineCAN HandoutJaffer HussainNessuna valutazione finora