Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ANSYS Steady-State Thermal Analysis Guide

Caricato da

Florian BăceanuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ANSYS Steady-State Thermal Analysis Guide

Caricato da

Florian BăceanuCopyright:

Formati disponibili

Chapter Six

Thermal Analysis

Steady-State Thermal Analysis

Chapter Overview

In this chapter, performing steady-state thermal analyses in

Simulation will be covered:

Geometry and Elements

Contact and Types of Supported Assemblies

Environment, including Loads and Supports

Solving Models

Results and Postprocessing

The capabilities described in this section are generally

applicable to ANSYS DesignSpace Entra licenses and

above, except for an ANSYS Structural license.

Some options discussed in this chapter may require more

advanced licenses, but these are noted accordingly.

ANSYS Workbench Simulation

Training Manual

It is assumed that the user has reviewed Chapters 1-3 prior to

this chapter. (Chapters 4-5 are optional)

March

Steady-State Thermal Analysis

Basics of Steady-State Heat Transfer

For a steady-state (static) thermal analysis in Simulation,

the temperatures {T} are solved for in the matrix below:

K T T Q T

This results in the following assumptions:

No transient effects are considered in a steady-state analysis

[K] can be constant or a function of temperature

Temperature-dependent thermal conductivity can be input for each

material property

{Q} can be constant or a function of temperature

Temperature-dependent film coefficients can be input for

convective boundary conditions

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Basics of Steady-State Heat Transfer

Training Manual

This means that the thermal analysis Simulation solves for is a

conduction-based equation.

Heat flow within a solid (Fouriers Law) is the basis of [K]

Heat flux, heat flow rate, and convection are treated as boundary

conditions on the system {Q}

No radiation is currently considered

No time-dependent effects are currently considered

Heat transfer analysis is different from CFD (Computational Fluid

Dynamics)

Convection is treated as a simple boundary condition, although

temperature-dependent film coefficients are possible.

If a conjugate heat transfer/fluid problem needs to be analyzed, one

must use ANSYS CFD tools instead.

ANSYS Workbench Simulation

Fouriers Law provides the basis of the previous equation:

It is important to remember these assumptions related to

performing thermal analyses in Simulation.

March

Steady-State Thermal Analysis

Physics Filters

Before proceeding to a detailed discussion on performing

thermal analyses in Simulation, it is useful to point out that

if a thermal-only solution is to be performed, the Physics

Filter can be useful to filter the GUI.

Under View menu > Physics Filter, unselect the Structural

option. Now, the available options in the Simulation GUI will

only reflect thermal analyses.

This applies to options in the

Environment and Solution

levels only.

If a thermal-stress simulation is to

be performed, do not turn off any

physics filters since both structural

and thermal options may be required.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

A. Geometry

In thermal analyses, all types of bodies supported by

Simulation may be used.

Solid, surface, and line bodies are supported by all products

which support thermal analyses.

For surface bodies, thickness must be input in the Details view of

the Geometry branch

The cross-section and orientation of line bodies is defined within

DesignModeler and is imported into Simulation automatically.

Although the cross-section and orientation is defined, this

information is meant for structural analyses, and the actual thermal

link element will have an effective cross-section based on the

input properties.

No heat flux or vector heat flux output is available with line bodies.

Only temperature results are available for line bodies.

The Point Mass feature is not applicable in thermal analyses

ANSYS Workbench Simulation

Training Manual

Point Mass is described in Chapter 4, Linear Structural Analysis.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

March

Steady-State Thermal Analysis

Geometry

It is important to understand assumptions related to using

shell and line bodies:

For shell bodies, through-thickness temperature gradients are

not considered. A shell body should be used for thin

structures when it can be safe to assume temperatures on top

and bottom of surface are the same.

Temperature variation will still be considered across the surface,

just not through the thickness, which is not explicitly modeled.

For line bodies, thickness variation in the cross-section is not

considered. A line body should be used for beam- or truss-like

structures, where the temperature can be assumed to be

constant across the cross-section.

Temperature variation will still be considered along the line body,

just not through the cross-section, which is not explicitly modeled.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Material Properties

Training Manual

Material input is under the Engineering Data tab, and material

assignment is per part under the Geometry branch

Thermal Conductivity is

input under the Engineering

Data tab.

Temperature-dependent

thermal conductivity can

be input as a table.

Other material input

is not used in thermal.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

If any temperature-dependent material properties exist, this will

result in a nonlinear solution. This is because the temperatures are

solved for, but the materials are dependent on the temperatures, so

it is not linear.

ANSYS Workbench Simulation

The only required material property is thermal conductivity.

March

Steady-State Thermal Analysis

B. Assemblies Solid Body Contact

When importing assemblies of solid parts, contact regions

are automatically created between the solid bodies.

Surface-to-surface contact allows non-matching meshes at

boundaries between solid parts

Contact enables heat transfer between parts in an assembly

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

x

Model shown is from a sample Inventor assembly.

March

Steady-State Thermal Analysis

Assemblies Contact Region

In Simulation, the concept of contact and target surfaces

are used for each contact region.

One side of the contact region is comprised of contact

face(s), the other side of the region is made of target face(s).

Heat flow is allowed between contact and target faces (based

on the contact normal direction)

When one side is the contact and the other side is the target, this is

called asymmetric contact. On the other hand, if both sides are

made to be contact & target, this is called symmetric contact.

However, the designation of which side is contact or target is

unimportant in thermal analysis.

By default, Simulation uses symmetric

contact for solid assemblies.

For ANSYS Professional licenses

and above, the user may change to

asymmetric contact, as desired.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

x

March

Steady-State Thermal Analysis

Assemblies Contact Region

As noted in the previous slide, heat flows within a contact

region in the contact normal direction

No heat spreading is considered in the contact/target interface

Heat spreading is considered within shell or solid elements at the

contact or target surfaces because of Fouriers Law

Heat flow within the contact region is in the contact normal

direction only

This means that, regardless of the definition of the contact region,

heat flows only if a target element is present in the normal

direction

In the figure on the left, the solid

green double-arrows indicate

heat flow within the contact

region. Heat flow only occurs if a

target surface is normal to a

contact surface.

The light, dotted green arrows

indicate that no heat transfer will

occur between parts.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

x

March

Steady-State Thermal Analysis

Assemblies Contact Region

In Simulation, various contact behaviors exist

The contact Type is meant for structural applications

If the parts are initially in contact, heat transfer will occur

between the parts. If the parts are initially out of contact, the

parts will not transfer heat between each other.

Based on the contact type, whether heat will be transferred

between contact and target surfaces is outlined below:

Contact Type

Bonded

No Separation

Rough

Frictionless

Heat Transfer Between Parts in Contact Region?

Initially Touching

Inside Pinball Region Outside Pinball Region

Yes

Yes

No

Yes

Yes

No

Yes

No

No

Yes

No

No

The pinball region is automatically defined and set to a

relatively small value to accommodate small gaps which may

present in the model. The pinball region will be discussed

next.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

x

March

Steady-State Thermal Analysis

Assemblies Contact Region

The pinball region may be input and

visualized in ANSYS Professional

licenses and above.

If the target nodes lie within the pinball region

and the contact is bonded or no separation,

then heat transfer will occur (solid green lines)

Otherwise, no heat transfer will occur between

nodes (dotted green lines)

Pinball Radius

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

In this figure on the right, the

gap between the two parts is

bigger than the pinball region,

so no heat transfer will occur

between the parts

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Assemblies Thermal Conductance

By default, a high thermal contact conductance (TCC) is

defined between parts of an assembly

The amount of heat flow between two parts is defined by the

contact heat flux q:

q TCC Ttarget Tcontact

where Tcontact is the temperature of a contact node and Ttarget

is the temperature of the corresponding target node located

in the contact normal direction.

By default, TCC is set to a relatively high value, based on the

largest material conductivity defined in the model KXX and the

diagonal of the overall geometry bounding box ASMDIAG.

TCC KXX 10,000 / ASMDIAG

This essentially provides perfect conductance between parts.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

x

March

Steady-State Thermal Analysis

Assemblies Thermal Conductance

Training Manual

One may want to include finite thermal conductance instead

Two surfaces (at different temperatures) in contact experience

a temperature drop across the interface. The drop is due to

imperfect contact between the two surfaces. The imperfect

contact, and hence the finite contact conductance, can be

influenced by many factors such as:

surface flatness

surface finish

oxides

entrapped fluids

contact pressure

surface temperature

use of conductive grease

ANSYS Workbench Simulation

Perfect thermal contact conductance between parts means

that no temperature drop is assumed at the interface.

T

x

March

Steady-State Thermal Analysis

Assemblies Thermal Conductance

In ANSYS Professional licenses and above, the user may

define a finite thermal contact conductance (TCC) if the

Pure Penalty or Augmented Lagrange Formulation is used.

The thermal contact conductance per unit area is input for

each contact region in the Details view, as shown below.

If thermal contact resistance is known, invert this value and

divide by the contacting area to obtain TCC value.

When this is done, there will now be a temperature drop

between the contact and target surfaces for a contact region.

If Thermal Conductance is left

at Program Chosen, nearperfect thermal contact

conductance will be defined.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

The user can change this to

Manual to input finite thermal

contact conductance instead,

which is the same as including

thermal contact resistance at a

contact interface.

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Assemblies Thermal Conductance

If using symmetric contact, the user does

not need to account for a double

thermal contact resistance.

Input values as normal

MPC bonded contact allows for perfect

thermal contact conductance.

In this case, no thermal contact

conductance is used nor defined because

contact is related via constraint

equations.

The contact node and corresponding

target node will have the same

temperature because of perfect contact

conductance.

Do not use Normal Lagrange

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

formulation for thermal analyses. If

selected, the ANSYS solver will actually

use Augmented Lagrange with a

perfect thermal contact conductance.

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Assemblies Surface Body Contact

For ANSYS Professional licenses and above, mixed

assemblies of shells and solids are supported

Allows for more complex modeling of assemblies, taking

advantage of the benefits of shells, when applicable

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

ANSYS Workbench Simulation

Training Manual

Availability

x

x

March

Steady-State Thermal Analysis

Assemblies Surface Body Contact

Edge contact is a subset of general contact

For contact including shell faces or solid

edges, only bonded or no separation

behavior is allowed.

For contact involving shell edges, only

bonded behavior using MPC formulation is

allowed.

For MPC-based bonded contact, user can set

the search direction (the way in which the

multi-point constraints are written) as either

the target normal or pinball region.

If a gap exists (as is often the case with

shell assemblies), the pinball region can be

used for the search direction to detect

contact beyond a gap.

ANSYS Workbench Simulation

Training Manual

MPC results in perfect contact conductance

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

March

Steady-State Thermal Analysis

Assemblies Spot Weld

Spot welds provide a means of connecting shell

assemblies at discrete points for heat transfer

Spotweld definition is done in the CAD software. Currently,

only DesignModeler and Unigraphics define spotwelds in a

manner that Simulation supports.

Spotwelds can also be created in Simulation manually, but

only at discrete vertices.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

DesignModeler

Pro/ENGINEER

Unigraphics

SolidWorks

Inventor

Solid Edge

Mechanical Desktop

CATIA V4

CATIA V5

ACIS (SAT)

Parasolid

IGES

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

C. Loads

There are three types of loads in thermal analyses:

Heat Loads:

These loads pump heat into the system.

Heat loads can be input as a known heat flow rate or heat flow rate

per unit area or unit volume.

Adiabatic Condition:

This is the naturally-occurring boundary condition, where there is

not heat flow through the surface.

Thermal Boundary Conditions:

These boundary conditions act as heat sources or heat sinks with

a known temperature condition.

These can be either a prescribed temperature or a convection

boundary condition with a known bulk temperature.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Heat Loads

Heat Flow:

A heat flow rate can be applied to a vertex, edge, or surface.

The load gets distributed for multiple selections.

Heat flow has units of energy/time (i.e., power).

Heat Flux:

A heat flux can be applied to surfaces only.

Heat flux has units of energy/time/area (i.e., power/area)

Internal Heat Generation:

An internal heat generation rate can be applied to bodies only.

Heat generation has units of energy/time/volume

A positive value for heat load will add energy to the system.

Also, if multiple loads are present, the effect is cumulative.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Adiabatic Conditions

Perfectly Insulated:

Perfectly insulated condition is applied to surfaces

Can be thought of as a zero heat flow rate loading

This is actually the naturally-occurring condition in thermal

analyses, when no load is applied.

Usually, one does not need to apply a perfectly insulated condition

on surfaces since that is the natural behavior for a regular surface.

Hence, this loading is meant to be used as a way to remove loading

on specified surfaces. For example, it may be easier for a user to

apply heat flux or convection on all surfaces, then use the perfectly

insulated condition to selectively remove the loading on some

surfaces (such as those in contact with other parts).

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Thermal Boundary Conditions

Training Manual

At least one type of thermal boundary condition must be present.

Otherwise, the steady-state temperature will be infinite if only heat

is pumped into a system!

Also, Given Temperature or Convection load should not be applied

on surfaces that already have another heat load or thermal

boundary condition applied to it.

If applied on an entity which also has a heat load, the

temperature boundary condition will override.

Perfect insulation will override thermal boundary conditions.

Given Temperature:

This imposes a temperature on vertices, edges, or surfaces.

Temperature is the degree of freedom solved for, but this fixes

the temperature on selected entities to a given value.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Thermal boundary conditions present a known local or

remote temperature condition.

March

Steady-State Thermal Analysis

Thermal Boundary Conditions

Convection:

Applied to surfaces only.

Convection relates a ambient temperature with the surface

temperature:

q hATsurface Tambient

where the convective heat flux q is related to a film coefficient

h, the surface area A, and the difference in the surface

temperature Tsurface & ambient temperature Tbulk.

Meant to provide a simplified way of accounting for heat

transport from a fluid. h and Tbulk are user-input values.

The film coefficient h can be constant or input from a file

(next)

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Thermal Boundary Conditions

Training Manual

If film coefficient h is input from a file, this can be a constant or

temperature-dependent value h(T).

Define a convection boundary condition under the Environment branch

and define the Type to be Temperature-Dependent. Next, select New

Convection for the Correlation. The Engineering Data tab will open

and the Coefficient Type can then be defined for the new convection load.

Determine what temperature is used for h(T) first, for temperaturedependent film coefficients. Temperature can be:

Average film temperature

T=(Tsurface+Tbulk)/2

Surface temperature

T= Tsurface

Bulk temperature

T= Tbulk

Difference of surface and

bulk temperatures

T=(Tsurface-Tbulk)

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

Select the temperaturedependency from the

pull-down menu

ANSYS Workbench Simulation

Temperature-Dependent Convection (continued):

March

Steady-State Thermal Analysis

Thermal Boundary Conditions

Temperature-Dependent Convection (continued):

After the type of temperature-dependency is selected, the user may

input the film coefficients and temperatures in a table. The values

are plotted on a graph, as shown below.

ANSYS Workbench Simulation

Training Manual

If any temperature-dependent

convection load is applied, this

will result in a nonlinear solution

since the surface temperature is

solved for, but the film coefficient

h is based on a function of the

surface temperature.

Right mouse click on the table

to add or delete values.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

The only exception is if the film

coefficient h is based on a

function of the bulk temperature

only. In Simulation, the bulk

temperature is constant and input

by the user, so this load will not

be nonlinear.

March

Steady-State Thermal Analysis

Thermal Boundary Conditions

Temperature-Dependent Convection (continued):

The convection data can also be imported from a file.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Thermal Loads Summary

For some structural users, it may be useful to provide an

analogy of structural and thermal analyses:

Structural

No external force

Natural Condition

Boundary

Conditions

Load

Inertial Loads

Direct

Indirect

Direct

Per Area

Per Volume

Given Displacement

Force

Pressure

Thermal Expansion

Acceleration

Thermal

Perfectly Insulated

(No heat flow rate)

Given Temperature

Convection

Heat Flow

Heat Flux

Internal Heat Generation

There are some types of loads that do not have any analogy

There is no thermal equivalent for inertial loads such as rotational

velocity or acceleration

The analogy of convective boundary condition is a foundation

stiffness support in structural terms, similar to a grounded spring

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

D. Solution Options

Solution options can be set under the Solutions branch:

The ANSYS database can be saved if Save

ANSYS db is set

Useful if you want to open a database in ANSYS

Two solvers are available in Simulation

The default solver is automatically chosen and

does not usually need to be changed.

The Iterative solver can be efficient for solving

large models whereas the Direct solver is a

robust solver and handles any situation.

The ability to change the default solver is under

Tools > Options > Simulation: Solution

> Solver Type

The Weak Springs and Large Deflection

options are meant for structural analyses only,

so they can be ignored for a thermal analysis.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Solution Options

Training Manual

For a regular thermal analysis, the Analysis Type

will be set to Static Thermal. If structural

supports and results are present, then the

analysis type will be Thermal Stress.

A nonlinear solution will be required if

temperature-dependent (a) material properties or

(b) convection film coefficients are present. This

means that several internal iterations will be run

to achieve heat equilibrium.

The solver working directory is where scratch files

are saved during the solution of the equations.

By default, the TEMP directory of your Windows

system environment variable is used, although this

can be changed in Tools > Options >

Simulation: Solution > Solver Working Directory.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Any solver messages which appear after

solution can be checked afterwards under

Solver Messages

Availability

x

x

x

x

ANSYS Workbench Simulation

Informative settings show the user the status of the analysis:

March

Steady-State Thermal Analysis

Solving the Model

To solve the model, request results first (covered next) and

click on the Solve button on the Standard Toolbar

By default, two processors (if present) will be used for parallel

processing. To change this, use Tools > Options >

Simulation: Solution > Number of Processors to Use

Recall that if a Solution Information branch is requested, the

details of the solution output can be examined.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Solving the Model

To perform a thermal-stress solution, simply add structural

support(s) and request structural results, then solve the

model.

Structural loads are optional but can also be added.

Simulation will know that a thermal-stress analysis is to be

performed (under Details view of the Solution branch). The

following will be performed automatically:

A steady-state thermal analysis will be performed

The temperature field will be mapped back onto the structural

model

A structural analysis will be performed

See Chapter 4 for details on Structural Analyses

Simulation automates this type of coupled-field solution, so

the user does not have to worry about the above details.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

E. Results and Postprocessing

Various results are available for postprocessing:

Temperature

Heat Flux

Reaction Heat Flow Rate

In Simulation, results are usually requested before solving,

but they can be requested afterwards, too.

If you solve a model then request results afterwards, click on

the Solve button

, and the results will be retrieved. A

new solution is not required for retrieving output of a solved

model.

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Temperature

Temperature contour plots can be requested:

Temperature is the degree of freedom solved for,

and it is the most basic output request.

Temperature is a scalar quantity and, therefore,

has no direction associated with it.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Heat Flux

Heat flux contour or vector plots are available:

Heat flux q is defined as

q KXX T

and is related to the thermal gradient T. The heat flux output

has three components and can aid the user in seeing how the

heat is flowing.

The magnitude plotted as contours: Total Heat Flux

The magnitude & direction as vectors: Vector Heat Flux

Recall that wireframe is best for viewing vectors

Components of heat flux

can be requested with

Directional Heat Flux

and can be mapped on

any coordinate system.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Reaction Heat Flow Rate

Reaction heat flow rates is available for any Given

Temperature or Convection boundary condition

Recall that both given temperature and convection supply a

known temperature, either directly or indirectly. Hence, this

acts as a heat source/sink, and the amount of heat flowing in

(positive) or out (negative) of the support can be output.

For each individual Given Temperature or

Convection load, the Reaction heat flow rate

is printed in the Details view after a solution.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

Reaction Heat Flow Rate

The Worksheet tab for Environment branch has a

tabular summary of reaction heat flow rates.

If a thermal support shares a vertex, edge, or surface with

another thermal support or load, the reported reaction heat

flow rate may be incorrect. This is due to the fact that the

underlying mesh will have multiple supports applied to the

same nodes. The solution will still be valid, but the reported

values may not be accurate because of this.

ANSYS License

DesignSpace Entra

DesignSpace

Professional

Structural

Mechanical/Multiphysics

Availability

x

x

x

x

ANSYS Workbench Simulation

Training Manual

March

Steady-State Thermal Analysis

F. Workshop 6

Workshop 6 Thermal Analysis

Goal:

Analyze the pump housing shown below for its heat transfer

characteristics.

ANSYS Workbench Simulation

Training Manual

March

Potrebbero piacerti anche

- Ansys Thermal Tutorial-2Documento14 pagineAnsys Thermal Tutorial-2dd hhNessuna valutazione finora

- AWS90 Ch10 HarmonicDocumento40 pagineAWS90 Ch10 Harmonicvikalp shri100% (1)

- AWS90 Structural Nonlin Ch02 NonlinearDocumento94 pagineAWS90 Structural Nonlin Ch02 NonlinearVivek KumarNessuna valutazione finora

- AWS90 Ch05 ModalDocumento7 pagineAWS90 Ch05 ModalrameshNessuna valutazione finora

- Chapter 8 - LoadingDocumento8 pagineChapter 8 - LoadingmuhdqasimNessuna valutazione finora

- AWS90 Ch05 ModalDocumento24 pagineAWS90 Ch05 ModalCinitha ANessuna valutazione finora

- AWS90 Ch01 IntroDocumento32 pagineAWS90 Ch01 IntroyuriNessuna valutazione finora

- ANSYS Mechanical APDL Element ReferenceDocumento1.498 pagineANSYS Mechanical APDL Element Referencesubhra_civ658Nessuna valutazione finora

- ANSYS DampingDocumento8 pagineANSYS Dampingsuresh_501Nessuna valutazione finora

- AM 12 Appendix ADocumento66 pagineAM 12 Appendix AMohamad Poortoosi100% (1)

- Final Project AnsysDocumento22 pagineFinal Project AnsysDaniyal AliNessuna valutazione finora

- A Comparison Study of Pressure Vessel Design Using Different StandardsDocumento116 pagineA Comparison Study of Pressure Vessel Design Using Different StandardsManasses junior100% (1)

- PADT Webinar Post26 2012 - 04 - 12Documento54 paginePADT Webinar Post26 2012 - 04 - 12Jack FusionNessuna valutazione finora

- Aeroelastic Analysis of A Wing (Pressentation)Documento66 pagineAeroelastic Analysis of A Wing (Pressentation)Muhammad AamirNessuna valutazione finora

- Multiphysics Simulation For Marine Applications: CD-adapcoDocumento100 pagineMultiphysics Simulation For Marine Applications: CD-adapcoesmaeil013100% (2)

- Fluent-Intro 16.0 L03 BoundaryConditions PDFDocumento51 pagineFluent-Intro 16.0 L03 BoundaryConditions PDFAnonymous 8209ZTNessuna valutazione finora

- Thermal-Stress Analysis Theory and Practices - Predictive Engineering White PaperDocumento24 pagineThermal-Stress Analysis Theory and Practices - Predictive Engineering White PaperL.a. MayorNessuna valutazione finora

- 123Documento74 pagine123rajeev50588Nessuna valutazione finora

- Openfoam ScilabDocumento30 pagineOpenfoam Scilababdelaziz_arbaoui6043Nessuna valutazione finora

- Overset Mesh in StarCCMDocumento43 pagineOverset Mesh in StarCCMKe YamNessuna valutazione finora

- Rotor - Dynamics - v14 - Open Days Feb 2012 PDFDocumento46 pagineRotor - Dynamics - v14 - Open Days Feb 2012 PDFAnder GogenolaNessuna valutazione finora

- Fluent-FSI 14.5 Lect-00 IntroDocumento16 pagineFluent-FSI 14.5 Lect-00 IntroEnrique Flores0% (1)

- 1way Transient FSI ACT Workshop 15.0Documento28 pagine1way Transient FSI ACT Workshop 15.0DaoudNessuna valutazione finora

- CAEfatigue Use CasesDocumento10 pagineCAEfatigue Use Casesgaurav patilNessuna valutazione finora

- ANSYS Fluent Meshing TutorialsDocumento6 pagineANSYS Fluent Meshing TutorialsAnonymous dtGbWVNessuna valutazione finora

- ANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFDocumento52 pagineANSYS FSI For Thermal Management and Aeroelasticity 11th May 2011 PDFdharmeswarNessuna valutazione finora

- CFD Lesson AnsysDocumento178 pagineCFD Lesson AnsysAditya JainNessuna valutazione finora

- Stress Classification of Blind FlangeDocumento13 pagineStress Classification of Blind FlangepajadhavNessuna valutazione finora

- MSC Nastran Rotor Dynamics Guide PDFDocumento258 pagineMSC Nastran Rotor Dynamics Guide PDFN.g. NagarajNessuna valutazione finora

- Mech HeatTransfer 15.0 L07 TransientThermalDocumento30 pagineMech HeatTransfer 15.0 L07 TransientThermalpercys99Nessuna valutazione finora

- Fluent-Intro 16.0 L06 SolverSettings PDFDocumento49 pagineFluent-Intro 16.0 L06 SolverSettings PDFAnonymous 8209ZTNessuna valutazione finora

- CFX Fsi 6dofDocumento26 pagineCFX Fsi 6dofCFDiran.irNessuna valutazione finora

- Cyclic Symmetry AnalysisDocumento26 pagineCyclic Symmetry AnalysisB Bala Venkata GaneshNessuna valutazione finora

- ANSYS Mechanical APDL Coupled-Field Analysis Guide - PDF (PDFDrive)Documento288 pagineANSYS Mechanical APDL Coupled-Field Analysis Guide - PDF (PDFDrive)engmimiNessuna valutazione finora

- Fluent Meshing 14.5 L03 Boundary FixDocumento77 pagineFluent Meshing 14.5 L03 Boundary FixShaheen S. RatnaniNessuna valutazione finora

- What Is Stress LinearizationDocumento9 pagineWhat Is Stress LinearizationamlanfacebookNessuna valutazione finora

- ANSYS - Fatigue Analysis - Simulation - ConfluenceDocumento6 pagineANSYS - Fatigue Analysis - Simulation - ConfluenceNur Rohman ArifNessuna valutazione finora

- ShipRight SDA SloshingLoadsAndScantlingAssessmentDocumento118 pagineShipRight SDA SloshingLoadsAndScantlingAssessmentjairamsaripilliNessuna valutazione finora

- ANSYS Mechanical APDL Advanced Analysis Guide PDFDocumento414 pagineANSYS Mechanical APDL Advanced Analysis Guide PDFMustafa Demir100% (1)

- Heat Transfer CoefficientDocumento5 pagineHeat Transfer CoefficientiitdvivNessuna valutazione finora

- 1 CD-Adapco Overset MeshDocumento47 pagine1 CD-Adapco Overset MeshRajaSekarNessuna valutazione finora

- Types of FEA AnalysisDocumento5 pagineTypes of FEA AnalysisRawendrraw KuriNessuna valutazione finora

- Multizone MeshingDocumento16 pagineMultizone Meshingpercys99Nessuna valutazione finora

- FractureDocumento57 pagineFractureAdool FighterNessuna valutazione finora

- The Most Accurate and Advanced Turbulence CapabilitiesDocumento47 pagineThe Most Accurate and Advanced Turbulence CapabilitiesaddafrrNessuna valutazione finora

- ANSYS PresentationDocumento48 pagineANSYS Presentationmagi100% (1)

- ANSYS Modal AnalysisDocumento40 pagineANSYS Modal AnalysisR.S.Vishwakarma5904Nessuna valutazione finora

- HTC Explained Star CCMDocumento25 pagineHTC Explained Star CCMramsinntNessuna valutazione finora

- Boundary Layer Analysis PDFDocumento242 pagineBoundary Layer Analysis PDFSekhar SamyNessuna valutazione finora

- CFX Intro 13.0 WS02 AirfoilDocumento27 pagineCFX Intro 13.0 WS02 Airfoilvicky3000Nessuna valutazione finora

- Schulung CERN 2014 MayDocumento1.085 pagineSchulung CERN 2014 Maydanaosajo100% (3)

- Fatigue 2013 Doc QuickstartDocumento932 pagineFatigue 2013 Doc QuickstartDasaka BrahmendraNessuna valutazione finora

- Fluent-Intro 14.5 WS09 DDPMDocumento14 pagineFluent-Intro 14.5 WS09 DDPMshah_aditkNessuna valutazione finora

- Ocean Loading in Ansys 14.5Documento29 pagineOcean Loading in Ansys 14.5Phúc Phan Tử100% (1)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityDa EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNessuna valutazione finora

- Rarefied Gas DynamicsDa EverandRarefied Gas DynamicsK KaramchetiValutazione: 5 su 5 stelle5/5 (1)

- Using HPC for Computational Fluid Dynamics: A Guide to High Performance Computing for CFD EngineersDa EverandUsing HPC for Computational Fluid Dynamics: A Guide to High Performance Computing for CFD EngineersNessuna valutazione finora

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsDa EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNessuna valutazione finora

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationDa EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNessuna valutazione finora

- Viscous Hypersonic Flow: Theory of Reacting and Hypersonic Boundary LayersDa EverandViscous Hypersonic Flow: Theory of Reacting and Hypersonic Boundary LayersNessuna valutazione finora

- Raport Sell-Out - L'OrDocumento3 pagineRaport Sell-Out - L'OrFlorian BăceanuNessuna valutazione finora

- Raport PivotDocumento254 pagineRaport PivotFlorian BăceanuNessuna valutazione finora

- READMEDocumento2 pagineREADMEFlorian BăceanuNessuna valutazione finora

- Alcatraz Island Prezentare PowerPoint EnglezaDocumento8 pagineAlcatraz Island Prezentare PowerPoint EnglezaFlorian BăceanuNessuna valutazione finora

- EulaDocumento5 pagineEulaMuhammad Usman AmirNessuna valutazione finora

- USB-DVD Tool ReadmeDocumento1 paginaUSB-DVD Tool ReadmehunttermadNessuna valutazione finora

- EulaDocumento5 pagineEulaMuhammad Usman AmirNessuna valutazione finora

- LicenseDocumento7 pagineLicenseAdnan AvdukićNessuna valutazione finora

- Electric Power Engineering Lecture NotesDocumento209 pagineElectric Power Engineering Lecture NotesRaj Boda0% (1)

- WWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsDocumento3 pagineWWW - Studyguide.pk: AS Physics - Revision Notes Unit 2 - Electricity and Thermal PhysicsHany ElGezawyNessuna valutazione finora

- Timber Columns: A. Axially Loaded ColumnsDocumento2 pagineTimber Columns: A. Axially Loaded ColumnsClarenz BragaNessuna valutazione finora

- JEE Mains 2024 Question Paper Shift 2 27 JanDocumento4 pagineJEE Mains 2024 Question Paper Shift 2 27 JanAnjali SahooNessuna valutazione finora

- Chemical Engineering ThermodynamicsDocumento40 pagineChemical Engineering ThermodynamicsSricharanNessuna valutazione finora

- Resonant Column Last VersionDocumento34 pagineResonant Column Last Versionkabasy2015Nessuna valutazione finora

- Aakash Daily TestsDocumento17 pagineAakash Daily TestsAdityanshu BeheraNessuna valutazione finora

- Autumn Break Home Work Class 9Documento4 pagineAutumn Break Home Work Class 9nashjrodrigues709Nessuna valutazione finora

- Homework 3 FebDocumento42 pagineHomework 3 FebEmmanuel Olowosulu100% (3)

- Examiners Report Breadth in Physics PDFDocumento32 pagineExaminers Report Breadth in Physics PDFNeural Spark PhysicsNessuna valutazione finora

- Vibration Measurement and Analysis FundamentalsDocumento28 pagineVibration Measurement and Analysis FundamentalsGilbertoAndresDuarteNessuna valutazione finora

- Conductors and Electric Field in Static EquilibriumDocumento1 paginaConductors and Electric Field in Static Equilibriumfrance villNessuna valutazione finora

- Magnetic Flow MeterDocumento3 pagineMagnetic Flow Meterniazakhtar100% (1)

- Electric Potential and CapacitanceDocumento31 pagineElectric Potential and CapacitanceSyco KillerNessuna valutazione finora

- Measurement and Prediction of Densities and Viscosities of Aqueous Binary and Ternary Solutions at Temperatures From 20 To 60 °c PDFDocumento42 pagineMeasurement and Prediction of Densities and Viscosities of Aqueous Binary and Ternary Solutions at Temperatures From 20 To 60 °c PDFnoviNessuna valutazione finora

- AQA Physics Students Book AnswersDocumento3 pagineAQA Physics Students Book AnswersT-Forty ArrowNessuna valutazione finora

- ESAC25 (C, N, D) : Fast Recovery Diodes PRV: 200 - 400 Volts Io: 10 AmperesDocumento2 pagineESAC25 (C, N, D) : Fast Recovery Diodes PRV: 200 - 400 Volts Io: 10 AmperesCarlos David MarquezNessuna valutazione finora

- VSEPR Theory5Documento18 pagineVSEPR Theory5Inaya ImranNessuna valutazione finora

- 14C ExamDocumento9 pagine14C ExamDerekNessuna valutazione finora

- MOTOR BASES FOR INDUSTRIAL APPLICATIONSDocumento8 pagineMOTOR BASES FOR INDUSTRIAL APPLICATIONSbogdanalaciNessuna valutazione finora

- Planar Waveguide PresentationDocumento16 paginePlanar Waveguide PresentationsaravananshheraNessuna valutazione finora

- Lab Experiment: Viscosity and Density: September 18, 2018Documento15 pagineLab Experiment: Viscosity and Density: September 18, 2018Luqman HakimNessuna valutazione finora

- References 3Documento2 pagineReferences 3Sumit ThakurNessuna valutazione finora

- P30 Unit Three Diploma ReviewDocumento30 pagineP30 Unit Three Diploma ReviewhelloNessuna valutazione finora

- DYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994Documento27 pagineDYNROT: A Matlab Toolbox For Rotordynamics Analysis: January 1994saurabhchandrakerNessuna valutazione finora

- Simulation of The Plug Assisted Thermoforming of Polypropylene Using A Large Strain Thermally Coupled Constitutive ModelDocumento26 pagineSimulation of The Plug Assisted Thermoforming of Polypropylene Using A Large Strain Thermally Coupled Constitutive ModelFadi DabbitNessuna valutazione finora

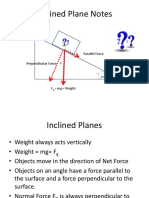

- Inclined Planes and Forces Notes PDFDocumento19 pagineInclined Planes and Forces Notes PDFLeroy JenkinsNessuna valutazione finora

- Kimet JusufiDocumento7 pagineKimet JusufiFatlum RushitiNessuna valutazione finora

- Force Between Two Parallel Current Carrying Conductors and Definition of Ampere PDFDocumento2 pagineForce Between Two Parallel Current Carrying Conductors and Definition of Ampere PDFPrabhuNessuna valutazione finora

- Optical Communication Past Questions and SolutionsDocumento25 pagineOptical Communication Past Questions and SolutionsMelsougly BryceNessuna valutazione finora