Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Presentation by Satnam Singh Sekhon M-Tech - 21016022

Caricato da

sandeepTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Presentation by Satnam Singh Sekhon M-Tech - 21016022

Caricato da

sandeepCopyright:

Formati disponibili

EFFECT OF DEEP

CRYOGENIC TREATMENT

ON HARDNESS AND

TENSILE PROPERTIES OF

ALSI 302 SS

ABSTRACT

Effects of deep cryogenic treatment (DCT) on static

mechanical properties of the AISI 302 austenitic

stainless steel were investigated through

experimental testing.

Results of the tensile and hardness tests are

discussed and compared to data and observations

from the DCT literature concerning the same material

Influence of two important treatment parameters,

such as the soaking-time and the minimum

temperature, is analysed to obtain confirmation and

suggestions about the possible use of the DCT as a

standard practice to improve the mechanical

properties of stainless steels

INTRODUCTION

Interesting positive effects were noticed on tool

steels, carburized steels, cast irons and on other

materials, from previous researches.

On austenitic stainless steels an extension of the

crack initiation process in DCT specimens was

noticed and it was ascribed to the presence of

strain induced martensite, which formed during

the cooling process,

It is not clear if the above results are strictly

related to the particular cryotreatment performed

or if a generic standard DCT could produce the

same effects.

Aim of this study is to clarify the above aspects.

MATERIALS AND METHODS

Testing specimens were obtained from a set of 12

mm diameter work-hardened AISI 302 bars

Bars were divided in two main families:

(H) to be machined as it is

(S) to be solubilized and then machined.

Solubilization process was realized by heating the

material up to 1325 K and then by suddenly cooling

it down to ambient temperature in water. The rapid

cooling prevent Chromium carbides formation. It is

done to get more homogeneous microstructure

Constant cooling rate of 21 K/h was applied for all

the DCT, while the return to the room temperature

was obtained at about 15 K/h.

Tensile tests were performed on a Schenck Trebel RSA-100

electromechanical device equipped with a 100 kN load cell

Strain rate was measured through a Schenck Trebel RDA-2

extensometer applied to the specimens.

All tests were conducted at a room temperature between

293 K and 298 K and with a displacement rate of 0.5

mm/min

Ultimate tensile strength (UTS) and yield stress (Rp0.2)

values were calculated from the acquired data

Rockwell hardness values was measured through a Galileo

durometer

RESULTS

Tensile test results

Solubilization process induced a drastic drop of the

strength properties and a remarkable change in the

tensile behaviour of the AISI 302 stainless steel

Although both materials shows a ductile behaviour

exceeding the 10% in elongation, the solubilized

one reaches a 40% in rupture elongation while the

hardened one breaks at about 15%.

HARDNESS

Results of the Rockwell hardness tests on box-plot

comparisons of the hardness data are as under

DISCUSSION

Tensile strength of the AISI 302 stainless steel, both hardened

and solubilized, is not significantly affected by the DCT, as

previously reported

The only measured change consists of a decrease in elastic

modulus for some of the treatment groups that were not

examined in the literature

Hardness test results suggest that, for the solubilized AISI 302,

the lower is the temperature reached during the DCT, the higher

is the hardness improvement

It emerges from the comparison of the S-C group (9 h at 88 K)

with the S-A group (24 h at 88 K) that, by prolonging the hold

time, some counterbalancing mechanism outweighs the induced

improvement, with the result of an overall loss in HRB

Similar behaviour is observed for the groups S-D (9 h at 143 K)

and S-B (24 h at 143 K)

To clarify the influence of the DCT time

parameter on both the elastic modulus and the

hardness it is useful to plot their values

against the treatment total time

The peak values (maximum hardness and

minimum E) are not exactly aligned in abscissa,

but they seems to be nearly related considering

the approximation of the total time estimation

Minimum of the elastic modulus, for both S and H

families, is estimated for about 23.3 h of DCT

total time

For both the material families the model

suggests that the prolongation of the soakingtime could lead to noticeable enhancement of

the hardness and of the Youngs modulus

CONCLUSION

Unexpected lowering of the elastic modulus

was noticed on some of the treatment groups,

suggesting the need for further investigations

focused on this aspect

Slight but significant improvements were

measured on the Rockwell-B hardness of the

solubilized material after cryotreating at 88 K.

Although it is not enough to produce an

appreciable alteration of the yield strength, it

could be effective in the case of the high-cycle

fatigue, which take place at lower stress levels

and future investigations will be oriented over

this field.

REFERENCES

[1] Mohan Lal D, Renganarayanan S, Kalanidhi A. Cryogenic

treatment to augment wear resistance of tool and die steels.

Cryogenics 2001;41(3):14955.

[2] Bensely A, Prabhakaran A, Mohan Lal D, Nagarajan G.

Enhancing the wear resistance of case carburized steel (En

353) by cryogenic treatment. Cryogenics2006;45(12):747

54.

[3] Bensely A, Senthilkumar D, Mohan Lal D, Nagarajan G,

Rajadurai A. Effect of cryogenic treatment on tensile

behavior of case carburized steel-815M17. Mater Charact

2007;58(5):48591.

[4] Bensely A, Venkatesh S, Mohan Lal D, Nagarajan G,

Rajadurai A, Junik K. Effect of cryogenic treatment on

distribution of residual stress in case carburized En 353 steel.

Mater Sci Eng: A 2008;479(12):22935.

[5] Liu H-h, Wang J, Yang H-s, Shen B-l, Gao S-j, Huang

S-j, et al. Journal of iron and steel research.

International 2006;13(6):438.

[6] Indumathi J, Bijwe J, Ghosh AK, Fahim M, Krishnaraj

N. Wear of cryo-treated engineering polymers and

composites. Wear 1999;225(Part 1):34353.

[7] Baldissera P, Delprete C. Deep cryogenic

treatment: a bibliographic review. Open Mech Eng J

2008;2:111. doi:10.2174/1874155X00802010001.

[8] Singh PJ, Mannan S, Jayakumar T, Achar D. Fatigue

life extension of notches in AISI 304L weldments using

deep cryogenic treatment. Eng Fail Anal

2005;12(2):26371.

THANK YOU

Potrebbero piacerti anche

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDa EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysValutazione: 1 su 5 stelle1/5 (1)

- Produktleitfaden Kubus 2016 - GBDocumento56 pagineProduktleitfaden Kubus 2016 - GBAlexandru PelinNessuna valutazione finora

- Turbine Maintenance BookDocumento223 pagineTurbine Maintenance Bookbarrunsiswo100% (9)

- Weld Repair of Grade 91 Piping and Components in PDocumento27 pagineWeld Repair of Grade 91 Piping and Components in PKyi HanNessuna valutazione finora

- Microstructure and Properties of DCT Treated HY-TUF SteelDocumento9 pagineMicrostructure and Properties of DCT Treated HY-TUF SteelManoela IaconelliNessuna valutazione finora

- Journal of Materials Processing TechnologyDocumento7 pagineJournal of Materials Processing TechnologyclebertasparNessuna valutazione finora

- Applied Sciences: Mechanical Properties of ASTM A572 Grades 50 and 60 Steels at High TemperaturesDocumento27 pagineApplied Sciences: Mechanical Properties of ASTM A572 Grades 50 and 60 Steels at High TemperaturesSon NguyenNessuna valutazione finora

- lee2017Documento12 paginelee2017Saiful ShokriNessuna valutazione finora

- The Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelDocumento8 pagineThe Effect of Large Heat Input On The Microstructure and Corrosion Behaviour of Simulated Heat Affected Zone in 2205 Duplex Stainless SteelAnonymous Qha8B2Nessuna valutazione finora

- Optimize 52100 Steel for Austenite and HardnessDocumento10 pagineOptimize 52100 Steel for Austenite and Hardnessermes_il_fisicoNessuna valutazione finora

- Physical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)Documento4 paginePhysical and Numerical Modelling of Heat Treatment The Precipitation-Hardening Complex-Phase Steel (CP)rodrigosiqueiraNessuna valutazione finora

- Effect of Deep Cryogenic Treatment On The Tensile Behavior of AISI 8620 Gear SteelDocumento5 pagineEffect of Deep Cryogenic Treatment On The Tensile Behavior of AISI 8620 Gear SteelEditor IJTSRDNessuna valutazione finora

- Effects of Cryogenic Treatment on Different Types of SteelsDocumento21 pagineEffects of Cryogenic Treatment on Different Types of SteelsSandeep KadamNessuna valutazione finora

- Effect of Subzero Treatment On Microstructure and Material Properties of EN24 SteelDocumento8 pagineEffect of Subzero Treatment On Microstructure and Material Properties of EN24 SteelIJMERNessuna valutazione finora

- Effect of Step Quenching On Microstructures and M 2016 Materials Science andDocumento8 pagineEffect of Step Quenching On Microstructures and M 2016 Materials Science andDanilo CostaNessuna valutazione finora

- Influence of deep cryogenic treatment on alloy carbide precipitations and mechanical properties of AISI M2 high speed tool steelDocumento28 pagineInfluence of deep cryogenic treatment on alloy carbide precipitations and mechanical properties of AISI M2 high speed tool steelclebertasparNessuna valutazione finora

- Weld Heat-Affected-Zone Response To Elevated-Temperature DeformationDocumento10 pagineWeld Heat-Affected-Zone Response To Elevated-Temperature DeformationTrushar ParmarNessuna valutazione finora

- Effect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Documento4 pagineEffect of Deformation On The Continuous Cooling Transformation (CCT) Diagram of Steel 32Crb4Najib RahmanNessuna valutazione finora

- Effect of hardening conditions on mechanical properties of high speed steelsDocumento9 pagineEffect of hardening conditions on mechanical properties of high speed steelsInisial DINessuna valutazione finora

- Steel GradeDocumento3 pagineSteel GradeErickNessuna valutazione finora

- Hot Deformation Behavior of 316LN Stainless SteelDocumento8 pagineHot Deformation Behavior of 316LN Stainless SteelMallikarjunrao PanabakaNessuna valutazione finora

- Cryogenic Treatment of Stainless SteelsDocumento3 pagineCryogenic Treatment of Stainless SteelsJoergen FJNessuna valutazione finora

- BA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsDocumento9 pagineBA GRaville - 1973 Cooling Rates and HAZ Hardness in Carbon SteelsBhavana ValetiNessuna valutazione finora

- Materials Science & Engineering A: G. Prieto, J.E. Perez Ipiña, W.R. TuckartDocumento8 pagineMaterials Science & Engineering A: G. Prieto, J.E. Perez Ipiña, W.R. TuckartLarissaNessuna valutazione finora

- Ductile-Brittle Transition Temperatures and Dynamic Fracture Toughness of 9Cr1Mo SteelDocumento9 pagineDuctile-Brittle Transition Temperatures and Dynamic Fracture Toughness of 9Cr1Mo Steelagilan89Nessuna valutazione finora

- Anand & SuDocumento13 pagineAnand & SuKanishkSinhaNessuna valutazione finora

- Microstructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersDocumento22 pagineMicrostructural Characterization, Strengthening and Toughening Mechanisms of A Quenched and Tempered Steel Effect of Heat Treatment ParametersAlmerindo JuniorNessuna valutazione finora

- Study The Effect of Cooling Medium On The Torsion Resistance and Hardness of Medium Carbon SteelDocumento10 pagineStudy The Effect of Cooling Medium On The Torsion Resistance and Hardness of Medium Carbon Steelمسعود بوزويرNessuna valutazione finora

- Jing 2021 Mater. Res. Express 8 036506Documento10 pagineJing 2021 Mater. Res. Express 8 036506Arturo CervantesNessuna valutazione finora

- National Institute of Technology Warangal Deptt. of Metallurgical and Materials EngineeringDocumento30 pagineNational Institute of Technology Warangal Deptt. of Metallurgical and Materials EngineeringKrishnakamlesh VermaNessuna valutazione finora

- 1 s2.0 S135063071930202X Main PDFDocumento10 pagine1 s2.0 S135063071930202X Main PDFsyaukatyNessuna valutazione finora

- Creep and Creep Damage Assessment in P91 Weld JointsDocumento12 pagineCreep and Creep Damage Assessment in P91 Weld JointsDeepakNessuna valutazione finora

- PUB 2005 - InTERESSANT - CRYOGENIE - Fatigue Life Extension of Notches in AISI 304L WeldmentsDocumento9 paginePUB 2005 - InTERESSANT - CRYOGENIE - Fatigue Life Extension of Notches in AISI 304L WeldmentsMohammed El Amine GUETNessuna valutazione finora

- Constitutive Relationships For Normal - and High-Strength Concrete at Elevated TemperaturesDocumento10 pagineConstitutive Relationships For Normal - and High-Strength Concrete at Elevated TemperaturesNirvana NguyenNessuna valutazione finora

- 508 2293 5 PB PDFDocumento9 pagine508 2293 5 PB PDFarjun prajapatiNessuna valutazione finora

- Nani Babu-High-Temperature Fatigue Crack Growth Behaviour of SS 316LN PDFDocumento10 pagineNani Babu-High-Temperature Fatigue Crack Growth Behaviour of SS 316LN PDFAvinash ChittellaNessuna valutazione finora

- Cardone 2019Documento9 pagineCardone 2019Constanza CornejoNessuna valutazione finora

- Aisi 4135Documento4 pagineAisi 4135saurabhsubhuNessuna valutazione finora

- Evaluation of The Austenite Recrystallization by Multideformation and DoubleDocumento10 pagineEvaluation of The Austenite Recrystallization by Multideformation and DoubleJoselo HRNessuna valutazione finora

- Elevated Temperature Material Behaviour of High Strength SteelDocumento22 pagineElevated Temperature Material Behaviour of High Strength SteelCaline NunesNessuna valutazione finora

- The Effects of Deep Cryogenic Treatment On The Hardness of SAE 52100 Bearing SteelDocumento9 pagineThe Effects of Deep Cryogenic Treatment On The Hardness of SAE 52100 Bearing SteelArun KumarNessuna valutazione finora

- CA 6NM CastingsDocumento11 pagineCA 6NM CastingsvasanthiNessuna valutazione finora

- To Study The Effect of Stress Concentration Factor On Mild Steel Due To Heat TreatmentDocumento5 pagineTo Study The Effect of Stress Concentration Factor On Mild Steel Due To Heat TreatmentEditor IJTSRDNessuna valutazione finora

- The Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCBDocumento5 pagineThe Effect of Repeated Post-Weld Heat Treatment On Low-Carbon Steel ASTM A216WCB78858799Nessuna valutazione finora

- Temperature Dependence of The Microstructure and MDocumento11 pagineTemperature Dependence of The Microstructure and MAlokNessuna valutazione finora

- 58 4 NieDocumento12 pagine58 4 Nieestag.engNessuna valutazione finora

- 3 13Documento8 pagine3 13pitoulabeteNessuna valutazione finora

- Modeling of The Yield Strength of A Stainless Maraging SteelDocumento4 pagineModeling of The Yield Strength of A Stainless Maraging SteelFernando HenriqueNessuna valutazione finora

- Effect of Heat Treatment Processes On THDocumento10 pagineEffect of Heat Treatment Processes On THMartins MichaelNessuna valutazione finora

- Sadeghi 2018Documento11 pagineSadeghi 2018Rami GhorbelNessuna valutazione finora

- Temperature Evolution Phase Ratio and Corrosion Resistance of Duplex Stainless Steels Treated by Laser Surface Heat TreatmentDocumento9 pagineTemperature Evolution Phase Ratio and Corrosion Resistance of Duplex Stainless Steels Treated by Laser Surface Heat Treatmentzidan ojaNessuna valutazione finora

- Obiukwu Osita, Udeani Henry, Ubani ProgressDocumento12 pagineObiukwu Osita, Udeani Henry, Ubani ProgressPrashant KumarNessuna valutazione finora

- Elevated Temperature Material Properties of Cold-Formed Steel Hollow Sections, 2015 (Finian McCann)Documento11 pagineElevated Temperature Material Properties of Cold-Formed Steel Hollow Sections, 2015 (Finian McCann)Phan Đào Hoàng HiệpNessuna valutazione finora

- Quench Sensitivity Al AlloysDocumento31 pagineQuench Sensitivity Al AlloysCatalin Marian Vartosu-TomaNessuna valutazione finora

- Fatigue Crack Growth Behavior of JIS SCM440 Steel N 2017 International JournDocumento13 pagineFatigue Crack Growth Behavior of JIS SCM440 Steel N 2017 International JournSunny SinghNessuna valutazione finora

- Heat Treatment Effects on CA-15 Martensitic Stainless Steel PropertiesDocumento8 pagineHeat Treatment Effects on CA-15 Martensitic Stainless Steel PropertiesFernando RomeroNessuna valutazione finora

- Improvement in Performance of Cold-Drawn SCM435 Alloy Steel Wires Through Optimization of Intercritical Annealing ParametersDocumento16 pagineImprovement in Performance of Cold-Drawn SCM435 Alloy Steel Wires Through Optimization of Intercritical Annealing Parametersenrico susantoNessuna valutazione finora

- Sigmajig Hot-Cracking Test Quantifies Stainless Steel SusceptibilityDocumento6 pagineSigmajig Hot-Cracking Test Quantifies Stainless Steel SusceptibilityElaine JohnsonNessuna valutazione finora

- 1 s2.0 S0921509322006979 MainDocumento13 pagine1 s2.0 S0921509322006979 MainAch KitevarzNessuna valutazione finora

- Numerical Modelling of Heat Transfer in A Tube Furnace For Steel Wire AnnealingDocumento10 pagineNumerical Modelling of Heat Transfer in A Tube Furnace For Steel Wire AnnealingEr Vijay MishraNessuna valutazione finora

- Proceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Da EverandProceedings of the 2014 Energy Materials Conference: Xi'an, Shaanxi Province, China, November 4 - 6, 2014Nessuna valutazione finora

- Database OverviewDocumento34 pagineDatabase OverviewAngelo Escoro DanteNessuna valutazione finora

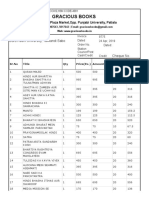

- Book GaciousDocumento6 pagineBook GacioussandeepNessuna valutazione finora

- Tech 149 Unit 1 NewDocumento104 pagineTech 149 Unit 1 NewsandeepNessuna valutazione finora

- Front of ThesisDocumento14 pagineFront of ThesissandeepNessuna valutazione finora

- cs559 10Documento30 paginecs559 10sandeepNessuna valutazione finora

- Chloride: Vapour Deposition Hard-Facing Miscellaneous TechniquesDocumento2 pagineChloride: Vapour Deposition Hard-Facing Miscellaneous TechniquessandeepNessuna valutazione finora

- Database OverviewDocumento34 pagineDatabase OverviewAngelo Escoro DanteNessuna valutazione finora

- CIM-Computer Integrated Manufacturing ExplainedDocumento16 pagineCIM-Computer Integrated Manufacturing ExplainedHarshad KondalkarNessuna valutazione finora

- Bibliography of ZrO2 and Y2O3 CoatingsDocumento4 pagineBibliography of ZrO2 and Y2O3 CoatingssandeepNessuna valutazione finora

- Time MGMT SP EditsDocumento29 pagineTime MGMT SP EditsRizul thakurNessuna valutazione finora

- Manager, Central Tool Room, A-5, Focal Point, LudhianaDocumento1 paginaManager, Central Tool Room, A-5, Focal Point, LudhianasandeepNessuna valutazione finora

- CompetitiveDestinationChap11 PDFDocumento17 pagineCompetitiveDestinationChap11 PDFsandeepNessuna valutazione finora

- Presentation (India)Documento42 paginePresentation (India)kanikatekriwal126Nessuna valutazione finora

- Real SummaryDocumento21 pagineReal SummarysandeepNessuna valutazione finora

- 8 Power ScrewsDocumento57 pagine8 Power ScrewsKristian Marlowe Ole100% (1)

- Honorarium, TA, DA BillDocumento2 pagineHonorarium, TA, DA BillsandeepNessuna valutazione finora

- Current Affairs March 2018Documento5 pagineCurrent Affairs March 2018Your mom gayNessuna valutazione finora

- Knuckle Joint Connection DesignDocumento1 paginaKnuckle Joint Connection DesignsandeepNessuna valutazione finora

- Terms ConditionsDocumento2 pagineTerms ConditionssandeepNessuna valutazione finora

- GURU KASHI BATCH 2014Documento91 pagineGURU KASHI BATCH 2014sandeepNessuna valutazione finora

- HuhDocumento1 paginaHuhdocument007Nessuna valutazione finora

- 1986604058form For InerviewDocumento1 pagina1986604058form For InerviewsandeepNessuna valutazione finora

- Jarnail Singh 21016009 5 SEMDocumento10 pagineJarnail Singh 21016009 5 SEMsandeepNessuna valutazione finora

- Last Modified On: 18-12-2013 No of Times Modified: 1Documento2 pagineLast Modified On: 18-12-2013 No of Times Modified: 1sandeepNessuna valutazione finora

- Unit 1 2 3 Hotel Engineering NotesDocumento5 pagineUnit 1 2 3 Hotel Engineering NotessandeepNessuna valutazione finora

- AdvertisementDocumento3 pagineAdvertisementSan Deep SharmaNessuna valutazione finora

- REACH Regulation Requirements for Oerlikon MetcoDocumento1 paginaREACH Regulation Requirements for Oerlikon MetcosandeepNessuna valutazione finora

- Chapter 17 I On Exchange SofteningDocumento6 pagineChapter 17 I On Exchange SofteningkatharguppeNessuna valutazione finora

- Water Purification Methods: What Are The Methods Used To Purify Water?Documento4 pagineWater Purification Methods: What Are The Methods Used To Purify Water?parapencarituhan100% (1)

- Series: Standard Product CapabilitiesDocumento4 pagineSeries: Standard Product Capabilitiespmfg847633Nessuna valutazione finora

- TDS MasterRheobuilld-623Documento2 pagineTDS MasterRheobuilld-623Taposh PaulNessuna valutazione finora

- Color Coding On Ships: Trainees DigestDocumento2 pagineColor Coding On Ships: Trainees DigestmmakdNessuna valutazione finora

- Method Statement FOR SIKATOP SEAL 107Documento4 pagineMethod Statement FOR SIKATOP SEAL 107faizbukhariNessuna valutazione finora

- Alkaline Sulfide Recovery of GoldDocumento13 pagineAlkaline Sulfide Recovery of GoldAFLAC ............100% (1)

- Tes Praktek Optimizer GoogleDocumento24 pagineTes Praktek Optimizer GooglePramudita BudiantiNessuna valutazione finora

- 39 Tractor EmulsionDocumento4 pagine39 Tractor EmulsionJaga NathNessuna valutazione finora

- 5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty TasksDocumento4 pagine5E Series Tractors from John Deere: 55-75hp Reliable Performance for Small Farms and Specialty Tasksbrujula24100% (1)

- CV TemplateV2Documento9 pagineCV TemplateV2Mark MarianoNessuna valutazione finora

- Flow Diagram SymbolsDocumento5 pagineFlow Diagram SymbolshussainNessuna valutazione finora

- Smart Axis Automatic Chasing Machine ManualDocumento38 pagineSmart Axis Automatic Chasing Machine Manualvser19Nessuna valutazione finora

- Contents Centrifugal Oil CleanersDocumento12 pagineContents Centrifugal Oil Cleanersg33sp0tNessuna valutazione finora

- Rehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageDocumento6 pagineRehabilitation and Upgradation of Nipania- Bitkuli - Latuva - Baloda Bazar Road PackageShrikishan Barbrik Joint Venture Pkg-07Nessuna valutazione finora

- Tension-Weld® Strapping Tool: Downloaded From Manuals Search EngineDocumento36 pagineTension-Weld® Strapping Tool: Downloaded From Manuals Search EnginePepeNessuna valutazione finora

- Heat Load Calculation IIDocumento2 pagineHeat Load Calculation IIsiruslara6491Nessuna valutazione finora

- Vane Axial Fan CatalogDocumento12 pagineVane Axial Fan CatalogMiroslav AleksicNessuna valutazione finora

- I. Statement of The ProblemDocumento5 pagineI. Statement of The ProblemFloredelNessuna valutazione finora

- SDLG Wheel Loader LG958 Complete Appliance Service Manua1 PDFDocumento268 pagineSDLG Wheel Loader LG958 Complete Appliance Service Manua1 PDFFrancisco Ferrer100% (1)

- 04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesDocumento1 pagina04-87RA9001-01 Installation Junction Box Main Field Signals 9000 SeriesRonaldNessuna valutazione finora

- Check List Roll Handling System - Tissue LineDocumento17 pagineCheck List Roll Handling System - Tissue LineDinhnamsgpNessuna valutazione finora

- Battery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsDocumento146 pagineBattery Manufacturing: Etools Home: Scope - References - Glossary - Viewing / Printing Instructions - CreditsLo Siento de VerdadNessuna valutazione finora

- NPSH - Net Positive Suction HeadDocumento5 pagineNPSH - Net Positive Suction HeadSutrisno KlsNessuna valutazione finora

- Articulado PDFDocumento90 pagineArticulado PDFMiguel Fuentes100% (1)

- Recycling ConcreteDocumento56 pagineRecycling ConcreteReshmita PallaNessuna valutazione finora

- 8000series Tech Datasheet 2018Documento3 pagine8000series Tech Datasheet 2018lucky414Nessuna valutazione finora

- Balancing Equations WorksheetDocumento4 pagineBalancing Equations WorksheetjoeNessuna valutazione finora

- General BrochureDocumento1 paginaGeneral BrochurerayscrubberNessuna valutazione finora

- Steval Isa172v2Documento12 pagineSteval Isa172v2Hasanudin UdinNessuna valutazione finora