Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

PH

Caricato da

cherif yahyaouiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

PH

Caricato da

cherif yahyaouiCopyright:

Formati disponibili

pH measurement

pH basics

pH

pH

pondus hydrogenii = Weight of hydrogen

potentia hydrogenii = Power of hydrogen

pH

Why pH measurement?

pH measurement is an important measurement

and touches us all the time in our daily life.

Cleaning solutions: Soap, bleach, etc.

Food products: Yogurt, Cheese, Coke, Beer,

Water etc.

Waste water: Industrial, Municipal

Chemical production: Pesticide, TiO2, synthetic dye, epoxy

resin

Plastic production: PVC, PP, etc.

Pharmaceutical: insulin, penicillin, anti bodies, etc.

Pulp & paper : inlet of paper machine

pH

pH scale

pH

Measuring principle

pH is a potentiometric measurement method.

The measuring effect is based on a pH sensitive glass

membrane whose surface reacts to the acid content with

a specific voltage.

This voltage is then measured relative to a reference

element.

pH is calculated according the Nernst law equation.

pH

Measuring and reference electrode

pH transmitter

Measuring

electrode

Reference

electrode

3 mol KCl

+

Internal buffer

Glass membrane

3 mol

KCl

Diaphragm

pH

Two half cells make one combination electrode

pH

Working principle of the glass

membrane

Glass membrane

thickness:

0.2-0.5 mm

Acid

solution

pH < 7

H+

Gel layer:

0,0001 mm

Internal

buffer

Alkaline

solution

pH > 7

+

+ pH 7 +

+

+

H

-

If inside pH = outside pH

---> no potential difference = 0 mV (= pH 7)

with excess of H+-ions

= positive

charge outside

(resp. less H+-ions

= negative charge

outside)

--> result: potential difference

pH measurement in process applications

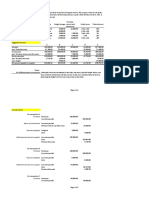

Nernst equation

Slope of the pH electrode:

54,20 mV/pH at 0 C

S lo p e at 25 C

59,16 mV/pH

0

74,04

5 9 , 1 6 mV/pH

m V a t at

2 5 100

C C

pH

pH calibration

+ mV

Zero

Slope

C02

9,2

4

Acid error

Alkali error

- mV

9,2

pH

Alkaline buffer

changes the

pH value !

pH

Types of diaphragms

Ceramic:

fast response

soiling sensitive

biocompatible

Open arperture:

very fast response

soiling sensitive

danger of poisoning

Liquid junction via

the diaphragm of

the

pH electrode

PTFE:

Very robust

slow response

dirt repellent

pH

Effects on the probe

pH

Installation of pH sensors

pH

Storing of pH sensors

Out of operation pH sensors should be stored

wet.

pH 7 or 3mol KCl-solution is the best storage

solution.

Do not store sensors in deionized water or

alkaline

buffers.

If a sensor dries out during storage, soaking it

overnight

in pH 7 or 3mol KCl will usually restore the

hydrated

glass layer and the reference junction.

pH

IsFET electrode - working principle

IsFET

H+

H+

H+

Gate

Source

Drain

-

Glass

H+

H+

H+

pH

IsFET-sensors

How it works:

Gate insulator:

Thickness: about 0,1 m

Material: Ta2O5 (Tantalum

oxide)

Reference system

H+

H+

IsFET

H+

IsFETs are

following the

NERNSTs law!

The insulator is an amphoteric

material (acting as acid or base),

thus surface charges are occuring

by the reversible reaction with H+

resp.

OH- -ions

Important:

Contrary to the

glass electrode no charges are

transported through the

insulator, it is just an

electrostatic effect.

pH

IsFet electrodes

Restricted life time in hot alkaline

safety: unbreakable

wider application range:

- higher amounts of solvents

- fast response at low temperatu

lower acidic and alcaline errors

pH

Fast response time of IsFET

electrode

9.0

8.5

8.0

pH

7.5

- 20-C20 C

7.0

6.5

CPS401 B2ESB1A1

IsFET electrode

pH - Glasselectrode

- Electrode

glass

6.0

5.5

5.0

10

Time/min

12

14

16

18

20

pH instrumentation

pH

The new pH sensor family

Glass pH-electrodes

OrbiSint

CPS 11/ CPS11D

CeraGel

OrbiPore

CeraLiquid

CPS 71/CPS71D CPS 91/CPS91D CPS 41/CPS41D

Non-glass electrodes

er

form 01

4

CPS

TopHit

CPS 471

Application

environmental

food/

pharma

TopHit

CPS 491

TopHit

CPS 441

chemical/

chemical/food/

environmental

pharma

pH

Sensor segmentation

CPS 11/CPS11D

CPS 71/CPS71D

CPS 471

CPS 91/CPS91D

CPS 491

CPS 41/ CPSD

CPS 441

ceramic

diaphragm

open

diaphragm

ceramic

diaphragm

double gel

double chamberreference

double gel

liquidreference

long-term

check of stable

processes

hygienic and

sterile applications

media with strong

changing

compositions

highest

accuracy

teflon diaphragm

poisoning media

suspensions

emulsions

ultrapure water

extremely

blocking media

precipitations

environmental

food / pharma

chemical,

environmental

chemical,

food, pharma

pH

Mounting options

Immersion mounting

Flow through

Pipe- or tankmounting

Flow through

pH

The Cleanfit family

CPA 471 / 472

selfsealing via

electrode lift tube

standard application

CPA473 / 474

ball valve sealing

to process

harsh process

application

CPA475

selfsealing via

electrode lift tube

hygienic application

pH

Electrode protection

CPA 471 / 472

CPA 475

inside and outside

O-ring

hygienic form

sealing

best results in

EHEDG certified

non abrasive media

cleanability

CPA 473

open

protection guard

CPA 474

stable

polymer guard

best result

for aggressive and

with fibrous

abrasive media

and abrasive media

pH

The new 2 wire instrument :

LIQUILINE

Easy and Safe

Quick set up within minutes via navigator button

Big graphic display and plain text menu

Strict safety requirement with SIL2

Flexible

SS or plastic housing

Quick parameter change via plug in module

All field bus protocols supported (HART, FF, ATEX)

Cost saving

No field calibration needed with Memosens sensors

Predictive maintenance system

pH

Liquiline M CM42 - Measuring

Parameters

pH and redox

conductivity

resistivity

concentration

dissolved

oxygen

Launching : 1st of Sept 05.

pH cleaning and calibration

systems

pH

Electrode cleaning

1. Rinse with tap water, if crystallization occurs

with hot tap water (> 70C)

2. Soak in cleaning agent for removal of:

Oil, fat:

Alkaline, Alcohol

Lime:

HCL (4%)

Metal hydroxide: HCL (4%)

Cyanide: HCL (4%)

Sulfide:

HCL (4%)+ thiourea (sat.)

Protein:

HCL (4%)+ pepsin (sat.)

Heavy biol. deposit:

HCL (4%)

Silicon:

Acetone

3. Wipe with paper tissue

4. Rinse with tap water

pH

CPA111 + CPM153 or CPM2x3 in

safe area

CCPM

P M 1153

5 2 // CCPM

P M 22x3

x3

Z e ile 1 z e ig t lin k s im m e r d e n

A u s w h lb a re P a r a m e te r w e r d e n in v e rs

pH

M EAS

CA L

DIAG

P A RA M

R e c o rd e r

re m o te

c o n tro l

Pow er

J u n c t io n

box

A c id

B ase

In le t

C PA 111

CYR 10

W a te r

C le a n in g a g e n t

pH

Automatic calibration - TopCal S

CPG 300

Mycom 153

air, water

CPA 471

air

buffer, cleaner

water, air

RS 485

supply

with TOP 68

container with

levelswitches

PA/DP

HART

power

max. 2 m

contol

Buffer 1+2+Cleaner

ISFET

2 add. valves

(optional)

CPS 71

pH applications

pH

Waste Water Treatment Plant

Overview

pH

Application: waste water treatment

Inlet waste water treatment: CPS11+CPM253, CPF81, CPR30

pH

pH-value in the wastewater lines of

the neutralisation basins

Challenge:

Monitoring the pH-value in

the waste water line of the

neutralisation basin

Environment:

Media: neutralised waste

water

Operation: 1 bar abs., max

20C

Meas. range: pH 6...8

Solution:

pH transmitter Liquisys with

pH electrode and flow

Benefit:

assembly electrode (with

pH combination

Product group: Analysis

Industry:

Power

Pt100) simplifies installation

and calibration

Optional contact outputs in

Liquisys for use in control

system

Bypass installation with pH-

pH

Fresh Water Treatment Plant

Overview

pH

pH measurement in tomato

slurry

Challenge:

pH-measurement in product,

no glass wanted

Viscous media

Environment:

Tomato slurry

Solution:

No-glass electrode TopHit

CPS471

Retractable holder CPS475

with special head

Product group:

Analysis

Industry:

Food

Installed at:

Netherlands

Benefit:

Unbreakable sensor (PEEK

100%)

EHEDG certified system

pH

pH measurement in saturation

process / sugar

Challenge:

pH-measurement high

viscous juice

soiling

Environment:

Sugar juice / carbonisation

Solution:

Orbisint CPS11

Retractable holder CPS473

with mechanical scraper and

cleaning flange

Cleaning with condensate

and 2% HCl

Product group:

Analysis

Industry:

Food

Installed at:

Hungary

Benefit:

Less maintenance with

automatic cleaning

Reliable measurement

pH

pH measurement in Saturation

Process

pH

Coal fired power plant

Process

View

power plant

DeNOx

Coal

handling

Steam

turbine

Generat

or

Steam

generator

Water-/steam

system

Electrosta

tic

precipitat

or

Residue

s

disposa

l

Desalinati

on

Cooling system

Desulphurizat

ion

Water

supply

Wastewater

treatment

pH

Flue Gas Desulphurisation in Power

Plant

Product group: Analysis

Industry:

Power

Installed at:

Plant Vresova,

Czech Republic

Challenge:

One of the most important

and decisive criteria for the

quality of flue gas washing

is the pH value of the

washing medium. Hence the

pH value should be closely

monitored.

Environment:

Temp. 5060C, Pressure :

2 bar g, medium : Gypsum

slurry

Solution:

CPS41

CPA 463S

Topcal S

Benefit:

Accurate and reliable pH

measurement

Increased lifetime of the

sensors via a retractable

assembly

pH

Automised pH in flue gas

desulphurization

Process:

gas washing

Process condition:

pH 0,5-0,6; T=75C

continuous measuring

lifetime electrode >4 weeks

Solution:

TopCal with CPS11

CPA463

pH

PuriSys CPF201

for high purity water pH measurement

designed to eliminate difficulties:

- flow sensitivity

- static charge

no electrolyte refill

for power plants, chemical-,

semiconductor-, pharmaceutical

industry

pH

pH measurement in resin

Challenge:

product is mixed with a fix

formulation,

exact dosing of caustic soda is

necessary due to an inconstant

quality of urea.

Product is gelatinizing if pH value is

not in the range of pH 7 0,15

Environment:

Very aggressive and sticky:

formalin, urea, caustic soda,

additives

Solution:

CPC 300, fully automatic

cleaning and calibration system

Cleaning chamber

Hygienic retractable holder

CPA475 with PTFE sealings

Liquid filled electrode CPS41

Benefit:

Cost saving inversion. With

the solution from E+H the

electrode lasts more than 3

months

Less maintenance

Product group: Analysis

Industry:

Industry

Chemical

Installed at:

Dynea, Austria

pH

pH Measurement in TiO2 pulp

Challenge:

The pH measurement in this

TiO2 pulp is decisive for the final

product quality. Highly abrasive

media. Each of the 4 reactors

work with two measuring units.

Environment:

Very corrosive.

Solution:

CPC 300, fully automatic

cleaning and calibration system.

Product group: Analysis

Benefit:

Industry:

Industry

Chemical

Installed at:

Altamira

DuPont,

Plant, Mexiko

Cost saving inversion. With

the solution from E+H the

electrode lasts more than 3

months

Less maintenance

Excellent service from E+H

Mexico

pH

Application: process

Measuring point:

nickel production

pH 7,7 /pH 8,8/ 81-90C / 0,8bar

Nickel precipitation

Nickel ore included also cobald

ore is desolved in H2SO4,

pH value < 3, NiSO4 and CoSO4

first precibitation step: at pH 7,7 cobald hydroxid

pH-value correction with soda ash Na2CO3

second precebitation step: at pH 8,8 nickel hydoxid

Instrumentation:

Liquisys M

CPA 111 with spray head

CPS 41, liquid filled electrode

Cleaning with HCl

pH

Application: process

Measuring point:

floatation cell, copper production

water, solids (40%) copper (7%)

stable pH value

Instrumentation:

TopCal S

CPA463

CPS 41

Advantages/Benefits:

dosing of lime can be

automised because of reliable

pH measurement

increased life time of

electrodes, ~4,5months

cost reduction

Memosens

pH

Todays solution - just working on

symptoms

Use of high sophisticated golden contacts

Use of high impedance material for the plugging

system, esp. round the

contacts (no absorption of water)

Watertight systems

Use of special cables with special isolating material

(no absorption of water)

Use of transmitters with ultra high impedance on

transmitter entrance

Avoid extended cable length

Use of 3- or 4-wire technique for temperature sensors

(esp. Pt 100 and long cables)

Nevertheless moisture is the main

reason for

breakdown of measuring point

pH

MemoSens

MemoSens converts the glass electrode into a digital

sensor

USP !!

contactless transfer of signal

USP !!

pH

MemoSens

r

Ene

fer

s

n

a

r

gy t

Sign

sfer

n

a

r

al t

Cable coupling

Sensor head

primary coil

coupling electronics

secondary coil

sensor electronics

pH

Memosens - electrical advantages

Cable design and attribute does

not affect the measurement

Semiconductor coated cables are not

anymore necessary,cable length is not any

more important

The pH electrode is a welldefined and

complete sensor

The sensor is self-checking, cable attributes

do not affect the sensor checks

pH

Memosens - analog vs. digital

Memosens:

pH signal gets digitised

and transferred contactless

= moisture is

not a

nightmare

anymore!

Standard electrodes:

Low impedance

components

UpH

(caused by moisture) lead to

Electrode with

plug-in head

Cablecoupling

Cable

Transmitter

diminished

electrode slope

because of voltage sharing

with internal resistance of the

electrodes

pH

Memosens - control of data

transmission

Cable pinched off ?

Cable defect ?

Cable disconnected from sensor ?

Standard pH-sensor:

No alarm,

pH-value shows around pH 7 (0mV)

Digital pH-sensor ( Memosens):

Alarm,

measured value is fixed (frozen)

No communication

between sensor and

transmitter results

in an alarm:

automatically !

pH

Memosens - total galvanic

separation

Contactless

coupling with

inductive data and

energy

transmission:

No interference between

potentials of solution and

transmitter

No EMC problems

No potential interference and

measured value shift

No choice symmetric - non

symmetric

No impedance converter

needed

pH

Memosens - sensor with memory

Memosens turns the pH

sensor into a digital

sensor

with integrated memory

pH sensors with Memosens technology store

the actual calibration data as well as other information

used for predictive maintenance eg. overall time in operation, maximum

and minimum pH value, maximum and minimum temperature.

pH

Calibration independent from

measuring point

The result :

A system breakdown caused by a faulty pH sensor is

reduced to the time between recognising and

sensor exchange.

pH sensors

with

Memosens

technology

are the very

first sensors

to allow a

calibration of

the sensor

independent

from the

actual

measuring

point in the

laboratory.

pH

Measurement

Calibration

in the field

Ins

th tall

e s ati

en on

so of

r

Sensor with

Memosens

Disassembly

of the sensor

Standard

sensor

Disassembly

of the sensor

Availability and work

Measurement

Calibration

in the lab

Calibration/adjustment

Storage of sensor data

of

n

tio

la sor

al

st en

In e s

th

Maintenance of the measuring point

QS documentation

Ideal laboratory conditions

Measurement

A measuring point failure is reduced to the space of

time between recognition and exchange of the

sensors.

pH

Memocal T - calibration unit

Based on:

- Liquisys M CPM253

Functionality:

- Measure pH by using digital

sensors

- Wet calibration (digital sensors)

- Numeric calibration (digital

sensors)

Handling:

- Like Liquisys M

Scope of supply:

- Transmitter Memocal T

- 3m CYK10

pH

Portfolio Memosens Functionality

CPS12D

CPS72D

CPS42D

CPS11D

CPS41D

CPS71D

CPS91D

pH

Memosens : what is available ?

New!

Upgrade Kit

for

CPM2x3 and

CPM153

CPS1xD - CPS91D CPS7xD CPS4xD

Liquisys M

CPM223/253 -

CYK10

Memocal T

Mycom S

CPM153 -

pH measurement

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Piping Checklist For 30% 3D Model ReviewDocumento3 paginePiping Checklist For 30% 3D Model Reviewcherif yahyaoui100% (5)

- Engine Interface ModuleDocumento3 pagineEngine Interface ModuleLuciano Pereira0% (2)

- Piping Checklist For 60% 3D Model ReviewDocumento4 paginePiping Checklist For 60% 3D Model Reviewcherif yahyaouiNessuna valutazione finora

- Lesson Plan - Organization and ManagementDocumento5 pagineLesson Plan - Organization and ManagementBilly Joe80% (15)

- Satellite Value Chain: Snapshot 2017Documento13 pagineSatellite Value Chain: Snapshot 2017syrijal26Nessuna valutazione finora

- Variable Frequency DriveDocumento5 pagineVariable Frequency Drivecherif yahyaouiNessuna valutazione finora

- SOW-subst R1Documento40 pagineSOW-subst R1cherif yahyaouiNessuna valutazione finora

- 1.1.4 Parties in The Construction IndustryDocumento1 pagina1.1.4 Parties in The Construction IndustryMohamed ShibleyNessuna valutazione finora

- Piping and Instrumentation DiagramDocumento1 paginaPiping and Instrumentation Diagramcherif yahyaouiNessuna valutazione finora

- Elec Check List - Earthing SystemDocumento1 paginaElec Check List - Earthing Systemcherif yahyaouiNessuna valutazione finora

- Omron RelayDocumento19 pagineOmron Relaycherif yahyaouiNessuna valutazione finora

- Elec Live TestDocumento1 paginaElec Live Testcherif yahyaouiNessuna valutazione finora

- PDMS MenusDocumento3 paginePDMS Menuscherif yahyaouiNessuna valutazione finora

- Section "E-E" Section "G-G": Saudi Arabian Oil CompanyDocumento1 paginaSection "E-E" Section "G-G": Saudi Arabian Oil Companycherif yahyaouiNessuna valutazione finora

- Lecture: PLC Hardware: Programmable ControllersDocumento18 pagineLecture: PLC Hardware: Programmable Controllersalexlenevez_1213Nessuna valutazione finora

- Main Single LineDocumento1 paginaMain Single LinesswahyudiNessuna valutazione finora

- Smart 3D - Electrical Substation Design, Engineering, Modeling and Layouts - Rev.0 - 1Documento34 pagineSmart 3D - Electrical Substation Design, Engineering, Modeling and Layouts - Rev.0 - 1rahul.srivastava100% (2)

- Part 9spec SCADA InstrumDocumento62 paginePart 9spec SCADA Instrumcherif yahyaouiNessuna valutazione finora

- ITP ElectricalDocumento7 pagineITP Electricalcherif yahyaouiNessuna valutazione finora

- Electrical Testing - Part 1Documento139 pagineElectrical Testing - Part 1vraja76Nessuna valutazione finora

- P&IDDocumento18 pagineP&IDhectornicolauNessuna valutazione finora

- Instrument Hookup DWG PDFDocumento26 pagineInstrument Hookup DWG PDFharshkumar patelNessuna valutazione finora

- Central Control Room Nawara Accommodation CampDocumento1 paginaCentral Control Room Nawara Accommodation Campcherif yahyaouiNessuna valutazione finora

- 7200039700-Jwwf-Ae-002 Plan (Documento1 pagina7200039700-Jwwf-Ae-002 Plan (cherif yahyaouiNessuna valutazione finora

- Wiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeDocumento2 pagineWiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeMario WiryaNessuna valutazione finora

- TMD-ER-104.22 Typical Mounting Detail Multiple Connection of Metallic Structure To Earthing System by Earthing Terminal Not Drawn To ScaleDocumento1 paginaTMD-ER-104.22 Typical Mounting Detail Multiple Connection of Metallic Structure To Earthing System by Earthing Terminal Not Drawn To Scalecherif yahyaouiNessuna valutazione finora

- Quick Reference: © 2003 Thomas & Betts Corporation. Specifications Are Subject To Change Without NoticeDocumento1 paginaQuick Reference: © 2003 Thomas & Betts Corporation. Specifications Are Subject To Change Without Noticecherif yahyaouiNessuna valutazione finora

- Selected Battery From IEEE 485 Battery CalculationDocumento1 paginaSelected Battery From IEEE 485 Battery Calculationcherif yahyaouiNessuna valutazione finora

- Recherche Des Livres PDFDocumento1 paginaRecherche Des Livres PDFcherif yahyaouiNessuna valutazione finora

- 7200039700-Jwwf-Ae-003 Plan (Documento1 pagina7200039700-Jwwf-Ae-003 Plan (cherif yahyaouiNessuna valutazione finora

- Electrical DetailsDocumento1 paginaElectrical Detailscherif yahyaouiNessuna valutazione finora

- TMD-ER-104.22 Typical Mounting Detail Multiple Connection of Metallic Structure To Earthing System by Earthing Terminal Not Drawn To ScaleDocumento1 paginaTMD-ER-104.22 Typical Mounting Detail Multiple Connection of Metallic Structure To Earthing System by Earthing Terminal Not Drawn To Scalecherif yahyaouiNessuna valutazione finora

- Technical Session - IDocumento47 pagineTechnical Session - IKalapala Nancharaiah100% (6)

- Handout No. 03 - Purchase TransactionsDocumento4 pagineHandout No. 03 - Purchase TransactionsApril SasamNessuna valutazione finora

- RULE 130 Rules of CourtDocumento141 pagineRULE 130 Rules of CourtalotcepilloNessuna valutazione finora

- Al-Ahbash Evolution and BeliefsDocumento4 pagineAl-Ahbash Evolution and BeliefskaptenzainalNessuna valutazione finora

- Physics Unit 3 Practice Test Dynamics5Documento5 paginePhysics Unit 3 Practice Test Dynamics5StephanieNessuna valutazione finora

- Content and Context Analysis of Selected Primary SourccesDocumento3 pagineContent and Context Analysis of Selected Primary SourccesToshi CodmNessuna valutazione finora

- Unit 2: TransducerDocumento24 pagineUnit 2: TransducerROYAL GAMER YTNessuna valutazione finora

- Tabulation Sheet (LABO)Documento9 pagineTabulation Sheet (LABO)KetIanCotalesNessuna valutazione finora

- CE 2812-Permeability Test PDFDocumento3 pagineCE 2812-Permeability Test PDFShiham BadhurNessuna valutazione finora

- How Do I Predict Event Timing Saturn Nakshatra PDFDocumento5 pagineHow Do I Predict Event Timing Saturn Nakshatra PDFpiyushNessuna valutazione finora

- Shower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZDocumento11 pagineShower Tapware: For More Information and Detailed Specifications Please Refer To Our Website: WWW - Plumbline.co - NZNoman KhanNessuna valutazione finora

- Agriculture: PAPER 3 Practical TestDocumento8 pagineAgriculture: PAPER 3 Practical Testmstudy123456Nessuna valutazione finora

- CH 3 TestDocumento50 pagineCH 3 TestVK ACCANessuna valutazione finora

- What Is E-CollaborationDocumento7 pagineWhat Is E-CollaborationToumba LimbreNessuna valutazione finora

- Chapter 2 Fluid StaticsDocumento26 pagineChapter 2 Fluid StaticsSoban Malik100% (1)

- Assignment 2 Management Perspective Son Leadership MotivationDocumento14 pagineAssignment 2 Management Perspective Son Leadership MotivationHoneyVasudevNessuna valutazione finora

- Jerehy's ReportDocumento65 pagineJerehy's Reportkupetroleum3Nessuna valutazione finora

- IRremote Library, Send & Receive Infrared Remote ControlDocumento4 pagineIRremote Library, Send & Receive Infrared Remote ControlJayant SwamiNessuna valutazione finora

- Durham E-ThesesDocumento203 pagineDurham E-ThesesH Man SharifNessuna valutazione finora

- Metric Conversion WorksheetDocumento3 pagineMetric Conversion WorksheetKaiden HughesNessuna valutazione finora

- Effect of Social Economic Factors On Profitability of Soya Bean in RwandaDocumento7 pagineEffect of Social Economic Factors On Profitability of Soya Bean in RwandaMarjery Fiona ReyesNessuna valutazione finora

- Olp Lesson PlanDocumento2 pagineOlp Lesson Planapi-654865620Nessuna valutazione finora

- Egalitarianism As UK: Source: Hofstede Insights, 2021Documento4 pagineEgalitarianism As UK: Source: Hofstede Insights, 2021kamalpreet kaurNessuna valutazione finora

- Draft Plant Design PaperDocumento65 pagineDraft Plant Design Paper202040336Nessuna valutazione finora

- BasicCalculus12 Q3 Ver4 Mod3 The Derivatives V4Documento34 pagineBasicCalculus12 Q3 Ver4 Mod3 The Derivatives V4karren100% (1)

- Lux Level Calculation: WILSON ELECTRICAL ENGINEERING BOOKS (Simplified Edition 2020)Documento1 paginaLux Level Calculation: WILSON ELECTRICAL ENGINEERING BOOKS (Simplified Edition 2020)Wilson (Electrical Engineer)Nessuna valutazione finora

- Fluid Management in NicuDocumento56 pagineFluid Management in NicuG Venkatesh100% (2)

- Bleeding Disorders in Pregnancy: Table 1Documento7 pagineBleeding Disorders in Pregnancy: Table 1KharismaNisaNessuna valutazione finora