Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Drilling Engineering - PE 311: Rock Failure Mechanisms

Caricato da

Nagaraju JallaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Drilling Engineering - PE 311: Rock Failure Mechanisms

Caricato da

Nagaraju JallaCopyright:

Formati disponibili

Drilling Engineering

Drilling Engineering - PE 311

Rock Failure Mechanisms

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Bits are designed to induce rock failure. Because rock failure can occur in different

ways, depending on the formation and on downhole conditions, there are a large

number of design variations among rolling cutter and fixed cutter bits. To evaluate

these design variations and select a bit, we first need a basic understanding of

how rocks fail and how formation conditions affect drilling performance.

The purpose of the design is to take advantage of the formation most efficient

failure mechanisms.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

Stress is the internal force applied to a unit area of material. An analysis of the

stresses acting on a particular object can become quite involved. For the purpose

of this discussion, however, we can define three basic components of stress:

Compressive stress: a pushing or squeezing force;

Tensile stress: a pulling or elongating force;

Shear stress: a slicing or cleaving force.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

Strain is the deformation experienced by a material in response to an applied

stress. This deformation may take one of two forms:

Elastic: If the applied stress is below the elastic limit of the material, the material

returns to its original shape and size once the stress is removed.

Plastic: if the applied stress exceeds the material's elastic limit, the material

experiences permanent deformation

Prepared by: Tan Nguyen

L L L0

L

1

L0

L0

L0

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

If rupture takes place before significant plastic deformation occurs, the material is

described as brittle. If the material ruptures only after experiencing significant

plastic deformation, it is considered ductile.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

If formation is under brittle failure, bits which have crushing and chipping actions

are preferred. On the other hand, if formation is under ductile failure, bits which

have gouging and scrapping actions are chosen.

All rocks exhibit brittle stage under atmosphere pressure. This is applicable for

under balanced drilling conditions

Under high pressure, the failure mechanism transfers from brittle to ductile. This

condition is for overbalanced drilling.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

At atmospheric pressure, sedimentary rocks are normally brittle. They become

ductile, however, under high confining stress if there is no communication between

the internal rock pore pressure and the surrounding pressure medium.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

The Stress/Strain Relationship

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Underbalanced Condition

If the pressure exerted by the fluid column is less than the pore pressure of the

formation, the differential pressure is less than zero, and the well is being drilled in

an underbalanced condition. This condition most often occurs when drilling with

air, fresh water or muds weighing less than 8.6 lb/gal.

In underbalanced drilling, the rock exhibits brittle behavior it has a relatively low

failure strength and fractures very easily. Because the rock surface is in tension, it

virtually explodes under the compressive loads of the bit. There is no downward

pressure to promote chip hold-down, and so there is very little regrinding of

already-drilled cuttings. This helps attain very high rates of penetration.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Balanced Condition

When the pressure of the fluid column is equal to the pore pressure, the hole is in

a balanced condition. This condition generally occurs when drilling with brine water

or mud weighing 8.6 lb/gal.

Under balanced conditions, the rock is still in the brittle state and fractures

relatively easily. The bottom of the hole is in pressure equilibrium, so there is

minimal stress concentration present to either enhance or slow penetration rates.

Penetration

rates

are

generally

slower

than

those

experienced

in

an

underbalanced drilling, because there is some chip hold-down resulting from

cohesive forces between the rock cuttings, along with interference due to fluid

viscosity.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Overbalanced Condition

In overbalanced drilling, the pressure of the mud column exceeds the formation

pore pressure. In areas with normal pressure gradients, this condition occurs when

the mud weight exceeds 8.6 Ib/gal. For safety reasons, overbalanced drilling is

normal practice in most areas.

As the differential pressure increases in an overbalanced hole, the rock below the

bit becomes increasingly strong and ductile. The hole bottom is in a state of

compression, thus retarding fracture propagation caused by the bit. These factors,

along with a high degree of chip hold-down, tend to slow penetration rates. If the

differential pressure is too high, the mud can fracture the formation, resulting in

lost circulation and possibly a blowout.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Overbalanced Condition

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms

Chip Hold Down

Penetration rate is also affected by a pressure-related phenomenon known as chip

hold-down. Chip hold-down occurs when a mud filter cake or fine solids block

fractures produced by the bit. This prevents the liquid phase of the mud from

invading the fractures, and results in a positive pressure differential across the top

surface of the chip. The hold-down force is equal to the area of the chip times the

differential pressure

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Introduction

Drag bits are designed to drill primarily by a wedging mechanism.

A vertical force is applied to the tooth as a result of applying drill collar weight to

the bit, and a horizontal force is applied to the tooth as a result of applying the

torque necessary to turn the bit. The result of these two forces defines the plane of

thrust of the tooth or wedge. The cuttings are sheared off in a shear plane at an

initial angle to the plane of thrust that is dependent on the properties of the rock.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

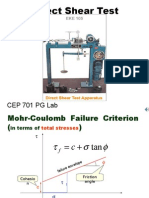

Mohr Failure Criterion

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

: Angle to the

direction of the

compressive load

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

Summing forces normal to the fracture plane gives

Where

dA3 = dAncos

and

dA1 = dAnsin

Making these substitutions in the force balance equation gives

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

Summing forces parallel to the fracture plane gives

With dA3 = dAncos

dA1 = dAnsin

These two equations represent graphically by the Mohrs circle. Any combination

between and n gives a new circle representing a new failure condition.

The rock will fail when the combination between WOB and shear force gives a

point out side the Mohrs circle

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohrs Circle

Positive

shear

would

cause

clockwise rotation of the element.

12 is negative and 21 is positive

Compression is positive

Tensile is negative

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohrs Circle

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

c = - ntan

is the angle of internal friction

n is the stress normal to the fracture plane

c is the cohesive resistance

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

Example: A rock sample under a 2,000 psi confining pressure fails when subjected

to a compressional loading of 10,000 psi along a plane that makes an angle of 27 0

with the direction of the compressive load. Using the Mohr failure criterion,

determine the angle of internal friction, the shear strength and the cohesive

resistance of the material.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Drag Bits

Mohr Failure Criterion

Solution: the angle and 2 must sum to 900. Thus the angle of internal friction is

given by

= 90 2(27) = 36 0

The shear strength is computed as follows

= (1 3)sin(2) = (10,000 2,000)sin(540) = 3,236 psi

The stress normal to the fracture plane is

n = (1 + 3) (1 3)cos(2) = 3,649 psi

The cohesive resistance can be computed

c = - ntan = 585 psi

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Rolling Cone Bits

Percussion or crushing action is the predominant mechanism present for the

rolling cutter bits. Since these types of bits are designed for use in hard, brittle

formations in which ROP tend to be low and drilling costs tend to be high, the

percussion mechanism is of considerable economic interest.

The apparatus allowed the borehole pressure, rock pore pressure, and rock

confining pressure to be varied independently. The apparatus was equipped with a

static loading device which used an air-actuated piston to simulate constant force

impacts similar to those produced in rotary drilling. Strain gauges and a linear

potentiometer were used to obtain force displacement curves.

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Rolling Cone Bits

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Rolling Cone Bits

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Rolling Cone Bits

As load is applied to a bit tooth (A), the constant pressure beneath the tooth

increases until it exceeds the crushing strength of the rock and a wedge of finely

powdered rock then is formed beneath the tooth (B). As the force on the tooth

increases, the material in the wedge compresses and exerts high lateral forces on

the solid rock surrounding the wedge until the shear stress exceeds the shear

strength of the solid rock and the rock factures (C).

The force at which fracturing begins beneath the tooth is called the threshold force.

As the force on the tooth increases above the threshold value, subsequent

fracturing occurs in the region above the initial fracture, forming a zone of broken

rock (D).

Prepared by: Tan Nguyen

Drilling Engineering

Rock Failure Mechanisms of Rolling Cone Bits

At low differential pressure, the cuttings formed in the zone of broken rock are

ejected easily from the crater (E). The bit tooth then moves forward until it reaches

the bottom of the crater, and the process may be repeated (F, G).

At high differential pressures, the downward pressure and frictional forces between

the rock fragments prevent ejection of the fragments (E). As the force on the tooth

is increased, displacement takes place along fracture planes parallel to the initial

fracture (F, G). This gives the appearance of plastic deformation, and craters

formed in the manner are called pseudo plastic craters.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

The most important variables affecting penetration rate that have been identified

and studied included: bit type, formation characteristics, drilling fluid properties, bit

operating conditions (WOB, and ROP), bit tooth wear, and bit hydraulics.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Bit Type

For rolling cutter bits, the initial ROP is often highest in a given formation when

using bits with long teeth and a large cone offset angle. However, these bits are

practical only in soft formations because of a rapid tooth destruction and decline in

penetration rate in hard formations.

Drag bits are designed to obtain a given penetration rate. Drag bits give a wedging

type rock failure in which the bit penetration per revolution depends on the number

of blades and the bottom cutting angle. The diamond and PCD bits are designed

for a given penetration per revolution by the selection of the size and number of

diamonds or PCD blanks.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Formation Characteristics

The elastic limit and ultimate strength of the formation are the most important

formation properties affecting ROP. The shear strength predicted by Mohr failure

criteria sometimes is used to characterize the strength of the formation. To

determine the shear strength from a single compression test, an average angle of

internal friction of 350 was assumed. The angle of internal friction varies from about

30 400 form most rocks

The mineral composition of the rock also has some effect on ROP. Rocks

containing hard, abrasive minerals can cause rapid dulling of the bit teeth. Rocks

containing gummy clay minerals can cause the bit to ball up and drill in a very

inefficient manner.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Formation Characteristics

The permeability of the formation also has a significant effect on the ROP. In

permeable rocks, the drilling fluid filtrate can move into the rock ahead of the bit

and equalize the pressure differential acting on the chips formed beneath each

tooth. This would tend to promote the more explosive elastic mode of crater

formation. it also can be argued that the nature of the fluids contained in the pore

spaces of the rock also affects this mechanism since more filtrate volume would

be required to equalize the pressure in rock containing gas than in a rock

containing liquid.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Drilling Fluid Properties

The properties of drilling fluid reported to affect the ROP include: density,

rheological flow properties, filtration characteristics, solids content and size

distribution, and chemical composition.

Penetration rate tends to decrease with increasing fluid density, viscosity and

solids content, and tends to increase with increasing filtration rate. The density,

solid, and filtration characteristics of the mud control the pressure differential

across the zone of crushed rock beneath the bit. The fluid viscosity controls the

system frictional losses in the drillstring and thus the hydraulic energy available at

the bit jets for cleaning. The most important factor out of the drilling fluid properties

is the density. Changing density will change the overbalance. The ROP decreases

as the overbalance increases.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Operating Conditions

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Operating Conditions

When plotting ROP vs. WOB obtained experimentally with all other drilling

variables held constant has the characteristic shape as shown:

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Operating Conditions

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Operating Conditions

No significant ROP is obtained until the threshold bit weight is applied (point a).

ROP then increases rapidly with increasing values of WOB. For moderate value of

bit weight, a linear curve is often observed (segment bc). However, at higher

values of bit weight, subsequent increase in bit weight causes only slight

improvements in ROP (cd). In some cases, a decrease in ROP is observed at

extremely high value of WOB (de). This type of behavior often is called bit

floundering. This poor response of ROP at high values of bit weight usually is

attributed to less efficient bottomhole cleaning at higher rates of cuttings.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Operating Conditions

A typical plot of ROP vs. rotary speed obtained with all other drilling variables held

constant is shown. ROP usually increases linearly with low RPM. At higher values

of RPM the response of ROP to increase RPM diminishes. The reason is due to

the poor hole cleaning.

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Bit Diameters

Prepared by: Tan Nguyen

Drilling Engineering

Factors Affecting Penetration Rate

Effecting of Bit Diameters

Generally, as the bit diameter

increases, the applied weight

on the bit is distributed over

the

larger

consequently

area

reduces

which

the

rate of penetration of the bit.

Prepared by: Tan Nguyen

Potrebbero piacerti anche

- Unit 3 Wellbore StabilityDocumento28 pagineUnit 3 Wellbore StabilityJagdish annayaNessuna valutazione finora

- Chapter 2. Blasting Effects and Their ControlDocumento14 pagineChapter 2. Blasting Effects and Their ControlLuis Iparraguirre Tandaypan100% (1)

- Ce 364 s2023 Lecture 1 Uyumluluk ModuDocumento65 pagineCe 364 s2023 Lecture 1 Uyumluluk Moduenes arikanNessuna valutazione finora

- Measurement of in Situ Shear Strength of Rock Mass: Rajbal SinghDocumento12 pagineMeasurement of in Situ Shear Strength of Rock Mass: Rajbal SinghManish Kumar SinghNessuna valutazione finora

- Lecture 19 Rheology PDFDocumento29 pagineLecture 19 Rheology PDFRiddhi Archon MandalNessuna valutazione finora

- With Compliments: by Claude Cunningham Consulting Mining Engineer African Explosives LimitedDocumento6 pagineWith Compliments: by Claude Cunningham Consulting Mining Engineer African Explosives LimitedRizky Da SilvaNessuna valutazione finora

- Kriteria Desain TunnelDocumento18 pagineKriteria Desain TunnelgrahazenNessuna valutazione finora

- Mine Waste Stability FactorsDocumento5 pagineMine Waste Stability FactorsWalay AllanNessuna valutazione finora

- ROCK FAILURE MECHANISMS AND DRILLING PERFORMANCEDocumento11 pagineROCK FAILURE MECHANISMS AND DRILLING PERFORMANCEZ Babar KhanNessuna valutazione finora

- Notes 1Documento9 pagineNotes 1Ruben ChirinosNessuna valutazione finora

- Strength and Yield 1.0Documento3 pagineStrength and Yield 1.0Ragde OjuaraNessuna valutazione finora

- Direct Shear TestDocumento32 pagineDirect Shear TestVarun Shastry0% (1)

- Shear Strength of Dam-Foundation Rock Interface PDFDocumento4 pagineShear Strength of Dam-Foundation Rock Interface PDFAdrian Luis Hernandez GarciaNessuna valutazione finora

- Hazeldon T Muchono R1915417W Level 3.2 HMINE 323Documento13 pagineHazeldon T Muchono R1915417W Level 3.2 HMINE 323Tinotenda MuchonoNessuna valutazione finora

- BlastDocumento12 pagineBlastemptyqqNessuna valutazione finora

- Shear Strength of Soil ReportDocumento2 pagineShear Strength of Soil ReportAryamaan SinghNessuna valutazione finora

- In-Situ Rock StressesDocumento16 pagineIn-Situ Rock StressesAslam KhanNessuna valutazione finora

- Literture Review Stone CrusherDocumento5 pagineLiterture Review Stone CrusherD.n.G StudiosNessuna valutazione finora

- Strength & failure modes of concreteDocumento12 pagineStrength & failure modes of concretemaneeshaNessuna valutazione finora

- Knowledge of In-situ Stress for Drilling Horizontal WellsDocumento5 pagineKnowledge of In-situ Stress for Drilling Horizontal WellsianherzogNessuna valutazione finora

- 10po WZ 1 4 PDFDocumento13 pagine10po WZ 1 4 PDFMarcelo Varejão CasarinNessuna valutazione finora

- In Situ Stress Measurement Techniques 18th Dec.Documento16 pagineIn Situ Stress Measurement Techniques 18th Dec.Chandrani PrasadNessuna valutazione finora

- Blast Design and Assessment For Surface Mines and QuarriesDocumento198 pagineBlast Design and Assessment For Surface Mines and QuarriesOmar Alex Meléndez HuamánNessuna valutazione finora

- Squeezing Ground ConditionDocumento16 pagineSqueezing Ground ConditionMourad HosniNessuna valutazione finora

- Factors That Influence The Tensile StrengthDocumento47 pagineFactors That Influence The Tensile StrengthOvidiu GalNessuna valutazione finora

- Rock Breakage and Blast Design Considerations in OpenpitDocumento34 pagineRock Breakage and Blast Design Considerations in Openpitpartha das sharma100% (5)

- A Graphical Hole Monitoring Technique To Improve Drilling-LenamondDocumento15 pagineA Graphical Hole Monitoring Technique To Improve Drilling-LenamondHafiz OthmanNessuna valutazione finora

- Blast Fragmentation in MinesDocumento32 pagineBlast Fragmentation in MinesFrancis LuckasNessuna valutazione finora

- Rock Drilling Techniques and FactorsDocumento20 pagineRock Drilling Techniques and Factorssudishett100% (1)

- Rock Failure CriteriaDocumento18 pagineRock Failure CriteriaNikhil SinghNessuna valutazione finora

- Optimizacion de Aceros PDFDocumento34 pagineOptimizacion de Aceros PDFKendra RobertsNessuna valutazione finora

- Energies: Numerical Investigation of The Impacts of Borehole Breakouts On Breakdown PressureDocumento23 pagineEnergies: Numerical Investigation of The Impacts of Borehole Breakouts On Breakdown PressureardabiliNessuna valutazione finora

- STABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsDocumento4 pagineSTABILTY ASSESSMENT OF HEADRACE TUNNEL SYSTEM FOR PUNATSANGCHHU II HYDROPOWER PROJECT, BHUTAN - Estimation of Seepage and Water Leakage in Underground TunnelsSudeep SharmaNessuna valutazione finora

- Directional Fracture Behavior and Stress Evolution Process of The Multi-Slit Charge BlastingDocumento13 pagineDirectional Fracture Behavior and Stress Evolution Process of The Multi-Slit Charge BlastingChandra HasanNessuna valutazione finora

- Precision Presplitting: Explosive Load Variations With SpacingDocumento10 paginePrecision Presplitting: Explosive Load Variations With SpacingJorge Ernesto de la RuaNessuna valutazione finora

- Chapter 13Documento36 pagineChapter 13pedroNessuna valutazione finora

- Borehole Geomechanics and Well DesignDocumento6 pagineBorehole Geomechanics and Well DesignMourad B. WassefNessuna valutazione finora

- Behavior and Failure Mode of Reinforced Concrete Members Damaged by Pre-CrackingDocumento10 pagineBehavior and Failure Mode of Reinforced Concrete Members Damaged by Pre-CrackingCaps LockNessuna valutazione finora

- In-Situ Shear Strength of Phyllite RockDocumento34 pagineIn-Situ Shear Strength of Phyllite RockRakesh ReddyNessuna valutazione finora

- Cost Effectiveness of Open-Pit Hard Rock Ore MiningDocumento14 pagineCost Effectiveness of Open-Pit Hard Rock Ore Miningpartha das sharma50% (2)

- Direct Shear TestDocumento32 pagineDirect Shear TestVinay YadavNessuna valutazione finora

- ISRM-8CONGRESS-1995-074 - A Comprehensive Peak Shear Strength Criterion For Rock JointsDocumento8 pagineISRM-8CONGRESS-1995-074 - A Comprehensive Peak Shear Strength Criterion For Rock Jointscastille1956Nessuna valutazione finora

- Critical State Soil Mechanics - by Jishnu R BDocumento265 pagineCritical State Soil Mechanics - by Jishnu R BJishnu Ramabhadran100% (1)

- Rock Bolting Techniques for Roof and Wall StabilizationDocumento9 pagineRock Bolting Techniques for Roof and Wall StabilizationsamratNessuna valutazione finora

- Mohr's Circle Analysis of Rock Failure Under StressDocumento26 pagineMohr's Circle Analysis of Rock Failure Under StressNitishNessuna valutazione finora

- 1 Lecture-8 Shear Strength of Soils Dr. Attaullah ShahDocumento5 pagine1 Lecture-8 Shear Strength of Soils Dr. Attaullah ShahHIMANSHUNessuna valutazione finora

- Load Testing SetupDocumento23 pagineLoad Testing SetupWalid TahhanNessuna valutazione finora

- Rock Excavation SystemsDocumento16 pagineRock Excavation SystemsKerim AydinerNessuna valutazione finora

- Research ArticleDocumento12 pagineResearch ArticleYasothorn SapsathiarnNessuna valutazione finora

- 1 s2.0 S1878522013000489 Main - 2Documento5 pagine1 s2.0 S1878522013000489 Main - 2Febry RomarioNessuna valutazione finora

- Squeezing Rock MechanismDocumento12 pagineSqueezing Rock MechanismSambhav PoddarNessuna valutazione finora

- Dir Exp Met RovshanvaliyevDocumento11 pagineDir Exp Met RovshanvaliyevRovshan ValiyevNessuna valutazione finora

- Perforación y Tronadura Unidad I: IntroducciónDocumento31 paginePerforación y Tronadura Unidad I: IntroducciónLaiss FernandaNessuna valutazione finora

- Geo-Mechanics IntroductionDocumento27 pagineGeo-Mechanics IntroductionRitik ThakurNessuna valutazione finora

- Lecture Notes on Reinforced Concrete DesignDa EverandLecture Notes on Reinforced Concrete DesignNessuna valutazione finora

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesDa EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNessuna valutazione finora

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesDa EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNessuna valutazione finora

- Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureDa EverandFault Zone Dynamic Processes: Evolution of Fault Properties During Seismic RuptureMarion Y. ThomasNessuna valutazione finora

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionDa EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNessuna valutazione finora

- Fault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionDa EverandFault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionNessuna valutazione finora

- Modern Physics For High SchoolDocumento3 pagineModern Physics For High SchoolOtoyo BarnabasNessuna valutazione finora

- Spe 148073 MSDocumento9 pagineSpe 148073 MSotoyo barnabasNessuna valutazione finora

- Spe 151628 MSDocumento13 pagineSpe 151628 MSOtoyo Barnabas100% (1)

- Avlonitis 1992Documento202 pagineAvlonitis 1992Otoyo BarnabasNessuna valutazione finora

- Chapter 1 Petroleum Accounting-5th Part2Documento10 pagineChapter 1 Petroleum Accounting-5th Part2GOONessuna valutazione finora