Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Water Part3

Caricato da

Mimi BarasaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water Part3

Caricato da

Mimi BarasaCopyright:

Formati disponibili

Supplementary Training Modules on

Good Manufacturing Practice

Water for

Pharmaceutical Use

Part 3:

Inspection of water

purification systems

WHO Technical Report Series

No 929, 2005. Annex 3

Water

Slide 1 of 30

January 2006

Water for Pharmaceutical Use

Objectives

To understand:

The specific requirements when inspecting water systems,

including associated documentation

Water system inspection techniques and approaches

Water

Slide 2 of 30

January 2006

Water for Pharmaceutical Use

Prepare an aide-memoire for items to inspect:

Schematic drawing review

Changes to system since installation

Sampling procedure and plan

Specifications, results and trends

Out-of-specification results

Annual system review

Deviations

Water

Slide 3 of 30

8.

January 2006

Water for Pharmaceutical Use

Prepare an aide-memoire for items to inspect (2):

Results of system performance monitoring

Out of limit results, failure investigations and alarms recorded

Sanitization procedures and records

Maintenance and repairs logs/records

Instrument calibration and standardization

Qualification and validation including DQ, IQ, OQ, PQ

Requalification when appropriate, etc.

8.

Water

Slide 4 of 30

January 2006

Water for Pharmaceutical Use

Where to start:

What is the water to be used for?

sterile products

non-sterile products, e.g. oral liquid products, external

applications

solid dosage forms

washing and rinsing

Start: Document review site verification followed by additional

document review

Water

Slide 5 of 30

January 2006

Water for Pharmaceutical Use

Verification:

Start with document review (e.g. schematic drawing of the

system, "water quality manual" if available)

Review change control (in case of changes after qualification

and validation)

On site verification (system in accordance with the drawing)

Start source water supply

Pre-treatment and treatment systems

Water

Slide 6 of 30

January 2006

Water for Pharmaceutical Use

Documentation should reflect information on:

Pipeline

Valves (non-return type)

Breather points

Couplings

Pipe slope

Velocities

Sampling points

Drain points

Instrumentation

Flow rates

Water

Slide 7 of 30

January 2006

Water for Pharmaceutical Use

Documentation should reflect information on (2):

Specification for each system element

Standard procedures for use

System changes

Routine and non-routine maintenance

Investigations and corrective action

Validation studies

Chemical and microbiological specifications

Sampling instructions

Test procedures

Responsible persons

Training requirements

Water

Slide 8 of 30

January 2006

Water for Pharmaceutical Use

On site review and verification:

Walk through the system, verifying the parts of the system

as indicated in the drawing

Review procedures and "on site" records, logs, results

Verify components, sensors, instruments

Inspect the finishing, state, calibration status, labels, pipes,

tanks etc as discussed in previous parts of this module

Start with source water supply follow whole system "loop"

Water

Slide 9 of 30

January 2006

Water for Pharmaceutical Use

Well water

Inspect exposed parts of the well, depth of well

Check for nearby septic systems, hazardous materials

usage (pesticides, fertilizers, etc.)

Well maintenance

Water

Slide 10 of 30

January 2006

Water for Pharmaceutical Use

Raw water storage

May be required prior to pre-treatment

Check material of construction

Concrete, steel are acceptable but check corrosion

Plastics or plastic linings may leach

Check cover

To keep out insects, birds and animals

Check disinfection practices

Water

Slide 11 of 30

January 2006

Water for Pharmaceutical Use

Water treatment system inspection (1)

Checks may include:

Water

dead legs

filters

pipes and fittings

Ionic beds

storage tanks

by-pass lines

Slide 12 of 30

January 2006

Water for Pharmaceutical Use

Water treatment system inspection (2)

Checks may include:

Water

pumps

UV lights

sample points

reverse osmosis

valves

heat exchangers

Instruments, controls, gauges, etc.

Slide 13 of 30

January 2006

Water for Pharmaceutical Use

Other checks (1)

Stainless steel PVC and most plastics not recommended

Weld quality

Hygienic couplings

Passivation

Air breaks or Tundish

Water

Slide 14 of 30

January 2006

Water for Pharmaceutical Use

Other checks (2)

Pipes and pumps

hygienic couplings

welded pipes

hygienic pumps

hygienic

sampling points

acceptable floor

no leaks

Water

Slide 15 of 30

January 2006

Water for Pharmaceutical Use

Other checks (3)

Check condition of equipment

Staining on

water storage

tanks

Corrosion on plates of heat exchangers

indicates possible contamination

Water

Slide 16 of 30

January 2006

Water for Pharmaceutical Use

Other checks (4)

Maintenance records, maintenance of pump seals and O rings

Water

Slide 17 of 30

January 2006

Water for Pharmaceutical Use

Other checks (5)

Air filters

Water

Integrity testing, sterilization

and replacement frequency

Check burst discs

Slide 18 of 30

January 2006

Water for Pharmaceutical Use

Other checks (6)

Softened water

out to deionizer

By-pass lines

By-pass valve

Carefully check by-pass

valves and lines

These sometimes leak or are

inadvertently left open

A blanking piece is better

during operation phase

Zeolite water softener

exchanges Ca and Mg for Na

Water

Slide 19 of 30

January 2006

Water for Pharmaceutical Use

Other checks (7)

Activated carbon bed sanitization

Temperature-compensated conductivity meters

Influence of plastic pipe adhesive on TOC

Non-condensable gases in pure steam

Water

Slide 20 of 30

January 2006

Water for Pharmaceutical Use

Other checks (8)

Polypropylene welding inspection

checking pin holes

Retrospective validation of WFI system

Rouging of WFI storage systems

Spray ball efficacy

Water

Slide 21 of 30

January 2006

Water for Pharmaceutical Use

Other checks (9)

UV light monitoring performance and lamp life and

intensity

Validating ozone dosage

Specifications for acids, alkalis for DI and sodium chloride

for water softener

Normally open and normally closed valves

Water

Slide 22 of 30

January 2006

Water for Pharmaceutical Use

Then review additional documentation

Qualification protocols and reports

Change control request (where applicable)

Requalification (where applicable)

QC and microbiology laboratory:

SOP for sampling

Procedures and records

Water

Slide 23 of 30

January 2006

Water for Pharmaceutical Use

Sampling (1)

There must be a sampling procedure

Sample integrity must be assured

Sampler training

Sample point

Sample size

Water

Slide 24 of 30

January 2006

Water for Pharmaceutical Use

Sampling (2)

Sample container

Sample label

Sample transport and storage

Arrival at the laboratory

Test method

When is the test started?

Water

Slide 25 of 30

January 2006

Water for Pharmaceutical Use

Testing

Review method verification

Chemical testing

Microbiological testing

test method

types of media used

incubation time and temperature

objectionable and indicator organisms

manufacturer must set specifications

Water

Slide 26 of 30

January 2006

Water for Pharmaceutical Use

Suggested bacterial limits (CFU /mL)

Target

Alert

Action

Raw water

200

300

500

Post multimedia filter

100

300

500

Post softener

100

300

500

Post activated carbon filter

50

300

500

Feed to RO

20

200

500

RO permeate

10

50

100

Points of Use

10

100

Sampling location

Water

Slide 27 of 30

January 2006

Water for Pharmaceutical Use

Pyrogens and endotoxins

Any compound injected into mammals which gives rise to fever is

a Pyrogen

Endotoxins are pyrogenic, come from Gram negative bacterial

cell wall fragments

Detect endotoxins using a test for lipopolysaccharides (LPS)

rabbit test detects pyrogens

LAL test detects endotoxins

Ultrafiltration, distillation and RO may remove pyrogens

Water

Slide 28 of 30

January 2006

Water for Pharmaceutical Use

Group Session

You are given a schematic drawing of a water system to discuss. List any

problems and their solutions

IN C O R R E C T W A T E R T R E A T M E N T PL A N T

Water

Slide 29 of 30

January 2006

Water for Pharmaceutical Use

Group Session

M O D IF IE D W A T E R T R E A T M E N T PL A N T

Water

Slide 30 of 30

January 2006

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Work Handling,: Insruction TransportationDocumento7 pagineWork Handling,: Insruction Transportationrajnish14feb8516Nessuna valutazione finora

- TOP RECOMMENDED SUPPLIERS OF LAB REAGENTS AND EQUIPMENTDocumento35 pagineTOP RECOMMENDED SUPPLIERS OF LAB REAGENTS AND EQUIPMENTmrescobedoNessuna valutazione finora

- GMP Training on Pharmaceutical Water PurificationDocumento44 pagineGMP Training on Pharmaceutical Water PurificationAndy RojasNessuna valutazione finora

- JTP Miter Gearbox CatalogueDocumento28 pagineJTP Miter Gearbox CatalogueNaveen KanchiNessuna valutazione finora

- Astm c478mDocumento8 pagineAstm c478mNelson HernandezNessuna valutazione finora

- Pizza Hut's Supply Chain and OperationsDocumento7 paginePizza Hut's Supply Chain and OperationsHamza Ahmed Abbasi88% (8)

- Phased PPAP Manual - June 2010Documento22 paginePhased PPAP Manual - June 2010frangeljediNessuna valutazione finora

- I 103 4 e MSD ManualDocumento29 pagineI 103 4 e MSD ManualAris Budianto100% (5)

- Water For Pharmaceutical Use: Water Purification and EngineeringDocumento19 pagineWater For Pharmaceutical Use: Water Purification and EngineeringJosé Manuel Pais-ChanfrauNessuna valutazione finora

- Hydrogen Transportation PipelinesDocumento83 pagineHydrogen Transportation PipelinesWolf1604100% (4)

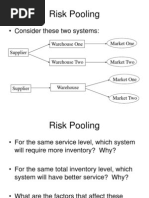

- Risk PoolingDocumento11 pagineRisk PoolingAshok100% (1)

- Color Coated Sheets ResearchDocumento8 pagineColor Coated Sheets ResearchGirish SahareNessuna valutazione finora

- The First Industrial Revolution: Machines Replace Human LaborDocumento44 pagineThe First Industrial Revolution: Machines Replace Human LaborRina100% (2)

- SOP Jahe InstanDocumento10 pagineSOP Jahe InstanCiiee Tyan TheLennonk100% (3)

- Vitamin EDocumento5 pagineVitamin EMimi BarasaNessuna valutazione finora

- 216 S11-Expt 1Documento2 pagine216 S11-Expt 1Mimi BarasaNessuna valutazione finora

- Medicated Lipstick FormulationDocumento6 pagineMedicated Lipstick FormulationMimi BarasaNessuna valutazione finora

- Farkim TralalaDocumento6 pagineFarkim TralalamimienamNessuna valutazione finora

- SDG GOAL 9: Industry, Innovation and Infrastructure: Mec600 - Engineer in SocietyDocumento9 pagineSDG GOAL 9: Industry, Innovation and Infrastructure: Mec600 - Engineer in SocietydasdasdNessuna valutazione finora

- Recycling of PVC Wastes PDFDocumento12 pagineRecycling of PVC Wastes PDFluanaheresNessuna valutazione finora

- Stainless Steel Pipe and Tube SpecificationsDocumento10 pagineStainless Steel Pipe and Tube SpecificationsDIBYENDU MONDALNessuna valutazione finora

- Freilog (Pty) LTD - 2014Documento6 pagineFreilog (Pty) LTD - 2014FreilogNessuna valutazione finora

- Removal of Phosphorous From Steel Produced by Melting Sponge Iron in Induction FurnaceDocumento5 pagineRemoval of Phosphorous From Steel Produced by Melting Sponge Iron in Induction Furnaceakshuk0% (1)

- RLMagazine Edition 53Documento22 pagineRLMagazine Edition 53liberrimoNessuna valutazione finora

- David McDowell ResumeDocumento2 pagineDavid McDowell ResumedmcdscribdocNessuna valutazione finora

- Flow Forming PresentationDocumento16 pagineFlow Forming PresentationNaveen C. Bhatia0% (1)

- En Slimstock RetailDocumento2 pagineEn Slimstock RetailDinesh PatilNessuna valutazione finora

- 0082Documento1 pagina0082buddhansamratNessuna valutazione finora

- El-Hofy Fundamentals of Machining Processes Tema 10Documento42 pagineEl-Hofy Fundamentals of Machining Processes Tema 10chompo83Nessuna valutazione finora

- Beyond ERP: Towards Intelligent Manufacturing Planning and ControlDocumento49 pagineBeyond ERP: Towards Intelligent Manufacturing Planning and ControldedikiNessuna valutazione finora

- Adhesives Plexus Ma830Documento2 pagineAdhesives Plexus Ma830Vinaya Almane DattathreyaNessuna valutazione finora

- Final IME Class Time Table 2012-2013-Sem-IDocumento2 pagineFinal IME Class Time Table 2012-2013-Sem-IMJNessuna valutazione finora

- SPI Tooling SpecificationsDocumento3 pagineSPI Tooling SpecificationsJanaka MangalaNessuna valutazione finora

- Nyloflex ACE Nyloflex ACE Digital: Sets The Standard in High Quality Flexo PrintingDocumento2 pagineNyloflex ACE Nyloflex ACE Digital: Sets The Standard in High Quality Flexo PrintingIoan-Alexandru CsinádyNessuna valutazione finora

- Bridge Deck HandbookDocumento136 pagineBridge Deck HandbookJib RanNessuna valutazione finora

- FKM 75 Compound 51414 Eriks' 51414Documento1 paginaFKM 75 Compound 51414 Eriks' 51414seeralan_1986Nessuna valutazione finora

- Alternative Strategies For Energy Recovery From Municipal Solid Waste Part A Mass and Energy BalancesDocumento14 pagineAlternative Strategies For Energy Recovery From Municipal Solid Waste Part A Mass and Energy BalancesPreetha SreekumarNessuna valutazione finora