Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Answers Drawing A

Caricato da

adeoye_okunoyeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Answers Drawing A

Caricato da

adeoye_okunoyeCopyright:

Formati disponibili

TECHNOLOGY

SWI 3.2

Answers Drawing A

BS EN 22553

Course Reference WIS 10

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

SWI 3.2

Remember in the CSWIP 3.2 Senior Welding Inspectors

examination your are required to interpret a fabrication

drawing and comment on the welding symbols

Time allowed 1 hour

The drawing will contain around 15 to 20

symbols

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

SWI 3.2

Drawings and Weld Symbol Interpretation

With the supplied drawing you are required to carry out the

following

1. Reference the drawing number onto your answer sheet

2. Specify the standard to which the weld symbols apply

3. Produce a neat sketch of how you see the welds,

numbering each weld individually.

4. Fully describe each weld symbol, example

Welded arrow side: Single-V butt

Welded other side: Sealing run.

5. On completion of the welding symbol interpretation, you

are then required to comment on the drawing with

reference to errors and incorrect set-ups

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

SWI 3.2

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

SWI 3.2

BS EN 22553 Answers DRG A

8

1.

2.

3.

12

4. Welded arrow side: 8mm leg length fillet, welded all

way around (peripheral weld) Toes to be blended

smooth

Welded other side: Single-J butt, welded all way

around. The drawing indicates the pipe to be

prepared, incorrect set-up.

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

BS EN 22553 Answers DRG A

SWI 3.2

5. Welded arrow side: Steep-flanked single-V butt weld,

with permanent backing strip.

6. Welded arrow side: Single-J butt weld, welded all way

around. Welding to be carried out on site.

7. Welded arrow side: 12mm leg length fillet weld, 8mm

throat thickness concave profile

8. Welded both sides: 6mm leg length fillet weld

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

BS EN 22553 Answers DRG A

SWI 3.2

9. Welded both sides: 8mm leg length fillet weld

10. Welded arrow side: Single-bevel butt, depth of

penetration 10mm, partial penetration.

Welded other side: 6mm leg length fillet weld.

11. Welded both sides : 8mm leg length fillet weld

12. Welded arrow side: 20mm leg length fillet weld, 14mm

throat thickness

Welded other side: 10mm leg length fillet weld, 7mm

throat thickness,

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

SWI 3.2

BS EN 22553 Answers DRG A

13. Welded arrow side: Single-J butt, welded using the

MAG process.

14. Welded both sides: 6mm leg length fillet welds, 50mm

in length, 25mm gap between each weld. Welds to be

staggered.

50

50

25

25

50

50

15. Welded arrow side: Baking run flat (flush) finish.

Welded other side: Single-V butt, 8mm depth of

preparation.

16. Welded arrow side: Single-J butt, flat (flush) finish.

Copyright 2003 TWI Ltd

M.S.Rogers

TECHNOLOGY

BS EN 22553 Answers DRG A

SWI 3.2

17. Welded all way around: Square butt weld cap

reinforcement convex profile. Welding to be carried out

on site. Note dotted line missing

18. Welded arrow side: Single-U butt.

19. Welded arrow side: Backing run

Welded other side: Single-V butt, flat (flush) finish.

20. Welded both sides: Double-J butt weld with a

superimposed 8mm leg length fillet welded arrow side

21. Welded arrow side: Single-bevel butt weld, 14mm

depth of penetration, 6mm leg length fillet weld

superimposed.

Welded other side: 4mm leg length fillet weld

Copyright 2003 TWI Ltd

M.S.Rogers

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Non Destructive Examination 2Documento148 pagineNon Destructive Examination 2adeoye_okunoyeNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- AKT ProjectDocumento1 paginaAKT Projectadeoye_okunoyeNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- UT PCN NotesDocumento113 pagineUT PCN NotesThiru Raja95% (19)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Radiographic Interpreter Weld DefectDocumento22 pagineRadiographic Interpreter Weld Defectadeoye_okunoyeNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- WIS 10 Interp ExeDocumento67 pagineWIS 10 Interp Exelembugs100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- 9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Documento77 pagine9 77 Pages Mutiple Questions For CSWIP Question Answers Solved Past Papers Cswip 3.1Umah SangarNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- DC-Voltage Gradient (DCVG) Surveys Using MCM's Integrated Pipeline Survey Test Equipment and Database Management PackageDocumento60 pagineDC-Voltage Gradient (DCVG) Surveys Using MCM's Integrated Pipeline Survey Test Equipment and Database Management Packageadeoye_okunoyeNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Calibration CertificateDocumento1 paginaCalibration Certificateadeoye_okunoye100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Ceramapure Repair ProcedureDocumento1 paginaCeramapure Repair Procedureadeoye_okunoyeNessuna valutazione finora

- CIPSDocumento6 pagineCIPSadeoye_okunoyeNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- DCVGDocumento8 pagineDCVGadeoye_okunoyeNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- B P S L: Redero Ipeline Ervices ImitedDocumento4 pagineB P S L: Redero Ipeline Ervices Imitedadeoye_okunoyeNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Tds Handy Cap Rev1 Aug13Documento2 pagineTds Handy Cap Rev1 Aug13adeoye_okunoyeNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairDocumento15 paginek2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Application Instruction & Data Sheet - Bitutape PrimerDocumento2 pagineApplication Instruction & Data Sheet - Bitutape Primeradeoye_okunoyeNessuna valutazione finora

- NE EFH 650 Cathodic Protection Maintenance Testing Pgs6-34g-kDocumento5 pagineNE EFH 650 Cathodic Protection Maintenance Testing Pgs6-34g-kadeoye_okunoyeNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Ng22 180 Cat ZBJ 000017 PCP Design NTDocumento22 pagineNg22 180 Cat ZBJ 000017 PCP Design NTadeoye_okunoyeNessuna valutazione finora

- Ethylene Vinyl Acetate WikipediaDocumento4 pagineEthylene Vinyl Acetate WikipediaxiaoboshiNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Housing TechnologiesDocumento9 pagineHousing TechnologiesKawaii CraftsNessuna valutazione finora

- Washbasins: Selector Pedestal/Wall Hung Semi-Countertop Countertop Under-Countertop Vessel Handrinse FittingsDocumento39 pagineWashbasins: Selector Pedestal/Wall Hung Semi-Countertop Countertop Under-Countertop Vessel Handrinse FittingsNaveen NtrNessuna valutazione finora

- Seamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Documento8 pagineSeamless Precision Steel Tubes For Hydraulic Cylinders - TN 008-00Erhan BeylihanNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 11 - Meher Prasad - Tech For Mass HousingDocumento35 pagine11 - Meher Prasad - Tech For Mass HousingKiran KoraddiNessuna valutazione finora

- Architectural Structural Holabird Bid Set DrawingsDocumento96 pagineArchitectural Structural Holabird Bid Set DrawingsM IQbal100% (1)

- Cathelco: Anode Length 100 8Documento1 paginaCathelco: Anode Length 100 8hakkıNessuna valutazione finora

- 8 SemDocumento22 pagine8 SemHarsh ShahNessuna valutazione finora

- BoQ - FSHDocumento273 pagineBoQ - FSHsrs_ce05Nessuna valutazione finora

- 1.7.4 Thermal Expansion Joint-HelsDocumento3 pagine1.7.4 Thermal Expansion Joint-HelsDat B. HuynhNessuna valutazione finora

- William Valve Catalogue Ball ValveDocumento24 pagineWilliam Valve Catalogue Ball ValveVinayNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Guia de Instalaciones DomiciliariasDocumento16 pagineGuia de Instalaciones Domiciliariaspaolamaldonado6082Nessuna valutazione finora

- BASF - Sports Flooring 2020Documento12 pagineBASF - Sports Flooring 2020Carlitos PrincipeNessuna valutazione finora

- Technical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Documento41 pagineTechnical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Lawrence Miguel FerrerNessuna valutazione finora

- ISO 4020 ExtractDocumento2 pagineISO 4020 ExtractBartek HajaNessuna valutazione finora

- Welding TechnologyDocumento218 pagineWelding Technologywbl_200789% (9)

- 1975 - New Materials Resistant To Wear and Corrosion To 1000 CDocumento11 pagine1975 - New Materials Resistant To Wear and Corrosion To 1000 CDrenkensteinNessuna valutazione finora

- Utilization of PTE and LDPE Plastic Waste and Building Material Waste As BricksDocumento6 pagineUtilization of PTE and LDPE Plastic Waste and Building Material Waste As BrickssamuelNessuna valutazione finora

- Sample Electrical PlanDocumento1 paginaSample Electrical PlanAl DrinNessuna valutazione finora

- Metric Steel Sheet / Plate - Hot RolledDocumento4 pagineMetric Steel Sheet / Plate - Hot RolledNurNessuna valutazione finora

- SSC Cat - Steam Relief ValvesDocumento15 pagineSSC Cat - Steam Relief ValvesArief sitompulNessuna valutazione finora

- Werkstoff 1.5217 (20MnV6)Documento2 pagineWerkstoff 1.5217 (20MnV6)alextentwentyNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Plain Plug Gage: Size (MM) Code Size (MM) Code Size (MM) Code Size (MM) CodeDocumento6 paginePlain Plug Gage: Size (MM) Code Size (MM) Code Size (MM) Code Size (MM) CodezeliaornelasNessuna valutazione finora

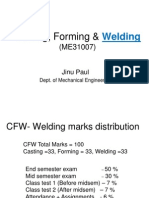

- Casting, Forming & WeldingDocumento90 pagineCasting, Forming & WeldingmahdiNessuna valutazione finora

- Sika Carbodur S Pds enDocumento5 pagineSika Carbodur S Pds enHarnawan Satya W ArsitekNessuna valutazione finora

- Sheet Metal DesignDocumento13 pagineSheet Metal Designsivakumar subramanianNessuna valutazione finora

- NDP-80 Data SheetDocumento9 pagineNDP-80 Data SheetSarah PerezNessuna valutazione finora

- Design of FRP-Profiles and All-FRP-StructuresDocumento67 pagineDesign of FRP-Profiles and All-FRP-StructuresSainey 班才傑Nessuna valutazione finora

- Kerbstones Installation GuidelinesDocumento4 pagineKerbstones Installation Guidelinespartha_svnitNessuna valutazione finora

- Du Pont KevlarDocumento23 pagineDu Pont Kevlarniks2409100% (3)