Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Workshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002

Caricato da

catio000Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Workshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002

Caricato da

catio000Copyright:

Formati disponibili

WORKSHOP 6

REAR RACK (MODAL) ANALYSIS

CAT509, Workshop 6, March 2002

WS6-1

CAT509, Workshop 6, March 2002

WS6-2

WORKSHOP 6 REAR RACK

Problem Description

Assume the dynamic characteristics of this bike with a 200 lb person

traveling at 40 mph down a cobble stone road is: Mode 1=95 Hz, Mode 2

= 100 Hz, Mode 3 = 110 Hz, Mode 4 = 120 Hz, Mode 5 = 135 Hz.

A rear rack accessory capable of supporting 150 lbs may be attached to

the frame. You are asked to analyze this rack under dynamic loading.

Perform a normal modes analysis to determine if the frequency of the

bike is close to one of the natural frequencies of the rack. This is to avoid

excessive vibrations and find soft spots (smooth, comfortable ride).

Aluminum

Elastic Modulus, E

10.15E6 psi

Poissons Ratio,

0.346

Density

.098 lb/in3

Yield Strength

13,778 psi

CAT509, Workshop 6, March 2002

WS6-3

WORKSHOP 6 REAR RACK

Suggested Exercise Steps

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

Open the existing CATIA part in the Part Design workbench.

Apply aluminum material properties to the part.

Create a Frequency analysis document (.CATAnalysis).

Pre-process initial finite element mesh.

Apply a clamp restraint.

Apply a mass equipment load.

Compute the analysis.

Visualize the analysis results.

Generate a report of the results.

Save the analysis document.

CAT509, Workshop 6, March 2002

WS6-4

Step 1. Open the existing CATIA part

Open the CATIA part

ws6rearRack.CATPart

in the Part Design

workbench.

Steps:

1. Select File and

Open from the top

pull-down menu.

2. Access the class

workshop directory

using the typical

Windows interface.

3. Open the rearRack

by double-clicking.

By default, the

rearRack and all other

CATPart documents

are opened in the Part

Design workbench.

CAT509, Workshop 6, March 2002

WS6-5

Step 2. Apply aluminum material properties to the part

3

1

Steps:

1. Click the Part

representation in the

features tree.

2. Click the Apply

Material icon.

3. Activate the Metal

tab in the Library

window.

4. Select Aluminum.

5. Select OK.

6. Make certain the

material is applied

properly in the tree.

CAT509, Workshop 6, March 2002

WS6-6

Step 3. Create a Frequency analysis document

2

4

Steps:

1. Start a GSA

workbench.

2. Select Frequency

Analysis, select OK.

3. Your Frequency

Analysis document

gets automatically

linked to the CATPart.

4. Note: your previous

results and

computations storage

location defaults to

your last path used.

CAT509, Workshop 6, March 2002

WS6-7

Step 3. Create a Frequency analysis document

4

Specify unique

External Storage

directory locations.

Steps:

1. Select the Storage

Location icon.

2

2. Modify the Results

Storage Location and

rename as shown.

3. Modify the

Computation Storage

Location and rename

as shown.

4. Note the Links

Manager in the

specification tree

reflects the paths.

5. Use Save

Management to save

CATAnalysis doc. as

rearRack.

CAT509, Workshop 6, March 2002

WS6-8

Step 4. Pre-process initial finite element mesh

Measure Dialogs

Measure to determine

initial mesh and sag

size.

Steps:

Exit Measure

1. Double Click the

OCTREE in the

features tree.

2. Measure part by

right clicking in the

Size box + measure.

3. Select two parallel

lines, note the

distance = 0.25in,

select Close.

4. Note the

measurement, select

NO.

Recommended rough

Global Size = the

thinnest section.

CAT509, Workshop 6, March 2002

4

WS6-9

Step 4. Pre-process initial finite element mesh

1

2

Define the global finite

element mesh

properties.

Steps:

1. Key in 0.125in

global mesh size.

2. Recommended Sag

= 10% of Global Size,

key in 0.013in.

3. Specify element

type Linear, select OK.

Parabolic elements

yield better results with

fewer elements, but in

the interest of time

and cpu space use

Linear.

CAT509, Workshop 6, March 2002

WS6-10

Step 5. Apply a clamp restraint

Steps:

1. Select the Clamp

Restraint

icon.

2. Select the inner

face where the rack

attaches to the frame,

select OK.

3. Note the Clamp

object added to the

specification tree.

CAT509, Workshop 6, March 2002

WS6-11

Step 6. Apply a mass equipment load

Steps:

1. Select the Mass icon.

2. Select the 2 faces as

shown.

3. Enter 150 lbs as the

mass, select OK.

4. Note the Distributed

Mass object added to

the specification tree.

4

3

English Mass Units:

1g=386.1 in/sec2

Length=in

Time=sec

Density=lb/in3

Mass=lb

CAT509, Workshop 6, March 2002

WS6-12

Step 7. Compute the analysis

Specify the number of

vibration modes to

compute

Steps:

1. Double click on the

Frequency Case

Solution in the spec.

tree.

2. Key in 5 vibration

modes to compute.

3. Select lanczos as

the compute method.

4. Specify maximum

number of iterations

and accuracy.

5. Select OK.

The Lanczos method

is most efficient for

computing a few

Eigenvalues of large,

sparce problems

(most structural

models fit into this

category).

CAT509, Workshop 6, March 2002

WS6-13

Step 7. Compute the analysis

1

Steps:

1. Select the Compute

icon.

2. Compute the

Frequency Case

Solution.1, select OK.

3. Notice the est. time,

memory and disk

space requirement,

select Yes.

CAT509, Workshop 6, March 2002

WS6-14

Step 8. Visualize the analysis results

Visualize the maximum

displacements to

locate the areas of max

strain energy.

Steps:

1. Select the

Displacement Image

Icon.

4b

4a

2. Double click to edit

image parameters.

3. Select Average-Iso

in Visu tab to switch

display.

4. Select Iso/Fringe

then select ISO

smooth, select OK,

OK.

Strain energy is helpful

in finding the area that

is most affected by the

vibration pattern from a

natural frequency.

CAT509, Workshop 6, March 2002

WS6-15

Step 8. Visualize the analysis results

Translational displacement Magnitude

Mode 1 Primary Bending

6.08 inch

Display all 5 dynamic

modes.

Mode 2 Primary Bending

10.1 inch

Steps:

1. Double click

Translational

displacement

magnitude to edit

image parameters.

1

Mode 3 Torsion

8.28 inch

2. View the displayed

frequency under tab Frequencies.

Mode 4 Secondary Bending

13.3 inch

3. Select and examine

each mode.

3

Mode 5 Secondary Bending

15.8 inch

Note the Translational

displacement

magnitude values are

arbitrary. The

displacement

distribution and

Frequency is what we

want.

CAT509, Workshop 6, March 2002

WS6-16

Step 8. Visualize the analysis results

Animate all 5 dynamic

modes.

Steps:

1. The Translational

displacement

magnitude image must

be active.

2. Select the Animate

an Analysis Image

icon.

3. Select Current

Occurrence to know

what mode you are

animating.

4

3

4. Select different

mode numbers and

select OK.

5. Use the controls in

the Animate Window

to animate the image.

CAT509, Workshop 6, March 2002

WS6-17

Step 8. Visualize the analysis results

Mode 5 has the

greatest displacement,

locate the element of

maximum strain

energy.

Steps:

1. The Translational

displacement

magnitude image must

be active. Then double

clicked.

5

1

2. Select mode

number 5 to make it

the current

occurrence, select OK.

3. Select the Search

Image Extrema icon.

2

4. Select Global and 2

maximum extrema at

most, select OK.

5. Location and value

are displayed.

CAT509, Workshop 6, March 2002

WS6-18

Step 9. Generate a report

After activating each

mode image at least

once, generate a

report.

If parabolic elements were used

Steps:

1. Select the Basic

Analysis Report icon.

2. Select an Output

directory.

3. Key in Title of the

report, select OK.

4. Review the HTML

report that is created.

If a structure has N

dynamic degrees of

freedom there are N

natural frequencies.

CAT509, Workshop 6, March 2002

WS6-19

Step 9. Generate a report

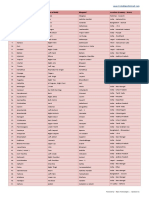

Conclusions

Comparing the natural frequency of the first 5 dynamic mode shapes shows a large

difference. This verifies that we will have smooth ride soft spots during this load case.

CAT509, Workshop 6, March 2002

Mode

Number

Bike Frequency

Hz (cycles/sec)

Rack Frequency Hz

Parabolic Elements

95

9.47

100

9.71

110

31.66

120

40.50

135

61.36

WS6-20

Step 10. Save the analysis document

Steps:

1. Select Save

Management from the

File menu.

2. Highlight document.

3. Click Save As to

specify name and

pathOK.

CAT509, Workshop 6, March 2002

WS6-21

CAT509, Workshop 6, March 2002

WS6-22

Potrebbero piacerti anche

- ANSYS Mechanical APDL for Finite Element AnalysisDa EverandANSYS Mechanical APDL for Finite Element AnalysisValutazione: 4.5 su 5 stelle4.5/5 (8)

- Workshop 4 Bicycle Pedal Mesh Refinement and Adaptivity: WS4-1 CAT509, Workshop 4, March 2002Documento32 pagineWorkshop 4 Bicycle Pedal Mesh Refinement and Adaptivity: WS4-1 CAT509, Workshop 4, March 2002catio000Nessuna valutazione finora

- 08b v5 Gpsfordesigner Ws 8b 030402Documento26 pagine08b v5 Gpsfordesigner Ws 8b 030402catio000Nessuna valutazione finora

- Workshop 7 Seat Post Assembly Analysis: WS7-1 CAT509, Workshop 7, March 2002Documento52 pagineWorkshop 7 Seat Post Assembly Analysis: WS7-1 CAT509, Workshop 7, March 2002catio000Nessuna valutazione finora

- CATIA V5 GPS For Designer - Cantilever Beam - 2012Documento22 pagineCATIA V5 GPS For Designer - Cantilever Beam - 2012Siow Shung ChurnNessuna valutazione finora

- 02 v5 Gpsfordesigner Ws 2 130402Documento18 pagine02 v5 Gpsfordesigner Ws 2 130402catio000Nessuna valutazione finora

- 10 v5 Gpsfordesigner Ws 10 030402Documento30 pagine10 v5 Gpsfordesigner Ws 10 030402catio000Nessuna valutazione finora

- 14 v5 Gpsfordesigner Ws 14 030402Documento20 pagine14 v5 Gpsfordesigner Ws 14 030402catio000Nessuna valutazione finora

- Getting Started With AbaqusDocumento6 pagineGetting Started With AbaqusingAlecuNessuna valutazione finora

- ANSYS Explicit Dynamics 120 Workshop 02Documento37 pagineANSYS Explicit Dynamics 120 Workshop 02avinashj18Nessuna valutazione finora

- Tube CreepDocumento40 pagineTube Creepchiru1010Nessuna valutazione finora

- EDEM-FLUENT Tutorial: 2-Phase Lagrangian Simulation: Revision 2.2/2Documento7 pagineEDEM-FLUENT Tutorial: 2-Phase Lagrangian Simulation: Revision 2.2/2gurpinder.rajgarh1331Nessuna valutazione finora

- Loading & Analysis of A Pipe's Vibrations: Module PartDocumento7 pagineLoading & Analysis of A Pipe's Vibrations: Module PartrigaschNessuna valutazione finora

- ANSYS Explicit Dynamics 120 Workshop 02Documento37 pagineANSYS Explicit Dynamics 120 Workshop 02Love SemsemNessuna valutazione finora

- Abaqus IntroductionDocumento20 pagineAbaqus IntroductionRavi KumarNessuna valutazione finora

- IET600 Training Rev 02Documento24 pagineIET600 Training Rev 02osmpot100% (1)

- Tutorial: Partially Premixed Combustion in A Co-Axial CombustorDocumento13 pagineTutorial: Partially Premixed Combustion in A Co-Axial CombustorGaurav SinglaNessuna valutazione finora

- Tutor NastranDocumento664 pagineTutor NastranNofryzāl HālohoNessuna valutazione finora

- MasterCam Mazak TutorialDocumento81 pagineMasterCam Mazak TutorialDracoRodriguezNessuna valutazione finora

- MAXSURF Motions QuickstartDocumento9 pagineMAXSURF Motions QuickstartbalintNessuna valutazione finora

- AAS6000 Manual Simplified Version 20120530Documento13 pagineAAS6000 Manual Simplified Version 20120530J Díaz SalaverríaNessuna valutazione finora

- Rotating SystemDocumento16 pagineRotating Systemsb aliNessuna valutazione finora

- Mulit Phase 3Documento30 pagineMulit Phase 3sb aliNessuna valutazione finora

- MontecarloDocumento44 pagineMontecarloAnand Krishna GhattyNessuna valutazione finora

- EQSAP2000Documento24 pagineEQSAP2000Chidanand BhimannavarNessuna valutazione finora

- Training Case 3 Centrifugal Pump 61Documento60 pagineTraining Case 3 Centrifugal Pump 61ufonpuNessuna valutazione finora

- The 2nd Assessment ProblemDocumento4 pagineThe 2nd Assessment ProblemrisirarocksNessuna valutazione finora

- Models - Cfd.baffled MixerDocumento12 pagineModels - Cfd.baffled MixerCARLOSNessuna valutazione finora

- SapTutor ExampleDocumento50 pagineSapTutor ExampleBesmirNessuna valutazione finora

- Sap TutorDocumento50 pagineSap TutorAndore BcNessuna valutazione finora

- Transient Compressible Flow Inside Convergent Divergent NozzleDocumento45 pagineTransient Compressible Flow Inside Convergent Divergent NozzlelitonNessuna valutazione finora

- Drill Bench-Kick Module User GuideDocumento103 pagineDrill Bench-Kick Module User GuideAmir O. OshoNessuna valutazione finora

- 11 v5 Gpsfordesigner Ws 11 030402Documento30 pagine11 v5 Gpsfordesigner Ws 11 030402catio000Nessuna valutazione finora

- ProCAST20091 TutorialsDocumento213 pagineProCAST20091 TutorialsKmilo Giraldo100% (1)

- Reichert 1998 Aquasim TutorialDocumento218 pagineReichert 1998 Aquasim TutorialPhạm Lê AnhNessuna valutazione finora

- Chapter 4: Modeling Periodic Flow and Heat TransferDocumento24 pagineChapter 4: Modeling Periodic Flow and Heat Transferfahrgeruste3961Nessuna valutazione finora

- Cam Rocker Mechanism PDFDocumento6 pagineCam Rocker Mechanism PDFAxel DominiqueNessuna valutazione finora

- Emilian Popa Mastercam Lathe 2008Documento42 pagineEmilian Popa Mastercam Lathe 2008Emilian PopaNessuna valutazione finora

- Module 3 Extraction Timing Analysis Optmization and CTSDocumento7 pagineModule 3 Extraction Timing Analysis Optmization and CTSVenkateshNessuna valutazione finora

- Discrete VariablesDocumento15 pagineDiscrete Variableseric-gonzaloNessuna valutazione finora

- 5 - Wave Fatigue AnalysisDocumento40 pagine5 - Wave Fatigue AnalysisUALU333Nessuna valutazione finora

- Tut 01 Intro Tut 16 Species TransportDocumento52 pagineTut 01 Intro Tut 16 Species Transportbecool_bcn75Nessuna valutazione finora

- Modeling Solid Processes in ASPENDocumento39 pagineModeling Solid Processes in ASPENRehan RafiqNessuna valutazione finora

- Laboratory Exercise 4 Cmos Inverter LayoutDocumento10 pagineLaboratory Exercise 4 Cmos Inverter Layoutapi-3696675Nessuna valutazione finora

- Raining Uide: UMC-750-O R - F & C 5 ADocumento50 pagineRaining Uide: UMC-750-O R - F & C 5 AsingourNessuna valutazione finora

- GE Test ProceduresDocumento54 pagineGE Test Proceduresaartb101Nessuna valutazione finora

- Premixed Combustion Tutorial FLUENT in Conical Chamber Using Zimont ModelDocumento17 paginePremixed Combustion Tutorial FLUENT in Conical Chamber Using Zimont ModelGowtham Mech100% (2)

- Lab-DC Motor ControlDocumento5 pagineLab-DC Motor Controlahmed3423Nessuna valutazione finora

- 3647 9555 1 PBDocumento130 pagine3647 9555 1 PBJay JaydenNessuna valutazione finora

- XF Stress Test Report Generator User GuideDocumento8 pagineXF Stress Test Report Generator User GuideLau GonzalezNessuna valutazione finora

- Abaqus Tutorial 11b PlyFailureDocumento23 pagineAbaqus Tutorial 11b PlyFailureManjinderSinghNessuna valutazione finora

- Important: Read First: Release Notes For PRO/II 8.3Documento46 pagineImportant: Read First: Release Notes For PRO/II 8.3tinhtinh8204Nessuna valutazione finora

- 8850 510DP Service Manual PDFDocumento442 pagine8850 510DP Service Manual PDFmixel2r78% (9)

- 4.1. Magnetic Analysis of A Solenoid Actuator: 4.1.1. Problem SpecificationDocumento9 pagine4.1. Magnetic Analysis of A Solenoid Actuator: 4.1.1. Problem SpecificationRickson Viahul Rayan CNessuna valutazione finora

- Firstlook Manual SenxDocumento22 pagineFirstlook Manual SenxschraeubleNessuna valutazione finora

- Tutorial For Generative Structural Analysis in Catia V5Documento23 pagineTutorial For Generative Structural Analysis in Catia V5mhuzaimi77Nessuna valutazione finora

- Machine Design Elements and AssembliesDa EverandMachine Design Elements and AssembliesValutazione: 3.5 su 5 stelle3.5/5 (2)

- The Thermoeconomics of Energy ConversionsDa EverandThe Thermoeconomics of Energy ConversionsValutazione: 5 su 5 stelle5/5 (2)

- 09b v5 Gpsfordesigner Ws 9b 030402Documento28 pagine09b v5 Gpsfordesigner Ws 9b 030402catio000Nessuna valutazione finora

- 13 v5 Gpsfordesigner Ws 13 130402Documento28 pagine13 v5 Gpsfordesigner Ws 13 130402catio000100% (1)

- 12 v5 Gpsfordesigner Ws 12 030402Documento24 pagine12 v5 Gpsfordesigner Ws 12 030402catio000Nessuna valutazione finora

- 10b v5 Gpsfordesigner Ws 10b 130402Documento22 pagine10b v5 Gpsfordesigner Ws 10b 130402catio000Nessuna valutazione finora

- 14 v5 Gpsfordesigner Ws 14 030402Documento20 pagine14 v5 Gpsfordesigner Ws 14 030402catio000Nessuna valutazione finora

- 13 v5 Gpsfordesigner Ws 13 130402Documento28 pagine13 v5 Gpsfordesigner Ws 13 130402catio000100% (1)

- 11 v5 Gpsfordesigner Ws 11 030402Documento30 pagine11 v5 Gpsfordesigner Ws 11 030402catio000Nessuna valutazione finora

- 08 v5 Gpsfordesigner Ws 8 030402Documento40 pagine08 v5 Gpsfordesigner Ws 8 030402catio000Nessuna valutazione finora

- 09 v5 Gpsfordesigner Ws 9 030402Documento26 pagine09 v5 Gpsfordesigner Ws 9 030402catio000Nessuna valutazione finora

- 12 v5 Gpsfordesigner Ws 12 030402Documento24 pagine12 v5 Gpsfordesigner Ws 12 030402catio000Nessuna valutazione finora

- 05 v5 Gpsfordesigner Ws 5 130402Documento32 pagine05 v5 Gpsfordesigner Ws 5 130402catio000Nessuna valutazione finora

- Workshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002Documento22 pagineWorkshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002catio000Nessuna valutazione finora

- 03 v5 Gpsfordesigner Ws 3 130402Documento22 pagine03 v5 Gpsfordesigner Ws 3 130402catio000Nessuna valutazione finora

- 01 v5 Gpsfordesigner Ws 1 130402Documento6 pagine01 v5 Gpsfordesigner Ws 1 130402catio000Nessuna valutazione finora

- 09b v5 Gpsfordesigner Ws 9b 030402Documento28 pagine09b v5 Gpsfordesigner Ws 9b 030402catio000Nessuna valutazione finora

- Workshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002Documento22 pagineWorkshop 6 Rear Rack (Modal) Analysis: WS6-1 CAT509, Workshop 6, March 2002catio000Nessuna valutazione finora

- MSC - Software Corporation: CATIA V5 Structural Analysis For The DesignerDocumento4 pagineMSC - Software Corporation: CATIA V5 Structural Analysis For The Designercatio000Nessuna valutazione finora

- 08 v5 Gpsfordesigner Ws 8 030402Documento40 pagine08 v5 Gpsfordesigner Ws 8 030402catio000Nessuna valutazione finora

- 11 v5 Gpsfordesigner Ws 11 030402Documento30 pagine11 v5 Gpsfordesigner Ws 11 030402catio000Nessuna valutazione finora

- 14 v5 Gpsfordesigner Ws 14 030402Documento20 pagine14 v5 Gpsfordesigner Ws 14 030402catio000Nessuna valutazione finora

- 10 v5 Gpsfordesigner Ws 10 030402Documento30 pagine10 v5 Gpsfordesigner Ws 10 030402catio000Nessuna valutazione finora

- 09 v5 Gpsfordesigner Ws 9 030402Documento26 pagine09 v5 Gpsfordesigner Ws 9 030402catio000Nessuna valutazione finora

- 12 v5 Gpsfordesigner Ws 12 030402Documento24 pagine12 v5 Gpsfordesigner Ws 12 030402catio000Nessuna valutazione finora

- 13 v5 Gpsfordesigner Ws 13 030402Documento28 pagine13 v5 Gpsfordesigner Ws 13 030402catio000Nessuna valutazione finora

- Bold Face Actions - G 450Documento4 pagineBold Face Actions - G 450sohaib arifNessuna valutazione finora

- Required Obstacle ClearanceDocumento14 pagineRequired Obstacle ClearancePero PericNessuna valutazione finora

- p14.6 - D.C. Motor - Igcse AidDocumento2 paginep14.6 - D.C. Motor - Igcse Aidrandom channelNessuna valutazione finora

- C-81-9903-17-82 Halal 100g 2024-06-08Documento1 paginaC-81-9903-17-82 Halal 100g 2024-06-08NURUL FAUZANY BINTI MOHD BASARUDDINNessuna valutazione finora

- Street Design Manual NYCDocumento312 pagineStreet Design Manual NYCgonleoNessuna valutazione finora

- Esthetics and Shade Communication: A Practical Approach: Clinical ApplicationDocumento21 pagineEsthetics and Shade Communication: A Practical Approach: Clinical Applicationcatalin_adinaNessuna valutazione finora

- Peethas ListDocumento1 paginaPeethas ListChetan PrajapatiNessuna valutazione finora

- Economics 526 - Mathematics For Economists: Day(s) Time LocationDocumento5 pagineEconomics 526 - Mathematics For Economists: Day(s) Time LocationGaurav JakhuNessuna valutazione finora

- SuctioningDocumento58 pagineSuctioningAyusa PradhanNessuna valutazione finora

- Vertical HabitatDocumento6 pagineVertical HabitatAbdul SakurNessuna valutazione finora

- Full Site PDFDocumento23 pagineFull Site PDFpursuwNessuna valutazione finora

- Details of Placed Students in Academic Session 2022-23Documento10 pagineDetails of Placed Students in Academic Session 2022-23Rahul MishraNessuna valutazione finora

- Therelek - Heat Treatment ServicesDocumento8 pagineTherelek - Heat Treatment ServicesTherelek EngineersNessuna valutazione finora

- Lit 1 ReportDocumento21 pagineLit 1 ReportTrexie De Vera JaymeNessuna valutazione finora

- IJHIM 6 - Nur Husnina (36 SD 42)Documento7 pagineIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNessuna valutazione finora

- Intercont Tersus DatasheetDocumento5 pagineIntercont Tersus DatasheetJocemir FerstNessuna valutazione finora

- Essentials of o Ste 00 DaveDocumento112 pagineEssentials of o Ste 00 DaveGeki Iovan100% (1)

- Wire Rope Forensics Letter PDFDocumento50 pagineWire Rope Forensics Letter PDFAshley DeanNessuna valutazione finora

- Catalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFDocumento123 pagineCatalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFBruno CecattoNessuna valutazione finora

- Chapter-01 Introduction: Sonadanga Residential Area (1st Phase)Documento17 pagineChapter-01 Introduction: Sonadanga Residential Area (1st Phase)MAFRID HAYDARNessuna valutazione finora

- Sale of Property When - KP AstrologyDocumento2 pagineSale of Property When - KP Astrologyprajishvet100% (1)

- Art Lab For Little Kids - Susan Schwake PDFDocumento146 pagineArt Lab For Little Kids - Susan Schwake PDFEmma Alfonzo67% (3)

- Philippine Airlines Reservation New Timings Dep - 230314 - 193643Documento7 paginePhilippine Airlines Reservation New Timings Dep - 230314 - 193643sophia buiserNessuna valutazione finora

- Bilingual-Paper WDocumento4 pagineBilingual-Paper WzNessuna valutazione finora

- Conference Programme Critical EmancipationsDocumento3 pagineConference Programme Critical Emancipationswr7md5b55fNessuna valutazione finora

- Antenatally Diagnosed Kidney AnomaliesDocumento17 pagineAntenatally Diagnosed Kidney AnomalieslauraNessuna valutazione finora

- Worksheet 3 (Partial Pressures)Documento2 pagineWorksheet 3 (Partial Pressures)Jose Ruben SortoNessuna valutazione finora

- DinmjgDocumento10 pagineDinmjghaker linkisNessuna valutazione finora

- CSR and Sustainability Initiatives of Starbucks IncDocumento20 pagineCSR and Sustainability Initiatives of Starbucks IncVidyut BanerjeeNessuna valutazione finora

- The Poet of NatureDocumento31 pagineThe Poet of NaturejulyNessuna valutazione finora