Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Sources of Error

Caricato da

Zeeshan Anwar100%(1)Il 100% ha trovato utile questo documento (1 voto)

5K visualizzazioni7 pagineThe three main sources of error in finite element modeling are discretization error, formulation error, and numerical error. Discretization error results from approximating the physical system with a finite element model. Formulation error occurs when unsuitable elements are used that do not accurately describe the physical behavior. Numerical error comes from numerical calculations like truncation and round-off errors.

Descrizione originale:

engineering

Copyright

© © All Rights Reserved

Formati disponibili

PPT, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe three main sources of error in finite element modeling are discretization error, formulation error, and numerical error. Discretization error results from approximating the physical system with a finite element model. Formulation error occurs when unsuitable elements are used that do not accurately describe the physical behavior. Numerical error comes from numerical calculations like truncation and round-off errors.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

5K visualizzazioni7 pagineSources of Error

Caricato da

Zeeshan AnwarThe three main sources of error in finite element modeling are discretization error, formulation error, and numerical error. Discretization error results from approximating the physical system with a finite element model. Formulation error occurs when unsuitable elements are used that do not accurately describe the physical behavior. Numerical error comes from numerical calculations like truncation and round-off errors.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPT, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 7

Sources of Error in the FEM

The three main sources of error in a typical FEM solution are

discretization errors, formulation errors and numerical errors.

Discretization error results from transforming the physical system

(continuum) into a finite element model, and can be related to

modeling the boundary shape, the boundary conditions, etc.

Discretizationerrorduetopoorgeometry

representation.

Discretizationerroreffectivelyeliminated.

Sources of Error in the FEM (cont.)

Formulation error results from the use of elements that don't precisely

describe the behavior of the physical problem.

Elements which are used to model physical problems for which they are not

suited are sometimes referred to as ill-conditioned or mathematically

unsuitable elements.

For example a particular finite element might be formulated on the assumption

that displacements vary in a linear manner over the domain. Such an element

will produce no formulation error when it is used to model a linearly varying

physical problem (linear varying displacement field in this example), but would

create a significant formulation error if it used to represent a quadratic or cubic

varying displacement field.

Sources of Error in the FEM (cont.)

Numerical error occurs as a result of numerical calculation

procedures, and includes truncation errors and round off

errors.

Numerical error is therefore a problem mainly concerning

the FEM vendors and developers.

The user can also contribute to the numerical accuracy,

for example, by specifying a physical quantity, say Youngs

modulus, E, to an inadequate number of decimal places.

Advantages of the Finite Element Method

Can readily handle complex geometry:

The heart and power of the FEM.

Can handle complex analysis types:

Vibration

Transients

Nonlinear

Heat transfer

Fluids

Can handle complex loading:

Node-based loading (point loads).

Element-based loading (pressure, thermal, inertial

forces).

Time or frequency dependent loading.

Can handle complex restraints:

Indeterminate structures can be analyzed.

Advantages of the Finite Element Method (cont.)

Can handle bodies comprised of nonhomogeneous materials:

Every element in the model could be assigned a different set of

material properties.

Can handle bodies comprised of nonisotropic materials:

Orthotropic

Anisotropic

Special material effects are handled:

Temperature dependent properties.

Plasticity

Creep

Swelling

Special geometric effects can be modeled:

Large displacements.

Large rotations.

Contact (gap) condition.

Disadvantages of the Finite Element Method

A specific numerical result is obtained for a specific problem. A

general closed-form solution, which would permit one to examine

system response to changes in various parameters, is not produced.

The FEM is applied to an approximation of the mathematical model

of a system (the source of so-called inherited errors.)

Experience and judgment are needed in order to construct a good

finite element model.

A powerful computer and reliable FEM software are essential.

Input and output data may be large and tedious to prepare and

interpret.

Disadvantages of the Finite Element Method

(cont.)

Numerical problems:

Computers only carry a finite number of significant digits.

Round off and error accumulation.

Can help the situation by not attaching stiff (small) elements

to flexible (large) elements.

Susceptible to user-introduced modeling errors:

Poor choice of element types.

Distorted elements.

Geometry not adequately modeled.

Certain effects not automatically included:

Buckling

Large deflections and rotations.

Material nonlinearities .

Other nonlinearities.

Potrebbero piacerti anche

- Numerical Examples PDFDocumento20 pagineNumerical Examples PDFHamid MasoodNessuna valutazione finora

- Matrix M of SA QuestionsDocumento14 pagineMatrix M of SA Questionsrajivkannan100% (1)

- Static CondensationDocumento5 pagineStatic Condensationsteven_gog100% (4)

- Static Failure TheoriesDocumento82 pagineStatic Failure TheoriesGUNJAN MUDGAL100% (2)

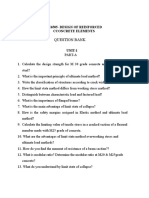

- Design of Reinforced Concrete Elements QuestionsDocumento16 pagineDesign of Reinforced Concrete Elements QuestionsbalabhaiNessuna valutazione finora

- FEA Questions & AnswersDocumento22 pagineFEA Questions & Answerspurojeetpttnk100% (1)

- ST5101-Advance Concrete StructuresDocumento16 pagineST5101-Advance Concrete Structurescmurugan100% (1)

- Nonlinear Analysis of Reinforced Concrete Structures Using ABAQUSCAE SoftwareDocumento60 pagineNonlinear Analysis of Reinforced Concrete Structures Using ABAQUSCAE SoftwareAvinashRai100% (1)

- Bolotin VV-The Dynamic Stability of Elastic SystemsDocumento455 pagineBolotin VV-The Dynamic Stability of Elastic Systemshspanda100% (2)

- Flash Butt Welding - Testing & Check List PDFDocumento45 pagineFlash Butt Welding - Testing & Check List PDFImran Khan60% (5)

- Principles of Structural Stability by A. Chajes (1974)Documento175 paginePrinciples of Structural Stability by A. Chajes (1974)jonathanbp92Nessuna valutazione finora

- Slope Deflection MethodDocumento34 pagineSlope Deflection MethodAshok PradhanNessuna valutazione finora

- Dokumen - Tips - Structural Analysis Volume 2 S Bhavikatti PDFDocumento2 pagineDokumen - Tips - Structural Analysis Volume 2 S Bhavikatti PDFVaish Nao100% (1)

- Finite Difference Buckling Analysis of Non Uniform ColumnsDocumento8 pagineFinite Difference Buckling Analysis of Non Uniform ColumnsumeshapkNessuna valutazione finora

- Chapter - 9: Axially Loaded Short ColumnDocumento17 pagineChapter - 9: Axially Loaded Short Columnsomesh dubeyNessuna valutazione finora

- Construction Planning and Management Question Papers of Wbut 2011Documento8 pagineConstruction Planning and Management Question Papers of Wbut 2011Suryasis DasguptaNessuna valutazione finora

- Unsymmetrical Bending and Shear CentreDocumento11 pagineUnsymmetrical Bending and Shear CentreNaveen ParthasarathyNessuna valutazione finora

- Unit 3 FEM Bar & Beam Elements PDFDocumento14 pagineUnit 3 FEM Bar & Beam Elements PDFHarsh PatelNessuna valutazione finora

- Timoshenko Beam TheoryDocumento8 pagineTimoshenko Beam Theoryksheikh777Nessuna valutazione finora

- Finite Element Analysis Questions OnlyDocumento9 pagineFinite Element Analysis Questions OnlyAeronaughtycs Hamdan100% (1)

- P. Karasudhi Foundations of Solid MechanicDocumento458 pagineP. Karasudhi Foundations of Solid MechanicSuraparb Keawsawasvong100% (2)

- Chapter 1 RC Column Design SlidesDocumento28 pagineChapter 1 RC Column Design SlidesMesfin Derbew100% (9)

- Fagan M. Finite Element Analysis. Theory and PracticeDocumento171 pagineFagan M. Finite Element Analysis. Theory and Practiceqazs67% (3)

- Steel - 04-Prof. Zahid Siddiqi PDFDocumento57 pagineSteel - 04-Prof. Zahid Siddiqi PDFMuhammad AhmedNessuna valutazione finora

- Hints For Obtaining A Converged Contact Solution in AbaqusDocumento8 pagineHints For Obtaining A Converged Contact Solution in AbaqusZhiqiang GuNessuna valutazione finora

- Bending Stresses & Direct Stresses CombinedDocumento12 pagineBending Stresses & Direct Stresses Combinedvsathees2350% (2)

- Part I - Basics FlexibilityDocumento17 paginePart I - Basics FlexibilityDawit Gebrehana100% (2)

- VCCT in AnsysDocumento13 pagineVCCT in AnsysbnidhalNessuna valutazione finora

- Theory of Elasticity Question PaperDocumento2 pagineTheory of Elasticity Question PaperDESHMUKH ANKIT PRAKASHRAONessuna valutazione finora

- Theory of Elasticity and PlasticityDocumento12 pagineTheory of Elasticity and PlasticityBharathi RajNessuna valutazione finora

- Iare Sa-Ii Lecture Notes PDFDocumento195 pagineIare Sa-Ii Lecture Notes PDFAkhilesh B.M100% (1)

- Beam Analysis Using The Stiffness Method in MATLAB ProgramDocumento14 pagineBeam Analysis Using The Stiffness Method in MATLAB ProgramUpadesh Shrestha100% (3)

- FEM Notes - IIT KharagpurDocumento308 pagineFEM Notes - IIT KharagpurAditya Singh100% (1)

- FEM-Intro-Pinto 2023Documento32 pagineFEM-Intro-Pinto 2023Izzan ZidniyNessuna valutazione finora

- Analytical Solutions Can Not Be ObtainedDocumento120 pagineAnalytical Solutions Can Not Be ObtainedMuket AgmasNessuna valutazione finora

- Analytical Solutions Can Not Be ObtainedDocumento73 pagineAnalytical Solutions Can Not Be ObtainedzetseatNessuna valutazione finora

- Finite Element LecturesDocumento153 pagineFinite Element LecturesLemi Chala Beyene100% (1)

- Introduction To Finite Elemnt Method: Analytical Solutions Can Not Be ObtainedDocumento73 pagineIntroduction To Finite Elemnt Method: Analytical Solutions Can Not Be ObtainedKéðìr ÅbðüríNessuna valutazione finora

- Introduction To Finite Elemnt MethodDocumento8 pagineIntroduction To Finite Elemnt MethodKéðìr ÅbðüríNessuna valutazione finora

- Finite Element Chapter 1Documento18 pagineFinite Element Chapter 1zetseatNessuna valutazione finora

- Introduction To FEMDocumento88 pagineIntroduction To FEMEndashaw AshafoNessuna valutazione finora

- FEM FundamentalsDocumento62 pagineFEM FundamentalsleleparthaNessuna valutazione finora

- New Finite Element Analysis Lec1Documento35 pagineNew Finite Element Analysis Lec1BookMaggotNessuna valutazione finora

- Introduction To Finite Element Method (FEM)Documento22 pagineIntroduction To Finite Element Method (FEM)goldencomet100% (1)

- Introduction To The Finite Element Method (FEM)Documento14 pagineIntroduction To The Finite Element Method (FEM)navin_csiNessuna valutazione finora

- 1 IntroductionDocumento23 pagine1 IntroductionSaeed RehmanNessuna valutazione finora

- Srm-Cad-Unit IvDocumento92 pagineSrm-Cad-Unit IvVikrant ThakurNessuna valutazione finora

- CAMA Lab Record: Course Code: 18MEL66 Course: Computer Aided Modelling and Analysis LabDocumento19 pagineCAMA Lab Record: Course Code: 18MEL66 Course: Computer Aided Modelling and Analysis LabVinayaka GpNessuna valutazione finora

- Finite Element Method (FEM) Module Code:: Lecture On Introduction To FEM, 15 September 2019Documento17 pagineFinite Element Method (FEM) Module Code:: Lecture On Introduction To FEM, 15 September 2019Mesay Alemu TolchaNessuna valutazione finora

- Unit 1 - Introduction To FEADocumento17 pagineUnit 1 - Introduction To FEArajeshNessuna valutazione finora

- Unit I: - Finite Element Formulation of Boundary Value ProblemsDocumento11 pagineUnit I: - Finite Element Formulation of Boundary Value Problemsjamunaa83Nessuna valutazione finora

- ME411 FEM - L4 - Practical ConsiderationsDocumento64 pagineME411 FEM - L4 - Practical ConsiderationsZain Mustafa100% (1)

- FEA Spring 2008 IntroDocumento11 pagineFEA Spring 2008 IntroVerma RvNessuna valutazione finora

- FEA Part1Documento26 pagineFEA Part1Rajanarsimha SangamNessuna valutazione finora

- Unit II-1 PDFDocumento19 pagineUnit II-1 PDFMUYENessuna valutazione finora

- Chapter 8 Numerical ModellingDocumento38 pagineChapter 8 Numerical ModellingKrishna GhimireNessuna valutazione finora

- Presentation 1Documento12 paginePresentation 1kalkidanNessuna valutazione finora

- Ch. 1. IntroductionDocumento9 pagineCh. 1. Introductionbhetuwalamrit17Nessuna valutazione finora

- Introduction To Finite Element Analysis: By, P Naga AchyuthDocumento15 pagineIntroduction To Finite Element Analysis: By, P Naga AchyuthزهديابوانسNessuna valutazione finora

- FEM - Cont. & Chapt-1 - Slide PresentationDocumento10 pagineFEM - Cont. & Chapt-1 - Slide PresentationMohammed B TuseNessuna valutazione finora

- Zener Tester: by MedhatkoDocumento6 pagineZener Tester: by Medhatkosaran gulNessuna valutazione finora

- InterviewDocumento8 pagineInterviewswapnadip kumbharNessuna valutazione finora

- PCM 2.4l Turbo 5 de 5Documento2 paginePCM 2.4l Turbo 5 de 5Felix VelasquezNessuna valutazione finora

- En 1993 09Documento160 pagineEn 1993 09Vio ChiNessuna valutazione finora

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Documento880 pagine1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- Why We Need A Flying Amphibious Car 1. CarsDocumento20 pagineWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedNessuna valutazione finora

- All Worksheets MYSQLDocumento33 pagineAll Worksheets MYSQLSample1Nessuna valutazione finora

- Most Dangerous City - Mainstreet/Postmedia PollDocumento35 pagineMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartNessuna valutazione finora

- Hemax-530 PDFDocumento2 pagineHemax-530 PDFNice BennyNessuna valutazione finora

- EXPERIMENT 1 - Bendo Marjorie P.Documento5 pagineEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- Waste Foundry Sand and Its Leachate CharDocumento10 pagineWaste Foundry Sand and Its Leachate CharJanak RaazzNessuna valutazione finora

- A Presentation On-: E-Paper TechnologyDocumento19 pagineA Presentation On-: E-Paper TechnologyRevanth Kumar TalluruNessuna valutazione finora

- INJkon 01 4.0 ManualDocumento93 pagineINJkon 01 4.0 ManualJansirani SelvamNessuna valutazione finora

- Probability Theory - VaradhanDocumento6 pagineProbability Theory - VaradhanTom HenNessuna valutazione finora

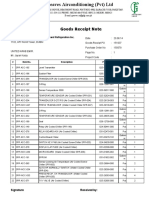

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- Namagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishDocumento10 pagineNamagunga Primary Boarding School: Primary Six Holiday Work 2021 EnglishMonydit santinoNessuna valutazione finora

- Scope and Sequence 2020 2021...Documento91 pagineScope and Sequence 2020 2021...Ngọc Viễn NguyễnNessuna valutazione finora

- Afa Coursework ExamplesDocumento6 pagineAfa Coursework Examplesiuhvgsvcf100% (2)

- Hume 100 ReviewerDocumento7 pagineHume 100 ReviewerShai GaviñoNessuna valutazione finora

- TR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance DataDocumento2 pagineTR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance Databayu enasoraNessuna valutazione finora

- The Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesDocumento456 pagineThe Confucian Transformation of Korea: Harvard-Yen Ching Institute Monograph SeriesAnna D.Nessuna valutazione finora

- Performance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationDocumento5 paginePerformance Comparison of VxWorks Linux RTAI and Xenomai in A Hard Real-Time ApplicationsatyanaryanakNessuna valutazione finora

- CS3501 Compiler Design Lab ManualDocumento43 pagineCS3501 Compiler Design Lab ManualMANIMEKALAINessuna valutazione finora

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocumento4 pagineHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

- Chapter 3 - Methods of Circuit Analysis and Circuit TheoremsDocumento125 pagineChapter 3 - Methods of Circuit Analysis and Circuit TheoremsNaim NizamNessuna valutazione finora

- Sustainable Development Precautionary PR 2Documento12 pagineSustainable Development Precautionary PR 2PramodNessuna valutazione finora

- 2018-2019 Annual Algebra Course 1 Contest: InstructionsDocumento2 pagine2018-2019 Annual Algebra Course 1 Contest: InstructionsNaresh100% (1)

- GE Uno Downlight Backlit BLDocumento2 pagineGE Uno Downlight Backlit BLChen KengloonNessuna valutazione finora

- Aectp 300 3Documento284 pagineAectp 300 3AlexNessuna valutazione finora

- WSI - Catalogue of O-Ring PDFDocumento37 pagineWSI - Catalogue of O-Ring PDFyearetg100% (1)