Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical and Installation Principles of Koneductor Click Type and Bolted Connections

Caricato da

Rehan AfzalDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical and Installation Principles of Koneductor Click Type and Bolted Connections

Caricato da

Rehan AfzalCopyright:

Formati disponibili

AKAPP-STEMMANN BV

KONeDUCTOR-X

Conductor systems with click type and

bolted connections

Technical & installation

principles

1

AKAPP-STEMMANN BV

KONeDUCTOR-X

Conductor systems with click or bolted

copper connections

AKAPP

Advantages of KONeDUCTOR-X

Mounting of KONeDUCTOR-X (video)

System build up & parts

Connecting the copper conductors

Clip video

Aligning collector trolleys

Maintenance and Troubleshooting

AKAPP-STEMMANNs history:

AKAPP-STEMMANN BV

1953: AKAPP founded,

1970: Production of Conductor bar systems started

1975: International Distribution network

1984: Spring cable reels type FKF sales

1992: Cooperation with Konecranes

1994: Introduction of RN4 continuous conductor system

1995: Sales of AM0951 cable reels

1998: Launch of Pro-Ductor PR7

1999: Launch of C7 Collector

2004: ISO 9001 and VCA* certified

AKAPP-STEMMANNs history:

AKAPP-STEMMANN BV

2005: AVS /AV spring Cable reels sales started

2007: New Feed boxes and Transition Boxes

2007: launch of high Capacity Click-Ductor up to 400 Amps

2007: Pro-Ductor PR10 introduced

2008 CL4-40 Collector introduced

AKAPP-STEMMANN BV

KONeDUCTOR-X Advantages

RC7G/RC4G main features:

Conductors with smart connections

50A, 80A, 110A all with smart Click type connections

125A, 160A, 200A, 250A (parallel), 320A (parallel), 400A (parallel)

with bolted connections

IP23 and IP44 (with additional rubber sealing) certified!

Very quick mounting

No tools required with Click type,

Easy to extend or to exchange system segments

Long brush life (25.000 km),

Wide temperature range -20C to +50 C

AKAPP-STEMMANN BV

KONeDUCTOR-X Advantages

RC7G/RC4G additional features:

3 and 4 mtr lengths available

4, 5 and 7-pole versions (in both 4 pole housing and 7 pole

housing

51,4

51,4

86,25

86,25

86,25

51,4

speeds (up to 80m/min.),

Calculation program QuickQuote integrated in MARKMAN and

CORONA

AKAPP-STEMMANN BV

KONeDUCTOR-X RC7G/RC4G

Advantages

Protection class IP23, IP44 possible

Safe, no direct contact with conductor

possible

Outside installation possible (rain)

Optimum Alignment / guidance of trolley

As of 125 Amp, the ground is CU125

(also in CU160 and CU200 versions)

Ground is 50% of Phase conductor size

in all 7 pole versions

7

AKAPP-STEMMANN BV

KONeDUCTOR-X RC7G/RC4G

Track lengths up to 400 m with end-feed and 800 mtr with

centre feed.

Multiple feed points possible.

Applications mainly for:

Standard crane applications

Higher amperages (parallel conductors)

Dusty and humid conditions

AKAPP-STEMMANN BV

In practice: mounting of KONeDUCTOR X

Video: Mounting ClickDuctor.mpg (Click!)

AKAPP-STEMMANN BV

System build up (Page 2 and 3)

10

AKAPP-STEMMANN BV

System Buildup Linefeed (Page 3)

11

AKAPP-STEMMANN BV

Sliding hangers and supports (Page 4)

12

Hangers should allow

expansion of PVC housing

(Page 4)

Note:

AKAPP-STEMMANN BV

check position of sliding hangers during maintenance for proper

alignment

13

AKAPP-STEMMANN BV

Connection of copper conductors (Page 5)

14

AKAPP-STEMMANN BV

Connection of copper conductors (Page 5)

15

AKAPP-STEMMANN BV

Connection of copper conductors (Page 6)

Please click for RC connection clip

Video: Mounting RC clip.wmv

16

Mounting joint covers (Page 7)

AKAPP-STEMMANN BV

17

AKAPP-STEMMANN BV

Mounting fixed point (Page 8)

18

Endfeedbox EBS32 (Page 9)

AKAPP-STEMMANN BV

19

AKAPP-STEMMANN BV

Endfeedbox EBS32 (Page 9)

20

AKAPP-STEMMANN BV

Endfeedboxes type EB40/EB63 (Page 10)

21

AKAPP-STEMMANN BV

Endfeedboxes type EB40/EB63 (Page 11)

for RC125 to RC200

22

AKAPP-STEMMANN BV

Endfeed boxes type EB40/EB63 (Page 11)

for RC125 to RC200

23

AKAPP-STEMMANN BV

Endfeedboxes type EB40/EB63 (Page

12)

24

AKAPP-STEMMANN BV

Linefeed boxes (Page 13)

For RC50 RC110

25

Line Feeds (Page 13)

For RC50 RC110

AKAPP-STEMMANN BV

26

AKAPP-STEMMANN BV

Line Feeds (Page 14)

For RC125 to RC200

27

AKAPP-STEMMANN BV

Line Feeds (Page 14)

For RC125-RC200

28

AKAPP-STEMMANN BV

Line Feed Boxes LB40/LB63 (Page 15)

29

Collector trolley and

AKAPP-STEMMANN BV

Towing arm adjustment (Page 16)

30

AKAPP-STEMMANN BV

Collectors

Alignment

Towing chain straight under housing (vertical)

Towing arm 20 to 60 mm lower as towing point trolley

31

Collector trolley and

AKAPP-STEMMANN BV

Towing arm adjustment (Page 17)

32

AKAPP-STEMMANN BV

Collector trolley alignment

Trolley Towing Arm - proper

alignment

Wrong mounting

Correct Mounting

33

AKAPP-STEMMANN BV

Endcaps RC4/RC7 (Page 18)

For RC50 RC110

34

AKAPP-STEMMANN BV

Endcaps RC4/RC7 (Page 18)

35

Endcaps RC4/EC7 (Page 19)

For RC125 RC200

AKAPP-STEMMANN BV

36

AKAPP-STEMMANN BV

Fitting Pieces (Page 20)

37

AKAPP-STEMMANN BV

Fitting Pieces (Page 20)

Make very sure that the selftapping screws are used properly. This

fixes the fitting piece to the rest of the system

38

AKAPP-STEMMANN BV

De-mounting of copper clips (Page 21)

39

AKAPP-STEMMANN BV

De-mounting of copper clips (Page 21)

40

AKAPP-STEMMANN BV

Maintenance Issues (Page 22)

41

AKAPP-STEMMANN BV

Maintenance Issues (Page 22)

42

AKAPP-STEMMANN BV

Maintenance & Troubleshooting

Trolley Towing Arm

- check for proper alignment as 90% of

problems

is caused by misaligned

collectors!

False mounting

Correct Mounting

43

AKAPP-STEMMANN BV

Maintenance & Troubleshooting

Carbon Brushes

- Wear marks

- Rough Spots

Brushes touch the interior parts of PVC housing and

gets stuck eventually. This can cause contact loss.

44

AKAPP-STEMMANN BV

Mounting Tools

Sealing strip

End user:

Professional:

45

AKAPP-STEMMANN BV

AS7-C

46

AKAPP-STEMMANN BV

Mounting tools

Click:

Video: OBA instructio

n_hq.wmv

47

Potrebbero piacerti anche

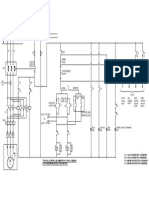

- RDOL - Belt MCC Control SchemeDocumento1 paginaRDOL - Belt MCC Control SchemeD VacNessuna valutazione finora

- Water Pump Pressure Control Switch Adjustment Nut Direction1Documento12 pagineWater Pump Pressure Control Switch Adjustment Nut Direction1ver_at_workNessuna valutazione finora

- Standard Wire Rope Hoists: Certified To ISO 9001:2000 StandardsDocumento6 pagineStandard Wire Rope Hoists: Certified To ISO 9001:2000 StandardsherikNessuna valutazione finora

- 5 MT DG Eot Crane Span 25 MeterDocumento1 pagina5 MT DG Eot Crane Span 25 MeterElencheliyan PandeeyanNessuna valutazione finora

- Multiconductor TechnicalDocumento24 pagineMulticonductor TechnicalJuan Felipe Vieira GaviriaNessuna valutazione finora

- Ebara Flow Switch Controlled Booster System-20100212101823 - TD - UdDocumento25 pagineEbara Flow Switch Controlled Booster System-20100212101823 - TD - Udriadazem2119Nessuna valutazione finora

- Main Hoist Power and Control Pendent Master Control: E.O.T. Crane Overall Control DiagramDocumento1 paginaMain Hoist Power and Control Pendent Master Control: E.O.T. Crane Overall Control DiagramhiteshNessuna valutazione finora

- Ebara Variable Speed and Constant Pressure BoosterDocumento27 pagineEbara Variable Speed and Constant Pressure BoosternettomdNessuna valutazione finora

- Specifications Welding Rectifier MillerDocumento76 pagineSpecifications Welding Rectifier Millerjumansyahamid1988Nessuna valutazione finora

- Danfoss Pressure Switch Type KPDocumento9 pagineDanfoss Pressure Switch Type KPMohammed RayanNessuna valutazione finora

- Enchlor Catalog 2013Documento8 pagineEnchlor Catalog 2013Pablo NavasNessuna valutazione finora

- Manual - Ace CraneDocumento60 pagineManual - Ace CraneManoj SinghNessuna valutazione finora

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enDocumento8 pagine376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevNessuna valutazione finora

- ABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListDocumento5 pagineABB Limited: LV Motors FRSM-57C Effective From 01.10.2012 Price ListSudipto MajumderNessuna valutazione finora

- Weidmuller Analog Signal ConditionersDocumento65 pagineWeidmuller Analog Signal ConditionersYaseen SagarNessuna valutazione finora

- Test Kits and MetersDocumento10 pagineTest Kits and MetersAbhijeet JhaNessuna valutazione finora

- Craneterminologygraphic Konecranes Dec2017Documento1 paginaCraneterminologygraphic Konecranes Dec2017Zendyka Satria Bimantara100% (1)

- Thesis On PneumaticDocumento87 pagineThesis On PneumaticKhaled AbdelfattahNessuna valutazione finora

- FDR3-10 Pro Tech DataDocumento20 pagineFDR3-10 Pro Tech DataMarzuki AliNessuna valutazione finora

- Sana'A South 30 MW Extension Yemen Diesel Power StationDocumento103 pagineSana'A South 30 MW Extension Yemen Diesel Power StationheemaNessuna valutazione finora

- Conexiones HokeDocumento59 pagineConexiones HokeRaul Guerra ヅNessuna valutazione finora

- Level Monitor DATUM SCU500 LOOPDocumento20 pagineLevel Monitor DATUM SCU500 LOOPJose Manuel Vazquez ZarcoNessuna valutazione finora

- Hydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentDocumento10 pagineHydraulic Brake Systems and Components For Off-Highway Vehicles and EquipmentJenner Volnney Quispe ChataNessuna valutazione finora

- ABB ACS560 DescriptionDocumento15 pagineABB ACS560 Descriptionbalaji ummadi100% (1)

- Mechanical Seals For ABS Pumps enDocumento4 pagineMechanical Seals For ABS Pumps enrpichoNessuna valutazione finora

- DFC Install MaintDocumento40 pagineDFC Install MaintAvinash Gamit100% (1)

- PI734DDocumento8 paginePI734Deng_hopaNessuna valutazione finora

- Motor IspDocumento136 pagineMotor IspKnjigescribd100% (1)

- Bajaj LuminairesDocumento51 pagineBajaj LuminairesNagesh Rao100% (1)

- Entice CatalogueDocumento12 pagineEntice Cataloguebharath sNessuna valutazione finora

- Valves & Manifold BrochureDocumento33 pagineValves & Manifold BrochurearavindNessuna valutazione finora

- BNS Cam SwitchesDocumento36 pagineBNS Cam Switchess_barriosNessuna valutazione finora

- ABB CatalogueDocumento6 pagineABB CatalogueNavneet SinghNessuna valutazione finora

- Auto Gate System: General DescriptionDocumento11 pagineAuto Gate System: General DescriptionmalbstNessuna valutazione finora

- Concrete Forming HardwareDocumento64 pagineConcrete Forming HardwarePrakashNessuna valutazione finora

- Encoders Catalog 2012Documento28 pagineEncoders Catalog 2012sreelakshmisnr100% (1)

- Shaft Mounted Speed Reducers SMSR & SMSR Plus SeriesDocumento32 pagineShaft Mounted Speed Reducers SMSR & SMSR Plus SeriesAmit KumarNessuna valutazione finora

- Fluid Lines FittingsDocumento61 pagineFluid Lines FittingsVy ThoaiNessuna valutazione finora

- Furutec HP-ES (FT (ES) @2012-08) PDFDocumento40 pagineFurutec HP-ES (FT (ES) @2012-08) PDFramadani bimaNessuna valutazione finora

- 2 Loadcell CablingDocumento8 pagine2 Loadcell CablingTong Van NgocNessuna valutazione finora

- Atv31 (E)Documento220 pagineAtv31 (E)Santos Zosimo Ocas GoicocheaNessuna valutazione finora

- Local Solutions For Individual Customers Worldwide: Accumulators & AccessoriesDocumento20 pagineLocal Solutions For Individual Customers Worldwide: Accumulators & Accessoriesamjed_de_enimNessuna valutazione finora

- Snu Worm GearDocumento29 pagineSnu Worm Gearmarisamy_lntNessuna valutazione finora

- Brevini Power Transmission Products 2008 UKDocumento14 pagineBrevini Power Transmission Products 2008 UKSabith MohammedNessuna valutazione finora

- ADOR Equipment BrochureDocumento36 pagineADOR Equipment BrochurePratap YallaNessuna valutazione finora

- Automatic Raising BollardsDocumento26 pagineAutomatic Raising BollardsK SubramaniNessuna valutazione finora

- Operating Instruction Gear Box AFM04,05,06Documento20 pagineOperating Instruction Gear Box AFM04,05,06Bang OchimNessuna valutazione finora

- ABB Drive Selection GuideDocumento12 pagineABB Drive Selection Guideprasad_rvsNessuna valutazione finora

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- Safety Catalog SOFAMEL 2011Documento80 pagineSafety Catalog SOFAMEL 2011antegeia2222100% (3)

- Nitrogen and Accumulator ChargingDocumento3 pagineNitrogen and Accumulator ChargingKarthikeyanNessuna valutazione finora

- Capitole 40Documento20 pagineCapitole 40ImtiazAhmedNessuna valutazione finora

- TTA Installation Operation Maint ManualDocumento28 pagineTTA Installation Operation Maint ManualcoronaqcNessuna valutazione finora

- Motors IEC Techinical Data PDFDocumento37 pagineMotors IEC Techinical Data PDFEmmanuel LaiNessuna valutazione finora

- PantografeDocumento12 paginePantografeAlex GeorgeNessuna valutazione finora

- Square D I-Line Panelboards TechnicalDocumento28 pagineSquare D I-Line Panelboards TechnicalhewankukerenNessuna valutazione finora

- 0001Documento9 pagine0001Mohamed AdelNessuna valutazione finora

- Actom DTRDocumento8 pagineActom DTRVikram BorawakeNessuna valutazione finora

- ACO Qmax OverviewDocumento8 pagineACO Qmax OverviewValiNessuna valutazione finora

- Sony KV-27V26 - KV-27V36 - KV-29V22M - KV-29V36C - KV-29V66M - KV-29V76M Ch-Aa2dDocumento56 pagineSony KV-27V26 - KV-27V36 - KV-29V22M - KV-29V36C - KV-29V66M - KV-29V76M Ch-Aa2dEdilberto Avila100% (1)

- Soil Investigation: Guidelines For Checking and Supervision of Field Geotechnical InvestigationDocumento36 pagineSoil Investigation: Guidelines For Checking and Supervision of Field Geotechnical InvestigationRehan AfzalNessuna valutazione finora

- Site Leveling & Other Enabling WorksDocumento26 pagineSite Leveling & Other Enabling WorksRehan AfzalNessuna valutazione finora

- Materials Management OF Free Issue Items: TTM (DS) - 4Documento7 pagineMaterials Management OF Free Issue Items: TTM (DS) - 4Rehan AfzalNessuna valutazione finora

- ExcavationDocumento23 pagineExcavationRehan AfzalNessuna valutazione finora

- 06 KoneductorDocumento2 pagine06 KoneductorRehan AfzalNessuna valutazione finora

- Tender System2Documento47 pagineTender System2Jatin ParmarNessuna valutazione finora

- Lecture 15B.2: Actions On BridgesDocumento18 pagineLecture 15B.2: Actions On Bridgeshanowuse179Nessuna valutazione finora

- VSB6 Vehicle RegulationDocumento35 pagineVSB6 Vehicle Regulationct0720054858Nessuna valutazione finora

- Students Guide 2019Documento32 pagineStudents Guide 2019Jeff DuffshmithNessuna valutazione finora

- 1.2 KM Connector - Straight Line Diagram - Adjusted Schedule - 11052020Documento3 pagine1.2 KM Connector - Straight Line Diagram - Adjusted Schedule - 11052020Markee Nepomuceno AngelesNessuna valutazione finora

- Penang JettyDocumento6 paginePenang JettyMuhammad RaimiNessuna valutazione finora

- 9A03502 Dynamics of MachineryDocumento4 pagine9A03502 Dynamics of MachinerysivabharathamurthyNessuna valutazione finora

- M.E. Laws, Contracts and Ethics PresentationDocumento28 pagineM.E. Laws, Contracts and Ethics PresentationLeo Paulo Del Rosario0% (1)

- DGsetDocumento28 pagineDGsetVikee BagaveNessuna valutazione finora

- Bogie SKRDocumento24 pagineBogie SKRhayatmdazharNessuna valutazione finora

- DG RDSO Mission Raftaar 230518Documento14 pagineDG RDSO Mission Raftaar 230518AjayNessuna valutazione finora

- Motor Control Centers-Low Voltage Section 12: Buylog CatalogDocumento22 pagineMotor Control Centers-Low Voltage Section 12: Buylog CatalogFabio Andrés CancinoNessuna valutazione finora

- Temporary Press - July 2023Documento10 pagineTemporary Press - July 2023ArtdataNessuna valutazione finora

- Unit 3 - Fire Service Operations and Incident Command: IFE Level 4 Certificate in Fire Science and Fire SafetyDocumento6 pagineUnit 3 - Fire Service Operations and Incident Command: IFE Level 4 Certificate in Fire Science and Fire SafetyDebayanbasu.juNessuna valutazione finora

- Railway Amenities Compilation As On 23 April 2023-CompressedDocumento1.146 pagineRailway Amenities Compilation As On 23 April 2023-CompressedDisability Rights AllianceNessuna valutazione finora

- Https WWW - Irctc.co - in Eticketing PrintTicketDocumento1 paginaHttps WWW - Irctc.co - in Eticketing PrintTicketAnkit ShrivastavaNessuna valutazione finora

- Bangladesh Railway e TicketDocumento1 paginaBangladesh Railway e TicketzahiruddinahmedNessuna valutazione finora

- GN0630Documento62 pagineGN0630wan marzukiNessuna valutazione finora

- Six-Pulse BridgeDocumento4 pagineSix-Pulse BridgeRAhul SinghNessuna valutazione finora

- Bangladesh Railway e TicketDocumento1 paginaBangladesh Railway e Ticket01911514616Nessuna valutazione finora

- CatalogDocumento48 pagineCatalogAhmad AshrafNessuna valutazione finora

- Carbody TiltingDocumento34 pagineCarbody TiltinggundunathNessuna valutazione finora

- UntitledDocumento8 pagineUntitledapi-126899826Nessuna valutazione finora

- Metro Line 5 (Thane-Bhiwandi-Kalyan)Documento285 pagineMetro Line 5 (Thane-Bhiwandi-Kalyan)Faihzan F Ahmad ShaikhNessuna valutazione finora

- Jan 3, 1973-Jan 13, 1975 - Pt3Documento194 pagineJan 3, 1973-Jan 13, 1975 - Pt3marylcookpubliclibraNessuna valutazione finora

- 8-Maintenance Handbook On Digital Axle Counter (Multi Section) PDFDocumento66 pagine8-Maintenance Handbook On Digital Axle Counter (Multi Section) PDFRohit Kumar100% (1)

- 01 2010 PDFDocumento2 pagine01 2010 PDFsrdsosonpurNessuna valutazione finora

- Check List For Safety Inspection at Crew LobbyDocumento3 pagineCheck List For Safety Inspection at Crew LobbyHanuma Reddy100% (1)

- PNR v. VizcarraDocumento12 paginePNR v. VizcarramisterdodiNessuna valutazione finora