Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Addistion Engineering - Silicon Wafer Processing

Caricato da

addisonengineering0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni16 pagineA leading supplier of silicon wafers, wafer processing, semiconductor Equipment, Ceramic Packages, Wafer fabrication and chip carriers

Copyright

© © All Rights Reserved

Formati disponibili

PPTX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoA leading supplier of silicon wafers, wafer processing, semiconductor Equipment, Ceramic Packages, Wafer fabrication and chip carriers

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni16 pagineAddistion Engineering - Silicon Wafer Processing

Caricato da

addisonengineeringA leading supplier of silicon wafers, wafer processing, semiconductor Equipment, Ceramic Packages, Wafer fabrication and chip carriers

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PPTX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 16

Silicon Wafer Processing

Addison Engineering has an extensive array

of processing capabilities. On our silicon or

yours, we can provide virtually any processing

service you may need, from a simple oxide

layer to completely patterned wafers.

Thermal oxide

Ion implant

Epitaxial deposition

Plasma nitride

Photoresist

Wafer bumping

Visit Our Website

Silicon Wafer Processing

About Wafers:

In electronics, a wafer (also called a slice or substrate)

is a thin slice of semiconductor material, such as a silicon

crystal, used in the fabrication of integrated circuits and

other microdevices.

The wafer serves as the substrate for microelectronic

devices built in and over the wafer and undergoes many

microfabrication process steps such as doping or ion

implantation, etching, deposition of various materials, and

photolithographic

patterning.

Visit Our Website

Silicon Wafer Processing

Formation:

Wafers are formed of highly pure (99.9999999%

purity) nearly defect free single crystal material.

One process for forming crystalline wafers is known as

Czochralski growth invented by the Polish chemist Jan

Czochralski.

In this process, a cylindrical ingot of high purity

monocrystalline semiconductor, such as silicon or

germanium, is formed by pulling a seed crystal from a

'melt'.

Visit Our Website

Silicon Wafer Processing

Donor impurity atoms, such as boron or phosphorus in

the case of silicon, can be added to the molten intrinsic

material in precise amounts in order to dope the

crystal, thus changing it into n-type or p-type extrinsic

semiconductor.

Visit Our Website

Silicon Wafer Processing

Thermal oxide:

Oxide

TEOS/PETEOS oxide

Gate oxide

Low temperature oxide

PSG glass

Silicon Nitride

LPCVD

Low Stress

Ultra-low Stress

Polysilicon (undoped)

Visit Our Website

Silicon Wafer Processing

Metal deposition

Evaporation

Sputter

Epitaxial deposition

Ion implantation

SOI

oxidation

wafer bonding

Photolithography

Visit Our Website

Silicon Wafer Processing

Clean

RCA clean

Mechanical

Ingot slicing

Lap & etch

Wafer thinning

Wafer downsize (diameter cut-down)

Wafer dicing

Visit Our Website

Silicon Wafer Processing

Wafer reclaim

Laser marking

Wafer bumping

MEMS - Silicon machining

Visit Our Website

Silicon Wafer Processing

Thin Film Processing:

LOW k

Black Diamond

Coral

Spin On

and more

OXIDE: CVD and Thermal

Thick Photoresist & Polymide

High Energy Deep Ion Implant

Nitrides (Si- and O-)

Visit Our Website

Silicon Wafer Processing

Low Stress Silicon Nitride

BPSG, PSG, USG

Amorphous Silicon

Diamond Like Carbon

Polysilicon (Doped and Undoped)

METALS: PVD, CVD, Electroplate

Ai, Cu, Au, Cr, Ta, Ti, TiN

TiW, TaN, WN, Ni, Ru

Co, NiSi, TiO2, Pt

Visit Our Website

Silicon Wafer Processing

Czochralski Growth:

Visit Our Website

Silicon Wafer Processing

Grinding and Slicing:

Visit Our Website

Silicon Wafer Processing

Lapping and Etching:

Visit Our Website

Silicon Wafer Processing

Polishing and Cleaning:

Visit Our Website

Silicon Wafer Processing

Sizes Available:

Silicon wafers are available in several

sizes (diameters)

1 (25mm)

2 (50mm)

3 (75 mm)

4 (100mm)

5 (125mm)

6 (150mm)

8 (200mm)

12 (300mm)

18 (450mm)

Visit Our Website

Silicon Wafer Processing

Addison Engineering provides Silicon wafers that

are available with a wide range of characteristics

(specifications) to select from.

Thank You

Visit Our Website

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Thermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10Documento11 pagineThermal Breakthrough Calculations To Optimize Design of Amultiple-Stage EGS 2015-10orso brunoNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- College of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurDocumento24 pagineCollege of Technology & Engineering: Practical Training at Hindustan Zinc Limited Zinc Smelter, Debari UdaipurPooja SahuNessuna valutazione finora

- Activating The Standard BI ReportDocumento17 pagineActivating The Standard BI ReportlearnsapbwNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Edan M3B Vital Signs Monitor User ManualDocumento92 pagineEdan M3B Vital Signs Monitor User ManualJosé marino Franco AlzateNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Polya Problem Solving StrategiesDocumento12 paginePolya Problem Solving StrategiesGwandaleana VwearsosaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Zener Barrier: 2002 IS CatalogDocumento1 paginaZener Barrier: 2002 IS CatalogabcNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- PistonDocumento7 paginePistongauravarora93100% (1)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- EConsole1 Quick Start Guide ENGDocumento21 pagineEConsole1 Quick Start Guide ENGManuel Casais TajesNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Pressure Sensor Air PST Datasheet 51 en 2780071435Documento3 paginePressure Sensor Air PST Datasheet 51 en 2780071435Luis GuevaraNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Ex450-5 Technical DrawingDocumento12 pagineEx450-5 Technical DrawingTuan Pham AnhNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Learning MenuDocumento8 pagineLearning Menuapi-464525668Nessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Translating Trig Graphs PDFDocumento4 pagineTranslating Trig Graphs PDFMark Abion ValladolidNessuna valutazione finora

- Class - B Complementary Symmetry Power AmplifierDocumento3 pagineClass - B Complementary Symmetry Power AmplifierAnonymous SH0A20Nessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- I C Engine LabDocumento3 pagineI C Engine LabDevNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Sqluser v11r1Documento199 pagineSqluser v11r1samnolenNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Product Specifications: Handheld Termination AidDocumento1 paginaProduct Specifications: Handheld Termination AidnormNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Motionless Electromagnetic GeneratorDocumento8 pagineMotionless Electromagnetic Generatorraja100% (1)

- Which Is The Best Solid Modelling - Dhyan AcademyDocumento3 pagineWhich Is The Best Solid Modelling - Dhyan Academydhyanacademy engineersNessuna valutazione finora

- Quant Short Tricks PDFDocumento183 pagineQuant Short Tricks PDFAarushi SaxenaNessuna valutazione finora

- List of GHS Hazard Statement & PictogramsDocumento33 pagineList of GHS Hazard Statement & PictogramsKhairul BarsriNessuna valutazione finora

- 003pcu3001 Baja California - JMH - v4 PDFDocumento15 pagine003pcu3001 Baja California - JMH - v4 PDFEmir RubliovNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Urban Road Types 25.01.2022Documento5 pagineUrban Road Types 25.01.2022Balogun IbrahimNessuna valutazione finora

- Network Command - HPUXDocumento5 pagineNetwork Command - HPUXRashid NihalNessuna valutazione finora

- Body Deassembly 9 Interior TrimDocumento7 pagineBody Deassembly 9 Interior TrimCarlos TecnicNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Sentinel Visualizer 6 User GuideDocumento227 pagineSentinel Visualizer 6 User GuideTaniaNessuna valutazione finora

- GMS60CSDocumento6 pagineGMS60CSAustinNessuna valutazione finora

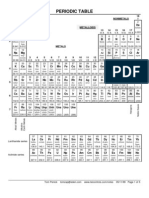

- Periodic Table and AtomsDocumento5 paginePeriodic Table and AtomsShoroff AliNessuna valutazione finora

- GTG - TFA Belt DrivenDocumento2 pagineGTG - TFA Belt Drivensuan170Nessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Life Processes: Science Unit 1Documento19 pagineLife Processes: Science Unit 1patil pratikNessuna valutazione finora

- Initial and Final Setting Time of CementDocumento20 pagineInitial and Final Setting Time of CementTesfayeNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)