Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

6i Titanium

Caricato da

Rajesh PatelDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

6i Titanium

Caricato da

Rajesh PatelCopyright:

Formati disponibili

Titanium

Resistance Welding

Lesson Objectives

When you finish this lesson

you will understand:

Learning Activities

1. View Slides;

2. Read Notes,

3. Listen to lecture

4. Do on-line workbook

Keywords

Donachie, Titanium,

ASM, 1988

Donachie, Titanium,

ASM, 1988

Unique Properties

Light Weight

Excellent Corrosion Resistance

Strong tightly adherent oxide

High strength-to-weight ratio

Applications

Chemical Industry

Aerospace Industry

Marine Fields

Medical Applications

Titanium

Melting

point

3035 F

1670 C

Boiling

Point

5900 F

3260 C

Coefficient

of

Expansion

F / in / in 67 . 4

Density

3

in / lb 163 . 0

UTS 30 ksi Pure Ti

200 ksi Alloys

Ductility 15 25%

Phases in Pure Titanium

Alpha {hcp} < 1620F (880C)

Beta {bcc} > 1620F

Classification of Titanium Alloys

Alpha & near Alpha Alloys

Alpha-Beta Alloys

Metastable Beta Alloys

AWS Welding Handbook

AWS Welding Handbook

Can Lead to Brittleness

Especially in welds (see below)

AWS Welding Handbook

Commercially Pure Titanium

Yield Strengths 35-80 ksi (interstitial O, N, C)

Alpha Titanium Alloys

Not heat treated to increase strength

Used for moderate elevated-temp strength and creep resistance

Near-alpha Alloys

Contain small amount of Beta stabilizers

Marginally heat treatable

Most contain Si for improved high temp properties

Alpha-Beta Alloys (e.g. Ti-6Al-4V)

Mixture of Alpha & Beta

Annealed or Solution heat treated and aged

Outstanding strength to density ratio in heat treated condition

Excellent fracture toughness when annealed

Metastable Titanium Alloys

Contain high percentage of Beta stabilizing elements

Slow transformation - air cooling gives 100% Beta

Aging precipitates of fine Alpha can occur

Aging give strength but ductility and fracture toughness sacrificed

Frequently used for fasteners and springs

Applications Using Titanium Alloys

For more information about applications see:

http://www.titanium.org/GIsec2a.htm

General Weld Problems

Oxygen Contamination Cracking

Oxygen > 3000ppm = WM & HAZ Cracking

Alpha (hcp) particularly susceptible

Removal of surface oxide film recommended

Gas shielding generally recommended (especially for seam welds)

Degree of Oxidation

Silver (mild oxidation)

Straw

Blue

White (severe oxidation - weld problems likely)

General Weld Problems

Iron Contamination Cracking

Iron particle dissolve into surface causing loss of :

Corrosion

Embrittlement (when sufficient iron)

Prevention

Avoid steel fabrication near titanium fabrication

Avoid airborne dust

Avoid tools used for both Fe and Ti

Scratch Brush just prior to welding

Use clean gloves for handling

Http://www.twi.co.uk/bestprac/jobknol/jk24.html

General Weld Problems

Hydrogen Embrittlement

Precipitation of titanium hydrides

Hydrogen > 200ppm can cause problems

Use low moisture shielding gas

AWS Welding Handbook

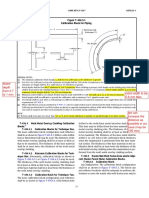

Example of Hydride Formation in Resistance Seam Weld

%

H

y

d

r

i

d

e

C

o

a

t

i

n

g

Days

100

0

500

2 days no hydrides

43 days-at toe

227 days-1/2 around

450 days-Full around

25 ppm Hydrogen

2056 ppm hydrogen

H

Toosky, R. Evaluation of Titanium

Hydride Formation in Resistance Seam

Welded Dissimilar Titanium Joints,

Boeing Co., 1998

Toosky, R. Evaluation of Titanium Hydride Formation in Resistance

Seam Welded Dissimilar Titanium Joints, Boeing Co., 1998

Seam Weld Start, Nugget Pull-Out

General Weld Problems

Porosity

H & O partitioned between solidifying dendrites

Micropores form when diatomic gas overcomes head pressure

AWS Welding Handbook

Mircopores coalesce to form macropores

To keep O & H out of weld pool, clean & degrease

AWS Welding Handbook

General Weld Problems

Ductility Dip

Alpha-beta alloys containing Nb rather than V more susceptible

Alpha films at prior beta boundaries more susceptible

Niobium Containing

Material in HAZ with these peak Temp can experience Dip

Cracks are intergranular

Believed to be caused by volumetric difference during

transformation

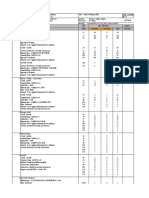

Resistance Spot Welding

Surface Cleaning - Mechanical or Chemical {HF-HNO

3

}

To lower surface resistance to below 50 microhms

To keep Titanium Oxide out of weld metal - embrittlement

Handle with gloves

Store in low-humidity less than 48 hours

Higher resistivity for Alloys than steel = lower current

Pure Ti can use SS Schedule

Class 2 Electrodes with 3 in radius spherical face

Gas shielding not required for spot welds

AWS Welding Handbook

Same Schedule

as SS for Pure

Titanium, But

Not For alloys

AWS Welding Handbook

Schedule for Two Typical Alloys

AWS Welding Handbook

Equiaxed Grains

Columnar Grains due to

Effect of Alloys

Resistance Seam Welding

AWS Welding Handbook

Same Cleaning procedures as spot welding

Class 2 Electrode Wheels with radius face = wheel radius

Inert shielding gas recommended

Electrode Force and Welding Current slightly

higher than for spot welds in the same material

Flash Welding Titanium

Use machine capacities similar to that for steel

Gas Shielding not absolutely necessary but recommended

(Titanium Oxidizes rapidly)

Use fast flashing rates & shorter flashing times than steel

(minimize weld contamination)

Lower upset force than for steel

Flashing and upset distances slightly less than for steel

Flash Welding Has Been Done on Following:

Commercially Pure Ti

Ti-6Al-4V

Ti-8Al-1Mo-1V

Ti-5Al-2.5Sn

Ti-6Al-2Sn-4Zr-2Mo

Ti-6Al-2Sn-4Zr-6Mo

Info from AWS and Titanium Industries Inc.

Some

Titanium

Welding

Applications

Froes, FH, et al, Non-Aerospace Applications of Titanium Feb 1998, TMS

SAAB 340 Aero Engine Shroud

constructed from commercially pure

titanium using resistance, spot and TIG

welding.

http://www.swantec.com/industry.htm

Welding Battery Connectors for Implantable Medical Device

Electrodes

Shield Gas (Ar) Tube

Battery Case

Battery Case Top

Feed Through Contacting Pin

(glass sealed in case top)

Battery Tab

Weld Conditions

1000 amps

40 msec

3.5 kgrams

Weld Combinations (inch)

0.018 Ti tab to 0.035 Nb pin

0.018 Ti tab to 0.020 Mo pin

0.018 Ti tab to 0.020 Ta pin

0.004 Ni tab to 0.020 Mo pin

Berkowitz, F, et al, Implantable Medical Device With High Reliability

Electrical Connection using Reactive Metals US Patent 5,712,462 Jan 27, 1998

Resistance Weld Ti Alloy Honeycomb

Structures for High Speed Civil Transport

(Requirement 72,000 hours @ 350F)

(Al-Li max use temp = 225F)

Weld

Heat Treat

1675-1825 F

15 min 4 hours

Weld between Ti 6242S face

sheet and Beta 21S honeycomb

low heat treatment Low

mechanical Boundary Present

Weld with heat treatment

good properties

El-Soudani, S, Process for Enhancing the Bond Strength of

Resistance Welded Joints Between Titanium Alloy Articles US

Patent 5,830,289 Nov 3, 1998

Potrebbero piacerti anche

- Soldering & Brazing: Unit-IvDocumento15 pagineSoldering & Brazing: Unit-IvRamu AmaraNessuna valutazione finora

- Weld Defect Tolerance Study PDFDocumento127 pagineWeld Defect Tolerance Study PDFKamarul NizamNessuna valutazione finora

- Welding ConsumablesDocumento128 pagineWelding ConsumablesErick Hogan75% (4)

- Ferrite No. and PercentageDocumento3 pagineFerrite No. and Percentagechowhk100% (3)

- WC-514 - Weld Discontinuities PDFDocumento1 paginaWC-514 - Weld Discontinuities PDFNathanLaertePiaiNessuna valutazione finora

- Titanium AlloysDocumento77 pagineTitanium AlloysvijayanmksNessuna valutazione finora

- Chapter-3 General Information of WeldingDocumento5 pagineChapter-3 General Information of WeldingKumar DneshNessuna valutazione finora

- 24 Practical Visual InspectionDocumento5 pagine24 Practical Visual InspectionMai Anh TaiNessuna valutazione finora

- Cswip Exams 1 PDFDocumento65 pagineCswip Exams 1 PDFFethi BELOUISNessuna valutazione finora

- Ferrite Weld Test Procedure-1Documento5 pagineFerrite Weld Test Procedure-1tedmer1Nessuna valutazione finora

- Is 7310 RequirementsDocumento4 pagineIs 7310 RequirementsRavichandran Tirupattur SubramaniamNessuna valutazione finora

- Welding ParametersDocumento34 pagineWelding ParametersmilindNessuna valutazione finora

- RT Level L FINALDocumento80 pagineRT Level L FINALSaad AfzalNessuna valutazione finora

- MEI - Aluminium MIG WeldDocumento56 pagineMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- WeldingDocumento23 pagineWeldingBilal TayyabNessuna valutazione finora

- GTAW Lesson PlanDocumento75 pagineGTAW Lesson PlanKentDemeterio100% (1)

- Titanium Welding Trips and TricksDocumento19 pagineTitanium Welding Trips and Tricksjayaarnav100% (2)

- 03 - GtawDocumento20 pagine03 - GtawEnache DaniNessuna valutazione finora

- Welding Complete PPT With QuestionDocumento50 pagineWelding Complete PPT With QuestionKBSMANITNessuna valutazione finora

- GMAW FundamentalsDocumento18 pagineGMAW FundamentalsYusup MulyanaNessuna valutazione finora

- Weld Defects and DiscontinuitiesDocumento78 pagineWeld Defects and DiscontinuitiesGilbert MendozaNessuna valutazione finora

- Demagnetization: BSS Non Destructive Testing PVT - LTDDocumento18 pagineDemagnetization: BSS Non Destructive Testing PVT - LTDSANU100% (1)

- Gta+sma PQRDocumento3 pagineGta+sma PQRRahul MoottolikandyNessuna valutazione finora

- Stainless Steel Electrode Comparison ChartDocumento7 pagineStainless Steel Electrode Comparison Chartmiker100Nessuna valutazione finora

- A General Review of Geometric Shape ImperfectionsDocumento12 pagineA General Review of Geometric Shape Imperfectionsbipete69Nessuna valutazione finora

- ASME & ISO ComparisonDocumento5 pagineASME & ISO Comparisonr0m14rNessuna valutazione finora

- Brazing BPS 107-1 PDocumento5 pagineBrazing BPS 107-1 Pmbe josephNessuna valutazione finora

- Murex Tig Poster 2008 PDFDocumento1 paginaMurex Tig Poster 2008 PDFPCNessuna valutazione finora

- AWS D1.1 GuidesDocumento7 pagineAWS D1.1 GuidesMuhammad FakhriNessuna valutazione finora

- Piping TCG Caliberation BlockDocumento1 paginaPiping TCG Caliberation BlockAhmed Abd ElmegeedNessuna valutazione finora

- Welding DefectsDocumento5 pagineWelding DefectsDEEPAKNessuna valutazione finora

- Welding Processes: EN358 - Ship StructuresDocumento27 pagineWelding Processes: EN358 - Ship Structuressuri345Nessuna valutazione finora

- GMAWDocumento12 pagineGMAWsushant47Nessuna valutazione finora

- E390-11 Standard Reference Radiographs For Steel Fusion WeldsDocumento4 pagineE390-11 Standard Reference Radiographs For Steel Fusion WeldsAhmed Shaban KotbNessuna valutazione finora

- Gas Metal Arc Welding (GMAW)Documento16 pagineGas Metal Arc Welding (GMAW)Akmal Bin Saipul AnuarNessuna valutazione finora

- International Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas WeldingDocumento60 pagineInternational Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas Weldingresky marantinanNessuna valutazione finora

- Basic Points of P91Documento4 pagineBasic Points of P91Asad Bin Ala Qatari100% (1)

- GTAW Welding of CP Titanium and Ti6Al4VDocumento1 paginaGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarNessuna valutazione finora

- Welding DefectDocumento33 pagineWelding DefectabdoNessuna valutazione finora

- Stainless Steel Technical GuideDocumento50 pagineStainless Steel Technical GuideHuỳnh TrươngNessuna valutazione finora

- NDT Steel CastingsDocumento17 pagineNDT Steel CastingsWoodrow FoxNessuna valutazione finora

- Defects in Smaw WeldingDocumento17 pagineDefects in Smaw WeldingRamesh R100% (1)

- RT SlideDocumento36 pagineRT SlidekbldamNessuna valutazione finora

- Usability Designators FCAWDocumento5 pagineUsability Designators FCAWAnonymous dh6DITNessuna valutazione finora

- Non Destructive Testing: CMR Institute of TechnologyDocumento32 pagineNon Destructive Testing: CMR Institute of TechnologyrajNessuna valutazione finora

- Manufacturing Technology: Unit - IDocumento12 pagineManufacturing Technology: Unit - Iapi-271354682Nessuna valutazione finora

- Como Soldar 4140Documento4 pagineComo Soldar 4140Luis Jose DuranNessuna valutazione finora

- CSWIP 3.1 Course Note 2016 With Question & AnswersDocumento3 pagineCSWIP 3.1 Course Note 2016 With Question & AnswersSakthi Pk100% (1)

- Welding BasicsDocumento37 pagineWelding BasicsSnehal DeshmukhNessuna valutazione finora

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEDocumento18 pagineAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreNessuna valutazione finora

- 3 Welding Imperfections and Materials InspectionDocumento31 pagine3 Welding Imperfections and Materials InspectionnanivenkatgauravNessuna valutazione finora

- WPS BhelDocumento2 pagineWPS BhelpradhankruhsnaNessuna valutazione finora

- 01 - WELDING DEFECTS (Surface) - May 2021Documento28 pagine01 - WELDING DEFECTS (Surface) - May 2021Gerry Dan ChanliongcoNessuna valutazione finora

- Module 8 Welding Metallurgy For The WIDocumento39 pagineModule 8 Welding Metallurgy For The WIMiki Jaksic100% (1)

- About Titanium WeldingDocumento6 pagineAbout Titanium Weldingckkashyap0007Nessuna valutazione finora

- Introduction To Ss Welding & Tig Weld: Er.A.Baranibas. Be., M.SC., DisDocumento41 pagineIntroduction To Ss Welding & Tig Weld: Er.A.Baranibas. Be., M.SC., DisaravindanNessuna valutazione finora

- Titanium - Welding and Heat Treating: Topics CoveredDocumento13 pagineTitanium - Welding and Heat Treating: Topics CoveredSisira Chandrasoma100% (1)

- Weldability and Joining of Materials: Titanium and Titanium AlloysDocumento4 pagineWeldability and Joining of Materials: Titanium and Titanium AlloysMehmet SoysalNessuna valutazione finora

- Stainless Steel With TIG WeldingDocumento41 pagineStainless Steel With TIG Weldingaravindan100% (3)

- Advances in Welding For Sanitary DesignsDocumento34 pagineAdvances in Welding For Sanitary Designskart_rlNessuna valutazione finora

- GF, FF, SFDocumento1 paginaGF, FF, SFamit_saxena_10Nessuna valutazione finora

- C.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water SupplyDocumento4 pagineC.0738.PP9.05P - Bulk Piping & Fittings BOQ For Process Water Supplyfakir mohammadNessuna valutazione finora

- Rigid PVC Conduit Installation GuideDocumento7 pagineRigid PVC Conduit Installation GuideReydel QuimnoNessuna valutazione finora

- LDPE Datasheet 2017Documento1 paginaLDPE Datasheet 2017Akram.yishakNessuna valutazione finora

- Presentation SG City 93 - 20.02.2023Documento44 paginePresentation SG City 93 - 20.02.2023IT TeamNessuna valutazione finora

- 0511 Grob PDFDocumento7 pagine0511 Grob PDFJ VeluNessuna valutazione finora

- Capral Industrial Products QLDDocumento41 pagineCapral Industrial Products QLDKevin YewNessuna valutazione finora

- ACI 318 History PDFDocumento106 pagineACI 318 History PDFvrb126Nessuna valutazione finora

- Sika JointDocumento16 pagineSika JointnasrulaminzubainiNessuna valutazione finora

- Beushausen, BesterDocumento10 pagineBeushausen, BesterEbrahim FlorisNessuna valutazione finora

- Unistrut CatalogDocumento12 pagineUnistrut CatalogElia Nugraha AdiNessuna valutazione finora

- Stainless Steel CatalogDocumento114 pagineStainless Steel CatalogSiva KumarNessuna valutazione finora

- M+H SOMOS Collaboration CatlogDocumento2 pagineM+H SOMOS Collaboration CatlogDhiman DodhiaNessuna valutazione finora

- Literature Review:: Polymer BlendsDocumento2 pagineLiterature Review:: Polymer BlendsWhy SadNessuna valutazione finora

- Site Office External BOQ ElectricalDocumento2 pagineSite Office External BOQ ElectricalShahed HussainNessuna valutazione finora

- Azolla TenderDocumento4 pagineAzolla TenderprashantkothariNessuna valutazione finora

- Fameg Pricelist2020 EURDocumento99 pagineFameg Pricelist2020 EURjganso0% (1)

- Astm C62 05Documento2 pagineAstm C62 05altaaeealaa0Nessuna valutazione finora

- Welding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Documento1 paginaWelding Procedure Specification: Wps Forcarbon Steel For Fillet and SW Joint Desighn (Smaw)Lipika GayenNessuna valutazione finora

- Specification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsDocumento7 pagineSpecification For Carbon and Alloy Steel Forgings For Thin-Walled Pressure VesselsAnilNessuna valutazione finora

- Residual Stresses & Fatigue Life With Case StudyDocumento13 pagineResidual Stresses & Fatigue Life With Case StudyDishant ShindeNessuna valutazione finora

- Caleffi Manifold DistributionDocumento44 pagineCaleffi Manifold Distributione-ComfortUSANessuna valutazione finora

- Crossheads For The Cable Industry: WWW - Unitek.at WWW - Unitek.atDocumento4 pagineCrossheads For The Cable Industry: WWW - Unitek.at WWW - Unitek.atAlyass EvanNessuna valutazione finora

- Directory of Operating Mines and QuarriesDocumento3 pagineDirectory of Operating Mines and QuarriesiaabaoNessuna valutazione finora

- Welded MasterlinkDocumento1 paginaWelded MasterlinkWerner SchulzNessuna valutazione finora

- TDS MasterRoc SA 192 PDFDocumento3 pagineTDS MasterRoc SA 192 PDFdana setiawanNessuna valutazione finora

- Monier Roofing Architectural Manual Section5Documento13 pagineMonier Roofing Architectural Manual Section5Christian LlorcaNessuna valutazione finora

- Method Statement of Casting SlabDocumento4 pagineMethod Statement of Casting SlabShakila Nishani100% (1)

- Building Inspection ChecklistDocumento3 pagineBuilding Inspection ChecklistDukeNessuna valutazione finora

- Fdez. Jove - Valvula 3 Vías - (SFERACO)Documento12 pagineFdez. Jove - Valvula 3 Vías - (SFERACO)Pedro VarelaNessuna valutazione finora