Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Water Treatment Plant Design: Sedimentation

Caricato da

nasaritaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Water Treatment Plant Design: Sedimentation

Caricato da

nasaritaCopyright:

Formati disponibili

Monroe L.

Weber-Shirk

School of Civil and

Environmental Engineering

Water Treatment Plant Design

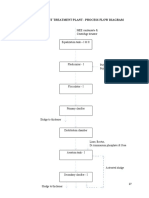

alum alum

Flocculation

Clear Well

Sedimentation

Overview

Safety

Competition guidelines

Trouble shooting guide

Hydraulic challenges

Surface tension

Startup requirements

Rapid Mix/Flocculation/Sedimentation

Parting Pointers

Laboratory Safety

Safety hazards

Electrical

Chemical

Aluminum Sulfate (alum)

Buddy System

Dont go into any other areas of the environmental

laboratory

Professional behavior

PPE: Safety glasses, lab coat

Project Expectations

Spend at least 4 hours per week working on WTP

outside of class

Keep an Excel time sheet (time in, time out, task,

and weekly totals) for each of you (email weekly

on Thursday to Jeff)

Work together as a team and divide up tasks

Spend time teaching each other what you are

learning

Professional Play! (Have fun!)

Team Work

Think efficiency

You cant all work on the same thing!

Compare your team work to soccer players

Dont bunch up!

Give each other permission to experiment with

the plant

Make a project schedule

Water Treatment Plant Goals

Best value (meets EPA turbidity standard with

lowest annual cost of production for NYC)

Longest continuous operation

Best plant control logic

Best plant design

Best maintenance plan for cleaning sedimentation

tank and flocculation tank

Documentation of experimentation, data analysis,

and appropriate plant modifications

EPA Turbidity Standards

As of January 1, 2002, turbidity may never exceed 1 NTU,

and must not exceed 0.3 NTU in 95% of daily samples in

any month.

Our requirement will be that the turbidity be less than or

equal to 0.3 NTU at all times

The [(flow rate at the time of a turbidity violation) x (12

hours)] will be deducted as a penalty from the total plant

production

Note that if the TAs collect more than 2 samples per day it will be

possible for the penalties to exceed the production!

TAs will measure the flow rates and the turbidity several

times per day and email results to the class

Economics

Capital costs

Cost of building the various components

building

Controls and sensors

Operation and Maintenance costs (O&M)

Chemicals (alum)

Electricity

Labor

Both capital and O&M costs contribute to the cost of the

water produced

We will only include the capital costs for this competition

Competition Economics

We will only include the costs for the processes

that you can control

The costs will be scaled as if your plant were full

scale

Otherwise the computer, data acquisition system,

and control hardware would completely dominate

the cost!

The clear well and the flow accumulator will not

be included in the economics

Capital Cost Estimates Used for the

Competition

Item cost unit

filters 8000 $/m

2

surface area of filter

garnet 90 $/m

3

volume of garnet

sand 20 $/m

3

volume of sand

anthracite 30 $/m

3

volume of anthracite

rapid mix tank 5000 $/m

3

volume of rapid mix tank

flocculation tank 2500 $/m

3

volume of flocculation tank

sedimentation 2000 $/m

3

volume of sedimentation

tank

lamella 20 $/m

2

total surface area of lamella

Calculating the cost of water from

your plant if applied to NYC

Calculate the cost of your plant

Assign cost for 1 week of operation assuming 25

year life (1/1300

th

of total capital cost)

Calculate the amount of water produced in the

week of the competition

Subtract any water that was produced within 12

hours of a turbidity standard violation

Calculate the cost per m

3

of water produced

Calculate the annual cost for using your process to

provide 60 m

3

/s to NYC

When it doesnt work!

You are creating a complex system

Any component that fails can lead to failure

in the system

How do you identify the source of a

problem?

Attempt to identify the events that could

cause a failure in advance

Scientific Method of

Troubleshooting

The Scientific method:

Clearly identify the problem

Create hypotheses

Design experiments to test the hypotheses

Draw conclusions based on the data

How can you choose which components to test

first?

Intuition?

Ask which component could cause the observed

symptoms

Requires an understanding of how the system works!

Modular Approach

How can you build a complex system with the

greatest probability of ultimate success?

Break a system down into its components and test

individual pieces

Only add components to the system after the

components have been tested

Begin with the system as simple as possible

What would the simplest operating rules be?

Add unit processes one by one

State Machines

What are the potential states for your water

filtration plant?

Off

Down flow

Backwash

Media settle

Filter to Waste

Plant State Logic

Assume your water treatment plant is

currently backwashing.

Under what conditions will the plant switch

to a different state?

Time greater than max set point

Time greater than min set point and

Above filter turbidity less than set point

Clear well empty

Output Device Control

Some of the controls are either on or off

depending on the state

Centrifugal backwash pump

Filter to waste valve

Some of the controls have variable settings

Alum pump rpm

Flow control valve

Alum pump rpm

How might a plant operator want to control

the alum pump?

Pump rpm

Alum stock flow rate

Alum mass rate

Alum concentration after mixing

Fully automatic based on raw water turbidity

What inputs are required?

Flow Control Valve

How should the

solenoid valve be

controlled?

What role does the

flow accumulator

play?

What will happen to

the flow rate if the

valve is opened for

a short period of

time?

Closed loop control logic

( )

1

c D

I

u t K t T

T t

e

e e

D

= + D +

D

P

I

D

Hydraulic Challenges

(getting the water to go where you want it to go)

Leaks

Connections not sufficiently tight

Improvised connections lacking a good seal

Overflows

Caused by water not going where you thought it was

going

Open channel flows (air and water) coming up

Excessive head loss

Tubing size too small

Filter clogging

Simplified WTP Schematic

Can the flow accumulator be on the bench top?

What controls the sedimentation tank water level?

Why does the water flow through the filter?

How would you start up the plant and get water to flow

through the filter the first time?

How much head loss can the filter cause before the

system fails?

Flocculation

Clear Well

Sedimentation

Yes

Overflow weir

Elevation difference

Backwash

Improved WTP

Why is this

better?

Max head loss?

How could you

measure head

loss through the

filter?

Clear Well

Open Channel Flow

Flocculation

Sedimentation

0.01

0.1

1

10

100

0.1 1 10 100

length scale (mm)

s

u

r

f

a

c

e

t

e

n

s

i

o

n

/

w

e

i

g

h

t

Relative Strength of Forces

3

F

g

gl r =

F l

s

s =

0.050

0.055

0.060

0.065

0.070

0.075

0.080

0 20 40 60 80 100

Temperature (C)

S

u

r

f

a

c

e

t

e

n

s

i

o

n

(

N

/

m

)

0.050

0.055

0.060

0.065

0.070

0.075

0.080

0 20 40 60 80 100

Temperature (C)

S

u

r

f

a

c

e

t

e

n

s

i

o

n

(

N

/

m

)

Surface tension Gravity

Stable* Unstable

?

* water column over air wont break

Open Channel Flows: Water and

Air

All overflows tubes are open channel flow

Minimum inside diameter for sink drain is

6.35 mm ()

Minimum inside diameter for line where

water level moves up and down based on

filter head loss is 9.5 mm (3/8)

What happens if the tubing isnt large

enough for open channel flow?

WTP

Leak and Overflow Prevention

Clear well overflow line must be horizontal or sloping

down (cant go up and down)

What happens if head loss through the filter increases too

much?

Check each tank or tube with an opening to the atmosphere

and ask:

What could cause an overflow at this location?

How could we design the system to reduce risk of failure

Turn off the manual supply valve when you arent using

the plant

Make sure that all solenoid valves are off when the plant

isnt being used.

WTP

Plant Layout

Design a plant layout that is easy to follow

Tubing lengths can be changed so you can

place your devices anywhere you want them

Beware of large diameter horizontal tubes

containing particles

Why?

WTP

Startup Requirements

Stamp module must be on the computer side of the

bench divider

Must prove that excessive head loss will cause the

filter to backwash before causing a flood!

Must show that backwash wont empty clear well

Must show that the plant switches between states

correctly

Pointers

Pressure sensors must be kept dry (they can fail if

one drop of water soaks into the terminals)

Use manual valves to make it easy to drain tanks

Make sure you are using the most recent method

file in your folder!

Save a new version of the method file every time

you make changes

Label all processes

Label the alum stock bottle

Label all containers containing fluids

Operating Criteria

Initial down flow rate of 5 m/h (40 ml/min)

If you increase the down flow rate make absolutely sure

that the plant doesnt overflow

Use your water treatment plant design homework

to calculate the best stock concentration of alum

The best stock concentration might change if you

significantly change the plant flow rate

Plan to have someone check on the plant at least

once per day (alum stock!)

Hydraulic Jump: Hydraulic Jump creates turbulence and

thus help better mixing.

Mechanical mixing

Inflow

Chemical

feeding

Chemical

feeding

Inflow

Back mix impeller flat-blade impeller

Rapid Mixing

In-line flash mixing

Coagulant

Goal?

Poor

Excellent

Flocculation Design

Goal: produce large flocs from tiny particles

Collision Mechanism:

SHEAR

We are doing research to find

Shear that will cause floc to break apart (floc strength)

Gq necessary to produce big floc (will dictate length of

tube flocculator)

Transfer into sedimentation tank must be done

without increasing the shear

How short can you make this?

Given Gq, Q and d, Find Floc Tube

Length

3

64

3

Q

G

d

2

4

d L

Q

2

3

64 16

4 3 3

d L Q L

G

Q d d

q

3

16

dG

L

q

True for laminar flow

q

Q

2

4

d

L

Q

Turbidity after Sedimentation

Increases with Maximum Shear

As shear increases

floc size decreases

Small floc settle more

slowly

It is possible that

some very small

colloids are produced

when large floc

breakup

Net result: higher

shear causes higher

turbidity after

sedimentation

0

0.5

1

1.5

2

2.5

3

3.5

4

0 50 100 150 200 250 300

Gmax (1/s)

R

e

s

i

d

u

a

l

T

u

r

b

i

d

i

t

y

(

N

T

U

)

max

3

32Q

G

d

Sedimentation Tank

Up flow through a sludge blanket at 50 m/day can

create excellent quality water

Additional flocculation occurs in the sludge

blanket

Lamella might increase particle capture

Lamella spacing must be larger than the flocs you

are trying to capture

You can save money by making this as small as

possible

How will your Team Win?

Produce the most clean water

Keep costs down

Efficient use of flocculation/sedimentation tanks

Judicious use of filter to waste

Only backwash when needed

Well designed filter media (donated by US Filter)

Document your design process

Get your plant running ASAP so you can improve

it before the competition begins.

Good Engineering?

How would you approach this task as a

Cornell engineer in a way that is different

then how you would approach it in

elementary school?

How do you learn about the physical world?

Competition Submission

Submit 5 copies by 5 pm on Thursday (May 5).

Executive Summary

A one page cover letter to the judges where you introduce your design

firm, identify the members of your design team, and describe the

important features of your water treatment plant.

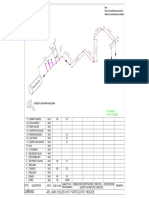

Final plant schematic

all valves, sensors, tanks, and pumps with correct relative elevations.

Clearly show the elevation of the laboratory bench top.

Description of your design and your design process

How did you size the unit processes in your plant? SHOW

CALCULATIONS

How did you test the plant?

How did you use data that you acquired to modify the design?

What are the special features of your plant that make it the best?

Parting Pointers

Hydraulics: water flows from higher

potential energy to lower potential energy

Leaks: fix them right away, clean up all

spills immediately, keep bench dry, sensors

and controls die when wet!

Save incremental versions of process

control method whenever you make

changes

Potrebbero piacerti anche

- 03 Conventional Water TreatmentDocumento80 pagine03 Conventional Water Treatmentbksri1239561Nessuna valutazione finora

- Ate Huber-1Documento47 pagineAte Huber-1Ravena RemaditaNessuna valutazione finora

- Design of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanDocumento47 pagineDesign of Arraba Waste Water Treatment Plant: Prepared By: Waleed Rahhal Hamed Daghles Saleh Abdel-RhmanMOHAMMED ABBAS NAJI MAALANessuna valutazione finora

- WT - Rapid Sand FiltrationDocumento5 pagineWT - Rapid Sand FiltrationObester Mudazvose ChimhandambaNessuna valutazione finora

- Slow Sand Filtration Dwfsom40 PDFDocumento4 pagineSlow Sand Filtration Dwfsom40 PDFjose03Nessuna valutazione finora

- Chapter 1 Basic Design ConsiderationDocumento38 pagineChapter 1 Basic Design ConsiderationAce ThunderNessuna valutazione finora

- Design of WTP and STPDocumento14 pagineDesign of WTP and STPVenu Ch100% (1)

- Hydraulics of Sewage Treatment Plants Sec-6Documento63 pagineHydraulics of Sewage Treatment Plants Sec-6hosny1987Nessuna valutazione finora

- Effluent Treatment Plant - Process Flow DiagramDocumento45 pagineEffluent Treatment Plant - Process Flow DiagramAmarnath PNessuna valutazione finora

- Physico-Chemical Wastewater Treatment IntroductionDocumento27 paginePhysico-Chemical Wastewater Treatment IntroductionmsinsigneNessuna valutazione finora

- Textile Environmental PresentationDocumento52 pagineTextile Environmental PresentationNayeem RahmanNessuna valutazione finora

- Characterization of Sewage and Design of Sewage Treatment PlantDocumento59 pagineCharacterization of Sewage and Design of Sewage Treatment PlantSaddam AnsariNessuna valutazione finora

- Effluent Treatmnt Plant (ETP) : Akash TikheDocumento44 pagineEffluent Treatmnt Plant (ETP) : Akash TikheArvind ShuklaNessuna valutazione finora

- WWT Secondary Clarifier PDFDocumento15 pagineWWT Secondary Clarifier PDFdzari6738Nessuna valutazione finora

- SLOW SAND FILTER (Everything You Need To Know) SSF DesignDocumento174 pagineSLOW SAND FILTER (Everything You Need To Know) SSF DesignMuhammad UsmanNessuna valutazione finora

- DesignDocumento3 pagineDesigntata_77Nessuna valutazione finora

- Sand FiltrationDocumento5 pagineSand FiltrationMa Vichelle Torrejos-UyNessuna valutazione finora

- Sanitation Module - IndiaDocumento48 pagineSanitation Module - IndiaHarish BabuNessuna valutazione finora

- DNIT Vol 2 Part 1Documento196 pagineDNIT Vol 2 Part 1JitendraHatwarNessuna valutazione finora

- Gravity SettlingDocumento10 pagineGravity SettlingNithinKallayil100% (1)

- Water Management Business Division: ClariflocculatorsDocumento2 pagineWater Management Business Division: ClariflocculatorsganeshNessuna valutazione finora

- Lesson Plan: How Do We Clean Polluted Water?Documento15 pagineLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyNessuna valutazione finora

- Operator - Book-StpDocumento113 pagineOperator - Book-StpAce Dynamics India100% (1)

- Rapid Sand FiltrationDocumento16 pagineRapid Sand FiltrationNurul ShafinazNessuna valutazione finora

- 2 Coagulation FlocculationDocumento26 pagine2 Coagulation FlocculationNurSyuhada ANessuna valutazione finora

- Rapid Sand Filter and Tube SettlersDocumento16 pagineRapid Sand Filter and Tube Settlersnp27031990Nessuna valutazione finora

- Aqua ChlorinatorDocumento2 pagineAqua ChlorinatorSumit MishraNessuna valutazione finora

- ActivateSludgeVS Membrane Reactor SLIDEDocumento36 pagineActivateSludgeVS Membrane Reactor SLIDEsebascian100% (1)

- Bar Screen-Grit ChamberDocumento10 pagineBar Screen-Grit ChamberRaja ManiNessuna valutazione finora

- Tech City-STP 100 KLD Price Comparison (03092016)Documento10 pagineTech City-STP 100 KLD Price Comparison (03092016)Preston VargheseNessuna valutazione finora

- PFD FileDocumento11 paginePFD FileNaveen MahawarNessuna valutazione finora

- Principles and Practices of Reverse OsmosisDocumento9 paginePrinciples and Practices of Reverse OsmosisMohamadNessuna valutazione finora

- M13 - L17 Grit ChamberDocumento6 pagineM13 - L17 Grit ChamberBerliana Cahya Ningtias0% (1)

- Secondary ClarifiersDocumento51 pagineSecondary ClarifiersmakortoNessuna valutazione finora

- Flocculator Eng PDFDocumento2 pagineFlocculator Eng PDFAbdul LatifNessuna valutazione finora

- V3i4 Ijertv3is040786 PDFDocumento5 pagineV3i4 Ijertv3is040786 PDFsarikagNessuna valutazione finora

- ClarifierDocumento10 pagineClarifierrasithapradeep0% (1)

- Sample WW QuestionsDocumento10 pagineSample WW QuestionsKrishna Kumar MeenaNessuna valutazione finora

- I Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeDocumento11 pagineI Electro Mechanical Equipments II STP Panel III Statutory Approval ChargeSajeshKumarNessuna valutazione finora

- 04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFDocumento8 pagine04 Sec. 3 Sewage Characteristics and Effluent Discharge Requirements PDFVic KeyNessuna valutazione finora

- Sewage Treatment WorksheetDocumento18 pagineSewage Treatment WorksheetRemedanNessuna valutazione finora

- Exercise 3 - Water Treatment2Documento8 pagineExercise 3 - Water Treatment2Vivekka Olivia John100% (1)

- Waste Water Treatment 2014Documento81 pagineWaste Water Treatment 2014ankur neogNessuna valutazione finora

- EE-2 Mini Project ReportDocumento7 pagineEE-2 Mini Project Report63GANESH SINGHCIVILNessuna valutazione finora

- SBR Sewage Treatment Plant Clear WaterDocumento12 pagineSBR Sewage Treatment Plant Clear WaterAndreea CalcanNessuna valutazione finora

- Dual MediaDocumento12 pagineDual MediaPraveen Kesavan NairNessuna valutazione finora

- 432 ProjectDocumento19 pagine432 ProjectSahil PalNessuna valutazione finora

- Project Report On Extended Aeration and Step AerationDocumento38 pagineProject Report On Extended Aeration and Step AerationHakim Asif Haider100% (2)

- Rapid Sand FilterDocumento30 pagineRapid Sand Filtersachinambekar100% (1)

- Mini Project ReportDocumento5 pagineMini Project ReportSaj BhaiNessuna valutazione finora

- 12 m3hr. WTP OFFER For Bore Well Water - BOQDocumento18 pagine12 m3hr. WTP OFFER For Bore Well Water - BOQt m murshedNessuna valutazione finora

- Microsoft Word - Festo Rain Water Harvesting Flow ChartDocumento5 pagineMicrosoft Word - Festo Rain Water Harvesting Flow Chartjeykumar.BalannairNessuna valutazione finora

- Aerobic and Anaerobic Wastewater TreatmentDocumento15 pagineAerobic and Anaerobic Wastewater TreatmentVictor100% (1)

- Final Project Content PDFDocumento24 pagineFinal Project Content PDFRahul SinghNessuna valutazione finora

- Shortcut Nitrogen Removal-Nitrite Shunt and DeammonificationDa EverandShortcut Nitrogen Removal-Nitrite Shunt and DeammonificationNessuna valutazione finora

- Sanitary Engineer II: Passbooks Study GuideDa EverandSanitary Engineer II: Passbooks Study GuideNessuna valutazione finora

- 07 WTP DesignDocumento38 pagine07 WTP DesignjnmanivannanNessuna valutazione finora

- Main Wheel ADocumento1 paginaMain Wheel AnasaritaNessuna valutazione finora

- T H T B BH I: 7 Guided Frame 1 ArrangementDocumento2 pagineT H T B BH I: 7 Guided Frame 1 ArrangementnasaritaNessuna valutazione finora

- CSI Sap2000 Bridge ExamplesDocumento78 pagineCSI Sap2000 Bridge ExamplesnasaritaNessuna valutazione finora

- Skin PlateDocumento1 paginaSkin PlatenasaritaNessuna valutazione finora

- Bearing and Uplift CapacityDocumento3 pagineBearing and Uplift CapacityJose HaroNessuna valutazione finora

- Bridge Superstructure DesignDocumento108 pagineBridge Superstructure Designstefanotomasi123550% (2)

- Analisis Debit Banjir RancanganDocumento10 pagineAnalisis Debit Banjir RancangannasaritaNessuna valutazione finora

- PR AQ 08 Aqueduct PierDocumento30 paginePR AQ 08 Aqueduct PiernasaritaNessuna valutazione finora

- PR AQ 08 Aqueduct PierDocumento30 paginePR AQ 08 Aqueduct PiernasaritaNessuna valutazione finora

- Counterfort Retaining Wall MCN PDFDocumento12 pagineCounterfort Retaining Wall MCN PDFHoshear BakrNessuna valutazione finora

- Lec 16Documento5 pagineLec 16Vimal KumarNessuna valutazione finora

- European Catalog Asia Pacific Express Asco en 5041722Documento70 pagineEuropean Catalog Asia Pacific Express Asco en 5041722treborNessuna valutazione finora

- Hydraulic Fluid - PropertiesDocumento7 pagineHydraulic Fluid - Propertiesprajapati1436Nessuna valutazione finora

- D-050 D-050-C D-052: Combination Air ValveDocumento6 pagineD-050 D-050-C D-052: Combination Air Valve7erick7Nessuna valutazione finora

- LubricantsDocumento29 pagineLubricantsmuhammadumeryaqoob16Nessuna valutazione finora

- Retention Time of A Horizontal Three Phase Vessel With Elliptical EndsDocumento7 pagineRetention Time of A Horizontal Three Phase Vessel With Elliptical EndsSaidNessuna valutazione finora

- 6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsDocumento9 pagine6-44-0013 2013 Standard Specification For Inspection, Flushing and Testing of Piping SystemsdgkmurtiNessuna valutazione finora

- BS EN 60534-8-4-2005 (2007) - Control Valves-Noise GeneratedDocumento30 pagineBS EN 60534-8-4-2005 (2007) - Control Valves-Noise GeneratedPraveenKatkooriNessuna valutazione finora

- Shell and Tube Heat ExchangerDocumento19 pagineShell and Tube Heat Exchangerhuangjl33% (3)

- European Patent Application: Quad-Redundant Hydraulic Trip SystemDocumento26 pagineEuropean Patent Application: Quad-Redundant Hydraulic Trip Systemw_sallumNessuna valutazione finora

- Pipe Friction Loss in Smooth Bore PipeDocumento7 paginePipe Friction Loss in Smooth Bore PipeAdnAnKhanNessuna valutazione finora

- Fuvahmullah Detld Desg Rept-23-05-10 PDFDocumento40 pagineFuvahmullah Detld Desg Rept-23-05-10 PDFTariq ShahzadNessuna valutazione finora

- Qiu 2018Documento14 pagineQiu 2018Marco CamposNessuna valutazione finora

- Pump Sizing Calculation - Twopump RunningDocumento2 paginePump Sizing Calculation - Twopump RunningMuthuKumar ArunachalamNessuna valutazione finora

- Air Compressor Lubricant: SOS-D1-100Documento2 pagineAir Compressor Lubricant: SOS-D1-100Orlando GalvanNessuna valutazione finora

- Discharge Calculation SheetDocumento2 pagineDischarge Calculation SheetAbdulRahmanshaheenNessuna valutazione finora

- Tarbela Reservoir Operations and ReleasesDocumento6 pagineTarbela Reservoir Operations and ReleasesARAR8789Nessuna valutazione finora

- High Institute of Engineering and Technology: (Water HammerDocumento6 pagineHigh Institute of Engineering and Technology: (Water HammerAhmed EbrahemNessuna valutazione finora

- Radial - Flow: (Centrifugal Pump)Documento17 pagineRadial - Flow: (Centrifugal Pump)John A. CenizaNessuna valutazione finora

- Reaction Paper/ Reflective ActivityDocumento2 pagineReaction Paper/ Reflective ActivityAriane Joy ManimtimNessuna valutazione finora

- Assignment Fall2018Documento2 pagineAssignment Fall2018Frans LoekitoNessuna valutazione finora

- Expro-API-RP-14E-Gas Wells PDFDocumento12 pagineExpro-API-RP-14E-Gas Wells PDFRuben VillegasNessuna valutazione finora

- Test On Fluid MechanicsDocumento11 pagineTest On Fluid MechanicsJonathan GreenNessuna valutazione finora

- Reverse Gravure Anilox-18 PDFDocumento6 pagineReverse Gravure Anilox-18 PDFQuan PhanNessuna valutazione finora

- Journal of Heat TransferDocumento9 pagineJournal of Heat TransferIsidora GoicocheaNessuna valutazione finora

- Data Sheet: Hydraulic Fluid P. 854Documento16 pagineData Sheet: Hydraulic Fluid P. 854aries_fransischoNessuna valutazione finora

- Questions 11-20Documento3 pagineQuestions 11-20Samuel Francisco SinagaNessuna valutazione finora

- CYCLONES0000Documento35 pagineCYCLONES0000Abdul HadiNessuna valutazione finora

- Hot Water System IsometricDocumento6 pagineHot Water System IsometricAzher ANessuna valutazione finora

- Velocity Boundary LayerDocumento3 pagineVelocity Boundary LayerThe UltimateNessuna valutazione finora