Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Heat Treatment

Caricato da

pandiangvTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Heat Treatment

Caricato da

pandiangvCopyright:

Formati disponibili

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

TWI

CSWIP 3.1

WIS 5

WELDING INSPECTION

HEAT TREATMENT

SECTION 18.

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

POST WELD HEAT TREATMENT

Many metals must be given heat treatment before and

after welding.

The inspectors function is to ensure that the treatment is

given correctly in accordance with the specification or as

per the details supplied.

Below are the types of heat treatment available.

Annealing

Normalising

Quench Hardening

Temper

Stress Relief

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

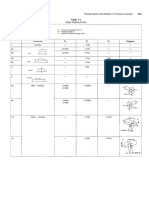

POST WELD HEAT TREATMENT

TEMP C

TIME (Hours & Minutes)

HEATING RATE

SOAK TIME (Time at attained temp)

COOLING RATE

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

POST WELD HEAT TREATMENT

(A) Normalised

(B) Fully Annealed

(C) Water-quenched

(D) Water-quenched & tempered

A B

C D

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The inspector, in general, should ensure that:

Equipment is as specified

Temperature control equipment is in good

condition

Procedures as specified, is being used e.g.

Method of application

Rate of heating and rate of cooling

Maximum temperature attained

Soak time

Temperature measurement (and calibration)

Documentation and records

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

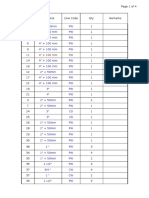

Process: Normalising

Temp: 920

0

C

Cooling: Hold, air cool

Result: Relieves internal stress,

improves mechanical properties,

Increases toughness

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

Process: Stress relief

Temp: 550-700

0

C

Cooling: Hold, furnace or controlled

cooling

Result: Relieves residual stresses,

improves stability during machining,

reduces hydrogen levels, prevents stress

corrosion cracking

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT .

QUESTIONS ?

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

QUESTIONS ?

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

Process: Quench, Harden

Temp: 920

0

C

Cooling: Hold, quench cool

Result: Hardens carbon steels,

prevents carbide precipitation in

austenitic steels, prevents temper

brittleness when cooling after tempering,

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

Process: Temper

Temp: 550-700

0

C

Cooling: Hold, air cool

Result: Increases toughness of

quenched steel

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

Process: Annealing

Temp: 920

0

C

Cooling: Hold, furnace cool

Result: Improves ductility,

Decreases toughness, Makes bending

etc easier, Lowers yield stress

Copyright 2004, TWI Ltd World Centre for Materials Joining Technology

HEAT TREATMENT

The temperatures mentioned are for

steels.

Process Pre-heat for welding

Temp 50-250

0

C. higher by

exception

Cooling Hold during welding.

Result Prevents cracking and hard

zones

Potrebbero piacerti anche

- Crosby Eye Bolt G 291Documento1 paginaCrosby Eye Bolt G 291pandiangvNessuna valutazione finora

- 999 Industrial Guide 2010Documento42 pagine999 Industrial Guide 2010kasosei100% (1)

- As Me Certificate Holder ReportDocumento5 pagineAs Me Certificate Holder ReportpandiangvNessuna valutazione finora

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Washer ThicknessDocumento2 pagineWasher ThicknesspandiangvNessuna valutazione finora

- Studding Outlets Dimensions & SpecificationsDocumento2 pagineStudding Outlets Dimensions & SpecificationspandiangvNessuna valutazione finora

- Xylan Offshore FlierDocumento2 pagineXylan Offshore FlierpandiangvNessuna valutazione finora

- Ship Motion LoadDocumento4 pagineShip Motion LoadpandiangvNessuna valutazione finora

- 06 Eurocodes Steel Workshop WALDDocumento6 pagine06 Eurocodes Steel Workshop WALDpandiangvNessuna valutazione finora

- Peppers Catalogue Approved AccessoriesDocumento16 paginePeppers Catalogue Approved AccessoriespandiangvNessuna valutazione finora

- Force and Moment Sketches ModelDocumento1 paginaForce and Moment Sketches ModelpandiangvNessuna valutazione finora

- CharttorqueswgDocumento2 pagineCharttorqueswgYutana RuxnakNessuna valutazione finora

- F1554 Grade 105 - F1554 Anchor BoltsDocumento2 pagineF1554 Grade 105 - F1554 Anchor BoltspandiangvNessuna valutazione finora

- Nut DetailsDocumento1 paginaNut DetailspandiangvNessuna valutazione finora

- Wind Load Calculation ReportDocumento2 pagineWind Load Calculation ReportpandiangvNessuna valutazione finora

- Buoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9Documento5 pagineBuoyancy: M. Bahrami Fluid Mechanics (S 09) Fluid Statics 9RonoNessuna valutazione finora

- Peppers Catalogue Approved AccessoriesDocumento16 paginePeppers Catalogue Approved AccessoriespandiangvNessuna valutazione finora

- A Lok Tube FittingsDocumento88 pagineA Lok Tube FittingsCesarNessuna valutazione finora

- UBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffDocumento4 pagineUBC DIVISION-III (Wind Design) : Ce Combined Height, Exposure & Gust Factor CoeffpandiangvNessuna valutazione finora

- Design Base Plate ThicknessDocumento6 pagineDesign Base Plate ThicknesspandiangvNessuna valutazione finora

- S2 - Jaw and Jaw-136Documento1 paginaS2 - Jaw and Jaw-136pandiangvNessuna valutazione finora

- Design and Development PlanningDocumento6 pagineDesign and Development PlanningpandiangvNessuna valutazione finora

- TMCP Steels For Offshore StructuresDocumento3 pagineTMCP Steels For Offshore StructurespandiangvNessuna valutazione finora

- Pub57 - CDS - Guide (2006 W-2010 Update)Documento78 paginePub57 - CDS - Guide (2006 W-2010 Update)Russ FordNessuna valutazione finora

- Guidance Notes RevisionDocumento8 pagineGuidance Notes RevisionpandiangvNessuna valutazione finora

- Project Execution PlanDocumento1 paginaProject Execution PlanpandiangvNessuna valutazione finora

- FAC1 Z 833001 - Rev 5Documento1 paginaFAC1 Z 833001 - Rev 5pandiangv100% (1)

- Load-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigDocumento12 pagineLoad-Carrying Capacity Analysis On Derrick of Offshore Module Drilling RigpandiangvNessuna valutazione finora

- WRC Input InstructionDocumento2 pagineWRC Input InstructionpandiangvNessuna valutazione finora

- N1192-ST - Colour CoadingDocumento4 pagineN1192-ST - Colour CoadingpandiangvNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (72)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- French Revolution - Information ResourcesDocumento3 pagineFrench Revolution - Information ResourcesRalph Adam100% (2)

- TDS - Penguard Primer - Issued.26.11.2010Documento4 pagineTDS - Penguard Primer - Issued.26.11.2010vitharvanNessuna valutazione finora

- The Orderflows Bulge Michael ValtosDocumento51 pagineThe Orderflows Bulge Michael Valtosmr100% (1)

- Mockups Showeet (Standard)Documento46 pagineMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoNessuna valutazione finora

- 17 Laws of TeamworkDocumento2 pagine17 Laws of TeamworkJesus Alarcon Z CantuNessuna valutazione finora

- SD ContentsDocumento18 pagineSD ContentsAnonymous gUjimJKNessuna valutazione finora

- Angle Types Acute Right ObtuseDocumento2 pagineAngle Types Acute Right ObtuseBenjamin DennisNessuna valutazione finora

- Psychometric Testing HandoutDocumento2 paginePsychometric Testing HandoutIchsan FaridzNessuna valutazione finora

- Midlands State University Library Department Course: Information Literacy Skills (Hcs135)Documento7 pagineMidlands State University Library Department Course: Information Literacy Skills (Hcs135)Loveniah Yemurai MbakataNessuna valutazione finora

- PROOFEX TORCHSEAL 3PV WATERPROOFING MEMBRANEDocumento1 paginaPROOFEX TORCHSEAL 3PV WATERPROOFING MEMBRANETharra AyurianyNessuna valutazione finora

- GRC Panels With Recess 4mx2mSIZE: Structural Calculation ForDocumento58 pagineGRC Panels With Recess 4mx2mSIZE: Structural Calculation ForvenkatNessuna valutazione finora

- Super UGC NET (Updated) - English - 1684164276Documento20 pagineSuper UGC NET (Updated) - English - 1684164276Anigrah Raj100% (1)

- Polytropic Process1Documento4 paginePolytropic Process1Manash SinghaNessuna valutazione finora

- Turban Dss9e Ch04Documento50 pagineTurban Dss9e Ch04Agha Agha FaisalNessuna valutazione finora

- CII4Q3 - Computer Vision-EAR - Week-11-Intro To Deep Learning v1.0Documento50 pagineCII4Q3 - Computer Vision-EAR - Week-11-Intro To Deep Learning v1.0Zee IngameNessuna valutazione finora

- Forte 2010Documento106 pagineForte 2010Javikoo Javier Chicaiza Meza100% (1)

- En 13364 - 2001Documento2 pagineEn 13364 - 2001Letícia Valdo0% (1)

- Steinel Springs CatalogDocumento49 pagineSteinel Springs CatalogRafael Zavaleta AhonNessuna valutazione finora

- Saudi 7th Scientific ConferenceDocumento383 pagineSaudi 7th Scientific ConferenceMairene0% (1)

- Detector Geam SpartDocumento16 pagineDetector Geam SpartGabrielNessuna valutazione finora

- Xylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsDocumento4 pagineXylux Lr3: High Output Emergency LED Luminaire Suitable For 10.8 Lux ApplicationsAtiqNessuna valutazione finora

- Irp NeerajDocumento90 pagineIrp NeerajNeeraj BalamNessuna valutazione finora

- Fujifilm Ga645 FullDocumento31 pagineFujifilm Ga645 FullWork In ArtNessuna valutazione finora

- File 1662629170Documento180 pagineFile 1662629170La IrenicaNessuna valutazione finora

- Outline Medical TerminologyDocumento3 pagineOutline Medical TerminologypearlparfaitNessuna valutazione finora

- Cold-Formed Steel Beam Design - ManualDocumento28 pagineCold-Formed Steel Beam Design - ManualEdwin RamirezNessuna valutazione finora

- Waste Management Report 08 PDFDocumento7 pagineWaste Management Report 08 PDFMikeRenderNessuna valutazione finora

- Mathematical-Olympiads PDFDocumento27 pagineMathematical-Olympiads PDFG100% (1)

- Acopl Todos - MétricoDocumento53 pagineAcopl Todos - MétricoDaniela E. Wagner100% (1)

- Reboiler Selection CriteriaDocumento5 pagineReboiler Selection CriteriamineralgroupstmfiNessuna valutazione finora