Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Lathe Machine Tool

Caricato da

Siva BhaskarCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Lathe Machine Tool

Caricato da

Siva BhaskarCopyright:

Formati disponibili

LATHE MACHINE

COURSE CONTENTS

Introduction & history of lathe.

Working principle of lathe.

Classification of lathe.

Construction and parts of lathe.

Accessories of lathe.

Specifications of lathe.

Lathe operations.

Work holding devices.

Conclusion

HISTORY

The inventor of center lathe is Henry

Maudsley.

The lathe machine is one of the oldest

and most important machine tools. As

early as 1569, wood lathes were in use

in France. The lathe machine was

adapted to metal cutting in England

during the Industrial Revolution.

Lathe machine also called Engine

Lathe because the first type of lathe

was driven by a steam engine.

Lathe is one of the most important machine tools in the

metal working industry. A lathe operates on the principle

of a rotating work piece and a fixed cutting tool.

The cutting tool is feed into the work piece, which rotates

about its own axis, causing the work piece to be formed

to the desired shape.

Lathe machine is also known as the mother/father of the

entire tool family.

WORKING PRINCIPLE OF LATHE

It holds the job between two rigid and strong supports

called centers which rotates the work piece.

The cutting tool held rigidly in tool post .

While job rotates about its own axis the cutting tool is fed

against the job either in parallel or at an inclination.

Type of job:

Majorly cylindrical ,conical shaped components can be

easily machined.

Type of cutting tool:

single point cutting tool is used.

WORKING PRINCIPLE OF LATHE

LATHE AND ITS PARTS

Main parts of lathe are :

Bed

Head stock

Tail stock

Carriage

Legs

Feed mechanism

Screw cutting mechanism

BED:

Made from cast iron or nickel cast iron alloy.

It supports head stock, tail stock & carriage.

Machining and scraping of lathe bed is done with

high precision.

On top section are machined ways guide and align

major parts of lathe.

Lathe beds are usually made of single piece

castings.

For extremely large machine, it can be of two or

more pieces.

Its cross section is box sections with cross ribs.

LEGS:

Supports which carry complete load of machine tool.

Both legs should be rigid and robust construction.

HEAD STOCK :

Clamped on left-hand end of bed.

Headstock spindle ,Hollow cylindrical shaft

supported by bearings provides drive through gears

to work-holding devices.

These bearings and gears are used to provide

required spindle speeds.

It is also called as Live centre.

NEED FOR CHANGE OF SPEED:

Work material: harder materials need slow speeds and soft

materials are machined at faster speeds.

Cutting tool materials: harder the cutting tool the higher is the

cutting speed to take the advantage of hot hardness of material.

Type of operation: external and internal threading done at

lower speeds.

Work size: larger diameter work at lower and small diameters

work at higher speed.

Surface finish:

Rough machining---- deep cut & low speed.

Finishing ----- low depth of cut & high speed.

TAIL STOCK: [LOOSE HEAD STOCK (OR) PUPPET HEAD STOCK]

Placed at right side of lathe.

To support long workpiece.

Operations like drilling, tapping, reaming can done

using sleeve of tailstock.

The body is a single piece casting fitted to a bottom plate,

carries a slot to prevent the longitudinal movements of the two.

The upper part of the body is hollow carries a sleeve or barrel

inside it.

Front end of the sleeve is fitted by dead centre.

Collar limits inward motion of the sleeve.

CARRIAGE:

It controls and supports the cutting tool.

Saddle: slides along the guide ways( H- shape)

Cross- slide: carries compound slide and tool post.

Compound rest: sets tool for angular cuts.

Tool post: to clam the cutting tool.

Apron: attached to saddle and hangs infront of bed.It has

gears,levers and clutches, for moving carriage with the lead and

thread screw.

CROSS SLIDE:

Fitted on the Saddle

Moves cutting tool at right angles to lathe bed

COMPOUND REST:

Fitted to top of Cross slide

Carries tool post and cutting tool

Can rotate to any angle (Swivel Plate)

Is used to turn tapers

It is also called as Tool Rest (or) Top Slide.

TOOL POST:

Adjust the height on some

4 different tool holders

APRON:

It is the hanging part infront of carriage.

It serves as housing for number of gear trains for smooth

movement of entire carriage.

FEED MECHANISM:

It is employed for imparting various feeds to cutting

tool.

longitudinal,cross,angular

It consists of feed reverse lever, change gears, feed

gear box, lead screw, feed rod, apron mechanism

and half nut mechanism.

SPECIFICATIONS OF LATHE:

Height of the centre : C :Vertical distance between the lathe bed &the

centre line of the lathe spindle.

Swing diameter over bed : ELargest diameter of the work that can be

revolved without touching bed. Equal to 2C.

Length between centre : A :Max. length of work piece that can be set

between centers.

Swing dia. Over carriage : D :Largest dia. of work piece that can be

revolved over the lathe saddle.

Max. bar dia. : Max. dia. Of bar stock that pass through the hole of head

stock

Length of bed : Total length of guide ways provided on the bed.

SPECIFICATIONS OF LATHE:

LATHE

BENCH SPEED ENGINE TOOL ROOM SEMI AUTO AUTOMATIC

WOOD WORKING

CENTERING

METAL SPINNING

POLISHING

BELT DRIVE

GEAR HEAD DRIVE

INDIVIDUAL MOTOR

CAPSTAN AND

TURRET

Bench Lathe:

small lathe mounted on bench or cabinet.

Used for very small and precision work.

Capable of performing almost all the lathe operations.

SPEED LATHES:

Due to high speed of spindle it is called Speed Lathe.

Speed of Spindle : 1200 to 3600 rpm.

It is mainly used for metal spinning, polishing etc.

These type of lathes does not have provision for power

feed because of no gear box.

Tool is mounted on tool post or supported by T-shape

supporter by hand.

METAL SPINNING VIDEO:

ENGINE LATHE:

In starting it was driven by steam engine, So it is called

as Engine lathe.

Not production lathe, found in school shops, tool rooms,

and job shops.

Primarily for single piece or short runs.

Manually operated.

Head stock is bigger in size provides mechanism for

multiple speeds in lathe.

Types :-

a) Belt driven lathe

b) Individual motor driven lathe

c) Gear head drive lathe

TOOL ROOM LATHE:

Same as Engine lathe.

It is used for production of small & precision works

like tools, gauges, fixtures and accurate parts in

tool room.

Different speeds can achieved.

Costly as compared to a same size Engine lathe.

SEMI AUTOMATIC LATHES: (CAPSTAN & TURRET LATHES)

Widely used in mass production.

It has special mechanisms for indexing of their tool heads.

To operated this low skill technician is enough.

Modified Engine lathe.

Capsten lathes are used in mass production used for light duty

workpieces.

Turret lathes are used in mass production and for heavy duty

workpieces.

No tailstock.

Instead of tailstock hexagonal turret is there.

No time waste for re-setting of tools.

AUTOMATIC LATHES:

Developed to meet all the required basic machining

processes can be done automatically.

Only mounting of work and removal of work is done by

operator.

Available in single or multiple spindles with heavy duty

& high speed lathes employed in mass production.

SPECIAL PURPOSE LATHES:

Suits to a definite class of work and to perform certained specified

operations only.

COPY LATHE:

TAPER TURNING

A taper may be defined as an uniform decrease or

increase in diameter of a piece of workpiece along

its length.

Taper turning methods:

Setting over the tailstock centre

Swiveling the compound rest

Using taper turning attachment

By form tool.

SETTING OVER TAILSTOCK:

Small tapers only.

Based on the principle of shifting the axis of rotation of

the work piece, at an angle to the axis and feeding the

tool parallel to the lathe axis.

SWIVELLING THE COMPOUND REST:

Best method as it does not effect the job centers.

In this method tool is fed at an angle to the axis of rotation of

workpiece.

Limited movement of the cross slide restricts this method to short

tapers.

Low production capacity and poor surface finish because the tool

movement is completely controlled by hand.

TAPER ATTACHMENT:

Provides wide range of tapers.

A tool is guided in a straight path set at an angle to the axis of

rotation of the workpiece, while the work is being revolved

between centres.

It consists of a bracket which is attached to the rear end of the

lathe bed and supports a guide bar provided at centre.

The bar is provided with graduations and may be swivelled on

either side of the zero graduation and can be set at desired

angles.

USING FORM TOOL:

Broad nose form tool is used.

Limited to shorter tapers only.

LATHE ACCESSORIES:

The devices employed for handling and support the work

and the tool on the lathe are called accessories.

Chucks

Face plate

Angle plate

Driving plate

Lathe carriers or dogs

Lathe mandrels

Rests

Jigs and fixtures.

CHUCKS:

Work holding device.

Commonly used chucks are:

Three jaw universal chuck

Four jaw independent chuck

Combination chuck

Magnetic chuck

Hydraulic or Air chucks

collect

THREE JAW & FOUR JAW CHUCK

Face plate: A circular cast iron disc ,having threaded hole

at its centre so it can be screwed to the threaded nose of the

spindle.

Angle plate: Used in conjunction with a face plate.

Driving plate: It is a circular disc having a projected boss

at its rear. It also have a hole to accommodate a pin which can

engages with the tail of a lathe dog or carrier.

Lathe mandrel: It is a solid steel shaft or spindle used for

holding bored parts for machining their outside surface on

lathe. They are also known as ARBORS. The common type of

mandrels are : solid & plain, collar, stepped, expanding and

double cone mandrels.

Rests:

SEMI AUTOMATIC LATHES:

SPECIFICATIONS & TYPES OF TURRET LATHES:

Specifications:

1. maximum diameter of bar

2. swing diameter of the workpiece

3. spindle speeds

4. feeds

5. chuck size

6. capacity of drive motor

Classified as:

1. Horizontal turret lathe

(a) Ram type.

(b)Saddle type.

2. Vertical turret lathe.

3. Numerically controlled turret lathe.

TYPES :

Horizontal turret : Two types RAM & SADDLE

RAM TYPE:

speed: 50 to 4000 r.p.m

work: light duty

Turret placed on a ram

SADDLE TYPE:

Turret mounted on saddle

speed: 20 to 1500 r.p.m

VERTICAL TURRET LATHE:

Consists of a rotating chuck or table in horizontal position with

the turret mounted above on cross rail.

To provide angular cuts ram and turret head may be swivell

right or left from centre.

Applicable for boring but not for bar work.

AUTOMATIC LATHES:

The lathe that have their tools automatically fed to work and

withdraw after the cycle is complete are know as automatic

lathes.

Types: 1. single spindle 2. multi spindle

cutt-off cutting off

swiss type drilling,milling,e.t.c

automatic screw bar

special special

AUTOMATIC SCREW MACHINES:

Single spindle:

1. designed for bar work of small diameter.

2. cross slide capable of carrying tools both front and rear and a

turret mounted in a vertical position on a slide with longitudinal

movement.

Multi spindle:

1. large no of spindles usually 4,6 or 8

Potrebbero piacerti anche

- Lathe WorkDocumento186 pagineLathe WorkAjay Sharma100% (1)

- Practical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsDa EverandPractical Lessons In Metal Turning - A Handbook For Young Engineers And Amateur MechanicsNessuna valutazione finora

- Lathe Part IDocumento151 pagineLathe Part Ishiva100% (1)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsDa EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNessuna valutazione finora

- Shaper MachineDocumento19 pagineShaper MachineMark Joseph Nambio Nieva0% (1)

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopDa EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNessuna valutazione finora

- Shaper MachineDocumento18 pagineShaper MachineSanyam JainNessuna valutazione finora

- Chapter 2 - Metal Cutting LatheDocumento165 pagineChapter 2 - Metal Cutting LathebmdbmdbmdNessuna valutazione finora

- MCP 101 Product Realization Lab ManualDocumento75 pagineMCP 101 Product Realization Lab ManualjasvindersinghsagguNessuna valutazione finora

- Grind basic lathe tools at homeDocumento18 pagineGrind basic lathe tools at homeAntónio FrançaNessuna valutazione finora

- JJ 104 Workshop Technology 1 MillingDocumento44 pagineJJ 104 Workshop Technology 1 MillingHusaini Zamzury0% (1)

- Lathe-1Documento26 pagineLathe-1Meer Umar100% (1)

- Milling MachineDocumento32 pagineMilling MachineIrfan Shaikh100% (2)

- Lathe MachineDocumento16 pagineLathe MachineVanamali Thirumalai100% (4)

- Shaping Machine Operations GuideDocumento25 pagineShaping Machine Operations Guidekatakamharish100% (1)

- Lathe MachineDocumento36 pagineLathe MachinePrem100% (3)

- Lathe Holding DeviceDocumento28 pagineLathe Holding Devicetere_aquinoluna828Nessuna valutazione finora

- Manufacturing Technology Lab Manual Safety RulesDocumento34 pagineManufacturing Technology Lab Manual Safety RulesSamuelPannierselvamShirleyNessuna valutazione finora

- Accessories and Attachments of Lathe MachineDocumento6 pagineAccessories and Attachments of Lathe MachinejadeNessuna valutazione finora

- Multi Point Cutting Tool Design PDFDocumento73 pagineMulti Point Cutting Tool Design PDFsrutiiNessuna valutazione finora

- LatheDocumento130 pagineLatheAjay Sharma86% (7)

- Knurling ToolDocumento5 pagineKnurling Tool4U6ogj8b9snylkslkn3nNessuna valutazione finora

- Various Types of Operations Performed in Lathe Machine - Education Discussion PDFDocumento13 pagineVarious Types of Operations Performed in Lathe Machine - Education Discussion PDFtinku meenaNessuna valutazione finora

- DrillingDocumento52 pagineDrillingMd AamerNessuna valutazione finora

- LatheDocumento6 pagineLatheRavichandran GNessuna valutazione finora

- Up and Down Milling TechniquesDocumento59 pagineUp and Down Milling TechniquesLibin AbrahamNessuna valutazione finora

- Theory of Metal CuttingDocumento147 pagineTheory of Metal Cuttingavutu_kunduru100% (1)

- Construction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill BitsDocumento8 pagineConstruction: Lathes Machining Metals Plastics Jargon Machine Tools Rotating Linear Tool Bits Drill Bitsviruz2_09Nessuna valutazione finora

- Grinding MachineDocumento9 pagineGrinding Machinejineesha p jNessuna valutazione finora

- BME Lecture 5 ShaperDocumento6 pagineBME Lecture 5 ShaperRoop LalNessuna valutazione finora

- LatheDocumento74 pagineLatheChandrakantha K100% (1)

- End Mills GeometryDocumento4 pagineEnd Mills GeometryIvan HrenNessuna valutazione finora

- 2016 Machine Shop Manual PDFDocumento95 pagine2016 Machine Shop Manual PDFShravan Shetty100% (1)

- Shaper MachineDocumento81 pagineShaper Machinesam clastineNessuna valutazione finora

- IndexingDocumento10 pagineIndexingsaddam hosenNessuna valutazione finora

- Drilling Machine Types GuideDocumento42 pagineDrilling Machine Types GuideSomenath RahaNessuna valutazione finora

- Experiment p1 Metal Cutting ProcessDocumento13 pagineExperiment p1 Metal Cutting Processvipin_shrivastava25Nessuna valutazione finora

- Mother of Machines - Lathe MachineDocumento5 pagineMother of Machines - Lathe MachineUsman KhalilNessuna valutazione finora

- Threading Operations of Lathe SystemDocumento37 pagineThreading Operations of Lathe SystemResshille Ann T. SalleyNessuna valutazione finora

- Screw Thread TypesDocumento7 pagineScrew Thread TypesVille4everNessuna valutazione finora

- Broaching (1)Documento16 pagineBroaching (1)patel ketan82% (11)

- Shaper and PlannerDocumento33 pagineShaper and PlannerCody Lee100% (1)

- Milling & Related OperationsDocumento22 pagineMilling & Related OperationsIzi80% (5)

- Workshop ManualDocumento96 pagineWorkshop ManualDatta YallapuNessuna valutazione finora

- Methods of Mounting of Jobs and Cutting ToolsDocumento19 pagineMethods of Mounting of Jobs and Cutting ToolsRaghav L NaikNessuna valutazione finora

- Broaching BasicsDocumento5 pagineBroaching Basicssaritha0003Nessuna valutazione finora

- Production Technology Lab FileDocumento45 pagineProduction Technology Lab FileSakshi RoyNessuna valutazione finora

- Lathe - LVDocumento23 pagineLathe - LVakshaygiitmNessuna valutazione finora

- Mill Keyways On LatheDocumento1 paginaMill Keyways On LatheJim100% (3)

- Lathe OperationsDocumento35 pagineLathe OperationsMuraliNessuna valutazione finora

- A Rotary Sine Bar For The LatheDocumento2 pagineA Rotary Sine Bar For The LatheTheodor EikeNessuna valutazione finora

- Lathe Machine GuideDocumento26 pagineLathe Machine GuideHarish Kumar S100% (3)

- MACHINING-lathe and Milling)Documento29 pagineMACHINING-lathe and Milling)YosephNessuna valutazione finora

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateDocumento7 pagineLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaNessuna valutazione finora

- 3 Jaw Chuck RepairDocumento2 pagine3 Jaw Chuck RepairbrianatburleighNessuna valutazione finora

- 21 Methods of Mounting of Jobs and Cutting Tools in Machine Tools.Documento29 pagine21 Methods of Mounting of Jobs and Cutting Tools in Machine Tools.PRASAD326100% (3)

- Fitting LabDocumento8 pagineFitting LabArun kumar rouniyarNessuna valutazione finora

- Lathe Machine OperationDocumento38 pagineLathe Machine OperationInilazi JimmyNessuna valutazione finora

- Application of Nano Cutting Fluid Under Minimum Quantity Lubrication MQL Technique To Improve Grinding of Ti 6al 4V AlloyDocumento5 pagineApplication of Nano Cutting Fluid Under Minimum Quantity Lubrication MQL Technique To Improve Grinding of Ti 6al 4V AlloySiva BhaskarNessuna valutazione finora

- Experimental Investigations of Graphite Nano Particles and Cutting Parameters in Turning of Aisi 1040 Steel With MQLDocumento10 pagineExperimental Investigations of Graphite Nano Particles and Cutting Parameters in Turning of Aisi 1040 Steel With MQLSiva BhaskarNessuna valutazione finora

- 8 - Solid SolutionsDocumento9 pagine8 - Solid Solutionstaak41Nessuna valutazione finora

- Welding PositionDocumento6 pagineWelding Positionenels77Nessuna valutazione finora

- Polymer Matrix CompositesDocumento121 paginePolymer Matrix CompositesHitesh Shah100% (6)

- Additve Manufacturing Systems ClassDocumento3 pagineAdditve Manufacturing Systems ClassSiva BhaskarNessuna valutazione finora

- Reliability Analysis of The Ceramic Cutt PDFDocumento4 pagineReliability Analysis of The Ceramic Cutt PDFSiva BhaskarNessuna valutazione finora

- EngineeringDrawingCD UserGuideDocumento2 pagineEngineeringDrawingCD UserGuidekameshvvNessuna valutazione finora

- Garments FinishingDocumento18 pagineGarments FinishingJames_45Nessuna valutazione finora

- A 204Documento1 paginaA 204AnuranjanNessuna valutazione finora

- MN 304 - Production Economics - 6Documento59 pagineMN 304 - Production Economics - 6Nipuna Thushara WijesekaraNessuna valutazione finora

- Casting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesDocumento11 pagineCasting Defects Analysis in Foundry and Their Remedial Measures With Industrial Case StudiesIOSRjournalNessuna valutazione finora

- Quality requirements for welding standards and testingDocumento1 paginaQuality requirements for welding standards and testingKristijan GeorgievskiNessuna valutazione finora

- Powercrete J ApplicationDocumento2 paginePowercrete J ApplicationJèfrì PìnémNessuna valutazione finora

- NESMAN Manpower Utilization and Costs ReportDocumento55 pagineNESMAN Manpower Utilization and Costs ReportFaiq RehmanNessuna valutazione finora

- Product ListDocumento2 pagineProduct ListMasood TariqNessuna valutazione finora

- (Corus) SHS Jointing - Flowdrill and Hollo-BoltDocumento13 pagine(Corus) SHS Jointing - Flowdrill and Hollo-Bolt_at_to_Nessuna valutazione finora

- Inyect orDocumento4 pagineInyect orFernando1205Nessuna valutazione finora

- Yarn RealizationDocumento9 pagineYarn RealizationHitesh Shah100% (1)

- Supply Chain Process of HPCLDocumento27 pagineSupply Chain Process of HPCLAvinaba HazraNessuna valutazione finora

- OcalDocumento38 pagineOcalSergio Daniel FernandezNessuna valutazione finora

- 07910Documento3 pagine07910sethu1091Nessuna valutazione finora

- ASMe Sec2 PartcDocumento53 pagineASMe Sec2 PartcSARSAN NDTNessuna valutazione finora

- QCBrochureDocumento3 pagineQCBrochureSinan AslanNessuna valutazione finora

- Reference Guide: When You Are Making A Polyurethane Rubber Mold - .Documento2 pagineReference Guide: When You Are Making A Polyurethane Rubber Mold - .Sergio Marcos KettmayerNessuna valutazione finora

- Productivity Improvement Through Lean Manufacturing ToolsDocumento23 pagineProductivity Improvement Through Lean Manufacturing ToolsSatadeep Datta0% (1)

- Street Furniture Factory and Prefabricated SystemsDocumento36 pagineStreet Furniture Factory and Prefabricated SystemsokisoundNessuna valutazione finora

- The Industrial Revolution 1750-1850: Changes in Technology, Population, and Social StructureDocumento8 pagineThe Industrial Revolution 1750-1850: Changes in Technology, Population, and Social Structurerpatel13Nessuna valutazione finora

- CAMERON France S.A.S: Front SheetDocumento27 pagineCAMERON France S.A.S: Front SheetkrishnsgkNessuna valutazione finora

- MCQ 1Documento90 pagineMCQ 1alfred basilyNessuna valutazione finora

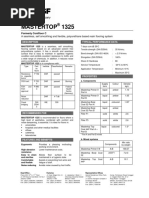

- Mastertop 1325Documento3 pagineMastertop 1325Doby YuniardiNessuna valutazione finora

- Lathe Bed DesignDocumento56 pagineLathe Bed DesignMike100% (4)

- Metal Coating Processes GuideDocumento9 pagineMetal Coating Processes GuideIrfan IslamyNessuna valutazione finora

- A Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing IndustryDocumento11 pagineA Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing IndustryVarunNessuna valutazione finora

- Hoja Datos Danfoso TermostotaosDocumento2 pagineHoja Datos Danfoso TermostotaosAlex Lopez0% (1)

- ISO/TS 29001:2010: Quality Management System For Oil, Gas and Petrochemical IndustriesDocumento2 pagineISO/TS 29001:2010: Quality Management System For Oil, Gas and Petrochemical Industriescelestialmusician100% (1)

- BHEL Quality Plan for Silicon Oil Filtration PlantDocumento7 pagineBHEL Quality Plan for Silicon Oil Filtration PlantAnonymous uXdS9Y7Nessuna valutazione finora

- Peri Komponentu Katalogas Klojiniams 2015 enDocumento948 paginePeri Komponentu Katalogas Klojiniams 2015 enLuôn HồNessuna valutazione finora