Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Chapter 4 - Refrigeration

Caricato da

Matthew ShieldsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Chapter 4 - Refrigeration

Caricato da

Matthew ShieldsCopyright:

Formati disponibili

Refrigeration

Systems

2

Objectives

Introduce the concepts of refrigerators and heat

pumps and the measure of their performance.

Analyze the ideal and actual vapor-compression

refrigeration cycles.

Discuss the operation of refrigeration and heat

pump systems.

Evaluate the performance of innovative vapor-

compression refrigeration systems.

3

4.1 Introduction

4.2 Reversed Heat Engine Cycle

4.3 Performance of Refrigeration Cycle and

Heat Pump

4.4 The Ideal Vapor-Compression

Refrigeration Cycle

4.5 The Practical Refrigeration Cycle

4.6 Refrigeration Load

4.7 Flash Chamber

4.8 Multistage Compression Refrigeration

System

4.9 Cascade Refrigeration System

4.10 Absorption Refrigeration Systems

Topics

4

Refrigerators And Heat Pumps

The transfer of heat from a low-temperature

region to a high-temperature one requires

special devices called refrigerators.

The objective of a refrigerator is to remove heat

(QL) from the cold medium; the objective of a

heat pump is to supply heat (QH) to a warm

medium.

Refrigerators and heat pumps are essentially

the same devices; they differ in their objectives

only.

Performance:

From 1

st

Law of thermodynamics

dQ=dW;

The net work input to the system,W=W12-W34

The net heat rejected by the system;Q=Q2-Q1

If COP

R

is positive, then COP

HP

> 1

The rate of heat removal from a system is called cooling capacity.

Cooling capacity is normally measured in tons of refrigeration

1 ton = 211 kJ/min

1

1

R HP

in

L

HP

in

in L

in

H

in L H

COP COP

W

Q

COP

W

W Q

W

Q

W Q Q

Refrigerators And Heat Pumps

6

The most efficient heat engine is represented by the

Carnot cycle. (Remember that Carnot cycle is reversible)

A reversed heat engine is represented by Carnot cycle

which operates in a reversed direction

This cycle is called a reversed Carnot cycle

A refrigerator/heat pump using this cycle is called Carnot

refrigerator/Carnot heat pump

Its function is to remove heat from a low-temperature

region to a high-temperature region.

The Reversed Carnot Cycle

7

(1 2)

Wet vapor enters compressor and

is compress (Isentropic)

Temperature is increased

(2 3)

Vapor is condensed at constant

temperature

Heat rejected by refrigerant

(3 4)

Isentropic expansion (Isentropic)

Temperature is reduced

(4 1)

Heat for evaporation process is

supplied from cold source in

evaporator at constant

temperature.

The Reversed Carnot Cycle

1

2 3

4

1

2 3

4

8

The Reversed Carnot Cycle

Schematic of a Carnot refrigerator

and T-s diagram of the reversed

Carnot cycle.

Both COPs increase as the

difference between the two

temperatures decreases, i.e.

as T

L

rises or T

H

falls.

The most efficient refrigeration cycle (the reversed Carnot cycle) operating between

T

L

and T

H

. But it is impractical model for refrigeration cycles because:

(i)process 1-2 involves compression of a liquidvapor mixture - requires a compressor

that will handle two phases,

(ii)process 3-4 involves expansion of high-moisture-content refrigerant in a turbine.

Reversed Carnot cycle is only for comparison with the actual

refrigeration cycles.

PERFORMANCE OF REFRIGERATION CYCLE AND HEAT

PUMP

From T-s diagram,

T

L

= T

1

= T

4

and T

H

= T

2

= T

3

s

1

= s

2

and s

4

= s

3

Q

L

= T

L

(s

1

s

4

) and Q

H

= -T

H

(s

3

s

2

)

W

in

= Q

H

- Q

L

= -T

H

(s

3

s

2

) T

1

(s

1

s

4

) = -T

2

(s

4

s

1

) T

1

(s

1

s

4

)

= (T

2

T

1

) (s

1

s

4

)

The Reversed Carnot Cycle

10

Similarly for COP

HP

, we get:

H

L

L H

H

HP

T

T

T T

T

T T

T

COP

1

1

1 2

2

1

1

1 2

1

4 1 1 2

4 1 1

L

H

L H

L

R

R

in

L

R

T

T

T T

T

T T

T

COP

s s T T

s s T

COP

W

Q

COP

So, COP

R

can be given as follows:

The Reversed Carnot Cycle

11

A steady-flow Carnot refrigeration cycle uses refrigerant-134a

as the working fluid. The refrigerant changes from saturated

vapor to saturated liquid at 30C in the condenser as it

rejects heat. The evaporator pressure is 160 kPa. Show the

cycle on a T-s diagram relative to saturation lines, and

determine:

(a)the coefficient of performance,

(b)the amount of heat absorbed from the refrigerated space,

and

(c)the net work input.

Answers: (a) 5.64, (b) 147 kJ/kg, (c) 26.1 kJ/kg

Problem 1

Ideal Vapor-compression Refrigeration Cycle

Is the ideal model for refrigeration systems. The refrigerant is vaporized

completely before it is compressed and the turbine is replaced with a

throttling device.

Schematic and T-s diagram for the ideal vapor-compression refrigeration cycle.

The most widely used cycle for

refrigerators, A-C systems, and

heat pumps.

13

Process

4-1 Constant Pressure Evaporation

Heat from a cold space is absorbed by the

refrigerant. As a result, the refrigerant

evaporates at a constant evaporator pressure,

from state 4 to become a drier saturated

vapor at state 1.

Ideal Vapor-compression Refrigeration Cycle

14

Process

1-2 Isentropic compression

The saturated vapor is compressed from

the evaporator pressure to the condenser

pressure, in a reversible adiabatic manner.

The refrigerant exits the compressor as a

superheated vapor at state 2.

Ideal Vapor-compression Refrigeration Cycle

15

Process

2-3 Constant Pressure Condensation

Heat is rejected from the refrigerant to a warm

space. As a result, the refrigerant condenses at a

constant condenser pressure until it becomes a

saturated liquid at state 3.

Ideal Vapor-compression Refrigeration Cycle

16

3-4 Constant Enthalpy Expansion

The refrigerant expands through the

throttle valve adiabatically. As a result, its

pressure drops from the condenser to the

evaporator pressure. The enthalpy is

constant during the process, i.e. h3 = h4.

Ideal Vapor-compression Refrigeration Cycle

Note: The expansion process is highly irreversible, thus

making the vapor-compression cycle an irreversible cycle.

Process

17

An ordinary

household

refrigerator.

The P-h diagram of an ideal

vapor-compression

refrigeration cycle.

The ideal vapor-compression refrigeration cycle involves an

irreversible (throttling) process to make it a more realistic model for

the actual systems.

Steady-flow energy

balance

18

Refrigeration Load

mass unit per effect ing refrigerat

capacity or refrigerat

m

Refrigeration Capacity,

defined as the amount of heat that has to be transferred from a cold

space per unit time

determines the mass flow rate of refrigerant

1 ton = 200Btu/min = 211kJ/min = 3.516kW

ton : the rate of heat transfer to produce 2000 lb of ice at 0

o

C (32

o

)F

from liquid water at 0

o

C (32

o

F) in 24 hours

Mass flow rate of refrigerant

L

Q

Solving Problem

2 methods can be used for cycle analysis.

Using property table for refrigerants

Using the P-h diagram

P

h

1

2 3

4

q

2

= h

2

h

3

q

2

= h

1

h

4

w

in

= h

2

h

1

20

P

-

h

D

i

a

g

r

a

m

f

o

r

R

e

f

r

i

g

e

r

a

n

t

1

3

4

a

21

A refrigerator uses refrigerant-134a as the working fluid and

operates on an ideal vapor-compression refrigeration cycle

between 0.12 and 0.7 MPa. The mass flow rate of the refrigerant

is 0.05 kg/s. Show the cycle on a T-s diagram with respect to

saturation lines. Determine:

a) the rate of heat removal from the refrigerated space,

b) the power input to the compressor,

c) the rate of heat rejection to the environment, and

d) the coefficient of performance.

Answers: (a) 7.41 kW, 1.83 kW, (b) 9.23 kW, (c) 4.06

Problem 2

Ideal and Actual Vapor-Compression Refrigeration Cycles

22

Actual Vapor-Compression Refrigeration Cycle

Schematic and T-s diagram for the actual vapor-compression refrigeration cycle.

An actual vapor-compression refrigeration cycle involves irreversibilities

in various components - mainly due to fluid friction (causes pressure

drops) and heat transfer to or from the surroundings. As a result, the

COP decreases.

Differences

Non-isentropic

compression;

Superheated vapor

at evaporator exit;

Sub-cooled liquid at

condenser exit;

Pressure drops in

condenser and

evaporator.

23

T

s

1

2

4

3

Cooling water

temperature

4

Undercooling (Subcooling) And Its Effects

In the condenser, the vapor can be further cooled at constant

pressure to a temperature that is lower than temperature in

condenser

3

24

Undercooling (subcooling) increases the refrigerating effect

(h1 h4) > (h1 h4) where h4 is enthalpy with undercooling (subcooling) and h4 is

initial enthalpy

Undercooling (subcooling) is limited by temperature of cooling water and

temperature difference of cycle

T

s

1

2

4

3

Cooling water

temperature

4

3

Undercooling (Subcooling) And Its Effects

26

Refrigerant-134a enters the compressor of a refrigerator as

superheated vapor at 0.14 MPa and - 10C at a rate of 0.12 kg/s, and

it leaves at 0.7 MPa and 50C. The refrigerant is cooled in the

condenser to 24C and 0.65 MPa, and it is throttled to 0.15 MPa.

Disregarding any heat transfer and pressure drops in the connecting

lines between the components, show the cycle on a T-s diagram with

respect to saturation lines, and determine:

a)the rate of heat removal from the refrigerated space,

b)the power input to the compressor,

c)the isentropic efficiency of the compressor, and

d)the COP of the refrigerator.

Answers: (a) 19.4 kW, 5.06 kW, (b) 82.5 percent, (c) 3.83

Ideal and Actual Vapor-Compression Refrigeration Cycles

Problem 4

28

Selecting the Right Refrigerant

Several refrigerants may be used in refrigeration systems such as chlorofluorocarbons (CFCs),

ammonia, hydrocarbons (propane, ethane, ethylene, etc.), carbon dioxide, air (in the air-

conditioning of aircraft), and even water (in applications above the freezing point).

R-11, R-12, R-22, R-134a, and R-502 account for over 90 percent of the market.

The industrial and heavy-commercial sectors use ammonia (it is toxic).

R-11 is used in large-capacity water chillers serving A-C systems in buildings.

R-134a is used in domestic refrigerators and freezers, as well as automotive air conditioners.

R-22 is used in window air conditioners, heat pumps, air conditioners of commercial

buildings, and large industrial refrigeration systems, and offers strong competition to

ammonia.

R-502 (a blend of R-115 and R-22) is the dominant refrigerant used in commercial

refrigeration systems such as those in supermarkets.

CFCs allow more ultraviolet radiation into the earths atmosphere by destroying the

protective ozone layer and thus contributing to the greenhouse effect that causes global

warming. Refrigerants that are friendly to the ozone layer have been developed.

Two important parameters to be considered - the temperatures of the refrigerated space

and the environment with which the refrigerant exchanges heat.

29

Innovative Vapor-compression Refrigeration

Systems

The simple vapor-compression refrigeration cycle is the most widely used

refrigeration cycle, and is adequate for most refrigeration applications.

The ordinary vapor-compression refrigeration systems are simple,

inexpensive, reliable, and practically maintenance-free.

However, for large industrial applications, efficiency (not simplicity) is the

major concern.

For some applications the simple vapor-compression refrigeration cycle is

inadequate and needs to be modified.

For moderately and very low temperature applications, some innovative

refrigeration systems are used. The following cycles will be discussed:

Cascade refrigeration systems

Multistage compression refrigeration systems

Multipurpose refrigeration systems with a single compressor

Liquefaction of gases

30

Cascade Refrigeration Systems

Some industrial applications require moderately low

temperatures, and the temperature range they involve may

be too large for a single vapor compression refrigeration

cycle to be practical.

A large temperature range also means a large pressure

range in the cycle and a poor performance for a

reciprocating compressor.

One way of dealing with such situations is to perform the

refrigeration process in stages, that is, to have two or more

refrigeration cycles that operate in series.

Such refrigeration cycles are called cascade refrigeration

cycles.

31

Cascade Refrigeration Systems

A two-stage compression refrigeration

system with a flash chamber.

A two-stage cascade refrigeration cycle is shown. The two cycles are connected through the

heat exchanger in the middle, which serves as the evaporator for the topping cycle and the

condenser for the bottoming cycle.

A two-stage cascade refrigeration system with the same refrigerant

in both stages.

32

Cascade Refrigeration Systems

Assuming the heat exchanger is well insulated and the

kinetic and potential energies are negligible, the heat

transfer from the fluid in the bottoming cycle should be

equal to the heat transfer to the fluid in the topping cycle.

Thus, the ratio of mass flow rates through each cycle should

be

The coefficient of performance of the cascade system is

33

1141

Consider a two-stage cascade refrigeration system operating between

pressure limits of 0.8 and 0.14 MPa. Each stage operates on the ideal

vapor-compression refrigeration cycle with refrigerant-134a as the

working fluid. Heat rejection from the lower cycle to the upper cycle

takes place in an adiabatic counter-flow heat exchanger where both

streams enter at about 0.4 MPa. If the mass flow rate of the refrigerant

through the upper cycle is 0.24 kg/s, determine the:

a)mass flow rate of the refrigerant through the lower cycle,

b)rate of heat removal from the refrigerated space,

c)power input to the compressor, and

d)coefficient of performance of this cascade refrigerator.

Answers: (a) 0.195 kg/s, (b) 34.2 kW, 7.63 kW, (c) 4.49

Problem 5

Cascade Refrigeration Systems

35

Multistage Compression Refrigeration Systems

A two-stage compression refrigeration system with a flash

chamber.

When the fluid used throughout the cascade

refrigeration system is the same, the heat exchanger

between the stages can be replaced by a mixing

chamber (called a flash chamber) since it has better

heat transfer characteristics.

36

FLASH CHAMBER

Flash chamber is used in a multi-staging refrigeration system

It separates vapor and liquid refrigerant during the throttling

process

The purpose is to avoid vapor refrigerants from entering evaporator

The vapor developed during throttling (flash vapor) is bled out of

the throttling device and fed back to the compressor

Multistage Compression Refrigeration Systems

37

A multistage compression

refrigeration system is

one example of a system

that uses a flash chamber

It can be carried out with

the use of one or more

compressors

2

Q

L

Q

H

Condenser

Evaporator

W

in

Expansion

Valve

1

4

4

5

Flash Chamber

Expansion

Valve

8

7

6

9

3

W

in

Cycle Layout of a Two-Stage Compression

Refrigeration System

Multistage Compression Refrigeration Systems

38

The T-s diagram representing the cycle of a two-stage vapor-

compression cycle

1

2

3

9

4

5

6

7

8

s

T

Multistage Compression Refrigeration Systems

39

Two-stage refrigeration cycle represented by the p-h diagram

The P-h diagram is a

more convenient

representation of

the cycle because it

can easily be

compared to the

plant layout

Multistage Compression Refrigeration Systems

7

5

P

h

1

2

9

4

6

8

3

Evaporator

Condenser

Flash Chamber

40

1kg refrigerant moves through condenser

1kg liquid enters 1

st

throttle valve

1kg (mostly liquid) enters flash chamber and

starts to evaporate and becomes mixture of

gas (x)kg and liquid (1x)kg

(x) moves towards 2

nd

stage compressor at P

i

(1x)kg liquid make its way through the 2

nd

throttle valve into the evaporator

(1x)kg vapor enters the 1

st

stage compressor

where it is compressed to P

i

At P

i

(state 3) (1-x)kg vapor mixes with (x)kg

vapor adiabatically and becomes 1kg vapor

1kg vapor is compressed in 2

nd

stage

compressor

1kg vapor enters condenser to be condensed

and becomes 1kg liquid

P

h

1

2

9

4

5

6

7

8

3

Condenser

Evaporator

Multistage Compression Refrigeration Systems

41

ANALYSIS

Fraction of refrigerant which evaporates in the flash chamber can be given as

follows.

Refrigerating Effect, Q

L

= (1 x)(h

1

h

8

)

Total work input, W

in

= W

12

+ W

94

= (1 x)(h

2

h

1

) + (h

4

h

9

)

Heat rejected in condenser

Q

H

= (h

4

h

5

)

i

i

fg

f

h

h h

x

6

Multistage Compression Refrigeration Systems

42

Coefficient of Performance

9 4 1 2

8 1

1

1

h h h h x

h h x

W

Q

COP

in

L

R

Multistage Compression Refrigeration Systems

43

1144

A two-stage compression refrigeration system operates with

refrigerant-134a between the pressure limits of 1 and 0.14 MPa. The

refrigerant leaves the condenser as a saturated liquid and is throttled

to a flash chamber operating at 0.5 MPa. The refrigerant leaving the

low-pressure compressor at 0.5 MPa is also routed to the flash

chamber. The vapor in the flash chamber is then compressed to the

condenser pressure by the high-pressure compressor, and the liquid is

throttled to the evaporator pressure. Assuming the refrigerant leaves

the evaporator as saturated vapor at a rate of 0.25 kg/s and that both

compressors are isentropic, determine the:

a) fraction of the refrigerant that evaporates in the flash chamber,

b) rate of heat removed from the refrigerated space, and

c) coefficient of performance.

Problem7

Two-Stage Compression Refrigeration Systems

45

Absorption Refrigeration Systems

Ammonia absorption refrigeration cycle.

Absorption refrigeration is

when there is a source of

inexpensive thermal

energy at a temperature of

100 to 200C.

Some examples include

geothermal energy, solar

energy, and waste heat

from cogeneration or

process steam plants, and

even natural gas when it is

at a relatively low price.

46

Absorption refrigeration systems (ARS) involve the absorption of a refrigerant by a

transport medium. The most widely used system is the ammoniawater system,

where ammonia (NH

3

) serves as the refrigerant and water (H

2

O) as the transport

medium.

Other systems include waterlithium bromide and waterlithium chloride

systems, where water serves as the refrigerant. These systems are limited to

applications such as A-C where the minimum temperature is above the freezing

point of water.

Compared with vapor-compression systems, ARS have one major advantage: A

liquid is compressed instead of a vapor and as a result the work input is very small

(on the order of one percent of the heat supplied to the generator) and often

neglected in the cycle analysis.

ARS are much more expensive than the vapor-compression refrigeration systems.

They are more complex and occupy more space, they are much less efficient thus

requiring much larger cooling towers to reject the waste heat, and they are more

difficult to service since they are less common.

Therefore, ARS should be considered only when the unit cost of thermal energy is

low and is projected to remain low relative to electricity.

ARS are primarily used in large commercial and industrial installations.

47

The maximum COP of an absorption

refrigeration system.

The COP of actual absorption

refri-geration systems is usually

less than unity.

Air-conditioning systems based

on absorption refrigeration,

called the absorption chillers,

perform best when the heat

source can supply heat at a high

temperature with little

temperature drop.

Potrebbero piacerti anche

- Chapter 11 Refrigeration CyclesDocumento20 pagineChapter 11 Refrigeration Cycleskalite123Nessuna valutazione finora

- Ciclos RefrigeracionDocumento64 pagineCiclos RefrigeracionSergyNessuna valutazione finora

- Rac Solution Set BDocumento12 pagineRac Solution Set BxofigoNessuna valutazione finora

- 05 RefrigerationDocumento17 pagine05 RefrigerationApostolos AvraamidesNessuna valutazione finora

- Part I Refrigeration Chapter 1Documento43 paginePart I Refrigeration Chapter 1eskewt0% (1)

- Vapor Compression Refrigeration SystemDocumento11 pagineVapor Compression Refrigeration Systemm_alodat6144Nessuna valutazione finora

- Lecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDocumento14 pagineLecture 1 Refrigerating Machine Reversed Carnot Cycle Simple Vapor Compression CycleDeniell Joyce MarquezNessuna valutazione finora

- Vapor-Compression Refrigeration CycleDocumento23 pagineVapor-Compression Refrigeration CycleJamshidNessuna valutazione finora

- Refrigeration Midterm Exam ###Documento3 pagineRefrigeration Midterm Exam ###Patience LastyNessuna valutazione finora

- Vortex Flowmeter 2Documento2 pagineVortex Flowmeter 2Prajyot ShendageNessuna valutazione finora

- At AssignmentDocumento3 pagineAt AssignmentYogesh PatilNessuna valutazione finora

- RefrigerantDocumento59 pagineRefrigerantObula Reddy KNessuna valutazione finora

- Experiment 1 RefrigerationDocumento4 pagineExperiment 1 RefrigerationErlangga Sulaiman Razak100% (1)

- Experiment No. 1Documento4 pagineExperiment No. 1subhamgupta7495100% (1)

- Unit Viib Fans and BlowersDocumento8 pagineUnit Viib Fans and BlowersRaffy Calamonte CanoyNessuna valutazione finora

- Tutorial QuestionsDocumento6 pagineTutorial QuestionsLadnilrebNessuna valutazione finora

- Performance Test of A Hydraulic Turbine Mid Term 2Documento8 paginePerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloNessuna valutazione finora

- LectureDocumento9 pagineLecturePrince Jonas Bautista CanlasNessuna valutazione finora

- p1 IntroductionDocumento55 paginep1 IntroductionJala GergesNessuna valutazione finora

- Reciprocating PumpsDocumento10 pagineReciprocating PumpsMae Ann Dolor EstrellanaNessuna valutazione finora

- Chapter 11-Refrigeration CyclesDocumento24 pagineChapter 11-Refrigeration CyclesAbas S. AcmadNessuna valutazione finora

- NOTES 5 - RefrigerationDocumento20 pagineNOTES 5 - RefrigerationMakoya_malumeNessuna valutazione finora

- Practice Problems (METE 40 2018)Documento2 paginePractice Problems (METE 40 2018)Sky FallNessuna valutazione finora

- Transmission of Air in Air Conditioning Ducts: LessonDocumento18 pagineTransmission of Air in Air Conditioning Ducts: Lessoncaptainhass100% (1)

- Multi Stage VapourDocumento20 pagineMulti Stage VapourMazhar UddeenNessuna valutazione finora

- CH 3 Gas Refrigeration CycleDocumento20 pagineCH 3 Gas Refrigeration CycleMeleseNessuna valutazione finora

- Reciprocating Pump: Group 3Documento13 pagineReciprocating Pump: Group 3Ariel GamboaNessuna valutazione finora

- c4 Tutorial TurbineDocumento2 paginec4 Tutorial TurbinehahahaNessuna valutazione finora

- RacDocumento26 pagineRacgurunakhale123Nessuna valutazione finora

- M8 - Vapor Absorption RefrDocumento29 pagineM8 - Vapor Absorption RefrAbraham KhaleedNessuna valutazione finora

- Experiment 7 (Refrigeration Unit)Documento16 pagineExperiment 7 (Refrigeration Unit)fadhilahmad50% (2)

- Boiler:: Working Principle of A BoilerDocumento22 pagineBoiler:: Working Principle of A BoilerZeshan AbdullahNessuna valutazione finora

- Reciprocating PUMPSDocumento15 pagineReciprocating PUMPSRyan LincayNessuna valutazione finora

- EngineeringLab4 Fluid Mechanics MANUALDocumento83 pagineEngineeringLab4 Fluid Mechanics MANUALAathera Wan100% (2)

- EXPERIMENT 2a-PERFORMANCE OF STEAM PLANT Thermo PDFDocumento8 pagineEXPERIMENT 2a-PERFORMANCE OF STEAM PLANT Thermo PDFNurul MardhatiNessuna valutazione finora

- Fluid MachineriesDocumento49 pagineFluid MachineriesRafael Nazareno RivadeneiraNessuna valutazione finora

- Experiment 1 Lab ReportDocumento25 pagineExperiment 1 Lab ReportJasper Laurence SyNessuna valutazione finora

- Chapter 11 PDFDocumento8 pagineChapter 11 PDFVisakan ParameswaranNessuna valutazione finora

- DZL Series Chain Grate Boiler OkDocumento10 pagineDZL Series Chain Grate Boiler OkCarlos LehmanNessuna valutazione finora

- 1 History of Refrigeration: LessonDocumento1.051 pagine1 History of Refrigeration: LessonJonathanE.TambanNessuna valutazione finora

- Vapor Compression Refrigration PDFDocumento155 pagineVapor Compression Refrigration PDFمحمد متوليNessuna valutazione finora

- Lecture-05 Reservoir Pressure&TemperatureDocumento20 pagineLecture-05 Reservoir Pressure&TemperatureShuvro Aakash100% (1)

- Fans-And-Blowers LecturesDocumento21 pagineFans-And-Blowers LecturesDeo WarrenNessuna valutazione finora

- Lab Exercise #4Documento12 pagineLab Exercise #4John Glenn Lausin MaticNessuna valutazione finora

- Innovative Vapor CompressionDocumento13 pagineInnovative Vapor CompressionCj MoLanoNessuna valutazione finora

- Assignment 2Documento1 paginaAssignment 2dhrumilNessuna valutazione finora

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocumento18 pagineBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilNessuna valutazione finora

- Chapter 6 TutorialsDocumento5 pagineChapter 6 TutorialsHafizi Naim IsmailNessuna valutazione finora

- Improved Steam Plant Examples AUG 2020Documento52 pagineImproved Steam Plant Examples AUG 2020Thabang0% (2)

- Calculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchDocumento4 pagineCalculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchFran CarnaceNessuna valutazione finora

- Venturimeter and Orifice MeterDocumento5 pagineVenturimeter and Orifice MeterVrushiket Patil100% (1)

- Characteristic of Laminar FlowDocumento1 paginaCharacteristic of Laminar FlowMohd Hafiz Ahmad100% (3)

- Centrifugal Pump Test RigDocumento4 pagineCentrifugal Pump Test RigSameer Tamboli100% (1)

- Aircond Ref1Documento33 pagineAircond Ref1Ghaith AlhadiNessuna valutazione finora

- Lecture 2. Refrigeration CyclesDocumento8 pagineLecture 2. Refrigeration CyclesaddisudagneNessuna valutazione finora

- Refrigeration System PDFDocumento39 pagineRefrigeration System PDFSiti Hajar Shamsul Kamar86% (7)

- Lecture 3. Refrigeration Cycles 2Documento37 pagineLecture 3. Refrigeration Cycles 2addisudagneNessuna valutazione finora

- Ch4 - Refrigeration SystemsDocumento47 pagineCh4 - Refrigeration SystemsShiau FenNessuna valutazione finora

- Reversed Carnot & VCR Cycle Part IIDocumento23 pagineReversed Carnot & VCR Cycle Part IISumran ShahidNessuna valutazione finora

- Refrigeration CycleDocumento32 pagineRefrigeration CycleAbdalla Faris100% (1)

- Guide-To Visual InspectionDocumento25 pagineGuide-To Visual InspectionMatthew ShieldsNessuna valutazione finora

- PDFSigQFormalRep PDFDocumento1 paginaPDFSigQFormalRep PDFJim LeeNessuna valutazione finora

- Elemental Analysis of Si in Plant Material HRDocumento5 pagineElemental Analysis of Si in Plant Material HRMatthew ShieldsNessuna valutazione finora

- Jurutera Dan Masyaraka T SlideDocumento9 pagineJurutera Dan Masyaraka T SlideMatthew ShieldsNessuna valutazione finora

- Wheelchair Guidelines (En For The Web)Documento131 pagineWheelchair Guidelines (En For The Web)Raj MalhotraNessuna valutazione finora

- Task 2Documento3 pagineTask 2Matthew ShieldsNessuna valutazione finora

- Chapter 05b Engineer in IndustryDocumento25 pagineChapter 05b Engineer in IndustryMatthew ShieldsNessuna valutazione finora

- 06 Jet ImpactDocumento7 pagine06 Jet ImpactTiffany JonesNessuna valutazione finora

- Assignment 3 BDA34003Documento3 pagineAssignment 3 BDA34003Matthew ShieldsNessuna valutazione finora

- CerrDocumento1 paginaCerrMatthew ShieldsNessuna valutazione finora

- CerrDocumento1 paginaCerrMatthew ShieldsNessuna valutazione finora

- Chapter 6.3 TranslationDocumento9 pagineChapter 6.3 TranslationMatthew ShieldsNessuna valutazione finora

- Engineering Economy 14th EdDocumento24 pagineEngineering Economy 14th EdMatthew ShieldsNessuna valutazione finora

- Air PollutionDocumento66 pagineAir PollutionMatthew ShieldsNessuna valutazione finora

- Soalan 1Documento11 pagineSoalan 1Matthew ShieldsNessuna valutazione finora

- Steady Heat Conduction: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento51 pagineSteady Heat Conduction: Heat and Mass Transfer: Fundamentals & ApplicationsMatthew ShieldsNessuna valutazione finora

- HW 11Documento7 pagineHW 11Devendraa MuniandyNessuna valutazione finora

- Lecture 9 - Techniques of Integration: AMA140/150 CalculusDocumento15 pagineLecture 9 - Techniques of Integration: AMA140/150 CalculusMatthew ShieldsNessuna valutazione finora

- Coordinate Coupling and Principal CoordinatesDocumento6 pagineCoordinate Coupling and Principal CoordinatesMatthew Shields100% (1)

- Introduction and Basic Concepts: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento46 pagineIntroduction and Basic Concepts: Heat and Mass Transfer: Fundamentals & ApplicationsMatthew ShieldsNessuna valutazione finora

- Integration RevsolDocumento14 pagineIntegration RevsolSubhojit PaulNessuna valutazione finora

- Integration ReviewDocumento10 pagineIntegration ReviewMatthew ShieldsNessuna valutazione finora

- GB ProjectProposalDocumento11 pagineGB ProjectProposalMatthew ShieldsNessuna valutazione finora

- Heat Conduction Equation: Heat and Mass Transfer: Fundamentals & ApplicationsDocumento48 pagineHeat Conduction Equation: Heat and Mass Transfer: Fundamentals & ApplicationsMatthew Shields100% (1)

- Justify 1Documento2 pagineJustify 1Matthew ShieldsNessuna valutazione finora

- 4 Risk AssessmentDocumento58 pagine4 Risk AssessmentMatthew Shields100% (1)

- 070 Acid Base TitrationDocumento6 pagine070 Acid Base TitrationagustiningsihNessuna valutazione finora

- Solid Modeling Project Sem 2 2014Documento5 pagineSolid Modeling Project Sem 2 2014Matthew ShieldsNessuna valutazione finora

- 170 Fric Inc PlaneDocumento3 pagine170 Fric Inc PlaneMatthew ShieldsNessuna valutazione finora

- 06 Jet ImpactDocumento7 pagine06 Jet ImpactTiffany JonesNessuna valutazione finora

- Separation Process 1Documento86 pagineSeparation Process 1hanisshi50% (4)

- Carta Psicrometrica PDFDocumento1 paginaCarta Psicrometrica PDFFederico Ferreira LopezNessuna valutazione finora

- TTCI Heat TransferDocumento14 pagineTTCI Heat TransferRerrysta YolandaNessuna valutazione finora

- Example Problems ConductionDocumento9 pagineExample Problems ConductionAJ100% (1)

- Heat & MassQuestion BankDocumento9 pagineHeat & MassQuestion Banksiva_marimuthu_2Nessuna valutazione finora

- Water Tube BoilersDocumento8 pagineWater Tube Boilershafidhrahadiyan2Nessuna valutazione finora

- Plug Flow Reactor Non IsothermalDocumento33 paginePlug Flow Reactor Non IsothermalMuqsit BramantiyaNessuna valutazione finora

- Third Law of ThermodynamicsDocumento4 pagineThird Law of Thermodynamicsandres arizaNessuna valutazione finora

- Steam Utilization PDFDocumento66 pagineSteam Utilization PDFMemoVillasenorNessuna valutazione finora

- CFD Parametric Investigation For Two Phase Flow of Refrigerant 134a in An Adiabatic Capillary TubeDocumento5 pagineCFD Parametric Investigation For Two Phase Flow of Refrigerant 134a in An Adiabatic Capillary TubeInfogain publication100% (2)

- AA283 Aircraft and Rocket Propulsion Table of Contents BJ CantwellDocumento5 pagineAA283 Aircraft and Rocket Propulsion Table of Contents BJ CantwellSsheshan PugazhendhiNessuna valutazione finora

- Heat Stress Management in Underground MinesDocumento5 pagineHeat Stress Management in Underground MinesJaimeMoralesNessuna valutazione finora

- 18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyDocumento3 pagine18Pph204: Statistical Mechanics and Thermodynamics: SRM Institute of Science and TechnologyVijayNessuna valutazione finora

- Forced CondensationDocumento9 pagineForced Condensationjohn rozz bbNessuna valutazione finora

- (Ebook) - Free Energy - Passive Solar Cooling, Part 2Documento12 pagine(Ebook) - Free Energy - Passive Solar Cooling, Part 2timannokaff100% (1)

- XII Phy Past PprsDocumento27 pagineXII Phy Past Pprsumairgul841Nessuna valutazione finora

- CET-305 Course SpecificationDocumento15 pagineCET-305 Course SpecificationAlia ShabbirNessuna valutazione finora

- GEMAS 472 Very Important TermsDocumento472 pagineGEMAS 472 Very Important TermsManoy BermeoNessuna valutazione finora

- Difference Between A Refrigerator, Heat Pump, and Heat Engine (PDF)Documento4 pagineDifference Between A Refrigerator, Heat Pump, and Heat Engine (PDF)Kyle LabileNessuna valutazione finora

- Termistor ValueDocumento4 pagineTermistor ValueGabor KomuvesNessuna valutazione finora

- Steam Turbine PerformanceDocumento16 pagineSteam Turbine PerformanceVILLANUEVA_DANIEL2064100% (2)

- E 01 Mean Activity FinalDocumento9 pagineE 01 Mean Activity FinalReine GNessuna valutazione finora

- Tephigrams For DummiesDocumento28 pagineTephigrams For DummiesmoipedrasNessuna valutazione finora

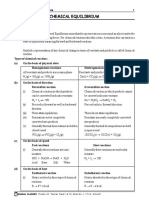

- Chemical EquilibriumDocumento68 pagineChemical Equilibriumhappy100% (1)

- Evaluation of Heater Size and External Enhancement Techniques in Pool Boiling Heat Transfer With Dielectric FluidsDocumento10 pagineEvaluation of Heater Size and External Enhancement Techniques in Pool Boiling Heat Transfer With Dielectric FluidsHao Wei PangNessuna valutazione finora

- Comparing R1233zd and R245fa For Low Temperature ORC Applications PDFDocumento8 pagineComparing R1233zd and R245fa For Low Temperature ORC Applications PDFpancawawanNessuna valutazione finora

- PB Ag SystemDocumento2 paginePB Ag SystemAtul Gautam100% (2)

- Heattransfer - : Md. Nur Alam MondalDocumento13 pagineHeattransfer - : Md. Nur Alam MondalMasudur RahmanNessuna valutazione finora

- Specifying The Thermal Performance of Cool Storage EquipmentDocumento19 pagineSpecifying The Thermal Performance of Cool Storage EquipmentNay MyoNessuna valutazione finora

- Thermodynamic of InterfacesDocumento33 pagineThermodynamic of InterfacesTeka KamNessuna valutazione finora